AATCC 112

- 格式:pdf

- 大小:651.71 KB

- 文档页数:5

AATCC标准(美国纺织印染业)发布办公室: 上海司达信产品检测中心[转摘] | 发布时间: 2008-4-29 9:32:28 AATCC标准(美国纺织印染业)标签:纺织品干洗织物地毯分散染料标准代号标准名称AATCC 6-2001 耐酸碱色牢度AATCC 8-2001 耐摩擦色牢度:AATCC耐摩擦色牢度测定器AATCC 15-2002 耐汗渍色牢度AATCC 16-2003 耐光色牢度AATCC 17-1999 湿润剂,评定AATCC 20-2002 纤维分析:质量AATCC 20A-2000 纤维分析:数量AATCC 22-2001 排水:喷雾试验AATCC 23-1999 耐烟熏色牢度AATCC 24-1999 昆虫,纺织品耐AATCC 26-1999 硫染纺织品用剂:加速AATCC 27-1999 湿润剂:再湿润剂评定AATCC 28-1999 纺织品防昆虫、害虫AATCC 30-1999 耐真菌活性,纺织品材料的评定:纺织品材料耐霉菌防腐烂AATCC 35-2000 耐水渍:雨水试验AATCC 42-2000 耐水渍:冲击穿透试验AATCC 43-1999 丝光处理湿润剂AATCC 61-2003 耐家庭、商业洗涤色牢度:加速AATCC 66-2003 机织物折痕回复:回复角AATCC 70-2000 排水:滚筒水击动态吸收试验AATCC 76-2000 纤维表面电阻AATCC 79-2000 漂白纺织品的吸收性AATCC 81-2001 湿加工时纺织品水萃取PH值AATCC 82-2001 漂白棉布中纤维素分散质的流度AATCC 84-2000 纱线电阻AATCC 86-2000 干洗:应用设计和整理的耐久性AATCC 88B-2003 多次家洗后织物缝线处的平滑性AATCC 88C-2003 织物多次家洗后留下的折痕AATCC 89-2003 棉的丝光处理AATCC 92-1999 氯,存留的,张力损耗:单个取样法AATCC 93-1999 织物耐磨:加速剂方法AATCC 94-2002 织物整理:鉴别AATCC 96-2001 机织和针织物(毛织物除外)商业洗涤后尺寸变化AATCC 97-1999 原纱和/或已处理纺织品的可提取成分AATCC 98-2002 含过氧化氢的漂白槽中的碱AATCC 99-2000 机织或针织毛纺织品尺寸变化:松弛、收缩和毡合AATCC 100-1999 纺织品材料上耐细菌整理:评定AATCC 101-1999 过氧化氢漂白色牢度AATCC 102-2002 过氧化氢漂白,高锰酸钾滴定法:测定AATCC 103-1999 用于退浆的细菌性α淀粉酶,化验AATCC 104-1999 耐水滴色牢度AATCC 106-2002 耐水浸色牢度:海水AATCC 107-2002 耐水浸色牢度AATCC 109-2002 耐低湿度大气臭氧色牢度AATCC 110-2000 纺织品的白色AATCC 111-2003 纺织品耐气候性AATCC 112-2003 织物挥发甲醛,测定:封罐法AATCC 114-1999 氯,存留的,张力损耗:多次取样法AATCC 115-2000 织物静电依附:织物—金属试验AATCC 116-2001 耐摩擦色牢度:旋转垂直耐摩擦色牢度测定器法AATCC 117-1999 耐高温色牢度:干燥(不包括熨烫)AATCC 118-2002 排油:耐烃试验AATCC 119-1999 平面磨蚀引起的色变(消光):屏蔽电线方法AATCC 120-1999 平面磨蚀引起的色变(消光):金刚砂方法AATCC 121-2000 地毯玷污:可视评定法AATCC 122-2000 地毯沾污:使用沾污法AATCC 123-2000 地毯沾污:加速沾污法AATCC 124-2001 织物多次家洗后外形AATCC 125-1991 