Ppt0000020

- 格式:ppt

- 大小:1.72 MB

- 文档页数:21

毕业答辩必看ppt幻灯片使用总结(00002)毕业答辩必看ppt幻灯片使用总结1.页面大小的选择打开「文件」→「页面设置」→选择「幻灯片大小」。

默认设置是屏幕大小,可根据需要更改设置。

2.幻灯片的通用模板大家可以通过搜索引擎可以找到许多通用模板,特别是Office XP系列。

由于同一个模板可选择不同的配色方案(页面击鼠标右键→「幻灯片配色方案」),从而有了很多的选择。

3.自己制作模板首先选择一个幻灯片模板,然后选择菜单「视图」→「母版」,一般有标题母板和文本母板二个式样,普通视图下不能更改的许多东西,在母板下就都可以编辑了。

例如想要每一张幻灯片都有自己学校的校徽,直接插入母板即可。

4.回归简单的模板模板太花哨,会影响到表达过程,让观众过多注意模板,从而忽略幻灯所要表达的实际内容。

若选择一个从来没有用过的模板也有风险。

如果对配色没有经验,计算机的色彩也未经过校正,电脑屏幕上的显示与投影仪屏幕上会有较大差别。

特别是底色和文字色相近的配置,在光线很亮的地方效果就会很差。

如果是答辩或学术汇报,推荐选择简洁明了的幻灯片,可以显示出严肃认真的学术气氛。

5.模板的基本要求(1)尽量选择同一个底色的模板,至少要在文字或图片的地方保持同一颜色。

以免文字颜色难以协调搭配。

(2)文字或图片颜色不能过于接近底色,要有一定对比度。

同张幻灯片上的颜色尽量不要超过3种,不要在一个主题下显示多种颜色。

(3)整个幻灯的配色方式要一致。

字号、字体、行间距保持一致,甚至插图位置、大小,均不应随意改变。

(4)文字、图表的「出现方式」的选择中可适当选用动画,但不可过多。

显示同一幻灯片上不同内容的情况下,可考虑使用动画。

6.推荐模板(1)白底:可选择黑字、红字和蓝字。

若觉得不够丰富,可改局部的底色。

(2)蓝底:深蓝更好,可配白字或黄字(浅黄和橘黄),但应避免暗红色。

这是最常用的配色方案。

(3)黑底:配以白字和黄字(橘黄比浅黄好)。

一般幻灯不应该只有文字,同时可适当加入模式图或流程图,使幻灯增加色彩。

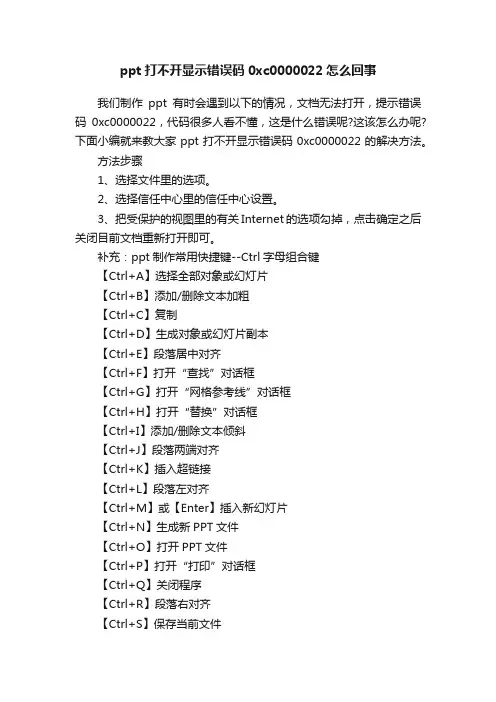

ppt打不开显示错误码0xc0000022怎么回事我们制作ppt有时会遇到以下的情况,文档无法打开,提示错误码0xc0000022,代码很多人看不懂,这是什么错误呢?这该怎么办呢?下面小编就来教大家ppt打不开显示错误码0xc0000022的解决方法。

