Lagged strain of laminates in RC beams strengthened with fiber-reinforced polymer

- 格式:pdf

- 大小:206.61 KB

- 文档页数:5

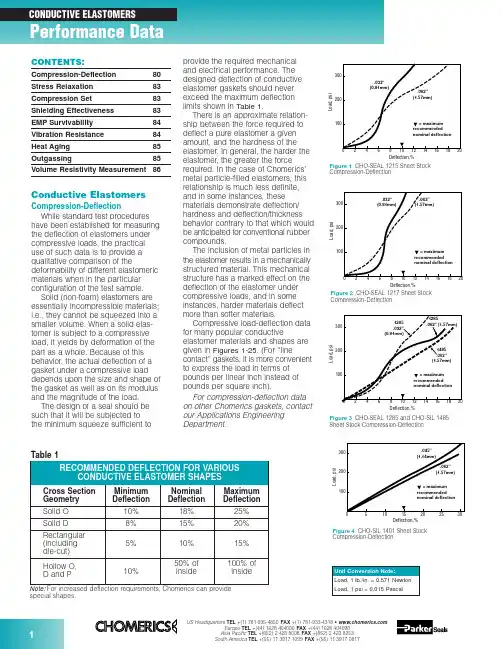

Figure 3CHO-SEAL 1285 and CHO-SIL 1485Sheet Stock Compression-DeflectionCompression-Deflectionspecial shapes.Conductive ElastomersCompression-DeflectionWhile standard test procedures have been established for measuring the deflection of elastomers under compressive loads, the practical use of such data is to provide a qualitative comparison of thedeformability of different elastomeric materials when in the particular configuration of the test sample.Solid (non-foam) elastomers are essentially incompressible materials;i.e., they cannot be squeezed into a smaller volume. When a solid elas-tomer is subject to a compressive load, it yields by deformation of the part as a whole. Because of this behavior, the actual deflection of a gasket under a compressive load depends upon the size and shape of the gasket as well as on its modulus and the magnitude of the load.The design of a seal should be such that it will be subjected to the minimum squeeze sufficient toprovide the required mechanical and electrical performance. The designed deflection of conductive elastomer gaskets should never exceed the maximum deflection limits shown in Table 1.There is an approximate relation-ship between the force required to deflect a pure elastomer a given amount, and the hardness of the elastomer. In general, the harder the elastomer, the greater the force required. In the case of Chomerics’metal particle-filled elastomers, this relationship is much less definite,and in some instances, these materials demonstrate deflection/hardness and deflection/thickness behavior contrary to that which would be anticipated for conventional rubber compounds.The inclusion of metal particles in the elastomer results in a mechanically structured material. This mechanical structure has a marked effect on the deflection of the elastomer under compressive loads, and in some instances, harder materials deflect more than softer materials.Compressive load-deflection data for many popular conductiveelastomer materials and shapes are given in Figures 1-25. (For “linecontact” gaskets, it is more convenient to express the load in terms of pounds per linear inch instead of pounds per square inch).For compression-deflection data on other Chomerics gaskets, contact our Applications Engineering Department.Compression-DeflectionCompression-DeflectionCONTENTS:Compression-Deflection 80Stress Relaxation 83Compression Set 83Shielding Effectiveness 83EMP Survivability 84Vibration Resistance 84Heat Aging 85Outgassing85Volume Resistivity Measurement86Figure 80.125 in. (3.18 mm) Dia. O-Strip Compression-DeflectionDeflection,%Compression-DeflectionCompression-DeflectionL o a d , l b ./i n c hDeflection, %Figure 210.156 in. (3.96 mm) High Hollow D-Strip Compression-DeflectionL o a d , l b ./i n c hDeflection, %Figure 220.312 in. (7.92 mm) High Hollow D-Strip Compression-DeflectionFigure 200.250 in. (6.35 mm) Dia. Hollow O-Strip Compression-DeflectionL o a d , l b ./i n c hDeflection, %L o a d , l b ./i n c hDeflection, %Figure 230.250 in. (6.35 mm) Dia. Hollow P-Strip Compression-DeflectionFigure 240.360 in. (9.14 mm) Dia. Hollow P-Strip Compression-DeflectionL o a d , l b ./i n c hDeflection, %L o a d , l b ./i n c hDeflection,%Figure 190.156 in. (3.96 mm) Dia. Hollow O-Strip Compression-DeflectionL o a d , l b ./i n c hDeflection, %Figure 170.250 in. (6.35 mm) Wide Rectangular Strip Compression-Deflection0.40.81.20.20.61.0C o m p r e s s i o n F o r c e (l b /i n )00.5 1.50.10.2Deflection (inch)1356P/N 10-09-W864-XXXXFigure 250.410 in. (10.41 mm) High V-Strip Compression-DeflectionStress RelaxationAs important as Compression Set and Compression-Deflection, is the Stress Relaxation characteristic of a gasket.If a rubber is subject to a com-pressive load, it will deflect. There is a stress/strain relationship, which for rubbers is generally non-linear except for very small deflections.After the load is applied, a stress decay occurs within the polymer resulting from the internal rearrange-ment of the molecular structure. An approximate rule is that the relaxed stress for cured silicone will finally settle at 70 to 75 percent of the initial stress.There are two ways in which a rubber gasket can be loaded to a desired value. One way is to load it to a point, let it relax, and reapply the load to restore the original stress. The next time it will relax, but not so much.If this is repeated a sufficient number of times, the correct static load on the gasket will reach equilibrium.A more practical way to reach the design value of stress is to load the gasket to 125 percent of its final design value, so that after the relax-ation process is completed the gasket will settle to 100 percent of the design load. This is very reproducible.Figure 26shows a typical stress relaxation curve for Chomerics’conductive elastomers.Compression SetWhen any rubber is deformedfor a period of time, some of the defor-mation is retained permanently even after the load is removed. The amount of permanent deformation, asmeasured by ASTM D395, is termed “Compression Set.” Compression set is measured under conditions of constant deflection (ASTM D395Method B) and is normally expressed as a percentage of the initialdeflection, not as a percentage of the initial height.For gaskets that are used once, or where the gasket/flange periphery relationship is constant (such as a door gasket), compression set is of minor significance if the original load condition and the service temperature are within the design limitations of the gasket material.For gaskets that are randomlyreseated one or more times in normal service life, it is important that the maximum change in gasket thickness does not exceed twice the maximum mismatch between the opposing mating surfaces.Shielding EffectivenessMost shielding effectiveness data given in Table 3 of the Conductive Elastomer section (pages 32-34) is based on a MIL-G-83528B testmethod, with a 24 in. x 24 in. aperture in a rigid enclosure wall and about 100 psi on the gasket. It is a valid and useful way of comparing variousgasket materials, but does not reflect the shielding effectiveness one can expect at seams of typical enclosures.CHO-TM-TP08 is a modified version of the MIL test that provides typical values achieved in actual applications.Since many factors will affect the actual shielding effectiveness of anenclosure seam (flange design,stiffness, flatness, surface resistivity,fastener spacing, enclosuredimensions, closure force, etc.), the only way to determine shielding effectiveness for real enclosures is to test them.Figures 28and 29provide dataon shielding effectiveness for actualFigure 27Formula for Calculation of Compression Setenclosures. The data in Figure 28shows the difference in attenuation between a shelter door