耐水耐光色牢度:交替暴露AATCC 127-2003 耐水性:流体静压试验AATCC 128-1999 织物折痕回复:外形AATCC 129-2001 耐高湿度大气臭氧色牢度AATCC 130-2000 排除污垢:油污排除法AATCC 131-2000 耐褶裥色牢度:蒸汽褶裥AATCC 132-2003 耐干洗色牢度AATCC 133-1999 耐高温色牢度:热压AATCC 134-2001 地毯的静电性AATCC 135-2003 机织和针织物自动家洗时尺寸变化AATCC 136-2003 黏合或层压织物的黏合强度AATCC 137-2002 瓷砖上小地毯背面沾污AATCC 138-2000 清洁:铺地织物的清洗AATCC 139-2000 耐光色牢度:致光色变现象的观察AATCC 140-2001 轧-烘处理过程中染料和涂剂泳移AATCC 141-1999 碱性染料与丙烯酸纤维的相容性AATCC 142-2000 植绒织物经多次家洗和/或在投币自动干洗后外形AATCC 143-2001 衣服和其他纺织成品多次家洗后的外形AATCC 144-2002 湿处理织物所含碱:整体AATCC 146-2001 分散染料的分散性:过滤试验AATCC 147-1998 织物材料抗菌活性测定:平行条纹法AATCC 149-2002 螯合剂:氨基聚羧酸螯合作用值及其盐分;草酸钙法AATCC 150-2003 服装自动家洗时尺寸的变化AATCC 151-2003 污物再沉积AATCC 154-2001 分散染料的热固定性AATCC 157-2000 耐溶剂滴色牢度:全氯乙烯AATCC 158-2000 全氯乙烯干洗后尺寸变化:机械法AATCC 159-1999 尼龙上酸和金属络合酸性染料的转移AATCC 161-2002 螯合剂:金属引起的分散染料色度阴暗;控制AATCC 162-2002 耐水浸色牢度:氯化水池AATCC 163-2002 色牢度:留存染料转印;织物对织物AATCC 164-2001 耐高湿度大气中氧化氮色牢度AATCC 165-1999 耐摩擦色牢度:铺地织物-AATCC耐摩擦色牢度测定器AATCC 167-2003 分散染料的起泡性AATCC 168-2002 螯合剂:聚氨基聚羧酸的活性成分含量极其盐分;铜硝酸过氧化乙酰法(PAN)AATCC 169-2003 织物的耐气候性:氙灯暴露AATCC 170-2001 粉状染料的喷撒性:评定AATCC 171-2000 地毯:热水萃取法AATCC 172-2003 家洗耐无氯漂白色牢度AATCC 173-1998 CMC:小色差合格率计算AATCC 174-1998 地毯耐微生物活性测定AATCC 175-2003 耐脏:绒毛铺地材料AATCC 176-2001 染料剂分散质斑点:评定AATCC 178-1999 纬向染疵:可视测定和渐次调和AATCC 179-2001 自动家洗时缠绕引起织物和衣服变形AATCC 180-1997 高温下耐光色牢度:受装置控制的天然光温度AATCC 181-1997 高温下耐光色牢度:受装置控制的天然光温度和湿度AATCC 182-2000 溶液中染料颜色的相对强度AATCC 183-2000 紫外线穿透织物强度AATCC 184-2000 染料喷撒性能:测定AATCC 185-2000 螯合剂:过氧化氢漂白槽中的百分含量:铜硝酸过氧化乙酰(PAN)指示剂方法;AATCC 186-2001 耐气候性:紫外线和湿度暴露AATCC 187-2002 织物的尺寸变化:加速的AATCC 188-2003 家洗耐钠、次氯盐酸漂白色牢度AATCC 189-2002 地毯纤维含氟量AATCC 190-2003 耐活性氧漂白洗涤剂家洗的色牢度:加速酸性纤维素酶,作用于:最大负荷量洗涤器AATCC 191-2003 木纤维质酵酶酸一洗衣机顶部装载的影响AATCC 192-2003 织物的耐久性:有水或者无水情况暴露于电孤光下。

