KA278RA33C中文资料

- 格式:pdf

- 大小:215.52 KB

- 文档页数:20

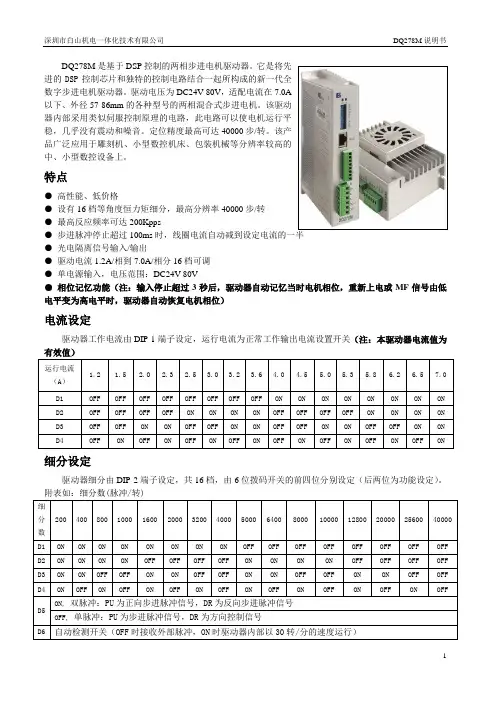

DQ278M是基于DSP控制的两相步进电机驱动器。

它是将先进的DSP控制芯片和独特的控制电路结合一起所构成的新一代全数字步进电机驱动器。

驱动电压为DC24V-80V,适配电流在7.0A以下、外径57-86mm的各种型号的两相混合式步进电机。

该驱动器内部采用类似伺服控制原理的电路,此电路可以使电机运行平稳,几乎没有震动和噪音。

定位精度最高可达40000步/转。

该产品广泛应用于雕刻机、小型数控机床、包装机械等分辨率较高的中、小型数控设备上。

特点●高性能、低价格●设有16档等角度恒力矩细分,最高分辨率40000步/转●最高反应频率可达200Kpps●步进脉冲停止超过100ms时,线圈电流自动减到设定电流的一半●光电隔离信号输入/输出●驱动电流1.2A/相到7.0A/相分16档可调●单电源输入,电压范围:DC24V-80V●相位记忆功能(注:输入停止超过3秒后,驱动器自动记忆当时电机相位,重新上电或MF信号由低电平变为高电平时,驱动器自动恢复电机相位)电流设定驱动器工作电流由DIP-1端子设定,运行电流为正常工作输出电流设置开关(注:本驱动器电流值为有效值)运行电流1.2 1.52.0 2.3 2.53.0 3.2 3.64.0 4.55.0 5.3 5.86.2 6.57.0(A)D1 OFF OFF OFF OFF OFF OFF OFF OFF ON ON ON ON ON ON ON ON D2 OFF OFF OFF OFF ON ON ON ON OFF OFF OFF OFF ON ON ON ON D3 OFF OFF ON ON OFF OFF ON ON OFF OFF ON ON OFF OFF ON ON D4 OFF ON OFF ON OFF ON OFF ON OFF ON OFF ON OFF ON OFF ON 细分设定驱动器细分由DIP-2端子设定,共16档,由6位拨码开关的前四位分别设定(后两位为功能设定)。

施耐德L C D接触器 HEN system office room 【HEN16H-HENS2AHENS8Q8-HENH1688】施耐德交流接触器LC1-D38M7C代表38A/220V的国产D系列交流接触器,工作频率为50Hz/60Hz。

其中每个数字字母的意义为:LC:交流线圈,1:单个接触器,D系列,线圈电流38A,M:代表电压220V,7:50Hz/60Hz通用,C国产。

0577保2788顺2628接触器分为交流接触器(电压AC)和直流接触器(电压DC),它应用于电力、配电与用电。

接触器广义上是指工业电中利用线圈流过电流产生磁场,使触头闭合,以达到控制负载的电器。

在电工学上,因为可快速切断交流与直流主回路和可频繁地接通与大电流控制(某些型别可达800安培)电路的装置,所以经常运用于电动机做为控制对象。

结构接触器主要由电磁系统、触点系统、灭弧系统及其它部分组成。

①电磁系统:电磁系统包括电磁线圈和铁心,是接触器的重要组成部分,依靠它带动触点的闭合与断开。

②触点系统:触点是接触器的执行部分,包括主触点和辅助触点。

主触点的作用是接通和分断主回路,控制较大的电流,而辅助触点是在控制回路中,以满足各种控制方式的要求。

③灭弧系统:灭弧装置用来保证触点断开电路时,产生的电弧可靠的熄灭,减少电弧对触点的损伤。

为了迅速熄灭断开时的电弧,通常接触器都装有灭弧装置,一般采用半封式纵缝陶土灭弧罩,并配有强磁吹弧回路。

④其它部分:有绝缘外壳、弹簧、短路环、传动机构等。

0577施耐德LC1-D09交流接触器2788施耐德LC1-D12交流接触器2628施耐德LC1-D18交流接触器施耐德LC1-D25交流接触器0577施耐德LC1-D32交流接触器2788施耐德LC1-D38交流接触器2628施耐德LC1-D40交流接触器施耐德LC1-D50交流接触器0577施耐德LC1-D65交流接触器2788施耐德LC1-D80交流接触器2628施耐德LC1-D95交流接触器施耐德LC1-D115交流接触器0577施耐德LC1-D150交流接触器2788施耐德LC1-D170交流接触器2628施耐德LC1-D205交流接触器施耐德LC1-D245交流接触器0577施耐德LC1-D300交流接触器2788施耐德LC1-D410交流接触器2628施耐德LC1-D475交流接触器施耐德LC1-D620交流接触器。

![磁碟储存盒[实用新型专利]](https://uimg.taocdn.com/2deb2d3984254b35effd34c8.webp)

专利名称:磁碟储存盒专利类型:实用新型专利发明人:郑刚

申请号:CN02226616.X 申请日:20020404

公开号:CN2535901Y 公开日:

20030212

专利内容由知识产权出版社提供

摘要:本实用新型提供一种磁碟储存盒,该磁碟储存盒包括有盒体、盒盖、活页式磁碟袋和活页导柱组成,其特征在于活页导柱由两根竖杆和呈一个冂字形的连接件以其两支向下的插杆活插至两根竖杆的内孔内而构成。