closed with no gasket and the same door closed against a CHO-SEAL 1215 hollow D-strip gasket. Instead of single data points at each frequency tested, a range of data is shown for eachfrequency, representing the worst and best readings measured at many points around the door. Figure 29 shows the effects of closure force on shielding effectiveness of an enclosure tested at high frequencies (1-40 GHz) using CHO-SEAL 1215 solid D-strip gaskets.In order to establish reasonable upper limits on gasket resistivity, it is necessary to understand the rela-tionship between flange interface resistance and EMI leakage through the flange. Figure 30presents this relationship for an aluminum enclosure 3 in. x 3 in. x 4 in. deep, measured at 700 MHz. Die-cut gaskets 0.144 in.wide by 0.062 in. thick, in a wide range of resistivities, were clamped between the gold-plated flanges of thisenclosure. Simultaneous measure-ments of flange interface resistance (all attributable to the gaskets) versus RF leakage through the seamproduced a classic S-shaped curve.For the gasket configuration used in this test, the dramatic change in shielding effectiveness occursbetween gasket volume resistivities of 0.01 and 0.4 ohm-cm. Since real enclosures do not have gold-plated flanges, but rather have surfacefinishes (such as MIL-C-5541 Class 3chromate conversion coatings) which also increase in resistance over time, it is recommended that gasket volume resistivity be specified at 0.01 ohm-cm max. for the life of the equipment.Frequency, HzA t t e n u a t i o n (dB )Figure 28Shielding Effectiveness of a Shelter Door Gasket (14 kHz to 10 GHz)kA/inch of gasket (peak-to-peak).Pure silver (1224) and silver-plated-aluminum filled (1285) gaskets have less current carrying capability than silver-plated-copper materials, but are generally acceptable for EMP hardened systems (depending on specific EMP threat levels, gasket cross section dimensions, etc.).Vibration ResistanceCertain conductive elastomers are electrically stable during aircraft-level vibration environments, while others are not. The key factor which deter-mines vibration resistance is theshape and surface texture of the filler particles. Smooth, spherical fillers (such as those used in silver-plated-Figure 32Scanning Electron Microscopy Illustrates EMP Damage Mechanism for Silver/Glass ElastomersL e a k a g e (d B )Vibration (g)Figure 33Effects of Vibration on Shielding Effectiveness of Conductive Elastomer GasketsEMP SurvivabilityIn order for an enclosure to continue providing EMI isolationduring and after an EMP environment,the conductive gaskets at joints and seams must be capable of carrying EMP-induced current pulses without losing their conductivity. Figure 31shows the EMP current response of various types of conductive elastomer gaskets. Note that gaskets based on silver-plated-glass fillers (1350)become nonconductive at low levels of EMP current, and should therefore not be used when EMP is a design consideration. Figure 32is an electron microscope photo which clearly shows the damage mechanism.Silver-plated-copper filled (1215)gaskets have the highest resistance to EMP type currents, showing no loss of conductivity even at 2.50102030405060Shielding Degradation, dBIn t e r f a c e R e s i s t a n c e , m i l l i o h m sFigure 30Interface Resistance vs. Shielding Degradation at a Flange Jointglass materials) tend to move apart during vibration, leading to dramatic increases in resistance and loss of shielding effectiveness (although they normally recover their initial properties after the vibration has ended). Rough, less spherical particles resist vibration with very little electrical degradation. Figure 33shows the effects of vibration on three types of conductive gaskets.Although Chomerics’ silver-plated-copper filled 1215 gasket, with rough,irregular particle agglomerations,exhibits excellent stability during vibration, users of conductive elastomers should be aware that smooth, spherical silver-plated-copper fillers can be almost asunstable as silver-plated-glass fillers.Frequency, GHzA t t e n u a t i o n (dB )Figure 29Effect of Closure Force on Shielding Effectiveness (1 GHz to 40 GHz)Heat AgingThe primary aging mechanism which affects electrical stability of conductive elastomers is the oxidation of filler particles. Formaterials based on pure silver fillers,particle oxidation is not generally a problem because the oxide of silver is relatively soft and reasonably conductive. If the filler particles are non-noble (such as copper, nickel,aluminum, etc.) they will oxidize readily over time and become nonconductive. Even silver-plated base metal powders, such as silver-V o l u m e R e s i s t i v i t y (o h m -c m )Hours at 150°C (Solid Line)Hours at 125°C (Dotted Line)Figure 34Typical heat aging characteristics of Chomerics’ plated-powder-filled conductiveelastomers. Flanged 1000-hr test recommended for qualification. Unflanged 48-hr. test recommended for QC acceptance.plated-copper or silver-plated-aluminum will become non-conductive over time if the plating is not done properly (or if other processingvariables are not properly controlled).These are generally batch control problems, with each batch being potentially good or bad.The most reliable method of predicting whether a batch will be electrically stable is to promote the rate at which poorly plated or processed particles will oxidize, by heat aging in an air circulating oven.For qualification, 1000 hours (42 days)at maximum rated use temperature (with the gasket sample deflected 7-10% between flanges) is the recommended heat aging test for accelerating the effects of long-term aging at normal ambient tempera-tures. A quicker heat aging test,which correlates well with the 1000hour test and is useful for QC acceptance testing, involves a 48hour/150°C oven bake with thegasket sample on an open wire-grid tray (rather than being clamped between flanges). Figure 34shows typical data for volume resistivity versus time for each of these tests.Note:It is essential that no source of free sulfur be placed in the aging oven, as it will cause the material to degrade electrically and mask any oxidation aging tendencies. Common sources of sulfur are neoprenes,most cardboards and other paper products.OutgassingMany spacecraft specifications require that nonmetallic components be virtually free of volatile residues which might outgas in the hard vacuum environment of space. The standard test method for determining outgassing behavior is ASTM E595-93, which provides for measurement of total mass loss (TML) and collected volatile condensable materials (CVCM) in a vacuum environment. Data for a number of Chomerics conductive elastomers,based on ASTM E595-93 testing done by NASA Goddard SpaceflightCenter, is presented in Table 2. The normal specification limits or guide-lines on outgassing for NASA applications are 1% TML max.,and 0.1% CVCM max.。