干洗色牢度(AATCC 132)1.仪器及材料1.1 水洗色牢度实验机1.2不锈钢洗杯:直径为75mm,高为125mm,容量为500ml。

1.3 不锈钢珠1.4 未染色斜纹棉布:克重为270+70g/m2,未经整理过的,切割成尺寸为120mm x120mm的布片1.5 全氯乙烯,干洗级1.6 AATCC变色灰卡,AATCC沾色灰卡1.7 分光光度计1.8 摩擦附布1.9 洗涤剂,Perk-Sheen2.测试样品2.1 如果被测试物为织物,每种样布取3块样品,每块样品尺寸为10x5cm。

长边方向平行于经向或纬向。

2.2 如果被测试物为纱线,将其织成尺寸为10x 5cm的织片,长边方向平行于经向或纬向。

2.3 样品准备3.测试程序3.1 将两块未染色的正方形棉斜纹布沿三边缝合,制成一个内尺寸为100mm x100mm的布袋,将一块试样和12片不锈钢圆片放入袋中,用任何方便的形式缝住袋口。

3.2 把装有试样和钢片的布袋放在容器内,在30C+2加入200ml全氯乙烯,如用其它溶剂,需在报告中说明。

在规定的装置中,30C+2C处理试样30min。

3.3 从溶剂中拿出布袋,取出试样,夹于吸水袋或布之间,挤压或离心去除多余的溶剂,将试样悬挂在温度为60+5的热空气中烘干。

3.4 用灰卡评定试样的变色3.5 实验结束后,用滤纸过滤留在容器中的溶剂。

将过滤后的溶剂和空白溶剂到入置于白卡前的比色管,采用透射光,用评定沾色用灰卡比较两者的染色。

汗渍色牢度(AATCC15)1.设备,材料和试剂1.1 AATCC 汗渍实验器或等同装置(带有塑料,玻璃压片)1.2 烘箱—对流式1.3 天平,精确度到0.0011.4 多纤维附布NO.10或FA1.5 pH计,精确度到0.01。

1.6 5步或9步AATCCA彩色沾色灰卡或沾色灰卡。

1.7 变色灰卡1.8 轧车1.9 白色吸水纸1.10 酸性人工汗液。

2.试剂的准备2.1 在一个容积为一升的容量瓶中装入半升蒸馏水。

AATCC标准测试完整版干洗色牢度-AATCC 1321.仪器及材料1.1 水洗色牢度实验机1.2不锈钢洗杯:直径为75mm~高为125mm~容量为500ml。

1.3 不锈钢珠1.4 未染色斜纹棉布:克重为270+70g/m2~未经整理过的~切割成尺寸为120mm x120mm的布片1.5 全氯乙烯,干洗级1.6 AATCC变色灰卡~AATCC沾色灰卡1.7 分光光度计1.8 摩擦附布1.9 洗涤剂~Perk-Sheen2.测试样品2.1 如果被测试物为织物~每种样布取3块样品~每块样品尺寸为10x5cm。

长边方向平行于经向或纬向。

2.2 如果被测试物为纱线~将其织成尺寸为10x 5cm的织片~长边方向平行于经向或纬向。

2.3 样品准备2.3.13.测试程序3.1 将两块未染色的正方形棉斜纹布沿三边缝合~制成一个内尺寸为100mmx100mm的布袋~将一块试样和12片不锈钢圆片放入袋中~用任何方便的形式缝住袋口。

3.2 把装有试样和钢片的布袋放在容器内~在30C+2加入200ml全氯乙烯~如用其它溶剂~需在报告中说明。

在规定的装臵中~30C+2C处理试样30min。

3.3 从溶剂中拿出布袋~取出试样~夹于吸水袋或布之间~挤压或离心去除多余的溶剂~将试样悬挂在温度为60+5的热空气中烘干。

3.4 用灰卡评定试样的变色3.5 实验结束后~用滤纸过滤留在容器中的溶剂。

将过滤后的溶剂和空白溶剂到入臵于白卡前的比色管~采用透射光~用评定沾色用灰卡比较两者的染色。

汗渍色牢度-AATCC151(设备~材料和试剂1.1 AATCC 汗渍实验器或等同装臵,带有塑料~玻璃压片,1.2 烘箱—对流式1.3 天平~精确度到0.0011.4 多纤维附布NO.10或FA1.5 pH计~精确度到0.01。