本实用新型与已有的磁碟储存盒相比,具有磁碟袋可随意更换或增减,磁碟袋翻动十分方便等优点,适合于携带磁碟使用。

申请人:郑刚

地址:528329 广东省顺德市均安镇卡斯华公司

国籍:CN

更多信息请下载全文后查看。

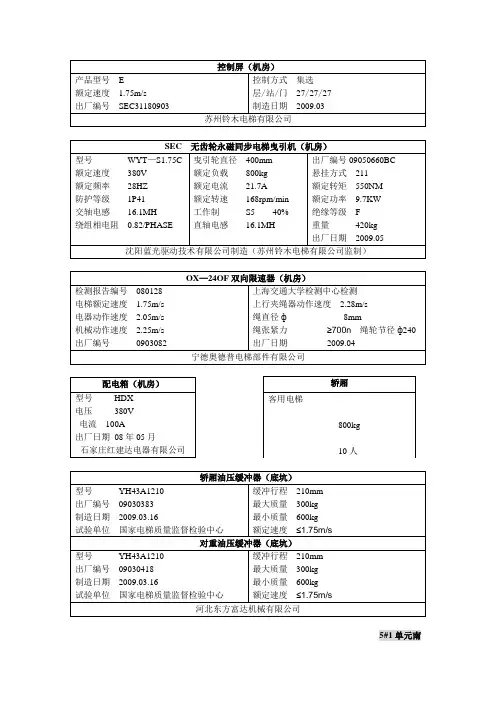

产品型号 E额定速度 1.75m/s出厂编号 SEC31180903 控制方式 集选 层/站/门 27/27/27 制造日期 2009.03苏州铃木电梯有限公司SEC 无齿轮永磁同步电梯曳引机(机房)型号 WYT —S1.75C 额定速度 380V 额定频率 28HZ 防护等级 1P41 交轴电感 16.1MH 绕组相电阻 0.82/PHASE曳引轮直径 400mm 额定负载 800kg 额定电流 21.7A额定转速 168rpm/min 工作制 S5 40% 直轴电感 16.1MH出厂编号09050660BC 悬挂方式 211 额定转矩 550NM 额定功率 9.7KW 绝缘等级 F 重量 420kg 出厂日期 2009.05沈阳蓝光驱动技术有限公司制造(苏州铃木电梯有限公司监制)OX —24OF 双向限速器(机房)检测报告编号 080128 电梯额定速度 1.75m/s 电器动作速度 2.05m/s 机械动作速度 2.25m/s 出厂编号 0903082 上海交通大学检测中心检测 上行夹绳器动作速度 2.28m/s 绳直径ф 8mm绳张紧力 ≥700n 绳轮节径ф240 出厂日期 2009.04宁德奥德普电梯部件有限公司配电箱(机房)型号 HDX 电压 380V 电流 100A出厂日期 08年05月石家庄红建达电器有限公司轿厢油压缓冲器(底坑)型号 YH43A1210 出厂编号 09030383 制造日期 2009.03.16试验单位 国家电梯质量监督检验中心 缓冲行程 210mm 最大质量 300kg 最小质量 600kg 额定速度 ≤1.75m/s 对重油压缓冲器(底坑)型号 YH43A1210 出厂编号 09030418 制造日期 2009.03.16试验单位 国家电梯质量监督检验中心 缓冲行程 210mm 最大质量 300kg 最小质量 600kg 额定速度 ≤1.75m/s河北东方富达机械有限公司5#1单元南轿厢客用电梯800kg10人产品型号 E额定速度 1.75m/s出厂编号 SEC31090903 控制方式 集选 层/站/门 27/27/27 制造日期 2009.03苏州铃木电梯有限公司SEC 无齿轮永磁同步电梯曳引机(机房)型号 WYT —S1.75C 额定速度 380V 额定频率 28HZ 防护等级 1P41 交轴电感 16.1MH 绕组相电阻 0.82/PHASE曳引轮直径 400mm 额定负载 800kg 额定电流 21.7A额定转速 168rpm/min 工作制 S5 40% 直轴电感 16.1MH出厂编号09050669BC 悬挂方式 211 额定转矩 550NM 额定功率 9.7KW 绝缘等级 F 重量 420kg 出厂日期 2009.05沈阳蓝光驱动技术有限公司制造(苏州铃木电梯有限公司监制)OX —24OF 双向限速器(机房)检测报告编号 080128 电梯额定速度 1.75m/s 电器动作速度 2.05m/s 机械动作速度 2.25m/s 出厂编号 不明 上海交通大学检测中心检测 上行夹绳器动作速度 2.28m/s 绳直径ф 8mm绳张紧力 ≥700n 绳轮节径ф240 出厂日期 2009.04宁德奥德普电梯部件有限公司配电箱(机房)型号 HDX 电压 380V 电流 100A出厂日期 08年05月石家庄红建达电器有限公司轿厢油压缓冲器(底坑)型号 YH43A1210 出厂编号 09030384 制造日期 2009.03.16试验单位 国家电梯质量监督检验中心 缓冲行程 210mm 最大质量 300kg 最小质量 600kg 额定速度 ≤1.75m/s 对重油压缓冲器(底坑)型号 YH43A1210 出厂编号 不明制造日期 2009.03.16试验单位 国家电梯质量监督检验中心 缓冲行程 210mm 最大质量 300kg 最小质量 600kg 额定速度 ≤1.75m/s河北东方富达机械有限公司5#1单元北轿厢客用电梯800kg10人产品型号 E额定速度 1.75m/s出厂编号 SEC31060903 控制方式 集选 层/站/门 27/27/27 制造日期 2009.03苏州铃木电梯有限公司SEC 无齿轮永磁同步电梯曳引机(机房)型号 WYT —S1.75C 额定速度 380V 额定频率 28HZ 防护等级 1P41 交轴电感 16.1MH 绕组相电阻 0.82/PHASE曳引轮直径 400mm 额定负载 800kg 额定电流 21.7A额定转速 168rpm/min 工作制 S5 40% 直轴电感 16.1MH出厂编号09050657BC 悬挂方式 211 额定转矩 550NM 额定功率 9.7KW 绝缘等级 F 重量 420kg 出厂日期 2009.05沈阳蓝光驱动技术有限公司制造(苏州铃木电梯有限公司监制)OX —24OF 双向限速器(机房)检测报告编号 080128 电梯额定速度 1.75m/s 电器动作速度 2.05m/s 机械动作速度 2.25m/s 出厂编号 不明 上海交通大学检测中心检测 上行夹绳器动作速度 2.28m/s 绳直径ф 8mm绳张紧力 ≥700n 绳轮节径ф240 出厂日期 2009.04宁德奥德普电梯部件有限公司配电箱(机房)型号 HDX 电压 380V 电流 100A出厂日期 08年05月石家庄红建达电器有限公司轿厢油压缓冲器(底坑)型号 YH43A1210 出厂编号 09030578 制造日期 2009.03.26试验单位 国家电梯质量监督检验中心 缓冲行程 210mm 最大质量 300kg 最小质量 600kg 额定速度 ≤1.75m/s 对重油压缓冲器(底坑)型号 YH43A1210 出厂编号 09030577 制造日期 2009.03.26试验单位 国家电梯质量监督检验中心缓冲行程 210mm 最大质量 300kg 最小质量 600kg 额定速度 ≤1.75m/s河北东方富达机械有限公司5#2单元南轿厢客用电梯800kg10人产品型号 E额定速度 1.75m/s出厂编号 SEC31070903 控制方式 集选 层/站/门 27/27/27 制造日期 2009.03苏州铃木电梯有限公司SEC 无齿轮永磁同步电梯曳引机(机房)型号 WYT —S1.75C 额定速度 380V 额定频率 28HZ 防护等级 1P41 交轴电感 16.1MH 绕组相电阻 0.82/PHASE曳引轮直径 400mm 额定负载 800kg 额定电流 21.7A额定转速 168rpm/min 工作制 S5 40% 直轴电感 16.1MH出厂编号09050658BC 悬挂方式 211 额定转矩 550NM 额定功率 9.7KW 绝缘等级 F 重量 420kg 出厂日期 2009.05沈阳蓝光驱动技术有限公司制造(苏州铃木电梯有限公司监制)OX —24OF 双向限速器(机房)检测报告编号 080128 电梯额定速度 1.75m/s 电器动作速度 2.05m/s 机械动作速度 2.25m/s 出厂编号 0904255 上海交通大学检测中心检测 上行夹绳器动作速度 2.28m/s 绳直径ф 8mm绳张紧力 ≥700n 绳轮节径ф240 出厂日期 2009.04宁德奥德普电梯部件有限公司配电箱(机房)型号 HDX 电压 380V 电流 100A出厂日期 08年05月石家庄红建达电器有限公司轿厢油压缓冲器(底坑)型号 YH43A1210 出厂编号 09030370 制造日期 2009.03.16试验单位 国家电梯质量监督检验中心 缓冲行程 210mm 最大质量 300kg 最小质量 600kg 额定速度 ≤1.75m/s 对重油压缓冲器(底坑)型号 YH43A1210 出厂编号 不明制造日期 2009.03.16试验单位 国家电梯质量监督检验中心缓冲行程 210mm 最大质量 300kg 最小质量 600kg 额定速度 ≤1.75m/s河北东方富达机械有限公司5#2单元北轿厢客用电梯800kg10人产品型号 E额定速度 1.75m/s出厂编号 SEC311040903 控制方式 集选 层/站/门 27/27/27 制造日期 2009.03苏州铃木电梯有限公司SEC 无齿轮永磁同步电梯曳引机(机房)型号 WYT —S1.75C 额定速度 380V 额定频率 28HZ 防护等级 1P41 交轴电感 16.1MH 绕组相电阻 0.82/PHASE曳引轮直径 400mm 额定负载 800kg 额定电流 21.7A额定转速 168rpm/min 工作制 S5 40% 直轴电感 16.1MH出厂编号09050655BC 悬挂方式 211 额定转矩 550NM 额定功率 9.7KW 绝缘等级 F 重量 420kg 出厂日期 2009.05沈阳蓝光驱动技术有限公司制造(苏州铃木电梯有限公司监制)OX —24OF 双向限速器(机房)检测报告编号 080128 电梯额定速度 1.75m/s 电器动作速度 2.05m/s 机械动作速度 2.25m/s 出厂编号 0904260 上海交通大学检测中心检测 上行夹绳器动作速度 2.28m/s 绳直径ф 8mm绳张紧力 ≥700n 绳轮节径ф240 出厂日期 2009.04宁德奥德普电梯部件有限公司配电箱(机房)型号 HDX 电压 380V 电流 100A出厂日期 08年05月石家庄红建达电器有限公司轿厢油压缓冲器(底坑)型号 YH43A1210 出厂编号 09030591 制造日期 2009.03.26试验单位 国家电梯质量监督检验中心 缓冲行程 210mm 最大质量 300kg 最小质量 600kg 额定速度 ≤1.75m/s 对重油压缓冲器(底坑)型号 YH43A1210 出厂编号 不明制造日期 2009.03.16试验单位 国家电梯质量监督检验中心 缓冲行程 210mm 最大质量 300kg 最小质量 600kg 额定速度 ≤1.75m/s河北东方富达机械有限公司6#1单元南轿厢客用电梯800kg10人产品型号 E额定速度 1.75m/s出厂编号 SEC311050903 控制方式 集选 层/站/门 27/27/27 制造日期 2009.03苏州铃木电梯有限公司SEC 无齿轮永磁同步电梯曳引机(机房)型号 WYT —S1.75C 额定速度 380V 额定频率 28HZ 防护等级 1P41 交轴电感 16.1MH 绕组相电阻 0.82/PHASE曳引轮直径 400mm 额定负载 800kg 额定电流 21.7A额定转速 168rpm/min 工作制 S5 40% 直轴电感 16.1MH出厂编号09050656BC 悬挂方式 211 额定转矩 550NM 额定功率 9.7KW 绝缘等级 F 重量 420kg 出厂日期 2009.05沈阳蓝光驱动技术有限公司制造(苏州铃木电梯有限公司监制)OX —24OF 双向限速器(机房)检测报告编号 080128 电梯额定速度 1.75m/s 电器动作速度 2.05m/s 机械动作速度 2.25m/s 出厂编号 不明 上海交通大学检测中心检测 上行夹绳器动作速度 2.28m/s 绳直径ф 8mm绳张紧力 ≥700n 绳轮节径ф240 出厂日期 2009.04宁德奥德普电梯部件有限公司配电箱(机房)型号 HDX 电压 380V 电流 100A出厂日期 08年05月石家庄红建达电器有限公司轿厢油压缓冲器(底坑)型号 YH43A1210 出厂编号 09030399 制造日期 2009.03.16试验单位 国家电梯质量监督检验中心 缓冲行程 210mm 最大质量 300kg 最小质量 600kg 额定速度 ≤1.75m/s 对重油压缓冲器(底坑)型号 YH43A1210 出厂编号 09030572 制造日期 2009.03.26试验单位 国家电梯质量监督检验中心 缓冲行程 210mm 最大质量 