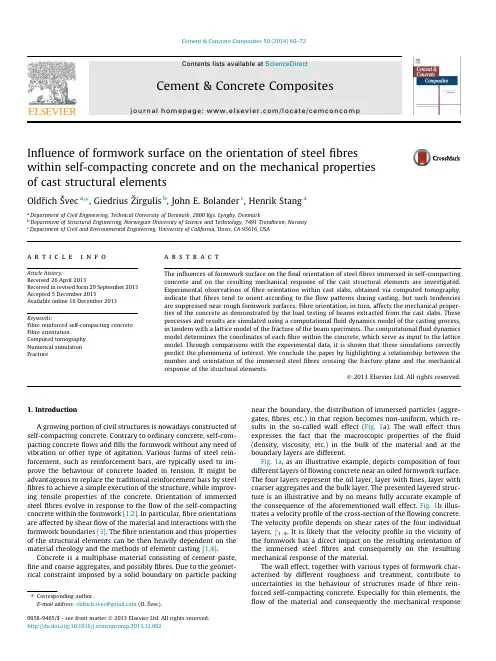

Influence of formwork surface on the orientation of steel fibres within self-compacting concrete and on the mechanical properties of cast structuralelementsOldrˇich Švec a ,⇑,Giedrius Z ˇirgulis b ,John E.Bolander c ,Henrik Stang a aDepartment of Civil Engineering,Technical University of Denmark,2800Kgs.Lyngby,DenmarkbDepartment of Structural Engineering,Norwegian University of Science and Technology,7491Trondheim,Norway cDepartment of Civil and Environmental Engineering,University of California,Davis,CA 95616,USAa r t i c l e i n f o Article history:Received 26April 2013Received in revised form 29September 2013Accepted 5December 2013Available online 16December 2013Keywords:Fibre reinforced self-compacting concrete Fibre orientationComputed tomography Numerical simulation Fracturea b s t r a c tThe influences of formwork surface on the final orientation of steel fibres immersed in self-compacting concrete and on the resulting mechanical response of the cast structural elements are investigated.Experimental observations of fibre orientation within cast slabs,obtained via computed tomography,indicate that fibres tend to orient according to the flow patterns during casting,but such tendencies are suppressed near rough formwork surfaces.Fibre orientation,in turn,affects the mechanical proper-ties of the concrete as demonstrated by the load testing of beams extracted from the cast slabs.These processes and results are simulated using a computational fluid dynamics model of the casting process,in tandem with a lattice model of the fracture of the beam specimens.The computational fluid dynamics model determines the coordinates of each fibre within the concrete,which serve as input to the lattice model.Through comparisons with the experimental data,it is shown that these simulations correctly predict the phenomena of interest.We conclude the paper by highlighting a relationship between the number and orientation of the immersed steel fibres crossing the fracture plane and the mechanical response of the structural elements.Ó2013Elsevier Ltd.All rights reserved.1.IntroductionA growing portion of civil structures is nowadays constructed of self-compacting concrete.Contrary to ordinary concrete,self-com-pacting concrete flows and fills the formwork without any need of vibration or other type of agitation.Various forms of steel rein-forcement,such as reinforcement bars,are typically used to im-prove the behaviour of concrete loaded in tension.It might be advantageous to replace the traditional reinforcement bars by steel fibres to achieve a simple execution of the structure,while improv-ing tensile properties of the concrete.Orientation of immersed steel fibres evolve in response to the flow of the self-compacting concrete within the formwork [1,2].In particular,fibre orientations are affected by shear flow of the material and interactions with the formwork boundaries [3].The fibre orientation and thus properties of the structural elements can be then heavily dependent on the material rheology and the methods of element casting [1,4].Concrete is a multiphase material consisting of cement paste,fine and coarse aggregates,and possibly fibres.Due to the geomet-rical constraint imposed by a solid boundary on particle packing near the boundary,the distribution of immersed particles (aggre-gates,fibres,etc.)in that region becomes non-uniform,which re-sults in the so-called wall effect (Fig.1a).The wall effect thus expresses the fact that the macroscopic properties of the fluid (density,viscosity,etc.)in the bulk of the material and at the boundary layers are different.Fig.1a ,as an illustrative example,depicts composition of four different layers of flowing concrete near an oiled formwork surface.The four layers represent the oil layer,layer with fines,layer with coarser aggregates and the bulk layer.The presented layered struc-ture is an illustrative and by no means fully accurate example of the consequence of the aforementioned wall effect.Fig.1b illus-trates a velocity profile of the cross-section of the flowing concrete.The velocity profile depends on shear rates of the four individuallayers,_c1À4.It is likely that the velocity profile in the vicinity of the formwork has a direct impact on the resulting orientation of the immersed steel fibres and consequently on the resulting mechanical response of the material.The wall effect,together with various types of formwork char-acterised by different roughness and treatment,contribute to uncertainties in the behaviour of structures made of fibre rein-forced self-compacting concrete.Especially for thin elements,the flow of the material and consequently the mechanical response0958-9465/$-see front matter Ó2013Elsevier Ltd.All rights reserved./10.1016/j.cemconcomp.2013.12.002Corresponding author.E-mail address:oldrich.svec@ (O.Švec).of the elements is significantly influenced by the formwork–fluid interaction.In the field of fibre reinforced self-compacting concrete,several authors discuss the influence of casting process on the orientation of steel fibres [3,5–7].Others study the impact of fibre orientation on the mechanical response of the structural elements [1,8–10].Jacobsen et al.[11]addresses the impact of the formwork surface on the pumpability of an ordinary concrete.The presented paper merges all the problems into one by study-ing the influence of the formwork surface on the flow pattern of steel fibre reinforced self-compacting concrete close to thework.The paper further studies the influence of the final tion of steel fibres on the resulting mechanical properties of material.The study is carried out through the combined use physical experiments and numerical modelling.The study was performed by means of tomographic imaging of specimens cast with fibre reinforced self-compacting and by means of three-and four-point bending tests of cut from the slabs.The numerical study was conducted by of two distinct numerical simulations developed by the (1)a computational fluid dynamics based procedure to simulatebre movement during the casting process,including interactions at the formwork boundaries and (2)a lattice model material elasticity and fracture,including the explicit tion of individual fibres within the specimen volumes.Fibre dinates determined through the computational fluid based simulation served as direct input to the lattice of the flexural test specimens.Materials and methods of the presented study are fully de-scribed in Section 2.The casting process and the data analysis pro-cess of the experimental study are explained in Section 2.1.The two distinct numerical simulations are introduced in Section 2.2.Section 3presents all the experimentally and numerically obtained results related to the orientation of steel fibres and related to the mechanical properties of the material.The aforementioned results are linked together in Section 3.3.Discussion of the results is pro-vided in Section 4.Section 5concludes the article.2.Materials and methodsThe following subsections describe experiments that were con-ducted to verify the hypothesis that formwork surface can influ-ence the orientation of fibres immersed in self-compacting concrete and,consequently,the mechanical response of the struc-ture.The numerical simulations,which were used to strengthen and complement the experimental observations,are also briefly introduced.2.1.ExperimentsSix slabs of fibre reinforced self-compacting concrete were cast using formwork of three different surface types.The following sub-sections describe the casting process of the slabs,methods for quantifying the orientations of fibres immersed in the slabs,and the subsequent mechanical testing of beam specimens cut from the slabs.2.1.1.Mixture design and casting processSix slabs of dimensions 1.2m Â1.2m Â0.15m were cast of fi-bre reinforced self-compacting concrete.The casting process was conducted from a rubber pipe inlet positioned near one of the cor-ners of the slab (Fig.2).The point of discharge was located at 0.2m above the base of the slab.Mixture design of the self-compacting concrete was:cement =388kg =m 3,silica fume =19:4kg =m 3,natural sand ð0—8mm Þ¼1182kg =m 3,crushed stone ð8—16mm Þ¼570kg =m 3,super plasti-ciser =4:66kg =m 3and air entrainer (1:7)=0:97kg =m 3.The water ce-ment ratio was 0.505.At the time of mixing,the fine and coarse aggregates were in the saturated-surface-dry condition.Hooked end steel fibres (Bekaert Dramix RL 80/60BN)were gradually added to the self-compacting concrete during the mixing process.The fibre volume ratio was 0.5%,corresponding to 40kg/m 3.The fibre length and the fibre diameter were 60mm and 0.75mm,respectively.Density of the steel fibres was 7850kg/m 3.Three different formwork surfaces were employed in the Supplementary video.The video a shows casting process of steel fibre self-compacting concrete into a formwork of three different surface roughnesses.O.