1.6 5步或9步AATCCA彩色沾色灰卡或沾色灰卡。

1.7 变色灰卡1.8 轧车1.9 白色吸水纸1 / 231.10 酸性人工汗液。

AATCC检测标准目录2012年版《AATCC技术手册》标准编号标准名称AATCC6-2011耐酸和碱色牢度AATCC8-2007耐摩擦色牢度:AATCC摩擦测试仪法AATCC15-2009耐汗渍色牢度AATCC16-2004耐光色牢度AATCC17-2010润湿剂效果的评价AATCC20-2011纤维分析:定性AATCC20A-2011纤维分析:定量AATCC22-2010拒水性:喷淋试验AATCC23-2010耐烟熏色牢度AATCC26-2009硫化染料染色纺织品的老化测试:快速法AATCC27-2009润湿剂:再润湿剂的评估方法AATCC28-2004纺织品的防害虫,作废无代替AATCC30-2004抗菌性:纺织品防发霉和腐烂性能AATCC35-2006拒水性:淋雨测试AATCC42-2007拒水性:冲击渗水性测试AATCC43-2009丝光润湿剂的测试方法AATCC61-2010耐洗涤色牢度:快速法AATCC66-2008机织物折皱回复性的测定:回复角法AATCC70-2010拒水性:滚筒罐动态吸水性测试AATCC76-2011织物表面电阻率AATCC79-2010纺织品的吸水性AATCC81-2006湿处理纺织品水萃取液pH值的测定AATCC82-2007漂白棉布的纤维素分散质流度的测定AATCC84-2011纱线的电阻AATCC86-2011印花图案及整理剂的干洗耐久性AATCC88B-2011织物经多次家庭洗涤后的缝线平整度AATCC88C-2011织物经多次家庭洗涤后的褶裥保持性AATCC89-2008棉花丝光AATCC90-2011纺织材料抗菌活性评定:琼脂平板测定法AATCC92-2009残留氯的强力损失:单试样法AATCC93-2011织物的耐磨性能:埃克西来罗测试仪法AATCC94-2007纺织品中整理剂:鉴别方法AATCC96-2009机织物和针织物(除毛织物外)商业洗涤后的尺寸变化AATCC97-2009坯布及前处理后纺织品中的可萃取物含量AATCC98-2007过氧化氢漂白浴中碱含量的测定AATCC99-2004机织或针织毛纺织品尺寸变化:松弛、毡合和毡缩,作废无代替AATCC100-2004纺织材料抗菌整理剂的评定AATCC101-2009耐过氧化氢漂白色牢度AATCC102-2007高锰酸钾滴定法测定过氧化氢AATCC103-2009退浆中使用的细菌α-淀粉酶的分析AATCC104-2010耐水斑色牢度AATCC106-2009耐水色牢度:海水AATCC107-2009耐水色牢度AATCC109-2011耐低湿大气中臭氧色牢度AATCC110-2011纺织品的白度AATCC111-2009纺织品耐气候性:日光和气候曝晒AATCC112-2008织物中释放甲醛:密封广口瓶法AATCC114-2011残留氯的强力损失:多样品法AATCC115-2011织物静电吸附:织物与金属测试AATCC116-2010耐摩擦色牢度:旋转垂直摩擦仪AATCC117-2009耐干热色牢度(热压除外)AATCC118-2007拒油性:抗碳氢化合物测试AATCC119-2009平磨变色(霜白):金属丝网法AATCC120-2009平磨变色(霜白):金刚砂法AATCC121-2010地毯沾污:视觉评级法AATCC122-2009地毯沾污:使用沾污法AATCC123-2000地毯沾污:快速污染法,作废无代替AATCC124-2011织物经多次家庭洗涤后的外观平整度AATCC125-2009耐汗光色牢度AATCC127-2008抗水性:静水压法AATCC128-2009织物折皱回复性:外观法AATCC129-2011耐高湿大气中臭氧色牢度AATCC130-2010去污性:油渍清除