300kg 最小质量 600kg 额定速度 ≤1.75m/s河北东方富达机械有限公司6#1单元北轿厢客用电梯800kg10人产品型号 E额定速度 1.75m/s出厂编号 SEC311020903 控制方式 集选 层/站/门 27/27/27 制造日期 2009.03苏州铃木电梯有限公司SEC 无齿轮永磁同步电梯曳引机(机房)型号 WYT —S1.75C 额定速度 380V 额定频率 28HZ 防护等级 1P41 交轴电感 16.1MH 绕组相电阻 0.82/PHASE曳引轮直径 400mm 额定负载 800kg 额定电流 21.7A额定转速 168rpm/min 工作制 S5 40% 直轴电感 16.1MH出厂编号09050653BC 悬挂方式 211 额定转矩 550NM 额定功率 9.7KW 绝缘等级 F 重量 420kg 出厂日期 2009.05沈阳蓝光驱动技术有限公司制造(苏州铃木电梯有限公司监制)OX —24OF 双向限速器(机房)检测报告编号 080128 电梯额定速度 1.75m/s 电器动作速度 2.05m/s 机械动作速度 2.25m/s 出厂编号 不明 上海交通大学检测中心检测 上行夹绳器动作速度 2.28m/s 绳直径ф 8mm绳张紧力 ≥700n 绳轮节径ф240 出厂日期 2009.04宁德奥德普电梯部件有限公司配电箱(机房)型号 HDX 电压 380V 电流 100A出厂日期 08年05月石家庄红建达电器有限公司轿厢油压缓冲器(底坑)型号 YH43A1210 出厂编号 09030594 制造日期 2009.03.26试验单位 国家电梯质量监督检验中心 缓冲行程 210mm 最大质量 300kg 最小质量 600kg 额定速度 ≤1.75m/s 对重油压缓冲器(底坑)型号 YH43A1210 出厂编号 09030592 制造日期 2009.03.26试验单位 国家电梯质量监督检验中心 缓冲行程 210mm 最大质量 300kg 最小质量 600kg 额定速度 ≤1.75m/s河北东方富达机械有限公司6#2单元南轿厢客用电梯800kg10人产品型号 E额定速度 1.75m/s出厂编号 SEC311030903 控制方式 集选 层/站/门 27/27/27 制造日期 2009.03苏州铃木电梯有限公司SEC 无齿轮永磁同步电梯曳引机(机房)型号 WYT —S1.75C 额定速度 380V 额定频率 28HZ 防护等级 1P41 交轴电感 16.1MH 绕组相电阻 0.82/PHASE曳引轮直径 400mm 额定负载 800kg 额定电流 21.7A额定转速 168rpm/min 工作制 S5 40% 直轴电感 16.1MH出厂编号09050654BC 悬挂方式 211 额定转矩 550NM 额定功率 9.7KW 绝缘等级 F 重量 420kg 出厂日期 2009.05沈阳蓝光驱动技术有限公司制造(苏州铃木电梯有限公司监制)OX —24OF 双向限速器(机房)检测报告编号 080128 电梯额定速度 1.75m/s 电器动作速度 2.05m/s 机械动作速度 2.25m/s 出厂编号 0904252 上海交通大学检测中心检测 上行夹绳器动作速度 2.28m/s 绳直径ф 8mm绳张紧力 ≥700n 绳轮节径ф240 出厂日期 2009.04宁德奥德普电梯部件有限公司配电箱(机房)型号 HDX 电压 380V 电流 100A出厂日期 08年05月石家庄红建达电器有限公司轿厢油压缓冲器(底坑)型号 YH43A1210 出厂编号 09030400 制造日期 2009.03.16试验单位 国家电梯质量监督检验中心 缓冲行程 210mm 最大质量 300kg 最小质量 600kg 额定速度 ≤1.75m/s 对重油压缓冲器(底坑)型号 YH43A1210 出厂编号 09030593 制造日期 2009.03.26试验单位 国家电梯质量监督检验中心 缓冲行程 210mm 最大质量 300kg 最小质量 600kg 额定速度 ≤1.75m/s河北东方富达机械有限公司6#2单元北轿厢客用电梯800kg10人产品型号 E额定速度 1.75m/s出厂编号 SEC31100903 控制方式 集选 层/站/门 27/27/27 制造日期 2009.03苏州铃木电梯有限公司SEC 无齿轮永磁同步电梯曳引机(机房)型号 WYT —S1.75C 额定速度 380V 额定频率 28HZ 防护等级 1P41 交轴电感 16.1MH 绕组相电阻 0.82/PHASE曳引轮直径 400mm 额定负载 800kg 额定电流 21.7A额定转速 168rpm/min 工作制 S5 40% 直轴电感 16.1MH出厂编号09050661BC 悬挂方式 211 额定转矩 550NM 额定功率 9.7KW 绝缘等级 F 重量 420kg 出厂日期 2009.05沈阳蓝光驱动技术有限公司制造(苏州铃木电梯有限公司监制)OX —24OF 双向限速器(机房)检测报告编号 080128 电梯额定速度 1.75m/s 电器动作速度 2.05m/s 机械动作速度 2.25m/s 出厂编号 不明 上海交通大学检测中心检测 上行夹绳器动作速度 2.28m/s 绳直径ф 8mm绳张紧力 ≥700n 绳轮节径ф240 出厂日期 2009.04宁德奥德普电梯部件有限公司配电箱(机房)型号 HDX 电压 380V 电流 100A出厂日期 09年06月石家庄红建达电器有限公司轿厢油压缓冲器(底坑)型号 YH43A1210 出厂编号 09030431 制造日期 2009.03.16试验单位 国家电梯质量监督检验中心 缓冲行程 210mm 最大质量 300kg 最小质量 600kg 额定速度 ≤1.75m/s 对重油压缓冲器(底坑)型号 YH43A1210 出厂编号 09030432 制造日期 2009.03.16试验单位 国家电梯质量监督检验中心 缓冲行程 210mm 最大质量 300kg 最小质量 600kg 额定速度 ≤1.75m/s河北东方富达机械有限公司7#3单元南轿厢客用电梯800kg10人产品型号 E额定速度 1.75m/s出厂编号 SEC31110903 控制方式 集选 层/站/门 27/27/27 制造日期 2009.03苏州铃木电梯有限公司SEC 无齿轮永磁同步电梯曳引机(机房)型号 WYT —S1.75C 额定速度 380V 额定频率 28HZ 防护等级 1P41 交轴电感 16.1MH 绕组相电阻 0.82/PHASE曳引轮直径 400mm 额定负载 800kg 额定电流 21.7A额定转速 168rpm/min 工作制 S5 40% 直轴电感 16.1MH出厂编号09050662BC 悬挂方式 211 额定转矩 550NM 额定功率 9.7KW 绝缘等级 F 重量 420kg 出厂日期 2009.05沈阳蓝光驱动技术有限公司制造(苏州铃木电梯有限公司监制)OX —24OF 双向限速器(机房)检测报告编号 080128 电梯额定速度 1.75m/s 电器动作速度 2.05m/s 机械动作速度 2.25m/s 出厂编号 不明 上海交通大学检测中心检测 上行夹绳器动作速度 2.28m/s 绳直径ф 8mm绳张紧力 ≥700n 绳轮节径ф240 出厂日期 2009.04宁德奥德普电梯部件有限公司配电箱(机房)型号 HDX 电压 380V 电流 100A出厂日期 09年06月石家庄红建达电器有限公司轿厢油压缓冲器(底坑)型号 YH43A1210 出厂编号 09030425 制造日期 2009.03.16试验单位 国家电梯质量监督检验中心 缓冲行程 210mm 最大质量 300kg 最小质量 600kg 额定速度 ≤1.75m/s 对重油压缓冲器(底坑)型号 YH43A1210 出厂编号 09030426 制造日期 2009.03.16试验单位 国家电梯质量监督检验中心 缓冲行程 210mm 最大质量 300kg 最小质量 600kg 额定速度 ≤1.75m/s河北东方富达机械有限公司7#3单元北轿厢客用电梯800kg10人产品型号 E额定速度 1.75m/s出厂编号 SEC31120903 控制方式 集选 层/站/门 27/27/27 制造日期 2009.03苏州铃木电梯有限公司SEC 无齿轮永磁同步电梯曳引机(机房)型号 WYT —S1.75C 额定速度 380V 额定频率 28HZ 防护等级 1P41 交轴电感 16.1MH 绕组相电阻 0.82/PHASE曳引轮直径 400mm 额定负载 800kg 额定电流 21.7A额定转速 168rpm/min 工作制 S5 40% 直轴电感 16.1MH出厂编号09050663BC 悬挂方式 211 额定转矩 550NM 额定功率 9.7KW 绝缘等级 F 重量 420kg 出厂日期 2009.05沈阳蓝光驱动技术有限公司制造(苏州铃木电梯有限公司监制)OX —24OF 双向限速器(机房)检测报告编号 080128 电梯额定速度 1.75m/s 电器动作速度 2.05m/s 机械动作速度 2.25m/s 出厂编号 不明 上海交通大学检测中心检测 上行夹绳器动作速度 2.28m/s 绳直径ф 8mm绳张紧力 ≥700n 绳轮节径ф240 出厂日期 2009.04宁德奥德普电梯部件有限公司配电箱(机房)型号 HDX 电压 380V 电流 100A出厂日期 09年06月石家庄红建达电器有限公司轿厢油压缓冲器(底坑)型号 YH43A1210 出厂编号 09030436 制造日期 2009.03.16试验单位 国家电梯质量监督检验中心 缓冲行程 210mm 最大质量 300kg 最小质量 600kg 额定速度 ≤1.75m/s 对重油压缓冲器(底坑)型号 YH43A1210 出厂编号 09030435 制造日期 2009.03.16试验单位 国家电梯质量监督检验中心 缓冲行程 210mm 最大质量 300kg 最小质量 600kg 额定速度 ≤1.75m/s河北东方富达机械有限公司7#4单元南轿厢客用电梯800kg10人产品型号 E额定速度 1.75m/s出厂编号 SEC31130903 控制方式 集选 层/站/门 27/27/27 制造日期 2009.03苏州铃木电梯有限公司SEC 无齿轮永磁同步电梯曳引机(机房)型号 WYT —S1.75C 额定速度 380V 额定频率 28HZ 防护等级 1P41 交轴电感 16.1MH 绕组相电阻 0.82/PHASE曳引轮直径 400mm 额定负载 800kg 额定电流 21.7A额定转速 168rpm/min 工作制 S5 40% 直轴电感 16.1MH出厂编号09050664BC 悬挂方式 211 额定转矩 550NM 额定功率 9.7KW 绝缘等级 F 重量 420kg 出厂日期 2009.05沈阳蓝光驱动技术有限公司制造(苏州铃木电梯有限公司监制)OX —24OF 双向限速器(机房)检测报告编号 080128 电梯额定速度 1.75m/s 电器动作速度 2.05m/s 机械动作速度 2.25m/s 出厂编号 0904263 上海交通大学检测中心检测 上行夹绳器动作速度 2.28m/s 绳直径ф 8mm绳张紧力 ≥700n 绳轮节径ф240 出厂日期 2009.04宁德奥德普电梯部件有限公司配电箱(机房)型号 HDX 电压 380V 电流 100A出厂日期 09年06月石家庄红建达电器有限公司轿厢油压缓冲器(底坑)型号 YH42A1160 最大允许总重量 3000kg 最小允许总重量 600kg试验单位 国家电梯质量监督检验中心 额定速度 ≤1.5m/s 缓冲行程 160mm 制造日期 20081126 产品编号 08110280 对重油压缓冲器(底坑)型号 YH42A1160 最大允许总重量 3000kg 最小允许总重量 600kg试验单位 国家电梯质量监督检验中心 额定速度 ≤1.5m/s 缓冲行程 160mm 制造日期 20081126 产品编号 08110281河北东方机械厂制造7#4单元北轿厢客用电梯800kg10人。