方法步骤1、选择文件里的选项。

2、选择信任中心里的信任中心设置。

3、把受保护的视图里的有关Internet的选项勾掉,点击确定之后关闭目前文档重新打开即可。

补充:ppt制作常用快捷键--Ctrl字母组合键【Ctrl+A】选择全部对象或幻灯片【Ctrl+B】添加/删除文本加粗【Ctrl+C】复制【Ctrl+D】生成对象或幻灯片副本【Ctrl+E】段落居中对齐【Ctrl+F】打开“查找”对话框【Ctrl+G】打开“网格参考线”对话框【Ctrl+H】打开“替换”对话框【Ctrl+I】添加/删除文本倾斜【Ctrl+J】段落两端对齐【Ctrl+K】插入超链接【Ctrl+L】段落左对齐【Ctrl+M】或【Enter】插入新幻灯片【Ctrl+N】生成新PPT文件【Ctrl+O】打开PPT文件【Ctrl+P】打开“打印”对话框【Ctrl+Q】关闭程序【Ctrl+R】段落右对齐【Ctrl+S】保存当前文件【Ctrl+T】打开“文字”对话框【Ctrl+U】添加/删除文本下划线【Ctrl+V】粘贴【Ctrl+W】关闭当前文件【Ctrl+X】剪切【Ctrl+Y】重复最后操作【Ctrl+Z】撤销操作相关阅读:制作PPT实用技巧:1、在PPT中加入公司LOGO(1)执行“视图-母版-幻灯片母版”这一命令;(2) 在“幻灯片母版视图”中,单击“插入”菜单下的“图片”,选择“来自文件”,将Logo放在合适的位置上(公司Logo可以进行修改设置);(3)关闭母版视图,返回到普通视图后,我们就能在PPT的每一页上看到公司LOGO了。

2、在PPT中插入flash动画(1)点击"视图”-“工具栏”-“控件工具箱”里点击“其他控件”,在弹出的下拉列表里选择“shockwave flash object”;(2)此时鼠标会变成一个十字架,按住左键画一个范围,这个范围就是我们播放flash动画的窗口。

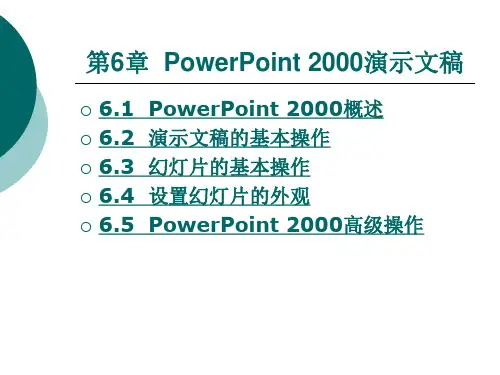

2000复习提纲一、2000概述1、2000的功能2000是一个专门编辑、制作和播放演示文稿的应用软件,也是微软公司办公自动化套装软件2000的组件之一。

用2000可以制作出精美的演示文稿(幻灯片),并可以设置幻灯片播放动画、幻灯片播放切换方式、设置排练时间、录音旁白以与直接添加其它多媒体对象等;用还可以创建联机演示文稿、网页文件、彩色和黑白投影机幻灯片、播放形式演示文稿;能实现彩色和黑白演示文稿幻灯片的打印和打包。

2、基本概念(1)、幻灯片——是演示文稿中的信息页,它一般包括文字、图形、图片、动画、声音、多媒体对象、背景、版式、配色方案和超链接等。

(2)、演示文稿——即是用2000建立的扩展名为文件,演示文稿由若干张幻灯片组成。

完整的演示文稿由四个部份组成:幻灯片、演示文稿大纲、观众讲义和演讲者备注。

(3)、母版——即是一类特殊的幻灯片,母版控制着幻灯片上某些文本特征(如字体、字号和颜色)、背景色和某些特殊效果(如阴影和项目符号样式)。

幻灯片母版包含文本占位符和页脚(如日期、时间和幻灯片编号)占位符。

如果要修改多张幻灯片的外观,不必一张张幻灯片进行修改,而只需在幻灯片母版上做一次修改即可。

将自动更新已有的幻灯片,并对以后新添加的幻灯片应用这些更改。

如果要更改文本格式,可选择占位符中的文本并做更改。

母版的类型有:标题母版、幻灯片母版、讲义母版和备注母版。

(4)、模板——一个特殊的演示文稿(扩展名为的演示文稿)。

提供两种模板:设计模板和内容模板。

设计模板包含预定义的格式和配色方案,可以应用到任意演示文稿中创建独特的外观。

内容模板包含与设计模板类似的格式和配色方案,加上带有文本的幻灯片,文本中包含针对特定主题提供的建议。

您可以修改任意模板以适应需要,或在已创建的演示文稿基础上建立新模板。

(5)、母版与模板的关系——每个模板都有自己的母版,母版是特殊的幻灯片,母版上的元素控制着模板的设计方案;应用模板后,会自动更新母版上的文本样式和图形,并按新模板的配色方案改变颜色;母版为所有幻灯片设置默认版式和格式,模板中包含有母版。