法AATCC131-2011耐褶裥色牢度:蒸汽褶裥AATCC132-2009耐干洗色牢度AATCC133-2009耐热色牢度:热压AATCC134-2011地毯的静电倾向AATCC135-2010织物经家庭洗涤后的尺寸稳定性AATCC136-2009粘合和层压织物的粘合强度AATCC137-2007小地毯背面对乙烯地板的玷污AATCC138-2010去污:纺织地毯的洗涤AATCC139-2005耐光色牢度:光致变色的测定,作废无代替AATCC140-2011染料和颜料在浸轧烘干过程中的泳移性评价AATCC141-2009用于腈纶纤维的碱性染料的配伍性AATCC142-2011植绒织物多次家庭洗涤和(或)商业干洗后的外观AATCC143-2011服装及其它纺织制品经多次家庭洗涤后的外观AATCC144-2007湿加工纺织品中的总碱量AATCC146-2011分散染料的分散性:过滤测试法AATCC147-2011纺织品的抗菌性:平行划线法AATCC149-2007螯合剂:氨基多元酸及其盐类的螯合值测定——草酸钙法AATCC150-2010服装经家庭水洗后的尺寸稳定性AATCC151-2003抗污垢再沉积:洗涤仪法,作废无代替AATCC154-2011分散染料的热固性AATCC157-2010耐溶剂斑色牢度:全氯乙烯AATCC158-2011全氯乙烯干洗的尺寸变化:机洗法AATCC159-2011酸性染料和酸性含媒染料在尼龙上的移染AATCC161-2007螯合剂:由金属引起的分散染料色变及对比AATCC162-2011耐水色牢度:氯化游泳池水AATCC163-2007色牢度:贮存中的染料转移织物到织物AATCC164-2006耐高湿大气中二氧化氮色牢度AATCC165-2008耐摩擦色牢度:铺地纺织品-AATCC摩擦仪法AATCC167-2008分散染料的发泡倾向AATCC168-2007螯合剂:聚氨基多元羧酸及其盐类活性成分含量分析:潘酚(PAN)铜法AATCC169-2009纺织品的耐气候性:氙弧灯曝晒AATCC170-2011粉末状染料粉尘化倾向的评定AATCC171-2010地毯去污:热水萃取法AATCC172-2010家庭洗涤中耐无氯漂白粉色牢度AATCC173-2009CMC:可接受的小色差计算AATCC174-2011地毯抗微生物活性的评定AATCC175-2008抗沾色性:毛绒地毯、AATCC176-2011染料分散液色斑现象的评定AATCC178-2004横档的视觉评定和评级AATCC179-2010经家庭洗涤的织物纬斜和成衣扭曲性能AATCC181-2005高温耐光色牢度:可控日光温度和湿度仪器法,作废无代替AATCC182-2011染料在溶液中的相对着色力AATCC183-2010紫外辐射通过织物的透过或阻挡性能AATCC184-2010染料粉尘化特性的测定AATCC185-2011螯合剂:过氧化氢漂白浴中螯合剂的百分含量;潘酚(PAN)铜指示剂法AATCC186-2009纺织品耐气候性:紫外光和湿态曝晒AATCC187-2009织物尺寸稳定性:快速法AATCC188-2010耐次氯酸钠家庭漂白洗涤色牢度AATCC189-2007地毯纤维的含氟量AATCC190-2010耐活性氧漂白剂家庭洗涤色牢度:快速法AATCC191-2009酸性纤维素酶对纤维素的影响测定:上装式洗衣机法AATCC192-2009纺织品耐气候性:给湿与不给湿条件下日弧灯曝晒AATCC193-2007拒水性:抗水/乙醇溶液测试AATCC194-2008纺织品在长期测试条件下抗室内尘螨性能的评定AATCC195-2011纺织物液态水分管理性能AATCC196-2011纺织物地毯耐次氯酸钠染色牢固度AATCC197-2011纺织物竖向线束AATCC198-2011纺织物横向线束AATCC199-2011纺织物干燥时间:采用水分分析仪。