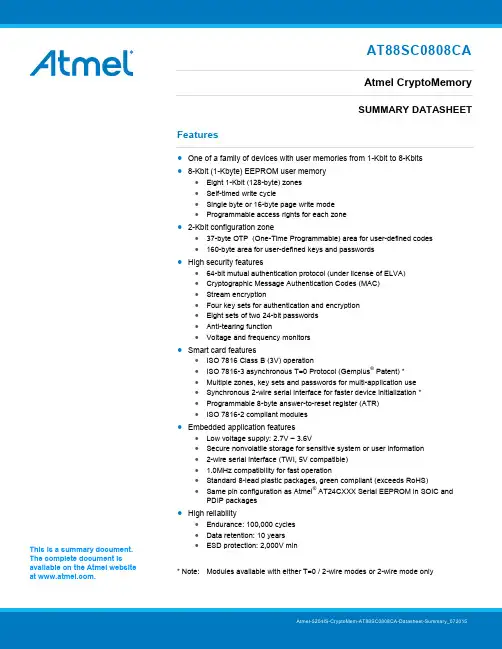

AT88SC0808CAAtmel CryptoMemorySUMMARY DATASHEETFeatures ∙ One of a family of devices with user memories from 1-Kbit to 8-Kbits ∙8-Kbit (1-Kbyte) EEPROM user memory∙ Eight 1-Kbit (128-byte) zones ∙ Self-timed write cycle∙ Single byte or 16-byte page write mode ∙ Programmable access rights for each zone∙ 2-Kbit configuration zone∙ 37-byte OTP (One-Time Programmable) area for user-defined codes ∙ 160-byte area for user-defined keys and passwords ∙High security features∙ 64-bit mutual authentication protocol (under license of ELVA) ∙ Cryptographic Message Authentication Codes (MAC) ∙ Stream encryption∙ Four key sets for authentication and encryption ∙ Eight sets of two 24-bit passwords ∙ Anti-tearing function∙ Voltage and frequency monitors∙Smart card features∙ ISO 7816 Class B (3V) operation∙ ISO 7816-3 asynchronous T=0 Protocol (Gemplus ®Patent) * ∙ Multiple zones, key sets and passwords for multi-application use ∙ Synchronous 2-wire serial interface for faster device initialization * ∙ Programmable 8-byte answer-to-reset register (ATR) ∙ISO 7816-2 compliant modules∙Embedded application features∙ Low voltage supply: 2.7V – 3.6V∙ Secure nonvolatile storage for sensitive system or user information ∙ 2-wire serial interface (TWI, 5V compatible) ∙ 1.0MHz compatibility for fast operation∙ Standard 8-lead plastic packages, green compliant (exceeds RoHS)∙Same pin configuration as Atmel ®AT24CXXX Serial EEPROM in SOIC and PDIP packages∙High reliability∙ Endurance: 100,000 cycles ∙ Data retention: 10 years ∙ ESD protection: 2,000V min* Note: Modules available with either T=0 / 2-wire modes or 2-wire mode onlyThis is a summary document. The complete document is available on the Atmel website at .AT88SC0808CA [Summary DATASHEET]Atmel-5204IS-CryptoMem-AT88SC0808CA-Datasheet-Summary_0720152Table 1. Pin AssignmentsPin Configuration123487658-lead SOIC, PDIPNC NCNC GNDV CCNC SCL SDA8-lead TSSOPNCV CC 81NC C N 72NCK L C 63GND 54SDA 12348765SDA GND CLK V CC8-lead Ultra Thin Mini-MAP (MLP 2x3)Bottom ViewNCNC NC NC TWI Smart Card ModuleV C C =C1 NC =C2 SCL/CLK=C3NC=C4C5=GND C6=NC C7=S D A /IO C8=NCISO Smart Card ModuleV C C =C1 RST=C2 SCL/CLK=C3NC=C4C5=GND C6=NC C7=S D A /IO C8=NCAT88SC0808CA [Summary DATASHEET]Atmel-5204IS-CryptoMem-AT88SC0808CA-Datasheet-Summary_07201531. DescriptionThe Atmel AT88SC0808CA member of the Atmel CryptoMemory ®family is a high-performance secure memory providing 8-Kbit of user memory with advanced security and cryptographic features built in. The user memory is divided into eight128-byte zones, each of which may be individually set with different security access rights or effectively combined together to provide space for one to eight data files. The AT88SC0808CA features an enhanced command set that allows directcommunication with microcontroller hardware 2-wire interface thereby allowing for faster firmware development with reduced code space requirements.1.1 Smart Card ApplicationsThe AT88SC0808CA provides high security, low cost, and ease of implementation without the need for a microprocessor operating system. The embedded cryptographic engine provides for dynamic, symmetric-mutual authentication between the device and host, as well as performing stream encryption for all data and passwords exchanged between the device and host. Up to four unique key sets may be used for these operations. The AT88SC0808CA offers the ability to communicate with virtually any smart card reader using the asynchronous T = 0 protocol (Gemplus Patent) defined in ISO 7816-3.1.2 Embedded ApplicationsThrough dynamic, symmetric-mutual authentication, data encryption, and the use of cryptographic Message Authentication Codes (MAC), the AT88SC0808CA provides a secure place for storage of sensitive information within a system. With its tamper detection circuits, this information remains safe even under attack. A 2-wire serial interface running at speeds up to 1.0MHz provides fast and efficient communications with up to 15 individually addressable devices. The AT88SC0808CA is available in industry standard 8-lead packages with the same familiar pin configuration as Atmel AT24CXXX Serial EEPROM devices. Note:Does not apply to either the TSSOP or the Ultra Thin Mini-Map pinoutsFigure 1-1. Block DiagramV CC GNDSCL/CLK SDA/IORSTAT88SC0808CA [Summary DATASHEET]Atmel-5204IS-CryptoMem-AT88SC0808CA-Datasheet-Summary_07201542. Connection DiagramFigure 2-1. Connection Diagram3.Pin Descriptions3.1Supply Voltage (V CC )The V CC input is a 2.7V to 3.6V positive voltage supplied by the host.3.2 Clock (SCL/CLK)When using the asynchronous T = 0 protocol, the CLK (SCL) input provides the device with a carrier frequency f . The nominal length of one bit emitted on I/O is defined as an “elementary time unit” (ETU) and is equal to 372/ f .When using the synchronous protocol, data clocking is done on the positive edge of the clock when writing to the device and on the negative edge of the clock when reading from the device.3.3 Reset (RST)The AT88SC0808CA provides an ISO 7816-3 compliant asynchronous answer-to-reset (ATR) sequence. Upon activation of the reset sequence, the device outputs bytes contained in the 64-bit ATR register. An internal pull-up on the RST input pad allows the device to operate in synchronous mode without bonding RST. The AT88SC0808CA does not support an ATR sequence in the synchronous mode of operation.3.4 Serial Data (SDA/IO)The SDA/IO pin is bidirectional for serial data transfer. This pin is open-drain driven and may be wired with any number of other open-drain or open-collector devices. An external pull-up resistor should be connected between SDA/IO and V CC . The value of this resistor and the system capacitance loading the SDA/IO bus will determine the rise time of SDA/IO. This rise time will determine the maximum frequency during read operations. Low value pull-up resistors will allow higher frequency operations while drawing higher average power supply current. SDA/IO information applies to both asynchronous andsynchronous protocols.AT88SC0808CA [Summary DATASHEET]Atmel-5204IS-CryptoMem-AT88SC0808CA-Datasheet-Summary_07201554. Absolute Maximum Ratings**Notice:Stresses beyond those listed under “AbsoluteMaximum Ratings” may cause permanent damage to the device. This is a stress rating only and functional operation of the device at these or any other condition beyond those indicated in the operational sections of this specification is not implied. Exposure to absolute maximum rating conditions for extended periods of time may affect device reliability.Table 4-1.DC CharacteristicsApplicable over recommended operating range from V CC = +2.7 to 3.6V, T AC = -40°C to +85°C (unless otherwise noted)Note:1. To prevent latch up conditions from occurring during power up of the AT88SC0808CA, V CC must be turned onbefore applying V IH . For powering down, V IH must be removed before turning V CC off.AT88SC0808CA [Summary DATASHEET]Atmel-5204IS-CryptoMem-AT88SC0808CA-Datasheet-Summary_0720156Table 4-2.AC CharacteristicsApplicable over recommended operating range from V CC = +2.7 to 3.6V, T AC = -40°C to +85°C, CL = 30pF (unless otherwise noted)5.Device Operations for Synchronous Protocols5.1Clock and Data TransitionsThe SDA pin is normally pulled high with an external device. Data on the SDA pin may change only during SCL low time periods (see Figure 5-3 on page 8). Data changes during SCL high periods will indicate a start or stop condition as defined below.5.1.1 Start conditionA high-to-low transition of SDA with SCL high defines a start condition which must precede all commands (see Figure 5-4 on page 8).5.1.2 Stop conditionA low-to-high transition of SDA with SCL high defines a stop condition. After a read sequence, the stop condition will place the EEPROM in a standby power mode (see Figure 5-4 on page 8).5.1.3 AcknowledgeAll addresses and data words are serially transmitted to and from the EEPROM in 8-bit words. The EEPROM sends a zero to acknowledge that it has received each word. This happens during the ninth clock cycle (see Figure 5-5 on page 8).AT88SC0808CA [Summary DATASHEET]Atmel-5204IS-CryptoMem-AT88SC0808CA-Datasheet-Summary_07201575.2 Memory ResetAfter an interruption in communication due protocol errors, power loss or any reason, perform "Acknowledge Polling" to properly recover from the condition. Acknowledge polling consists of sending a start condition followed by a valid CryptoMemory command byte and determining if the device responded with an acknowledge. Figure 5-1. Bus Time for 2-wire Serial CommunicationsSCL: Serial Clock, SDA: Serial Data I/OFigure 5-2. Write Cycle TimingSCL: Serial Clock, SDA: Serial Data I/ONote:The write cycle time t WR is the time from a valid stop condition of a write sequence to the end of the internal clear/write cycleSCLSDA INSDA OUTAT88SC0808CA [Summary DATASHEET]Atmel-5204IS-CryptoMem-AT88SC0808CA-Datasheet-Summary_0720158Figure 5-3. Data ValidityFigure 5-4. START and STOP DefinitionsFigure 5-5. Output AcknowledgeST ARTACKNOWLEDGESCLDAT A INDAT A OUT189AT88SC0808CA [Summary DATASHEET]Atmel-5204IS-CryptoMem-AT88SC0808CA-Datasheet-Summary_07201596.Device Architecture6.1User ZonesThe EEPROM user memory is divided into eight zones of 1-Kbit each. Multiple zones allow for storage of different types of data or files in different zones. Access to user zones is permitted only after meeting proper security requirements. These security requirements are user definable in the configuration memory during device personalization. If the same security requirements are selected for multiple zones, then these zones may effectively be accessed as one larger zone. Figure 6-1. User Zones7. Control LogicAccess to the user zones occur only through the control logic built into the device. This logic is configurable through access registers, key registers and keys programmed into the configuration memory during device personalization. Also implemented in the control logic is a cryptographic engine for performing the various higher-level security functions of the device.AT88SC0808CA [Summary DATASHEET]Atmel-5204IS-CryptoMem-AT88SC0808CA-Datasheet-Summary_072015108. Configuration MemoryThe configuration memory consists of 2048 bits of EEPROM memory used for storage of passwords, keys, codes, and also used for definition of security access rights for the user zones. Access rights to the configuration memory are defined in the control logic and are not alterable by the user after completion of personalization. Figure 8-1. Configuration Memory9. Security FusesThere are three fuses on the device that must be blown during the device personalization process. Each fuse locks certain portions of the configuration zone as OTP (One-Time Programmable) memory. Fuses are designed for the modulemanufacturer, card manufacturer and card issuer and should be blown in sequence, although all programming of the device and blowing of the fuses may be performed at one final step.10. Communication Security ModesCommunications between the device and host operate in three basic modes. Standard mode is the default mode for thedevice after power-up. Authentication mode is activated by a successful authentication sequence. Encryption mode isactivated by a successful encryption activation following a successful authentication.Table 10-1. Communication Security Modes(1)Note: 1. Configuration data include viewable areas of the configuration zone except the passwords:•MDC: Modification Detection Code•MAC: Message Authentication Code11. Security Options11.1 Anti-TearingIn the event of a power loss during a write cycle, the integrity of the device’s stored data is recoverable. This function isoptional: the host may choose to activate the anti-tearing function, depending on application requirements. When anti-tearing is active, write commands take longer to execute, since more write cycles are required to complete them, and data is limited toa maximum of eight bytes for each write request.Data is written first into a buffer zone in EEPROM instead of the intended destination address, but with the same accessconditions. The data is then written in the required location. If this second write cycle is interrupted due to a power loss, the device will automatically recover the data from the system buffer zone at the next power-up. Non-volatile buffering of the data is done automatically by the device.During power-up in applications using anti-tearing, the host is required to perform ACK polling in the event that the deviceneeds to carry out the data recovery process.11.2 Write LockIf a user zone is configured in the write lock mode, the lowest address byte of an 8-byte page constitutes a write access byte for the bytes of that page.Example: The write lock byte at $080 controls the bytes from $081 to $087Figure 11-1. Write Lock ExampleThe write lock byte itself may be locked by writing its least significant (rightmost) bit to “0”. Moreover, when write lock mode is activated, the write lock byte can only be programmed – that is, bits written to “0” cannot return to “1”.In the write lock configuration, write operations are limited to writing only one byte at a time. Attempts to write more than one byte will result in writing of just the first byte into the device.11.3 Password VerificationPasswords may be used to protect read and/or write access of any user zone. When a valid password is presented, it ismemorized and active until power is turned off, unless a new password is presented or RST becomes active. There are eight password sets that may be used to protect any user zone. Only one password is active at a time. Presenting the correct write password also grants read access privileges.11.4 Authentication ProtocolThe access to a user zone may be protected by an authentication protocol. Any one of four keys may be selected to use with a user zone.Authentication success is memorized and active as long as the chip is powered, unless a new authentication is initialized or RST becomes active. If the new authentication request is not validated, the card loses its previous authentication which must be presented again to gain access. Only the latest request is memorized. Figure 11-2. Password and Authentication OperationsNote:Authentication and password verification may be attempted at any time and in any order. Exceedingcorresponding authentication or password attempts trial limit renders subsequent authentication or password verification attempts futile.READ ACCESSWRITE ACCESS11.5 Cryptographic Message Authentication CodesAT88SC0808CA implements a data validity check function in the standard, authentication or encryption modes of operation.In the standard mode, data validity check is done through a Modification Detection Code (MDC), in which the host may read an MDC from the device in order to verify that the data sent was received correctly.In authentication and encryption modes, the data validity check becomes more powerful since it provides a bidirectional data integrity check and data origin authentication capability in the form of a Message Authentication Codes (MAC). Only thehost/device that carried out a valid authentication is capable of computing a valid MAC. While operating in the authentication or encryption modes, the use of MAC is required. For an ingoing command, if the device calculates a MAC different from the MAC transmitted by the host, not only is the command abandoned but the security privilege is revoked. A new authentication and/or encryption activation will be required to reactivate the MAC.11.6 EncryptionThe data exchanged between the device and the host during read, write and verify password commands may be encrypted to ensure data confidentiality.The issuer may choose to require encryption for a user zone by settings made in the configuration memory. Any one of four keys may be selected for use with a user zone. In this case, activation of the encryption mode is required in order to read/write data in the zone and only encrypted data will be transmitted. Even if not required, the host may still elect to activate encryption provided the proper keys are known.11.7 Supervisor ModeEnabling this feature allows the holder of one specific password to gain full access to all eight password sets, including the ability to change passwords.11.8 Modify ForbiddenNo write access is allowed in a user zone protected with this feature at any time. The user zone must be written during device personalization prior to blowing the security fuses.11.9 Program OnlyFor a user zones protected by this feature, data can only be programmed (bits change from a “1” to a “0”), but not erased (bi ts change from a “0” to a “1”).12. Protocol SelectionThe AT88SC0808CA supports two different communication protocols.∙ Smartcard Applications:Smartcard applications use ISO 7816-B protocol in asynchronous T = 0 mode for compatibility and interoperability with industry standard smartcard readers.∙ Embedded Applications:A 2-wire serial interface provides fast and efficient connectivity with other logic devices or microcontrollers.The power-up sequence determines establishes the communication protocol for use within that power cycle. Protocol selection is allowed only during power-up.12.1 Synchronous 2-wire Serial InterfaceThe synchronous mode is the default mode after power up. This is due to the presence of an internal pull-up on RST. For embedded applications using CryptoMemory in standard plastic packages, this is the only available communication protocol.∙ Power-up V CC , RST goes high also∙ After stable V CC , SCL(CLK) and SDA(I/O) may be driven∙ Once synchronous mode has been selected, it is not possible to switch to asynchronous mode without first poweringoff the deviceFigure 12-1. Synchronous 2-wire ProtocolNote: Five clock pulses must be sent before the first command is issued.V cc I/O-SDARST CLK-SCL1234512.2 Asynchronous T = 0 ProtocolThis power-up sequence complies to ISO 7816-3 for a cold reset in smart card applications.∙ V CC goes high; RST, I/O (SDA) and CLK (SCL) are low ∙ Set I/O (SDA) in receive mode ∙ Provide a clock signal to CLK (SCL) ∙RST goes high after 400 clock cyclesThe device will respond with a 64-bit ATR code, including historical bytes to indicate the memory density within the CryptoMemory family.Once asynchronous mode has been selected, it is not possible to switch to synchronous mode without first powering off the device.Figure 12-2. Asynchronous T = 0 Protocol (Gemplus Patent)13. Initial Device ProgrammingEnabling the security features of CryptoMemory requires prior personalization. Personalization entails setting up of desired access rights by zones, passwords and key values, programming these values into the configuration memory with verification using simple write and read commands, and then blowing fuses to lock this information in place.Gaining access to the configuration memory requires successful presentation of a secure (or transport) code. The initial signature of the secure (transport) code for the AT88SC0808CA device is $22 E8 3F. This is the same as the Write 7 password. The user may elect to change the signature of the secure code anytime after successful presentation.After writing and verifying data in the configuration memory, the security fuses must be blown to lock this information in the device. For additional information on personalizing CryptoMemory, please see the application notes ProgrammingCryptoMemory for Embedded Applications and Initializing CryptoMemory for Smart Card Applications from the product page at /products/securemem .V cc I/O-SDARSTCLK-SCL14. Ordering InformationNote: 1. Formal drawings may be obtained from an Atmel sales office.2. Both the J and P module packages are used for either ISO (T=0 / 2-wire mode) or TWI (2-wire mode only).15. Package InformationOrdering Code: MJ or MJTG Ordering Code: MP or MPTGModule Size: M2Dimension*: 12.6 x 11.4 [mm] Glob Top: Round - ∅8.5 [mm] Thickness: 0.58 [mm]Pitch: 14.25mm Module Size: M2Dimension*: 12.6 x 11.4 [mm]Glob Top: Square - 8.8 x 8.8 [mm] Thickness: 0.58 [mm]Pitch: 14.25mmNote: *The module dimensions listed refer to the dimensions of the exposed metal contact area. The actual dimensions of the module after excise or punching from the carrier tape are generally 0.4mm greater in both directions(i.e., a punched M2 module will yield 13.0 x 11.8mm).15.1 Atmel AT88SC0808CA Package Marking Information15.2 Ordering Code: SH8S1 – 8-lead JEDEC SOIC15.3 Ordering Code: PU8P3 – 8-lead PDIPAT88SC0808CA [Summary DATASHEET]Atmel-5204IS-CryptoMem-AT88SC0808CA-Datasheet-Summary_0720152115.4Ordering Code: TH 8X – 8-lead TSSOPAT88SC0808CA [Summary DATASHEET]Atmel-5204IS-CryptoMem-AT88SC0808CA-Datasheet-Summary_0720152215.5Ordering Code: Y6H-T8MA2 – 8-lead Ultra Thin Mini-MapAT88SC0808CA [Summary DATASHEET]Atmel-5204IS-CryptoMem-AT88SC0808CA-Datasheet-Summary_0720152316. Revision History。

NZM 1-4系列塑壳断路器目录1.1系统综览1.2产品概述1.3断路器1.4隔离开关1.6用于北美地区的断路器1.11 断路器,隔离开关NZM 1-4系列塑壳断路器断路器,隔离开关 (2)断路器,隔离开关,3/4极 (4)热磁式脱扣器,3极磁式3极短路脱扣器电子式脱扣器,3极热磁式脱扣器,4极电子式脱扣器,4极 (6) (10) (12) (16) (20)热磁式脱扣器,3极磁式3极短路脱扣器电子式脱扣器,3极 (28) (32) (34)辅助触点带螺钉端子带弹簧压接端子欠压脱扣器带螺钉端子分励脱扣器带螺钉端子门联动旋转手柄门联锁功能的旋转手柄,用于具有UL/CSA认证的NA开关旋转手柄门联锁功能的旋转手柄主开关旋转手柄组件附件机械联锁 (46) (48) (55) (62) (64) (66) (67) (68) (70) (72)3极4极 (24) (25)1.7用于北美地区的塑壳开关3极 (40)1.5产品概述用于北美地区的断路器、隔离开关,3极 (26)1.8技术概述用于1000V AC的断路器和隔离开关,3极 (41)1.9断路器用于是1000V,3极 (42)1.10 安装布线辅助触点,脱扣指示辅助触点 (44)结构紧凑,仅四种电流壳架等级具有3极和4极产品额定电流达到1600A 多种安装方式可选择50℃环境温度下无需降容适用于世界范围市场,通过IEC、UL/CSA,CCC认证安全可靠地对电能进行分配、通断和控制,应用于工业、建筑和机器设备制造业。