Švec et al./Cement &Concrete Composites 50(2014)60–7261which shows the casting of the fibre reinforced self-compact-ing concrete into the glue-laminated plywood formwork,ordin-ary plywood formwork and into the glued-sand plywood formwork.Rheology of the fresh fibre reinforced self-compacting concrete was evaluated during the casting process by means of the stan-dardized slump flow test according to EN 12350-2.Spread of the slump was measured and read 620mm.Rheological parameters,following a Bingham plastic rheological model,were obtained by means of 4C-Rheometer [13].Yield stress and plastic viscosity of the fibre reinforced self-compacting concrete were estimated to be 22Pa and 75Pa s,respectively.The measured density and air content of the fresh concrete were 2318kg/m 3and 3.5%,respectively.After casting,the slabs were covered with cloth saturated with water.The slabs were then sealed within a polyethylene film and left to harden for a period of 28days at ambient temperatures.In total six beam specimens of dimensions 0.6m Â0.15m Â0.15m were then cut out from each of the slabs,as indicated by the 1red and green prisms in Fig.4.Orientation of the steel fibres present in the beams specimens was studied by means of the computed tomography and subse-quent image analysis.The resulting mechanical response of the beam specimens was studied by means of the three-and four-point bending tests.puted tomography and image analysisComputed Tomography (CT)is an advanced radiographic tech-nique for obtaining 3D images of the internal structure of an ele-ment.The method has been among others widely used in the field of steel fibre reinforced concrete [1,14–16].The CT and subse-quent image analyses were employed to obtain a 3D representa-tion of the steel fibres located in the beam specimens.The 3D representation was subsequently approximated by a set of 3D ori-entation tensors [17].We used a former medical CT scanner,Siemens Somatom Sen-sation 4,to scan three beam specimens out of each slab.The three scanned beam specimens are depicted in Fig.4as red prisms.Sequential spine routine of the medical CT scanner was employed to interpret approximately 600successive slices normal to the x axis (Fig.4).A typical slice image produced by the CT scanner is presented in Fig.5.The red regions in Fig.5b are the voxels with maximum brightness.The red regions were obtained by threshold-ing the image.The zone marked by the green rectangle in Fig.5b reveals that not only fibres but also parts of aggregates are marked in red.This is caused by a relatively low tube voltage of the medical CT scanner and results in a more complicated image analysis.An open-source application Fiji 2was used to crop,threshold and skeletonise the sequence of the approximately 600successive slice images.The skeletonisation technique of the Fiji application output-ted a skeleton,i.e.a large set of 3D line segments located in space.Fig.6as an example shows a small part of the skeleton.Red region in Fig.6shows 3D line segments that were probably created by skeletonising aggregates depicted in Fig.5b.Fig.6re-veals that although the majority of the 3D line segments represent individual parts of steel fibres,some of the 3D line segments rep-resent other concrete constituents such as aggregates.The primary interest of the paper is to study orientation of steel fibres.The 3D line segments were therefore converted into a set of second-order orientation tensors [17].The second-order tensors can be visual-ised by means of 3D ellipsoids in space or by means of 2D ellipses in plane.All the CT scanned beam specimens were volumetrically split into a series of cubic regions (see Fig.7b for a 2D projection).Sec-ond-order orientation tensors were computed for all the 3D line segments located in each of the cubic regions.Fig.7c illustrates the second-order tensors by projecting the 3D orientation ellip-soids into 2D orientation ellipses.The second-order orientation tensors can be computed as [17]:a ij ¼1tPLp x p xP Lp x p y P Lp x p zPLp y p yP Lp y p z sym :PLp z p z264375;ð1Þwhere the summation is taken through all the line segments located in the cubic region of interest.Values of p x ;p y and p z are compo-nents of the normalised vector pointing in the direction of the indi-vidual line segments located in the cubic region of interest.Valueofsurface views of three different formwork types.(a)Glue-laminated plywood.(b)Ordinary plywood.(c)Glued-sand1For interpretation of colour in Figs.4–6,the reader is referred to the web version of this article.2http://fiji.sc/.L is the length of the individual line segments length of the line segments located in the L t ¼P L .The summation of the main diagonal of must be equal to unity,i.e.,a 1;1þa 2;2þa directions of the axes of the orientation ellipsoids eigenvalues and eigenvectors of the second-order sors,respectively.Results of the computed are presented in Section 3.1.1.2.1.3.Three-and four-point bending testsAll the six beam specimens indicated obtain their mechanical response in flexure.depicted by green prisms in Fig.4were bending according to the Norwegian sawn After the CT scanning,as presented in specimens depicted as red prisms in Fig.vide a notch at mid-span and tested according to EN 14651.During the test,the beam specimens were oriented in the casting direction,such that the tensile face was the bottom cast surface of the beam which EN 14651.Fig.8depicts a typical fracture of bending test.The degree of planarity of that these surface views of fracture represent pattern well.Fig.5.(a)A typical slice image of the scanned beam specimens.(b)Regions with the maximum brightness.6.Result of the skeletonisation technique of the CT images.Black lines are the individual 3D line segments.(a)(b)(c)7.Process for obtaining the second-order orientation tensors:(a)skeleton image of fibres within beam specimen;(b)volumetric discretization into cubic regions;and (c)second-order tensor representation of fibre orientation within each 8.A typical frontal view of the fractured beam specimens.Top:three-point bending test.Bottom:four-point bending test.CMOD.For the four-point bending tests,load and respective mid-span deflections of the beam specimens,d m,were recorded.For the purpose of comparing results of the different types of beam tests,an effective CMOD for the case of four-point bending was computed based on[18]ascmod4pt¼4h d ml4pt;ð2Þwhere hð¼0:15mÞis the height of the beam specimen and l4ptð¼0:45mÞis the distance between the beam supports.In the case of the three-point bending tests,theflexural stresses of beam specimens were computed as[19]r3pt¼3Fl3pt2bh2sp;ð3Þwhere bð¼0:15mÞis the width of the beam specimen and h spð¼0:125mÞis the distance between tip of the notch and top of cross section[20].Value of l3ptð¼0:5mÞstands for the span between the beam supports.In the case of the four-point bending tests,theflexural stress of a beam specimen was computed asr4pt¼Fl4ptbh:ð4ÞResults of the three-and four-point bending tests are presented in Section3.2.1.2.1.4.Fibre count local to the fracture planeSection2.1.2described the process of scanning of the beam specimens depicted by red prisms in Fig.4.For each3D image of the beam specimens produced by CT scanning,we selected the im-age slice located closest to the fracture plane.The number of steel fibres crossing the fracture plane was estimated by manually counting thefibres visible on the slice images similarly to [10,?,21,22].In addition,all the beam specimens tested by the three-and four-point bending tests were cut in the vicinity of the main crack. The cut plane was polished and the number of steelfibres visible at the cut plane was manually counted.The number of steelfibres crossing the fracture plane or the cut plane was related to theflex-ural stresses of the individual beam specimens at an arbitrarily chosen crack mouth opening displacement,as will be presented in Section3.3.2.2.Numerical simulationsTwo distinct types of numerical simulation were run to strengthen the experimental observations and to shed light on the phenomenological processes observed in the experiments. Thefirst type simulates theflow of thefibre reinforced self-com-pacting ingfibre coordinate data from theflow simu-lations,the second type simulates the fracture behaviour of the hardenedfibre reinforced self-compacting concrete.2.2.1.Numerical simulation offlowIn recent years there have been growing fundamental and prac-tical interests in numerically simulating theflow of concrete mate-rials,includingfibre reinforced concrete[23].Roussel et al.