April 22, 2010Rapid Improvement at ShuntatAssessment of Opportunities and Execution RoadmapBackground• The Shenzhen based ShuntatElectric Accessories Co has been a long time partner of Volex in plug and electric accessory products• The company has been contracted by Volex to provide plug components for the new Apple products for all key markets• Ramping-up of production started about a month ago and has encountered many technical and process challenges given the new specifications that Apple has envisioned• The biggest issue so far has been the unstable yield for the UK standard plugs since the surface finishing has a set of new requirements, which are not common in this industry• The challenge, therefore, facing Volex and its supplier is to quickly bring the yield to a stable level with right quantityYield is a result of many factorsWe will look into all three drivers with different prioritiesRTY- Current Process ViewMachining CopperMachining PolishingHand Surface Polishing MachinePolishing Surface Polishing Sand Blasting NE Plating Molding Assembly FixtureAssembly Huge improvement potentials for both process technologiesRTY Calculation Needs Good MSA• As the process output involves both quantitative (size and geometric measures of the pins) and qualitative CTQs (surface quality), it is very important to have a reliable measurement system before we can do a trustworthy RTY calculation• Due to the time constraint, we couldn’t conduct a through MSA for each key step, but this is something we have to do before we are engaged in any quick fix or longer term process changes• We feel Shuntat, its copper rod supplier and Volex final assembly needs to develop coherent and agreeable measurements for key dimensional and surface quality CTQs since many CTQs are based on human judgment and hence subjective, which may create problems for the Gage R&RHuge Bottleneck in Capacity UtilizationMachiningCopper Machining CuttingCleansing Polishing ChamferingCleansing Polishing TrimmingCleansingPolishingCurrent designed capacity should be able to handle 8k daily outputHowever, Surface Grinding is Very ProblematicFurther Discussion of HSP and MSPAll agreed MSP ought to be made better to replace HSP ASAP!TAKT Opportunities• TAKT is a function of many factors• Currently, Shuntat is employing a two-shift work day with each shift lasting about 12 hours• Considering Shuntat is confident to deliver 3000 sets daily, TAKT, therefore, is easily calculated as 28.8 Seconds/set (24x60x60/3000)• We need the TAKT to be at least 7.2 Seconds/set (16x60x60/8000)- We assume a two-shift work day with 8 hours each- Suppose 8000 sets stable demand from Volex• From Volex standpoint, TAKT is more of an indicator for internal process efficiency and operating cost, as long as the process reaches a steady state (8k daily delivery). It is more an issue that Shuntat management ought to be concernedThe Rough Estimation of VSM• We did an elementary exercise to find out the VSM of the UK Duckhead manufacturingChange Opportunities and PrioritiesDiscussion of the Opportunities• All the proposed changes are closely related to each other; the priority is decided based on Volex’s immediate needs of satisfying Apple’s delivery requirements• A sound measure system is the foundation for effective process change and control activities and during our assessment we could not find solid evidence to demonstrate the measure system is already well established and propagated• Even though the Hand Surface Polishing/Machine Surface Polishing step is only a workaround to guarantee the surface quality, elimination of it requires thorough study of the copper machining procedure and alternative ways to ensure the surface quality CTQ, which is both time consuming and risky. We, therefore, propose a high priority action to make the machine polishing better• No doubt, current process is push in nature with large amount of WIP inventories among the steps and since some of them are of batch processing while others are single flow. This creates serious waiting, transportation and other wastes in the process. All the cleansing, polishing, quality check, etc. slow down the flow dramatically and they don’t add value at all. We feel there is big opportunity to streamline the process by introducing pull principals (with some sort of Kanban/Supermarket mechanism implemented) and a good raw material planning practice• The last suggestion mounts to a Lean exercise, which can be done while we sort out the quality issues firstImprovement roadmapThe following are trademarks and service marks of Six Sigma Academy International, LLC: Breakthrough Lean ®, Breakthrough Strategy ®, Breakthrough Value Services ®, Breakthrough Change Strategy SM , Breakthrough Design SM , Breakthrough Diagnosis SM , Breakthrough Execution SM , Breakthrough Sigma Lean SM , Breakthrough Six Sigma SM , Breakthrough Software Design SM , FASTART SM , Six Sigma Gold Belt TM , SOLVING YOUR BUSINESS PROBLEMS FOR THE LAST TIME SM . Six Sigma is a federally registered trademark of Motorola, Inc. MINITAB is a federally registered trademark of Minitab, Inc. SigmaFlow is a federally registered trademark of Compass Partners, Inc. VarTran is a federally registered trademark of Taylor Enterprises.SSA & Company 630 Fifth Ave., Suite 1900New York, NY 10111Tel. (212) SSA & Company 09D2招商局大厦建国路118号朝阳区,北京1000220106566 。