创新的保护理念,具有故障诊断和通信功能。

断路器系列NZM1到NZM4• •• • ••Page 4具有故障诊断数据记录和调试功能在运行中可进行负荷分析诊断软件NZM-XPC-SOFT• • • 下载网址:/en/support/ser-viceresult.jsp合闸延时短,60~100 ms 可加锁、铅封,确保安全操作远程操作机构• • Page 74不同型号具有统一的开孔尺寸自动调节,定位中心位置侧面操作功能,节约了主开关的安装空间门联动旋转手柄••• Page 62同一型号的辅助触点安装在不同位置,具有不同功能减少了型号种类,降低了库存要求直接卡装,节约了安装成本标准/脱扣指示辅助触点与Titan系列产品通用• • • Page 46NZM 1-4系列塑壳断路器产品描述塑壳断路器NZM 1,2,3,4,至1600A产品描述NZM 1-4系列塑壳断路器目录 1.11 断路器,隔离开关1.12 选择性保护,线路保护,后备保护NZM 1-4系列塑壳断路器平形联动机构远程操作机构插拔式单元,抽屉式单元NZM1接线端子NZM2接线端子NZM3接线端子NZM4接线端子附件绝缘外壳接地保护脱扣器漏电保护附件多功能适配元件........................................................................................................73......................................................................................................74....................................................................................76....................................................................................................92....................................................................................................96..................................................................................................100..................................................................................................106..................................................................................................................114..............................................................................................................116...............................................................................................118....................................................................................................119. (121)断路器脱扣特性断路器允通特性剩余电流继电器的频率响应.................................................................................................127.................................................................................................131 (135)断路器隔离开关塑壳开关功率耗散接线能力辅助触点辅助触点的安装,ON-OFF时间差欠压脱扣器,分励脱扣器远程操作机构,电容单元数据管理界面(DMI模块)总线连接剩余电流继电器压力释放方向,最小安装间隙,管状接线头................................................................................................................136.............................................................................................................141............................................................................................................142............................................................................................................144............................................................................................................146............................................................................................................148....................................................................149..................................................................................150..................................................................................151.................................................................................152...........................................................................................................153................................................................................................155 (156)在进线断路器NZM...和出线断路器FAZ-B(C),PKZ...之间实现选择性保护在进线断路器NZM...和出线断路器NZM...之间实现选择性保护线路保护,后备保护................................................................................122........................................................................................................124 (126)1.14 技术数据1.13 脱扣特性机械联锁用于远程操作机构的机械联锁 (157) (158)1.15 安装设计NZM型号说明隔离开关型号说明....................................................................................................204.. (205)1.17 型号规则1.16 尺寸断路器,隔离开关 (159)NZM 1-4系列塑壳断路器系统总览NZM 1-4系列塑壳断路器系统总览1.11.1断路器,隔离开关断路器,隔离开关断路器额定持续电流,最大1600 A 分断能力25, 50, 100, 150 kA 于415 V过载保护和短路保护范围可调节时间选择性可调节接地保护低压系统保护,电缆保护,电动机保护,发电机保护3极和4极,IEC/EN 60947隔离开关额定持续电流,最大1600 A 远程脱扣功能,需带欠压或分励脱扣器3极和4极,IEC/EN 60947附加功能安装附件标准辅助触点随主触头动作而动作用于脱扣指示和电气互锁功能脱扣指示辅助触点指示因过载、短路和欠压而产生的脱扣提前闭合辅助触点用于电气互锁和减负荷功能,及在主回路/急停电路应用中欠压脱扣器的提前闭合电压脱扣器电压脱扣器·瞬时·延时分励脱扣器垫块欠压线圈的延时单元门联动旋转手柄门·可加锁·有门联锁功能用于柜体侧面安装的断路器旋转手柄延长杆可以切割成任意长度旋转手柄可加锁远程操作机构通过2线和3线控制实现ON,OFF 复位上下扳动手柄的锁定装置侧面操作手柄数据管理界面(DMI模块)可以查询诊断数据和运行数据记录电流值利用电子式脱扣器对断路器进行参数设置和控制EASY-LINK-DS数据插头PROFIBUS-DP通讯接口1165538971817241125252613, 151214161920212223241011控制回路端子顶部或底部管状式接线端子,铜线或铝线标准配置控制回路端子盒式接线端子框架1的标准配置安装干开关壳体内端子盖在使用电缆接线片,母排或管状接线端子处,防止直接接触安装支架NZM1-XC35用于35 mm导轨NZM1-XC75用于75 mm导轨后部接线端子插拔式和抽屉式单元绝缘框用于上下扳动式手柄,带有旋转驱动机构的旋转式手柄和远程操作机构外部警示牌/显示板指触防护等级为IP2X的防护盖用于盒式接线端子指触防护等级为IP2X的防护盖用于相间隔板NZM 1-4系列塑壳断路器产品概述NZM 1-4系列塑壳断路器产品概述1.21.2断路器隔离开关适用于世界范围的断路器和隔离开关的选型,从第26页起。

齿轮的hs编码摘要:一、齿轮的定义与用途二、齿轮的HS 编码概述三、齿轮HS 编码的具体分类1.可调速齿轮2.传动齿轮3.齿轮箱4.齿轮配件四、齿轮HS 编码在我国的进出口情况五、齿轮HS 编码在国际贸易中的重要性正文:齿轮是一种机械传动装置,由两个或多个相互啮合的齿轮组成,用于在不同轴之间传递动力和运动。

齿轮广泛应用于各种工业领域,如汽车、飞机、机床、船舶等。

齿轮的HS 编码是国际贸易中用于区分和统计齿轮类产品的重要编码。

HS 编码,即国际商品编码,全称为Harmonized Commodity Description and Coding System,是由国际海关合作理事会(WCO)制定的一种商品分类编码体系。

在我国,齿轮的HS 编码属于8413 税则号列。

根据齿轮的类型和用途,HS 编码8413 下的齿轮可以细分为以下几类:1.可调速齿轮:这类齿轮具有可调整转速的功能,通常用于需要调速的场合,如汽车、摩托车等。

2.传动齿轮:主要用于传递动力,具有固定的齿数和齿轮直径,如工业机器人、机床等。

3.齿轮箱:是一种将动力从高速轴传递至低速轴的装置,具有多个齿轮组成的传动系统。

齿轮箱广泛应用于工程机械、风力发电等领域。

4.齿轮配件:包括齿轮轴、齿轮架、齿轮座等,用于支撑和固定齿轮,保证齿轮传动的稳定性和可靠性。

在我国,齿轮产业已经成为机械制造业的重要组成部分。

随着我国工业的快速发展,齿轮的进出口贸易也日益繁荣。

准确的齿轮HS 编码对于我国齿轮产品在国际市场的竞争力和进出口统计具有重要意义。

在国际贸易中,齿轮HS 编码的准确性有助于各国海关对齿轮类产品进行有效的监管和征税。

此外,HS 编码也是国际贸易合同、发票、装箱单等单证的重要内容,直接关系到贸易双方的利益。

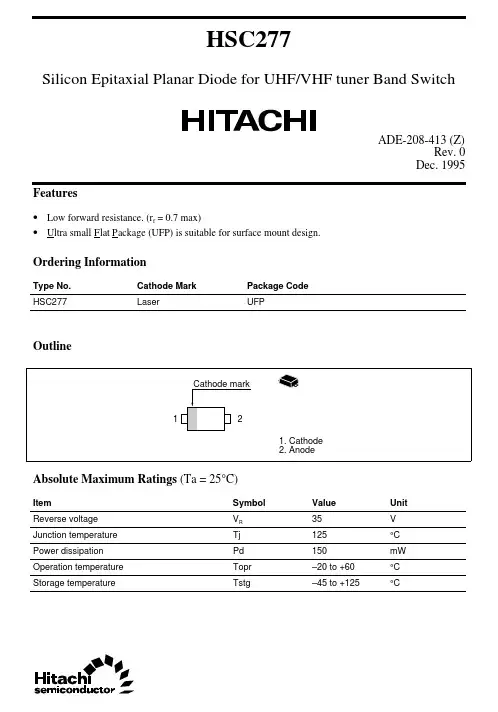

HSC277Silicon Epitaxial Planar Diode for UHF/VHF tuner Band SwitchADE-208-413 (Z)Rev. 0Dec. 1995 Features• Low forward resistance. (r f = 0.7max)• U l tra small F l at P a ckage (UFP) is suitable for surface mount design.Ordering InformationType No.Cathode Mark Package CodeHSC277Laser UFPOutlineAbsolute Maximum Ratings (Ta = 25°C)Item Symbol Value Unit35VReverse voltage VRJunction temperature Tj125°CPower dissipation Pd150mWOperation temperature Topr–20 to +60°CStorage temperature Tstg–45 to +125°CHSC2772Electrical Characteristics (Ta = 25°C)ItemSymbol Min Typ Max Unit Test Condition Reverse voltage V R 35——V I R = 10µA Reverse current I R ——50µA V R = 25V Forward voltage V F —— 1.0V I F = 10mA Capacitance C —— 1.2pF V R = 6V, f = 1MHz Forward resistancer f——0.7ΩI F = 2mA, f = 100MHzFig.1 Forward current Vs. Forward voltageHSC277Fig.2 Reverse current Vs. Reverse voltageFig.3 Capacitance Vs. Reverse voltage3HSC277Fig.4 Forward resistance Vs. Forward current 4HSC277 Package Dimensions5Cautions1.Hitachi neither warrants nor grants licenses of any rights of Hitachi’s or any third party’s patent,copyright, trademark, or other intellectual property rights for information contained in this document.Hitachi bears no responsibility for problems that may arise with third party’s rights, includingintellectual property rights, in connection with use of the information contained in this document.2.Products and product specifications may be subject to change without notice. Confirm that you have received the latest product standards or specifications before final design, purchase or use.3.Hitachi makes every attempt to ensure that its products are of high quality and reliability. However,contact Hitachi’s sales office before using the product in an application that demands especially high quality and reliability or where its failure or malfunction may directly threaten human life or cause risk of bodily injury, such as aerospace, aeronautics, nuclear power, combustion control, transportation,traffic, safety equipment or medical equipment for life support.4.Design your application so that the product is used within the ranges guaranteed by Hitachi particularly for maximum rating, operating supply voltage range, heat radiation characteristics, installationconditions and other characteristics. Hitachi bears no responsibility for failure or damage when used beyond the guaranteed ranges. Even within the guaranteed ranges, consider normally foreseeable failure rates or failure modes in semiconductor devices and employ systemic measures such as fail-safes, so that the equipment incorporating Hitachi product does not cause bodily injury, fire or other consequential damage due to operation of the Hitachi product.5.This product is not designed to be radiation resistant.6.No one is permitted to reproduce or duplicate, in any form, the whole or part of this document without written approval from Hitachi.7.Contact Hitachi’s sales office for any questions regarding this document or Hitachi semiconductor products.Hitachi, Ltd.Semiconductor & Integrated Circuits.Nippon Bldg., 2-6-2, Ohte-machi, Chiyoda-ku, Tokyo 100-0004, Japan Tel: Tokyo (03) 3270-2111 Fax: (03) 3270-5109Copyright ' Hitachi, Ltd., 1999. All rights reserved. Printed in Japan.Hitachi Asia Pte. Ltd.16 Collyer Quay #20-00Hitachi TowerSingapore 049318Tel: 535-2100Fax: 535-1533URLNorthAmerica : http:/Europe : /hel/ecg Asia (Singapore): .sg/grp3/sicd/index.htm Asia (Taiwan): /E/Product/SICD_Frame.htm Asia (HongKong): /eng/bo/grp3/index.htm Japan : http://www.hitachi.co.jp/Sicd/indx.htmHitachi Asia Ltd.Taipei Branch Office3F, Hung Kuo Building. No.167, Tun-Hwa North Road, Taipei (105)Tel: <886> (2) 2718-3666Fax: <886> (2) 2718-8180Hitachi Asia (Hong Kong) Ltd.Group III (Electronic Components)7/F., North Tower, World Finance Centre,Harbour City, Canton Road, Tsim Sha Tsui,Kowloon, Hong Kong Tel: <852> (2) 735 9218Fax: <852> (2) 730 0281 Telex: 40815 HITEC HXHitachi Europe Ltd.Electronic Components Group.Whitebrook ParkLower Cookham Road MaidenheadBerkshire SL6 8YA, United Kingdom Tel: <44> (1628) 585000Fax: <44> (1628) 778322Hitachi Europe GmbHElectronic components Group Dornacher Stra§e 3D-85622 Feldkirchen, Munich GermanyTel: <49> (89) 9 9180-0Fax: <49> (89) 9 29 30 00Hitachi Semiconductor (America) Inc.179 East Tasman Drive,San Jose,CA 95134 Tel: <1> (408) 433-1990Fax: <1>(408) 433-0223For further information write to:。