[24] review the advantages and disadvantages of several strategies for simulating concreteflow.We have developed a numerical frame-work capable of predictingflow of explicitly represented rigid par-ticles immersed in the free surfaceflow of a homogeneous non-Newtonianfluid,such as fresh concrete.One of the primary goals of the numerical framework has been to quantitatively predict the distribution and orientation of the steelfibres immersed in the self-compacting concrete during casting.The numerical frame-work is explained in detail in[25].We discussed the implementa-tion of the immersed rigidfibres into the framework in[26].The ability of the numerical framework to properly simulate various formwork surfaces was introduced in[27].Fig.9presents a3D view of the numerical simulation of slab casting at an intermediate step.The numerical simulation was run with the same physical input parameters(fluid density,yield stress plastic viscosity,fibre type,etc.)as presented in Section 2.1.1.As a possibility for future research,the determination of in-put parameters could be supported by predictive models[28,29]. The numerical framework is devoid of any non-physical input parameters.The self-compacting concrete was modelled as a free surfaceflow of a homogeneous Bingham plasticfluid.The steel fibres were modelled as thin rigid cylinders immersed in the homogeneousfluid.The steelfibres were modelled explicitly,one by one,including various features of the numerical framework such as the two-way coupled interaction between thefluid and thefibres,plastic collisions among thefibres or plastic collisions of thefibres with the formwork.The formwork was modelled as Navier’s slip boundary condition of a specific Navier’s slip length [27].Thefluid domain was discretized as1cm=1discrete unit.In total three different numerical simulations were run differen-tiated by the type of the formwork surface used in the numerical simulation.The three different Navier’s slip lengths were then equal to0cm,8cm and1.Each numerical simulation was run in parallel on25computer cores and lasted approximately4days.The peak number of explic-itly simulated steelfibres was approximately41,000.Results of the numerical simulation offlow are presented in Section3.1.2.2.2.2.Numerical simulation of fracture behaviourA lattice-type model is used to simulate the fracture behaviour of thefibre-reinforced concrete.Both the matrix andfibre element formulations are based on the concept of a rigid-body-spring mod-el,as described in previous publications[30–32].The concrete ma-trix is assumed to be homogeneous and exhibit bilinear softening after fracture.Material disorder is solely due to the presence of the short-fibre reinforcement,which is explicitly represented within the model framework.Domain discretization is based on the Delaunay/Voronoi tessellation of a set of nodes[33].Discretiza-tion of thefibre-reinforced concrete specimens is presented in Fig.10a.Stiffness contributions of thefibres before concrete cracking are derived from elastic shear lag theory.After concrete cracking,fibre contributions to strength and stiffness across the open crack ac-count for debonding and slip at thefibre–matrix interface.The ef-fect of the hooked end of thefibres was approximated as a frictional force,distributed uniformly over thefibre embedded length.The pullout behaviour of individualfibres was modified to account for snubbing effect and the potential for matrix spalling whenfibres are lowly inclined to the fracture plane[34].The lattice model was used to simulate fracture behaviour of each of the four-point bend tests(B1a,B2a,and B3a)for the case of glue-laminated plywood as formwork.This case exhibited the largest variation in load–displacement behaviour with respect to beam position in the slab.Thefinal positions of the steelfibres within the cast slab spec-imens were supplied by the aforementioned numerical simulations offlow.Thereafter,the slabs were sectioned to produce models of the beam specimens,as shown in Fig.4,in a way that mimicked the physical cutting process.Fibres intersecting the cut planes were cut at the point of intersection,retaining the portion inside the beam volume.Fig.10b as an example illustrates steelfibres present in one of the tested beam specimens.64O.Švec et al./Cement&Concrete Composites50(2014)60–72Fracture of the beam specimens was restricted to occur along the central plane within the beam span(see Fig.10).This simplifi-cation allows for the grading of nodal point density in the vicinity of the crack plane to reduce computational expense.As discussed later,however,restricting the location of cracking can affect the mechanical response of the beams.Tensile strength of the matrix and the pullout resistance of individualfibres were adjusted to achieve rough agreement between the load–displacement curve of the model and that of the B1a specimen.The following settings were used as a result of the calibration process:uniaxial tensile strength r t¼2MPa; r1¼r t=4;w1¼0:05mm;traction-free crack opening displace-ment w c¼0:3mm;and frictional resistance s f¼4MPa[31].The same parameter set was then used for the simulations of specimens B2a and B3a.The results for specimens B2a and B3a can be therefore viewed as predictive simulations.The assumptions made herein,including thefitting of param-eter values for the B1a specimen,were deemed reasonable for achieving the primary goal of the fracture simulations,which is to demonstrate the effects offibre distribution on the fracture behaviour of theflexural specimens.Results of the numerical simulation of fracture behaviour are presented in Section3.2.2.3.ResultsThis section presents results obtained by CT scanning and by the three-and four-point bending tests.These experimental results are then compared to results obtained from their respective numerical simulations.3.1.Fibre orientationThe following two subsections study the average planar(x–y) orientation of the steelfibres by means of the second-order orientation parisons are made between the orienta-tion of the steelfibres obtained by experiments and the results ob-tained by the numerical simulations that we developed.puted tomography and image analysisFig.11presents projected top views of the orientation ellipsoids for the bottom half of the CT scanned beam specimens for the dif-ferent formwork surfaces.The positions of the beam specimens (CT1,CT2,CT3)within the cast slabs are indicated in Fig.4.Fig.11a and b indicates that the ordinary plywood formwork and the glued-sand plywood formwork provide similar orientations of the immersed steelfibres in the bottom half of the slabs.Steelfibres in the bulk of beam specimens CT1and CT2seem to be more or less randomly oriented as there is no prevailing pattern of the orienta-tion ellipses.The steelfibres become fairly oriented along the y coordinate at the bottom and top edges of the beam specimens CT1and CT2,respectively.This is caused by the wall-effect induced by the