书山有路勤为径;学海无涯苦作舟AATCC 系列常见日晒色牢标准简介及测试仪器AATCC标准目录列表:AATCC 8-1996 耐摩擦色牢度:AATCC 摩擦仪法AATCC 15-1997 耐汗渍色牢度AATCC 16-1997 耐光色牢度AATCC TM 16-2003 耐光色牢度AATCC 61-1996 耐家庭和商业洗涤色牢度:快速法AATCC 66-1998 织物折皱回复性:回复角法AATCC 93-1994 织物的耐磨性:快速法AATCC 96-1997 除毛织物处的机织物和针织物在商业洗涤中的尺寸变化AATCC 99-1993 羊毛机织和针织物的尺寸变化:松驰、固化和缩绒AATCC 104-1994 耐水斑色牢度AATCC 106-1997 耐水色牢度:海水AATCC 107-1997 耐水色牢度AATCC 111-1996 耐气候:总体介绍AATCC 111A- 1996 耐气候:日光弧灯光照带润湿AATCC 111B-1996 耐气候:自然光和自然气候AATCC 111C-1996 耐气候:日光弧灯光照不带润湿AATCC 111D- 1996 耐气候:透过玻璃的自然光和自然气候AATCC 116-1996 耐摩擦我牢度:立式旋转摩擦仪法AATCC 117-1994 耐热色牢度:干热门(不包括熨烫) AATCC 124-1996 重复家庭洗涤后织物的外观常见AATCC测试标准:AATCC-TM125标准:AATCC-TM125标准简介:耐光汗色牢度:本方法旨在测定染色纺织试样在汗渍溶液和光曝晒复合作用下对色牢度的影响。