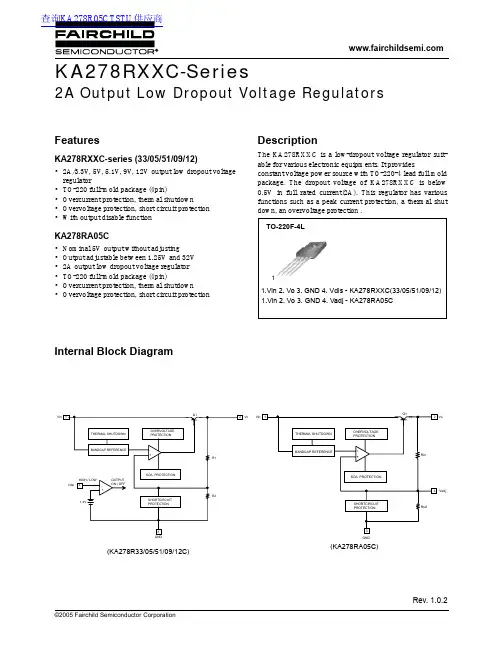

Rev. 1.0.2FeaturesKA278RXXC-series (33/05/51/09/12)•2A/3.3V , 5V , 5.1V , 9V , 12V output low dropout voltage regulator•TO-220 full-mold package (4pin)•Overcurrent protection, thermal shutdown•Overvoltage protection, short circuit protection •With output disable functionKA278RA05C•Nominal 5V output without adjusting•Output adjustable between 1.25V and 32V •2A output low dropout voltage regulator •TO-220 full-mold package (4pin)•Overcurrent protection, thermal shutdown•Overvoltage protection, short circuit protectionDescriptionThe KA278RXXC is a low-dropout voltage regulator suit-able for various electronic equipments. It providesconstant voltage power source with TO-220-4 lead full mold package. The dropout voltage of KA278RXXC is below 0.5V in full rated current(2A). This regulator has various functions such as a peak current protection, a thermal shut down, an overvoltage protection .TO-220F-4L1.Vin2. Vo3. GND4. Vdis - KA278RXXC(33/05/51/09/12)11.Vin2. Vo3. GND4. Vadj - KA278RA05CKA278RXXC-Series2A Output Low Dropout Voltage RegulatorsKA278RXXC-SERIESAbsolute Maximum RatingsKA278RXXC, KA278RA05CParameter Symbol Value Unit Remark Input voltage Vin35V-Disable voltage KA278RXXC Vdis35V-Output current Io 2.0A-Power dissipation 1Pd1 1.5W No heatsink Power dissipation 2 Pd215W With heatsink Junction temperature Tj150°C-Operating temperature Topr-20 ~ 80°C-Thermal resistance, junction-to case (note2)Rθjc 2.9°C/W-Thermal resistance, junction-to-air (note2)Rθja48.51°C/W-KA278RXXC-SERIESElectrical Characteristics(Vin=Note3, Io=1.0A, Ta=25°C , unless otherwise specified)Note:1.These parameters, although guaranteed, are not 100% tested in production.2. Junction -to -case thermal resistance test environments.-. Pneumatic heat sink fixture.-. Clamping pressure 60psi through 12mm diameter cylinder.-. Thermal grease applied between PKG and heat sink fixture.3. KA278R33C : Vin = 5VKA278R05C : Vin = 7V KA278R09C : Vin = 11V KA278R12C : Vin = 15V 4. KA278R33C : Vin =4 to 10VKA278R05C, KA278R51C : Vin=6 to 12V KA278R09C : Vin=10 to 25V KA278R12C : Vin = 13V to 29VParameterSymbolConditionsMin.Typ.Max.UnitOutput voltageKA278R33C Vo - 3.22 3.3 3.38V KA278R05C- 4.885 5.12KA278R51C - 4.98 5.1 5.22KA278R09C -8.7899.22KA278R12C-11.71212.3Load regulation Rload 5mA < Io < 2A-0.1 2.0%Line regulation Rline Note4-0.5 2.5%Ripple rejection ratio RR Note14555-dB Dropout voltage Vdrop Io = 2A --0.5V Disable voltage high KA278RXXC VdisH Output active 2.0--V Disable voltage low KA278RXXC VdisL Output disabled --0.8V Disable bias current high KA278RXXCIdisH Vdis = 2.7V --20µA Disable bias current low KA278RXXCIdisL Vdis = 0.4V ---0.4mA Quiescent current Iq Io = 0A--10mA Reference voltageKA278RA05C Vref- 1.241.271.30VKA278RXXC-SERIESTypical Performance CharacteristicsKA278R33CFigure 1. Output Voltage vs. Input VoltageFigure 2. Quiescent Current vs. Input VoltageFigure 4. Output Voltage vs. Temperature(Tj)Figure 3. Output Voltage vs. Disable VoltageFigure 5. Quiescent Current vs. Temperature(Tj)Figure 6. Dropout Voltage vs.Junction TemperatureKA278RXXC-SERIESTypical Performance Characteristics (Continued)Figure 9. Output Peak Currenrt vs.Input-Output Differential VoltageFigure 7. Power Dissipation vs. Temperature(Tj)Figure 8. Overcurrent Protection Characteristics(Typical Value)KA278RXXC-SERIESTypical Performance Characteristics (Continued)KA278R05CFigure 1. Output Voltage vs. Input VoltageFigure 2. Quiescent Current vs. Input VoltageFigure 4. Output Voltage vs. Temperature(Tj)Figure 3. Output Voltage vs. Disable Voltage Figure 5. Quiescent Current vs. Temperature(Tj)Figure 6. Dropout Voltage vs.Junction TemperatureKA278RXXC-SERIESTypical Performance Characteristics (Continued)Figure 7. Power Dissipation vs. Temperature(Tj)Figure 8. Overcurrent Protection Characteristics(Typical Value)Figure 9. Output Peak Currenrt vs.Input-Output Differential VoltageKA278RXXC-SERIESTypical Performance Characteristics (Continued)KA278R51CFigure 1. Output Voltage vs. Input VoltageFigure 2. Quiescent Current vs. Input VoltageFigure 4. Output Voltage vs. Temperature(Tj)Figure 3. Output Voltage vs. Disable VoltageFigure 5. Quiescent Current vs. Temperature(Tj)Figure 6. Dropout Voltage vs. Junction TemperatureFigure 7. Power Dissipation vs. Temperature(Tj)Figure 8. Overcurrent Protection CharacteristicsFigure 9. Ripple Rejection vs. Input Ripple FrequencyFigure 10. Line Transient ResponseFigure 11. Load Transient Response(Typical value)Figure 12. Output Peak Currenrt vs.Input-Output Differential VoltageKA278R09CFigure 1. Output Voltage vs. Input VoltageFigure 2. Quiescent Current vs. Input VoltageFigure 3. Output Voltage vs. Disable VoltageFigure 4. Output Voltage vs. Temperature(Tj)Figure 5. Quiescent Current vs. Temperature(Tj)Figure 6. Dropout Voltage vs.Junction Temperature11Figure 7. Power Dissipation vs. Temperature(Tj)Figure 8. Overcurrent Protection Characteristics(Typical Value)Figure 9. Output Peak Currenrt vs.Input-Output Differential Voltage12KA278R12CFigure 1. Output Voltage vs. Input VoltageFigure 2. Quiescent Current vs. Input VoltageFigure 4. Output Voltage vs. Temperature(Tj)Figure 3. Output Voltage vs. Disable VoltageFigure 5. Quiescent Current vs. Temperature(Tj)Figure 6. Dropout Voltage vs.Junction Temperature13Figure 7. Power Dissipation vs. Temperature(Tj)Figure 8. Overcurrent Protection Characteristics(Typical Value)Figure 9. Output Peak Currenrt vs.Input-Output Differential Voltage14KA278RA05CFigure 1. Output Voltage vs. Input VoltageFigure 2. Quiescent Current vs. Input VoltageFigure 3. Output Voltage vs. Temperature(Tj)Figure 6. Power Dissipation vs. Temperature(Tj)Figure 5. Dropout Voltage vs.Junction Temperature* Fixed Mode (Vo=5V)Figure 4. Quiescent Current vs. Temperature(Tj)Figure 7. Overcurrent ProtectionCharacteristics(Typical value)Figure 8. Output Peak Currenrt vs.Input-Output Differential Voltage15Typical ApplicationKA278R33/05/51/09/12CFigure 1.Application Circuit•Ci is required if regulator is located at an appreciable distance from power supply filter.•Co improves stability and transient response.(Co > 47µF)KA278RA05Figure 2. Application Circuit (Adjustable Mode)•Ci is required if regulator is located at an appreciable distance from power supply filter.•Co improves stability and transient response.(C O > 47µF)Figure 3. Internal Resistor(R1,R2) Variation vs. Temperature(Tj)Figure 4. Application Circuit (Fixed Mode)1617Mechanical DimensionsPackageDimensions in millimeters TO-220F-4LPackageDimensions in millimeters18PackageDimensions in millimeters192/18/05 0.0m 001Stock#DSxxxxxxxx2005 Fairchild Semiconductor CorporationLIFE SUPPORT POLICYFAIRCHILD’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT OF FAIRCHILD SEMICONDUCTOR CORPORATION. As used herein:1.Life support devices or systems are devices or systemswhich, (a) are intended for surgical implant into the body, or (b) support or sustain life, and (c) whose failure to perform when properly used in accordance with instructions for use provided in the labeling, can bereasonably expected to result in a significant injury of the user.2. A critical component in any component of a life supportdevice or system whose failure to perform can bereasonably expected to cause the failure of the life support device or system, or to affect its safety or effectiveness.DISCLAIMERFAIRCHILD SEMICONDUCTOR RESERVES THE RIGHT TO MAKE CHANGES WITHOUT FURTHER NOTICE TO ANY PRODUCTS HEREIN TO IMPROVE RELIABILITY, FUNCTION OR DESIGN. FAIRCHILD DOES NOT ASSUME ANYLIABILITY ARISING OUT OF THE APPLICATION OR USE OF ANY PRODUCT OR CIRCUIT DESCRIBED HEREIN; NEITHER DOES IT CONVEY ANY LICENSE UNDER ITS PATENT RIGHTS, NOR THE RIGHTS OF OTHERS.Ordering InformationProduct Number PackageOperating TemperatureKA278R33CTU TO-220F-4L -20°C to +80°CKA278R05CTU KA278R51CTU KA278R09CTU KA278R12CTU KA278RA05CTU KA278R33CYDTU TO-220F-4L(Forming)KA278R05CYDTU KA278R09CYDTU KA278R12CYDTU KA278RA05CYDTU KA278R33CTSTU TO-220F-4L (Short Lead)KA278R05CTSTU KA278R12CTSTU。