vertical parts of the formwork.Beam specimens CT3of Fig.11a and b reveal a slight degree of orientation of the steelfibres along the x coordinate.By observing Fig.11a and b,we can conclude that the ordinary plywood formwork and the glued-sand plywood formwork possess similar apparent slip characteristics.At the bottom half of the slabs,the rough surface of the formwork seems to result infibre orientations that are more or less independent of theflow pattern.Fig.11c on the other hand shows a completely different pattern of the orientation of the steelfibres.The observation suggests that,3D view of the simulated slab casting at an intermediate step.Left:immersed steelfibres.Right:Bingham plastic four-point bend specimen under loading and(b)fibres within the computational domain for specimen B1a(forwithin the bottom half of the slab,the fibres tend to orient under the flow of the self-compacting concrete when a smooth-surface formwork such as glue-laminated plywood is applied.Fig.12presents the experimentally obtained orientation of the steel fibres for the upper half of the slabs for the three formwork surfaces.Contrary to Fig.11,all results indicate a similar pattern in which fibres seem to be oriented according to the flow of the self-compacting concrete.Fig.12c indicates a slightly higher de-gree of the orientation of the steel fibres compared to those of Fig.12a and b but the difference is much less pronounced than for the case of the bottom half of the slabs.3.1.2.Numerical simulation of flowThe casting process of the slabs of the three formwork surfaces was simulated by means of the numerical framework that we developed and have described in [25–27].The formwork of the castslabs was modelled using Navier’s slip boundary condition.Numerical simulations were run for Navier’s slip lengths of 0cm,8cm and 1.The numerically obtained orientation of the steel fibres was subsequently compared to the experimental results presented in Section 3.1.1.Fig.13shows the resulting orientation of the steel fibres for the slab with Navier’s slip length equal to 0cm.The orientation of the steel fibres is depicted as the top view projection of the orientation ellipsoids (marked with black stroke).Within the bottom half of the slab (Fig.13a ),the steel fibres tend to orient in the regions close to the vertical walls of the formwork,which is primarily caused by the wall effect.In the bulk of the slab,the steel fibres remain in a more or less random orientation state.In the upper half of the slab (Fig.13b ),the steel fibres exhibit a relatively high degree of orientation following the flow pattern of the self-compactingconcrete.66O.Švec et al./Cement &Concrete Composites 50(2014)60–72O.Švec et al./Cement&Concrete Composites50(2014)60–7267Fig.13also compares the simulated fibre orientations with the experimentally measured orientations for the bottom and upper halfs of the slab.The comparison indicates a relatively high degree of agreement between the experimentally and numerically ob-tained results.The comparison indicates that glued-sand plywood formwork or formworks of similar roughness can be successfully modelled using the Navier’s slip boundary condition with a slip length of 0cm.Fig.14presents the simulated fibre orientations for the slab with Navier’s slip length equal to 8cm .In the bulk of the bottom half of the slab (Fig.14a ),the steel fibres seem to orient to a higher degree compared to the slab with slip length equal to 0cm (see Fig.13a).The steel fibres of the upper half of the slab exhibit a high degree of orientation,following the flow pattern of the self-com-pacting concrete.The results of the numerical simulation agree well with the experimental (CT)results for the slab having the glue-laminated plywood as the formwork (Fig.14).Fig.15presents the orientation of the steel fibres for the extreme case of the Navier’s slip length equal to 1.In such a case the steel fibres exhibit a high degree of orientation in all the parts of the slab,except for immediately under the inlet pipe.There were no respective experimental results for comparison with these numerical results.3.2.Mechanical propertiesThis subsection illustrates the influence of the formwork sur-face on the mechanical properties of the fibre reinforced self-com-pacting concrete material.Results of the three-and four-point bending tests are presented.For the case of glue-laminated ply-wood formwork,tested under four-point bending,the experimen-tal results are compared to those of the lattice model simulations.3.2.1.Three-and four-point bending testsFigs.16–18present mechanical responses of the beam speci-mens for the three different formwork surfaces in terms of load–displacement curves.Two nominally identical slabs were cast for each formwork surface type and,therefore,two flexural test results are provided for each case.Individual plots thus contain results of two beam specimens of the same origin,e.g.B1,a and B1,b.Fig.16indicates a substantial difference in the flexural behav-iour of the individual beam specimens,ranging from deflection hardening to almost complete loss of residual strength after first cracking.For example,beam specimens marked CT3and B3expe-rience more than 5Âand 10Âhigher post-cracking strengths com-pared to beam specimens CT1and B1,respectively.The observations suggest that,when using a smooth-surface formwork,structural elements extracted from different locations can possess considerably diverse mechanical properties.Figs.17and 18on the other hand indicate a significantly lower spread of the flexural stresses of the individual beam specimens.The highest post-cracking strength of the beam specimens is approximately 2Âhigher compared to the lowest mechanical re-sponse of the beam specimens.Structural elements cast into form-work with a rough surface generally seem to result in considerably less diverse mechanical properties compared to the structural elements cast into a formwork with a smooth surface.Relative to the four-point bending tests,the three-point bending tests exhibit higher peak strengths and somewhat larger variations of the load–displacement curves.The higher strengths are likely caused by restricting fracture to occur from the notch at midspan.The four-point loading configuration produces a larger volume of highly stressed material and allows for failure to occur at potentially weaker locations.Markovic [35]observed less engagement of the hooked end of steel fibres during fracture of unnotched specimens,compared to notched specimens.The unnotched case facilitates fracture along paths of least resistance that,to some degree,avoid full deformation of the fibre hooks during pullout.Such behaviour contributes to lower strength and toughness of unnotched speci-mens.The larger variation in the load–displacement curves of the three-point bending tests is likely due to variations in fibre count and fibre orientation in the ligament zone above the notch tip.How-ever,additional data points are needed to make statistically signif-icant conclusions regarding differences between the three-and four-point bending test results.3.2.2.Numerical simulation of fracture behaviourFracture behaviour of the four-point bend specimens,taken from the slab having glue-laminated plywood as the formwork,was numerically simulated by means of the lattice model.Fig.19presents both the numerically and experimentally obtained load–displacement curves for beams B1a,B2a and B3a.As explained in Section 2.2.2,model parameters were adjusted to achieve close agreement with the load–displacement curve of beam B1a.The same parameter set was used for beams B2a and B3a,so the corre-sponding simulations may be viewed as predictions.The trends with respect to first cracking strength,peak strength,and evolution of post-cracking residual strength are in good qualitative agree-ment with the experimental results.3.3.Fibre count local to the fracture planeThis subsection relates the number and orientation of the im-mersed steel fibres to the fracture behaviour of the beam speci-mens in a quantitative manner.Fig.20presents flexuralstresses68O.Švec et al./Cement &Concrete Composites 50(2014)60–72。