因此,此测试中仅使用汗渍溶液。

原理:待测的染色试样浸入汗渍溶液中一定时间,立即在耐光色牢度仪中曝晒一定时间。

适用测试仪器:Q-SUN B02-S日晒色牢度检测仪AATCC TM 16 标准:AATCC TM16标准简介:“耐光色牢度”:AATCC TM 16 标准:试验方法提供的一般原则和程序,是目前用于确定纺织材料的耐光照色牢度的方法。

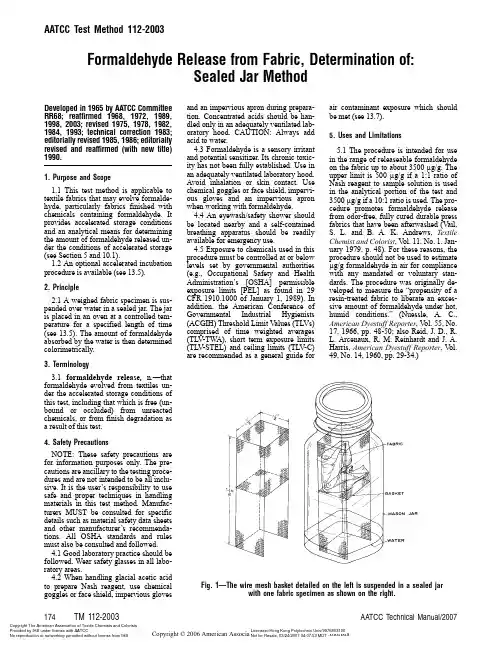

Copyright © 2006 American Association of Textile Chemists and Colorists 174TM 112-2003AATCC Technical Manual/2007Developed in 1965 by AATCC Committee RR68; reaffirmed 1968, 1972, 1989,1998, 2003; revised 1975, 1978, 1982,1984, 1993; technical correction 1983;editorially revised 1985, 1986; editorially revised and reaffirmed (with new title)1990.1. Purpose and Scope1.1 This test method is applicable to textile fabrics that may evolve formalde-hyde, particularly fabrics finished with chemicals containing formaldehyde. It provides accelerated storage conditions and an analytical means for determining the amount of formaldehyde released un-der the conditions of accelerated storage (see Section 5 and 10.1).1.2 An optional accelerated incubation procedure is available (see 13.5).2. Principle2.1 A weighed fabric specimen is sus-pended over water in a sealed jar. The jar is placed in an oven at a controlled tem-perature for a specified length of time (see 13.5). The amount of formaldehyde absorbed by the water is then determined colorimetrically.3. Terminology 3.1 formaldehyde release, n.—that formaldehyde evolved from textiles un-der the accelerated storage conditions of this test, including that which is free (un-bound or occluded) from unreacted chemicals, or from finish degradation as a result of this test.4. Safety PrecautionsNOTE: These safety precautions are for information purposes only. The pre-cautions are ancillary to the testing proce-dures and are not intended to be all inclu-sive. It is the user’s responsibility to use safe and proper techniques in handling materials in this test method. Manufac-turers MUST be consulted for specific details such as material safety data sheets and other manufacturer’s recommenda-tions. All OSHA standards and rules must also be consulted and followed.4.1 Good laboratory practice should be followed. Wear safety glasses in all labo-ratory areas.4.2 When handling glacial acetic acid to prepare Nash reagent, use chemical goggles or face shield, impervious gloves and an impervious apron during prepara-tion. Concentrated acids should be han-dled only in an adequately ventilated lab-oratory hood. CAUTION: Always add acid to water.4.3 Formaldehyde is a sensory irritant and potential sensitizer. Its chronic toxic-ity has not been fully established. Use in an adequately ventilated laboratory hood.Avoid inhalation or skin contact. Use chemical goggles or face shield, impervi-ous gloves and an impervious apron when working with formaldehyde.4.4 An eyewash/safety shower should be located nearby and a self-contained breathing apparatus should be readily available for emergency use.4.5 Exposure to chemicals used in this procedure must be controlled at or below levels set by governmental authorities (e.g., Occupational Safety and Health Administration’s [OSHA] permissible exposure limits [PEL] as found in 29CFR 1910.1000 of January 1, 1989). In addition, the American Conference of Governmental Industrial Hygienists (ACGIH) Threshold Limit V alues (TLVs)comprised of time weighted averages (TLV-TWA), short term exposure limits (TLV-STEL) and ceiling limits (TLV-C)are recommended as a general guide for air contaminant exposure which should be met (see 13.7).5. Uses and Limitations 5.1 The procedure is intended for use in the range of releaseable formaldehyde on the fabric up to about 3500 µg/g. The upper limit is 500 µg/g if a 1:1 ratio of Nash reagent to sample solution is used in the analytical portion of the test and 3500 µg/g if a 10:1 ratio is used. The pro-cedure promotes formaldehyde release from odor-free, fully cured durable press fabrics that have been afterwashed (Vail,S. L. and B. A. K. Andrews, Textile Chemist and Colorist , V ol. 11, No. 1, Jan-uary 1979, p. 48). For these reasons, the procedure should not be used to estimate µg/g formaldehyde in air for compliance with any mandated or voluntary stan-dards. The procedure was originally de-veloped to measure the “propensity of a resin-treated fabric to liberate an exces-sive amount of formaldehyde under hot,humid conditions.” (Nuessle, A. C.,American Dyestuff Reporter , V ol. 55, No.17, 1966, pp. 48-50; also Reid, J. D., R.L. Arcenaux, R. M. Reinhardt and J. A.Harris, American Dyestuff Reporter , V ol.49, No. 14, 1960, pp. 29-34.)AATCC Test Method 112-2003Formaldehyde Release from Fabric, Determination of:Sealed Jar MethodFig. 