Product DescriptionThe Cutler -Hammer ா AT3 Automatic Transfer Switch from Eaton’s electri-cal business is designed to provide unmatched performance, reliability and versatility for critical standby power applications. AT3 switches are equipped with the high-performance ATC-300 digital transfer controller for rock-solid monitoring, status reporting and transfer control operation. Superior design and robust construction make the AT3the industry benchmark for critical and distributed power systems.Electrical RatingsI Ratings 30 – 1000 amperes.I 2, 3 or 4-poles.I Up to 600 Vac, 50/60 Hz.I NEMA ா 1, 3R, 12, open.I Suitable for emergency and standby systems (all loads).I UL ா 1008 listed.ICSA ா C22.2 No. 178 certified.Industrial Design HighlightsI Double-throw, mechanicallyinterlocked transfer mechanism.I High withstand and closing ratings.ISeismic Zone 4 qualified (BOCA ா, CBC, IBC, UBC ா).Standard FeaturesIAuxiliary relay contacts:I Source 1 Present 2NO & 2NC I Source 2 Present 2NO & 2NC ISwitch position indication contacts:I Source 1 Position 1NO & 1NC I Source 2 Position 1NO & 1NCISource 1 & Source 2 sensing:I Undervoltage/under frequency I Overvoltage/over frequency I 3-phase rotation protectionI 3-phase voltage unbalance/loss I Pre-transfer signal contacts 1NO/1NC.I Go to Emergency (Source 2).I Seven field programmable time delays.ILCD-based display for program-ming, system diagnostic and Help message display.IMimic diagram with source available and connected LED indication.I Time-stamped history log.I System test pushbutton.IProgrammable plant exerciser —OFF , daily, 7, 14, 28-day interval selectable run time 0 – 600 min-utes no load/load with failsafe.ISafe manual operation under full load with permanently affixed operating handle.Optional FeaturesISuitable for Use as Service Equipment in the standard enclosure size.IAvailable TVSS surge suppres-sion for power/controller, engine start circuit, phone and cable connections.I Integrated distribution panels.IField-selectable multi-tap trans-former panel permits operation on a wide range of system voltages.I Integral overcurrent protection.I Space heater with thermostat.I Ammeter — load side.IStainless steel cover for controller.Service Entrance EquipmentThe AT3 transfer switch is available as rated as Suitable for Use as Service Equipment in the standard enclosure size. Cutler-Hammer Service Equip-ment rated transfer switches with integral overcurrent protection may be installed at the point of ServiceEntrance without the need for separate upstream disconnect devices and additional power connections.Eaton Electrical Inc.1000 Cherrington Parkway Moon Township, PA 15108United States tel: 1-800-525-2000©2005 Eaton Corporation All Rights Reserved Printed in USAPub. No. PA01602002E / Z2897April 2005CSA is a registered trademark of the Canadian Standards Association. Cutler -Hammer is a federally registered trademark of Eaton Corporation. NEMA is the registered trademark and service mark of the National Electrical Manufacturers Association. UL is a federally registered trademark of Underwriters Laboratories Inc. BOCA is a registered trademark of Building Officials and Code Administrators International, Inc. Uniform BuildingCode (UBC) is a trademark of the International Conference of Building Officials (ICBO).Table 1. UL 1008 Withstand and Close-On Ratings (kA)ᕃ240 Vac.Switch Rating Amperes UL 1008 3-Cycle “Any Breaker” Rating Rating When Used With Upstream Fuse240 Vac 480 Vac 600 Vac Maximum Fuse Rating Fuse Type 600 Vac30 – 100 150150 – 225 225100100100100656565 ᕃ6525252525 200 400 400 400J, T J, T J, T J, T 200200200200 300 400 600100100100656565252525 400 6001200J, T J, T J, T 200200200 800100065 655050252516001600L L200200Table 2. Wall Mount Transfer Switch Standard Terminal Data for Power Cable ConnectionsNote: All terminals suitable for copper or aluminum conductors.Note: For alternate terminal sizes, contact Eaton.Switch Rating Amperes Breaker Frame Line Side (Normal and Standby Source)LoadConnection Neutral Connection 30 – 100 150 – 225 150 – 225 225 – 300HFD HFD HKD HKD (1) #14 – 1/0(1) #6 – 300(1) #3 – 350(1) #3 – 350(1) #14 – 1/0(1) #6 – 300(1) #6 – 360(1) #6 – 350(3) #14 – 1/0(3) #4 – 300(3) #4 – 350(3) #4 – 350 400 600 600HLD HLD HMDL (1) 4/0 – 600(2) 3/0 – 350(2) #1 – 500(2) #1 – 500(2) #1 – 500(2) #1 – 500(6) 250 – 350(6) 250 – 350(12) 4/0 – 500 600 (4-pole) 800 8001000NB HMDL HNB HNB(3) 3/0 – 400(3) 3/0 – 400(4) 4/0 – 500(4) 4/0 – 500(3) 3/0 – 400(3) 3/0 – 400(4) 4/0 – 500(4) 4/0 – 500(3) 3/0 – 400(12) 4/0 – 500(12) 4/0 – 500(12) 4/0 – 500Table 4. AT3 Transfer Switch Catalog Numbering SystemFD = 200 and 225 amperes, LD = 600 amperes, MD = 800 amperes for 240/120 Vac single-phase, 3-wire and 208Y/120 Vac 3-phase, 4-wire systems only.Table 3. Dimensions in Inches (mm) and Approximate Shipping in Lbs. (kg)ᕄ240/120 volt, single-phase, 3-wire or 208 volt, 3-phase, 4-wire systems only.ᕅWith multi-tap voltage selection panel.Switch TypeAmperesEnclosure Gutter Space Bolt PatternWeight Lbs. (kg)A (Height)B (Width)C (Depth)D (Width)E (Depth)G (Horizontal)H (Vertical)HFD ᕄHFD ᕄHFD ᕅ30 – 100150 – 225 30 – 10047.74 (1213.0)47.74 (1213.0)47.74 (1213.0)20.81 (528.6)20.81 (528.6)20.81 (528.6)17.22 (437.0)17.22 (437.0)17.22 (437.0)8.00 (203.2)8.00 (203.2)8.00 (203.2)4.00 (101.6)4.00 (101.6)4.00 (101.6)10.75 (273.0)10.75 (273.0)10.75 (273.0)46.44 (1180.0)46.44 (1180.0)46.44 (1180.0)232 (105)232 (105)240 (190)HFD ᕅHFD ᕄHKDHKD150150 – 225150 – 22530047.74 (1213.0)35.61 (904.0)48.00 (1219.2)56.00 (1422.4)20.81 (528.6)20.06 (509.5)20.81 (528.6)20.81 (528.6)17.22 (437.0)13.34 (339.0)18.40 (467.4)18.40 (467.4)8.00 (203.2)8.00 (203.2)8.00 (203.2)8.00 (203.2)4.00 (101.6)4.00 (101.6)4.00 (101.6)4.00 (101.6)10.75 (273.0)10.75 (273.0)11.00 (279.4)11.00 (279.4)46.44 (1180.0)34.31 (904.0)45.50 (1155.7)53.50 (1358.9)240 (190)150 (68)305 (138)295 (134)HLD HLD ᕄHMDL40060060053.00 (1346.0)64.00 (1625.6)76.74 (1949.2)25.81 (655.6)25.81 (655.6)25.81 (655.6)18.40 (467.4)18.40 (467.4)19.50 (495.3)8.00 (203.2)8.00 (203.2)8.00 (203.2)4.00 (101.6)4.00 (101.6)4.00 (101.6)16.00 (406.4)16.00 (406.4)16.00 (406.4)51.50 (1308.0)62.50 (1588.0)75.15 (1908.8)425 (193)475 (214)480 (218)HMDL ᕄHNB 800800 – 100076.74 (1949.2)76.74 (1949.2)25.81 (655.6)25.81 (655.6)19.50 (495.3)19.50 (495.3)8.00 (203.2)8.00 (203.2) 4.00 (101.6)4.00 (101.6)16.00 (406.4)16.00 (406.4)75.15 (1908.8)75.15 (1908.8)510 (232)540 (245)Typical (225 – 1000 A) Vertical Design Transfer Switch Equipment (Door Open and Deadfront Cover Removed)Power Panel NormalPower Source Molded Case Switch VoltageSelection Panel (Domestic)Emergency Power Source Molded Case SwitchMotorBrake BoardTransfer Mechanism Indicator Wheel Manual Operating Handle NeutralConnections Load Lugs (T op Entry)Service Disconnect。

26.10.2016 06:39:33hDatasheet AZM 170SK11/02ZRK2197AZM 170SK11/02ZRK219724VAC/DCSolenoid interlock / AZM 170(Minor differences between the printed image and the originalproduct may exist!)• Thermoplastic enclosure • Doubleinsulated • Compact design• 90 mm x 84 mm x 30 mm • 1 Cable entry M 20 x 1.5• Interlock with protection against incorrect locking.• Long life• High holding force• Manual release from side • Screw connectionOrdering detailsProduct type descriptionAZM 170SK11/02ZRK2197 24VAC/DC Article number 101183249EAN code 4030661319049eCl@ss 27272603ApprovalApprovalBG USA/CAN CCCClassificationStandards EN ISO 138491B 10d Opener (NC) 2.000.000Mission time 20 Y earsnoticeGlobal PropertiesProduct name AZM 170StandardsEN 6094751, BGGSET19Compliance with the Directives (Y/N)Y esNumber of actuating directions2 pieceActive principle electromechanicalDuty cycle Magnet 100 %Materials Material of the housings Plastic, glassfibre reinforced thermoplastic, selfextinguishing Material of the contacts SilverHousing coating NoneWeight320 gMechanical dataDesign of electrical connection Screw connectionCable section Min. Cable section1 x 0,25 mm² Max. Cable section1 x 1.5 mm², flexibleMechanical life> 1.000.000 operationsEmergency unlocking device (Y/N)NoManual release (Y/N)Y es rightEmergency release (Y/N)NoLatching force30 NPositive break force17 Npositive break travel11 mmClamping force F1000 NMax. Actuating speed2 m/sAmbient conditionsAmbient temperature Min. environmental temperature−25 °C Max. environmental temperature+60 °CProtection class IP67 to IEC/EN 60529Electrical dataDesign of control element Normally open contact (NO), Opener (NC)notice changeover contact with double break, type Zb or 2 NC contacts,with galvanically separated contact bridgesSwitching principle Creep circuit elementNumber of auxiliary contacts1 pieceNumber of safety contacts3 piecePower to unlock Y esPower to lock NoRated control voltage U s24 VAC/DCPower consumption max. 10 WRated impulse withstand voltage U imp4 kVRated insulation voltage U i250 VThermal test current I the10 AUtilisation category AC15: 230 V / 4 ADC13: 24 V / 4 AMax. fuse rating6 A gG DfuseATEXExplosion protection categories for gases NoneExplosion protected category for dusts NoneMiscellaneous dataApplicationssliding safety guard,removable guard,hinged safety guardDimensionsDimensions of the sensor Width of sensor108 mm Height of sensor100.5 mm Length of sensor30 mmnoticeIndividual coding available on requestManual release from side• For manual release using M5 triangular key, available as accessory• Additional manual release on sideDiagramNote Diagrampositive break NC contactactiveno activeNormallyopen contactNormallyclosed contactOrdering suffixThe applicable ordering suffix is added at the end of the part number of the safety switch.Order example: AZM 170SK11/02ZRK2197 24VAC/DC1637...16370,3 µm goldplated contacts...ST2431connector M12 , Individual solenoid monitoringOrdering codeAZM 170(1)(2)Z(3)K(4)(5)(6)(7)(1)without IDC method of terminationSK Screw connection(2)111 Normally open contact (NO) / 1 Opener (NC)022 Opener (NC)12/0.01 Normally open contact (NO), 2 Opener (NC) / (3)without Latching force 5 NR Latching force 30 NI Individual coding(4)without Power to unlockA Power to lock(5)without cable glandST Connector M12 x 1ST2431Connector M12 x 1, Individual solenoid monitoring(6)24VAC/DC U s 24 VAC/DC110VAC U s 110 VAC230VAC U s 230 VAC(7)without Manual release2197Manual release from side (Power to unlock) 1637goldplated contactsAZM 170ST and AZM 170SKAZM 170ST(1)Z(2)K(3)(4)(5)024AZM 170SK(1)Z(2)K(3)(4)(5)024(1)11/111 Normally open contact (NO), 1 Opener (NC) / 1Normally open contact (NO), 1 Opener (NC) 11/021 Normally open contact (NO), 1 Opener (NC) / 2Opener (NC)12/001 Normally open contact (NO), 2 Opener (NC) / 12/111 Normally open contact (NO), 2 Opener (NC) / 1Normally open contact (NO), 1 Opener (NC) 12/021 Normally open contact (NO), 2 Opener (NC) / 2Opener (NC)02/012 Opener (NC), / 1 Opener (NC), 02/102 Opener (NC), / 1 Normally open contact (NO), (2)without Latching force 5 NR Latching force 30 N(3)without Power to unlockA Power to lock(4)1637goldplated contacts(5)2197Manual release for Power to unlockDocumentsOperating instructions and Declaration of conformity (en) 509 kB, 21.04.2016Code: mrl_azm170xxxx_enOperating instructions and Declaration of conformity (da) 509 kB, 24.11.2015Code: mrl_azm170xxxx_daOperating instructions and Declaration of conformity (it) 509 kB, 22.04.2016Code: mrl_azm170xxxx_itOperating instructions and Declaration of conformity (nl) 511 kB, 24.11.2015Code: mrl_azm170xxxx_nlOperating instructions and Declaration of conformity (de) 494 kB, 21.04.2016Code: mrl_azm170xxxx_deOperating instructions and Declaration of conformity (cs) 546 kB, 24.11.2015Code: mrl_azm170xxxx_csOperating instructions and Declaration of conformity (pt) 384 kB, 26.06.2012Code: mrl_azm170xxxx_ptOperating instructions and Declaration of conformity (jp) 601 kB, 07.09.2016Code: mrl_azm170xxxx_jpOperating instructions and Declaration of conformity (fr) 511 kB, 28.04.2016Code: mrl_azm170xxxx_frOperating instructions and Declaration of conformity (es) 512 kB, 24.11.2015Code: mrl_azm170xxxx_esOperating instructions and Declaration of conformity (pl) 543 kB, 10.09.2015Code: mrl_azm170xxxx_plBGtest certificate (en) 260 kB, 09.12.2015Code: z_m17p02BGtest certificate (de) 257 kB, 09.12.2015Code: z_m17p01CCC certification (en) 933 kB, 16.08.2016Code: q_371p02CCC certification (cn) 932 kB, 16.08.2016Code: q_371p03EAC certification (ru) 809 kB, 05.10.2015Code: q_6040p17_ruImagesDimensional drawing (basic component)Detail photoSystem componentsActuator101122893 AZ 17/170B1• Particularly suitable for sliding doors101137406 AZ 17/170B12245• Particularly suitable for sliding doors • Damps vibration on guard device101122895 AZ 17/170B5• Particularly suitable for sliding doors101139788 AZ 17/170B11• Particularly suitable for sliding doors101139789 AZ 17/170B15• Particularly suitable for sliding doors101123391 AZM 170B6• Particularly suitable for hinged guards • For very smal actuating radii• The direction of actuation can be selected by applicable insertion of the insertAccessories101208493 AZM 170B CENTERING GUIDE• for AZ 17 and AZM 170101100887 TRIANGULAR KEY TKM5• For manual release using M5 triangular key, available asaccessory• For maintenance, installation, etc.ConnectorAK4M12• Prewired cable• 4poleSK4M12• Connector without cable• 4poleK.A. Schmersal GmbH & Co. KG, Möddinghofe 30, D42279 WuppertalThe data and values have been checked throroughly. Technical modifications and errors excepted.Generiert am 26.10.2016 06:39:33h Kasbase 3.2.5.F.64I。