力学名词中英对照2007-12-15 09:59:20 楼主A 安全因数safety factorB半桥接法half bridge闭口薄壁杆thin-walled tubes比例极限proportional limit边界条件boundary conditions变截面梁beam of variable cross section变形deformation变形协调方程compatibility equation标距gage length泊松比Poisson's ratio补偿块compensating blockC材料力学mechanics of materials冲击荷载impact load初应力,预应力initial stress纯剪切pure shear纯弯曲pure bending脆性材料brittle materialsD大柔度杆long columns单位荷载unit load单位力偶unit couple单位荷载法unit-load method单向应力,单向受力uniaxial stress等强度梁beam of constant strength低周疲劳low-cycle fatigue电桥平衡bridge balancing电阻应变计resistance strain gage电阻应变仪resistance strain indicator叠加法superposition method叠加原理superposition principle动荷载dynamic load断面收缩率percentage reduction in area多余约束redundant restraint2E二向应力状态state of biaxial stressF分布力distributed force复杂应力状态state of triaxial stress复合材料composite materialG杆,杆件bar刚度stiffness刚架,构架frame刚结点rigid joint高周疲劳high-cycle fatigue各向同性材料isotropical material功的互等定理reciprocal-work theorem工作应变计active strain gage工作应力working stress构件structural member惯性半径radius of gyration of an area惯性积product of inertia惯性矩,截面二次轴距moment of inertia广义胡克定律generalized Hook's lawH横向变形lateral deformation胡克定律Hook's law滑移线slip-linesJ基本系统primary system畸变能理论distortion energy theory畸变能密度distortional strain energy density极惯性矩,截面二次极矩polar moment of inertia 极限应力ultimate stress极限荷载limit load挤压应力bearing stress剪力shear force剪力方程equation of shear force剪力图shear force diagram剪流shear flow剪切胡克定律Hook's law for shear剪切shear3交变应力,循环应力cyclic stress截面法method of sections截面几何性质geometrical properties of an area截面核心core of section静不定次,超静定次数degree of a statically indeterminate problem 静不定问题,超静定问题statically indeterminate problem静定问题statically determinate problem静荷载static load静矩,一次矩static moment颈缩neckingK开口薄壁杆bar of thin-walled open cross section抗拉强度ultimate stress in tension抗扭截面系数section modulus in torsion抗扭强度ultimate stress in torsion抗弯截面系数section modulus in bendingL拉压刚度axial rigidity拉压杆,轴向承载杆axially loaded bar理想弹塑性假设elastic-perfectly plastic assumption力法force method力学性能mechanical properties连续梁continuous beam连续条件continuity condition梁beams临界应力critical stress临界荷载critical loadM迈因纳定律Miner's law名义屈服强度offset yielding stress莫尔强度理论Mohr theory of failure敏感栅sensitive gridN挠度deflection挠曲轴deflection curve挠曲轴方程equation of deflection curve挠曲轴近似微分方程approximately differential equation of the deflection curve 内力internal forces扭力矩twisting moment扭矩torsional moment4扭矩图torque diagram扭转torsion扭转极限应力ultimate stress in torsion扭转角angel of twist扭转屈服强度yielding stress in torsion扭转刚度torsional rigidityO欧拉公式Euler's formulaP疲劳极限,条件疲劳极限endurance limit疲劳破坏fatigue rupture疲劳寿命fatigue life偏心拉伸eccentric tension偏心压缩eccentric compression平均应力average stress平面弯曲plane bending平面应力状态state of plane stress平行移轴定理parallel axis theorem平面假设plane cross-section assumptionQ强度strength强度理论theory of strength强度条件strength condition切变模量shear modulus切应变shear strain切应力shear stress切应力互等定理theorem of conjugate shearing stress屈服yield屈服强度yield strength全桥接线法full bridgeR热应力thermal stressS三向应力状态state of triaxial stress三轴直角应变花three-element rectangular rosette三轴等角应变花three-element delta rosette失稳buckling伸长率elongation5圣维南原理Saint-V enant's principle实验应力分析experimental stress analysis塑性变形,残余变形plastic deformation塑性材料,延性材料ductile materials塑性铰plastic hingeT弹簧常量spring constant弹性变形elastic deformation弹性模量modulus of elasticity体积力body force体积改变能密度density of energy of volume change 体应变volume strainW弯矩bending moment弯矩方程equation of bending moment弯矩图bending moment diagram弯曲bending弯曲刚度flexural rigidity弯曲正应力normal stress in bending弯曲切应力shear stress in bending弯曲中心shear center位移法displacement method位移互等定理reciprocal-displacement theorem稳定条件stability condition稳定性stability稳定安全因数safety factor for stabilityX细长比,柔度slenderness ratio线性弹性体linear elastic body约束扭转constraint torsion相当长度,有效长度equivalent length相当应力equivalent stress小柔度杆short columns形心轴centroidal axis形状系数shape factor许用应力allowable stress许用应力法allowable stress method许用荷载allowable load许用荷载法allowable load method6Y应变花strain rosette应变计strain gage应变能strain energy应变能密度strain energy density应力stress应力速率stress ratio应力比stress ratio应力幅stress amplitude应力状态state of stress应力集中stress concentration应力集中因数stress concentration factor应力-寿命曲线,S-N 曲线stress-cycle curve 应力-应变图stress-strain diagram应力圆,莫尔圆Mohr's circle for stressesZ正应变normal strain正应力normal stress中面middle plane中柔度杆intermediate columns中性层neutral surface中性轴neutral axis轴shaft轴力axial force轴力图axial force diagram轴向变形axial deformation轴向拉伸axial tension轴向压缩axial compression主平面principal planes主应力principal stress主应力迹线principal stress trajectory主轴principal axis主惯性矩principal moment of inertia主形心惯性矩principal centroidal moments of inertia 主形心轴principal centroidal axis转角angel of rotation转轴公式transformation equation自由扭转free torsion组合变形combined deformation组合截面composite area最大切应力理论maximum shear stress theory。