©2002 Fairchild Semiconductor CorporationRev. 1.0.2Features•Single or Dual Supply Operation •Wide Range of Supply V oltageKA239/KA239A, KA339/KA339A, KA2901 : 2 ~ 36V (or ±1 ~ ±18V)KA3302 : 2 ~ 28V (or ±1 ~ ±14V)•Low Supply Current Drain 800µA Typ.•Open Collector Outputs for Wired and Connectors •Low Input Bias Current 25nA Typ.•Low Input Offset Current ±2.3nA Typ.•Low Input Offset V oltage ±1.4mV Typ.•Input Common Mode V oltage Range Includes Ground.•Low Output Saturation V oltage•Output Compatible With TTL, DTL and MOS Logic SystemDescriptionThe KA239/KA239A, KA339/KA339A, KA3302, KA2901consist of four independent voltage comparators designed to operate from single power supply over a wide voltage range.14-SOP14-DIP11Internal Block Diagram141131*********4567-+--+++-OUT3OUT4IN4(+)GNDIN4(-)IN3(+)IN3(-)OUT2OUT1IN1(+)IN1(-)IN2(-)IN2(+)V CC KA239/KA239A,KA339/KA339A KA3302,KA2901Quad ComparatorKA239/KA239A,KA339/KA339A KA3302,KA29012Schematic DiagramAbsolute Maximum RatingsParameter Symbol Value Unit Supply VoltageV CC ±18 or 36V Supply Voltage Only KA3302V CC ±14 or 28V Differential Input VoltageV I(DIFF)36V Differential Input Voltage Only KA3302V I(DIFF)28V Input VoltageV I -0.3 to +36V Input Voltage Only KA3302V I -0.3 to +28V Output Short Circuit to GND -Continuous-Power Dissipation P D570mWOperating Temperature KA339/KA339A KA239/KA239A KA2901/KA3302T OPR 0 ~ +70-25 ~ +85-40 ~ +85°C Storage TemperatureT STG-65 ~ +150°CV CCQ9Q12Q14Q3Q1Q2Q7Q13Q8Q5Q6Q4D4D5D6D1D2D3R2R1GNDOUTPUTIN(-)IN(+)KA239/KA239A,KA339/KA339A KA3302,KA29013Electrical Characteristics(V CC = 5V, T A = 25°C, unless otherwise specified)Note:1. KA339 / KA339A: 0 ≤ T A ≤ +70°CKA239 / KA239A: -25 ≤ T A ≤ +85°C KA2901 / KA3302: -40 ≤ T A ≤ +85°C2. These parameters, although guaranteed, are not 100% tested in production.ParameterSymbol ConditionsKA239A/KA339A KA239/KA339Unit Min.Typ.Max.Min.Typ.Max.Input Offset Voltage V IO V O(P) = 1.4V, R S = 0Ω-12- 1.45mVNote1-- 4.0--9.0Input Offset Current I IO I IN(+) - I IN(-), V CM = 0V- 2.350- 2.350nA Note1--150--150Input Bias Current I BIAS V CM = 0V-57250-57250nA Note1--400--400Input Common Mode Voltage Range V I(R)V CC = 30V0-V CC -1.50-V CC -1.5V Note10-V CC -20-V CC -2Supply Current I CC V CC = 5V, R L = ∞- 1.1 2.0- 1.1 2.0mA Voltage Gain G V V CC = 15V, R L ≥ 15k Ω(for large swing)50200-50200-V/mV Large Signal Response Time T LRES V I = TTL Logic Swing V REF = 1.4V, V RL = 5V, R L = 5.1k Ω (Note2)-300--300-ns Response Time T RES V RL = 5V, R L = 5.1k Ω (Note2)- 1.3-- 1.3-µs Output Sink Current I SINK V I(-) ≥ 1V, V I(+) = 0V, V O(P) ≤ 1.5V 618-618-mA Output Saturation Voltage V SAT V I(-) ≥ 1V, V I(+) = 0V -140400-140400mV I SINK = 4mA Note1--700--700Output Leakage CurrentI o(LKG)V I(-) = 0V V I(+) = 1VV O(P) = 5V -0.1--0.1-nA V O(P) =30V -- 1.0-- 1.0µA Differential VoltageV I(DIFF)Note1--36--36VKA239/KA239A,KA339/KA339A KA3302,KA29014Electrical Characteristics (Continued)(V CC = 5V, T A = 25°C, unless otherwise specified)Note:1. KA339 / KA339A: 0 ≤ T A ≤ +70°CKA239 / KA239A: -25 ≤ T A ≤ +85°C KA2901 / KA3302: -40 ≤ T A ≤ +85°C2. These parameters, although guaranteed, are not 100% tested in production.ParameterSymbol ConditionsKA2901KA3302Unit Min.Typ.Max.Min.Typ.Max.Input Offset Voltage V IO V O(P) = 1.4V, R S = 0Ω-27-220mV Note1-915--40Input Offset Current I IO - 2.350-3100nA Note1-50200--300Input Bias Current I BIAS-57250-57250nANote1-200500--1000Input Common ModeVoltage Range V I(R)KA2901, V CC =30V KA3302, V CC =28V0-V CC -1.50-V CC -1.5VNote10-V CC -20-V CC -2Supply CurrentI CC R L =∞, V CC =5V- 1.1 2.0- 1.1 2.0mA R L =∞, V CC =30V (KA3302, V CC =28V)- 1.6 2.5- 1.6 2.5Voltage Gain G V V CC =15V, R L ≥15k Ω(for large swing)25100-230-V/mV Large Signal Response Time T LRES V I =TTL Logic Swing V REF =1.4V, V RL = 5V, R L =5.1k Ω (Note2)-300--300-ns Response Time T RES V RL = 5V, R L =5.1k Ω (Note2)- 1.3-- 1.3-µs Output Sink Current I SINK V I(-) ≥ 1V, V I(+) = 0V, V O(P) ≤ 1.5V 618-618-mA Output Saturation Voltage V SAT V I(-) ≥ 1V, V I(+) =0V -140400-140400mV I SINK = 4mA Note1--700--700Output Leakage CurrentI O(LKG)V I(-) = 0V V I(+) = 1VV O(P) = 5V -0.1--0.1-nA V O(P) = 30V -- 1.0-- 1.0µA Differential VoltageV I(DIFF)-Note1--36--28VKA239/KA239A,KA339/KA339A KA3302,KA29015Typical Performance CharacteristicsFigure 1.Supply Current vs Supply Voltage Figure 2.Input Current vs Supply VoltageFigure 3.Output Saturation Voltage vs Sink CurrentFigure 4.Response Time for Various InputOverdrive-Negative TransitionFigure 5.Response Time for Various InputOverdrive-Positive TransitionKA239/KA239A,KA339/KA339A KA3302,KA2901Mechanical DimensionsPackageDimensions in millimeters14-DIP6KA239/KA239A,KA339/KA339A KA3302,KA2901 Mechanical Dimensions (Continued)PackageDimensions in millimeters14-SOP7KA239/KA239A,KA339/KA339A KA3302,KA290111/19/02 0.0m 001Stock#DSxxxxxxxx2002 Fairchild Semiconductor CorporationLIFE SUPPORT POLICYFAIRCHILD’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT OF FAIRCHILD SEMICONDUCTOR CORPORATION. As used herein:1.Life support devices or systems are devices or systemswhich, (a) are intended for surgical implant into the body, or (b) support or sustain life, and (c) whose failure to perform when properly used in accordance with instructions for use provided in the labeling, can bereasonably expected to result in a significant injury of the user.2. A critical component in any component of a life supportdevice or system whose failure to perform can bereasonably expected to cause the failure of the life support device or system, or to affect its safety or effectiveness.DISCLAIMERFAIRCHILD SEMICONDUCTOR RESERVES THE RIGHT TO MAKE CHANGES WITHOUT FURTHER NOTICE TO ANY PRODUCTS HEREIN TO IMPROVE RELIABILITY, FUNCTION OR DESIGN. FAIRCHILD DOES NOT ASSUME ANYLIABILITY ARISING OUT OF THE APPLICATION OR USE OF ANY PRODUCT OR CIRCUIT DESCRIBED HEREIN; NEITHER DOES IT CONVEY ANY LICENSE UNDER ITS PATENT RIGHTS, NOR THE RIGHTS OF OTHERS.Ordering InformationProduct NumberPackage Operating TemperatureKA33914-DIP0 ~ +70°CKA339A KA339D 14-SOP KA339AD KA23914-DIP-25 ~ +85°CKA239A KA239D 14-SOP KA239AD KA290114-DIP -40 ~ +85°C KA2901D 14-SOP KA330214-DIP KA3302D14-SOP。

安装及操作说明名称:透平压缩机系统型号:3(2)VRZ 250/430/16 G序言本安装和操作说明是对3(2)VRZ 250/430/16 G 型透平压缩机开车、操作、维修的重要描述。

因此,在初次开车前,你必须认真阅读安装和操作说明以及LCP的操作手册,已确保安全、经济的使用此透平压缩机。

压缩机的关键部件,例如电机、齿轮单元、油冷器、油过滤器、油泵等也必须遵守此操作说明。

所有的维修活动必须由相关的专家进行。

由于操作疏忽或者维修不当而造成的设备故障,我们将不接受任何质保要求。

我们将为你解决你在此安装和操作说明中遇到的任何问题。

我们希望你们能在不出现任何问题的情况下顺利运行这套系统。

目录表格清单 (6)图纸清单 (6)简介 (7)用途 (7)1.安全规程及说明 (8)1.1安全规程................................................................................. .8 1.2安全说明. (8)1.3重点 (10)2.技术资料 (11)2.1压缩机 (11)2.2与压缩机相连的冷却器............................................................. (16)2.2.1冷却器 (16)2.2.2连接管道 (16)2.2.3冷却器使用的弹簧垫圈........................................................ (16)2.3电机 (16)2.4增速器 (17)2.5联轴器 (17)2.6设备底座 (17)2.7润滑油系统 (18)2.7.1油箱 (18)2.7.2油冷却器 (18)2.7.2.1辅助油泵 (19)2.7.2.2油冷却器 (19)2.7.2.3油过滤器 (19)2.8设备底座、油系统和油冷却器的安装 (20)2.9消耗定额............................................................................. (20)2.9.1润滑油.......................................................................... (20)2.9.1.1过滤油量..................................................................... (20)2.9.1.2润滑油量.................................................. (21)2.9.2密封气.............................................. (22)2.9.3电力消耗....................................................................... (22)2.9.3.1压缩机电机.................................................................. (22)2.9.3.2辅助油泵电机 (22)2.9.3.3油箱加热器 (22)3.压缩机组的各部件名称及功能 (23)3.1压缩机.............................................. . (23)3.1.1压缩机的一般资料 (23)3.1.2设计说明 (27)3.1.2.1转子 (33)3.1.2.2机壳 (33)3.1.2.3导轮和迷宫密封.............................................. . (33)3.1.2.4压缩机转子轴承的安装 (33)3.1.3中冷器和后冷器 (34)3.2驱动系统 (34)3.2.1电机 (34)3.2.2增速器 (34)3.2.3联轴器 (34)3.3润滑油供应 (35)3.4测量和控制技术 (39)3.4.1测量点—密封—连锁........................................................ (39)3.4.2控制点 (39)3.4.2.1进口导叶 (39)3.4.2.2电涌调节 (39)3.4.2.3密封器调节 (40)3.4.3轴振动和径向位移 (40)4.压缩机组的安装 (41)4.1压缩机的安装 (41)4.2辅助单元的安装 (41)4.3铺设油、气、冷却水管线 (41)4.4校正 (42)4.4.1连接加速器和压缩机的联轴器的校正 (42)4.4.2连接电机和加速器的联轴器的校正 (44)5.压缩机装置的试车和操作 (46)5.1初次开车前的准备工作 (46)5.2初始试车 (48)5.2.1机械运转测试 (48)5.2.2操作测试 (48)5.3正常开车 (48)5.4投入氯气开车 (50)5.5停车 (51)5.5.1正常停车 (51)5.5.2故障停车 (52)5.6维护 (53)6.操作故障 (54)6.1主电机 (54)6.1.1主电机不启动 (54)6.1.2主电机停机 (54)6.2加速器 (54)6.2.1油循环温度太高 (54)6.2.2轴承温度太高 (54)6.2.3加速器内突然出现不正常运行噪音 (54)6.3压缩机 (55)6.3.1运行不稳定 (55)6.3.2所有轴承温度升高 (55)6.3.3某一个轴承温度升高 (55)6.3.4压缩机出口气体温度升高 (55)6.3.5密封气压力降低 (55)6.4润滑油系统 (55)6.4.1过滤器出口油压降低 (55)6.4.2冷却器出口油温太高 (55)7.预防性的维修、拆卸和安装 (56)7.1压缩机 (56)7.2检查 (61)7.3联轴器 (62)7.4冷却器 (62)7.5主电机 (62)7.6增速器 (62)7.7油冷却器 (62)7.8油过滤器 (62)7.9油泵 (62)7.10油箱 (63)7.11附录:安装和拆卸斜垫轴承的说明书 (63)8.运输 (70)9.备用和防护部件 (73)9.1防护部件 (73)9.1.1压缩机 (73)9.1.2增速器 (73)9.2备用配件 (73)9.2.1压缩机 (73)9.2.2增速器 (74)9.2.3联轴器 (74)9.2.4油冷却器 (74)9.2.5油过滤器 (74)9.2.6连接管线 (74)9.3安装和控制设备 (74)10.版权 (75)表格清单表 1.压缩机单元部件清单 (24)表 2.压缩机单元部件清单 (28)表 3.进口可调导叶设备清单 (30)表 4.油系统设备清单 (36)图纸清单图 1.压缩机工作特征图 (15)图 2.压缩机单元 (25)图 3.压缩机单元 (26)图4压缩机剖视图 (29)图5入口可调导叶 (31)图 6.入口可调导叶 (32)图7.油系统 (37)图8.油系统 (38)图9.增速器和压缩机之间的连接 (44)图10.电机和增速器之间的连接设备 (45)图11.方框图 (49)图12.松开连接杆 (56)图13.压缩机控制点 (59)图14.压缩机控制点 (60)图15.径向轴泵倾斜垫的安装位置 (64)图16.倾斜垫的拆卸 (66)图17.止推轴承 (67)图18.止推轴承结构图 (68)图19.止推轴承热探测器 (69)图20.止推轴承热探测器 (69)图21.压缩机系统运输说明 (70)图22.压缩机运输说明 (71)图23.油系统运输说明 (72)简介此压缩机单元包括1个带有中冷器的二级离心式压缩机、1个透平增速齿轮系统、一个电动机、一个压缩机底座、一个增速器单元和电机、两个中冷却器及连接管道、一个润滑油系统、一个密封气系统以及必要的检测和控制技术。