第32卷 第5期 岩 土 工 程 学 报 Vol.32 No.5 2010年 5月 Chinese Journal of Geotechnical Engineering May 2010岩土应变硬化指数理论及其分数阶微积分理论基础殷德顺,和成亮,陈 文(河海大学工程力学系,江苏 南京 210098)摘 要:应变硬化型岩土的三轴试验应力应变曲线能够表现出不同的弯曲程度,而应力应变曲线的弯曲程度是岩土应变硬化能力的体现,但已有的研究中还没有相应的参数来描述岩土的硬化能力。

为了获得反映岩土应变硬化能力的参数,从而有助于了解岩土的塑性性能和指导土体的合理承载,根据Hollomon 提出的描绘金属塑性拉伸变形的指数方程(经验公式),提出了岩土应变硬化指数理论。

通过许多三轴试验,发现岩土应变硬化指数理论提出的岩土应力应变关系符合乘幂函数关系的假设能够被验证,岩土的应变硬化指数能够反映岩土的硬化能力。

岩土的力学性质介于理想固体和理想流体之间,其应力应变关系既不遵守胡克定律,也不遵守牛顿黏性定律,而是遵守介于它们之间的某种关系。

利用分数阶微积分理论给出了恒应变率加载情况下的土应力应变关系。

关系式显示应力应变之间也呈乘幂函数关系,说明岩土分数阶应力应变关系能够为岩土应变硬化指数理论提供理论基础。

关键词:应变硬化指数;分数阶微积分;三轴试验;理论基础中图分类号:TU43 文献标识码:A 文章编号:1000–4548(2010)05–0762–05作者简介:殷德顺(1972– ),男,副教授,主要从事土的本构模型及基本理论研究。

E-mail: yindeshun@ 。

Theory of geotechnical strain hardening index and its rationale fromfractional order calculusYIN De-shun, HE Cheng-liang, CHEN Wen(Department of Engineering Mechanics, Hohai University, Nanjing 210098, China)Abstract : The curvature of stress-strain curves from triaxial tests on harden soil is a reflection of hardening ability, but there isn’t a parameter of hardening ability in geotechnical mechanics. In order to gain such a parameter that can help us to know plasticity and proper bearing capacity of soil, a theory of geotechnical strain hardening index (TAGSHI) in response to exponential equation (an empirical equation) which Hollomon established from experience in metal tensile deformation is developed. Based on a lot of triaxial tests, it is shown that the assumption in TAGSHI is right, which thinks that stress-strain relationship of soil is the power function in triaxial tests, and the strain hardening index may reflect geotechnical hardening ability. As we all know that geotechnical mechanical property should be intermediate between that of an ideal solid and an ideal fluid, so its stress-strain relation should neither follow the Hook’s law nor obey the Newton's law of viscosity, and it should be consistent with the fractional expression ()d ()d t t t ββσε=, (01β<<). The geotechnical stress-strain relation is derived byapplying the theory of fractional order calculus operator under the condition of loading with constant strain rate. The analytic results show that the geotechnical stress-strain curves exhibit power relation, and it is consistent with the assumption in TAGSHI. This indicates that the fractional expression ()d ()t t t ββσε=, (01β<<) can give a rationale for TAGSHI.Key words : strain hardening index; fractional order calculus; triaxial test; rationale0 前 言常规三轴试验是研究岩土材料力学性质的重要手段,无论是砂土[1]、黏土[2-3],还是岩石材料[4],它们的三轴试验已经积累了大量的试验数据和经验。