1—The wire mesh basket detailed on the left is suspended in a sealed jar with one fabric specimen as shown on the right.Copyright The American Association of Textile Chemists and Colorists Provided by IHS under license with AATCC Licensee=Hong Kong Polytechnic Univ/9976803100 Not for Resale, 03/24/2007 04:07:53 MDT No reproduction or networking permitted without license from IHSCopyright © 2006 American Association of Textile Chemists and Colorists AATCC Technical Manual/2007TM 112-20031756. Apparatus and Materials6.1 Mason or equivalent canning jars,0.95 L (1 qt) and gas sealing caps.6.2 Small wire mesh baskets (or other suitable means for suspending fabric above the water level inside the jars; see 13.1). As an alternative to the wire mesh baskets, a double strand of sewing thread may be used to make a loop in the fabric that has been folded in half twice, sus-pended above the water level. The two double-thread ends are draped over the top of the jar and held securely by the jar cap.6.3 Thermostatically controlled oven,49 ± 1°C (120 ± 2°F) (see 13.5).6.4 Nash reagent prepared from ammo-nium acetate, acetic acid and acetylace-tone and water (see7.1).6.5 Formaldehyde solution, approxi-mately 37%.6.6 V olumetric flasks, 50, 500 and 1000 mL.6.7 Mohr pipettes, graduated in tenths of a mL; and 5, 10, 15, 20, 25, 30 and 50mL volumetric pipettes, all calibrated “to deliver” and meeting Class B volume ac-curacy and flow time requirements (see 13.2).6.8 Graduated cylinders, 10 and 50mL, graduated in mL, calibrated “to de-liver” and meeting Class A volume accu-racy requirements (see 13.2).6.9 Photoelectric colorimeter or spec-trophotometer (see 10.2).6.10 Test tubes or colorimeter tubes (see 13.2).7.Preparation of Nash Reagent7.1 In a 1000 mL volumetric flask, dis-solve 150 g of ammonium acetate in about 800 mL of distilled water; add 3mL of glacial acetic acid and 2 mL of acetylacetone. Make up to the mark with distilled water and mix. Store in a brown bottle.7.2 The reagent darkens in color slightly on standing over the first 12 h.For this reason the reagent should be held 12 h before use. Otherwise, the reagent is usable over a considerable period of time,at least 6-8 weeks. However, since the sensitivity may change slightly over a long period of time, it is good practice to run a calibration curve weekly to correct for slight changes in the standard curve.8.Preparation of Standard Solution andCalibration (Caution)8.1 Prepare an approximately 1500 µg/mL stock solution of formaldehyde by di-luting 3.8 mL of reagent grade formalde-hyde solution (approximately 37%) to one liter with distilled water. Equilibrate the stock solution for at least 24 h before standardization. Determine the concen-tration of formaldehyde in the stock solu-tion by a standard method (see 13.6 or any other suitable procedure such as so-dium sulfite titration using 0.1 N HCl.Reference: J. Frederick Walker, Formal-dehyde , 3rd Ed. Reinhold Publ. Co., New York, 1964, p. 486). Record the actual concentration of this standardized stock solution. This stock solution will keep for at least four weeks and is used to prepare standard dilutions. A 1:10 dilution of the standardized formaldehyde stock solution is prepared by pipetting 25 mL of the standardized stock solution into a 250 mL volumetric flash and diluting to the mark with distilled water. If the stock solution is titrated and found to be different than 1500 µg/mL, three methods that can be used for preparing the calibration curves are:8.1.1 Calculate new volumes of stock solution aliquots to pipette to achieve ex-actly 1.5, 3.0, 4.5, 6.0 and 9.0 µg/mL, re-spectively. (For example, if the formalde-hyde stock solution were found to be 1470 µg/mL by titration, not 1500 µg/mL, pipette 5.1 mL, 10.2 mL, 15.3 mL,20.4 mL and 30.6 mL of the 147 µg/mL dilution into a 500 mL volumetric flask and dilute to mark with distilled water.)(NOTE: It is easy to make errors using a graduated pipette!)8.1.2 Pipette 5, 10, 15, 20 and 30 mL of the 1:10 dilution into a 500 mL volu-metric flask and dilute to mark with dis-tilled water. (If, for example, the stan-dardized stock solution were found to be 1470 µg/mL by titration, calculate new values for the calibration curve abscissa;i.e., 1.47, 2.94, 4.41, 5.88, 8.82 µg/mL.)This is the preferred method for those with a microprocessor spectrophotometer or computer. However, it is harder to plot manually.8.1.3 Calculate a concentration correc-tion factor for each sample. Correct the concentration for the dilution value using this factor. Plot the curve as if each of the dilutions were exactly 1.5, 3.0, 4.5, 6.0and 9.0 µg/mL. Calculate the correct con-centration for each of these values using the factor. For example, if the standard-ized stock solution were found to be 1470µg/mL by titration, then the correction factor (CF ) is:8.2 When 5, 10, 15, 20 and 30 mL ali-quots of the 1:10 dilution of the standard-ized stock solution from 8.1 are diluted with distilled water in 500 mL volumetric flasks, formaldehyde solutions contain-ing approximately 1.5, 3.0, 4.5, 6.0 and 9.0 µg/mL formaldehyde respectively will be obtained. Record accurately the concentration of solutions. The equiva-lent concentrations of the formaldehyde in the test fabric based on the weight of CF Actual Nominal --------------------14701500-----------0.980===1g of the test fabric and 50 mL of water in the test jars, will be 50 times the accu-rate concentrations of these standard so-lutions.8.3 Use 5 mL aliquots of each of the standard solutions and the procedure de-scribed in 10.4-10.7 to prepare a calibra-tion chart in which µg/mL formaldehyde are plotted against absorbance.9. Test Specimens 9.1 Cut approximately 1 g specimens;weigh each one to ± 0.01 g.10. Procedures 10.1 Place 50 mL of distilled water in the bottom of each jar. Suspend one fab-ric specimen above the water in each jar,using a wire mesh basket or other means (see Fig. 1). Seal the jars and place them in the oven at 49 ± 1°C (120 ± 2°F) for 20h (see 13.5).10.2 Remove and cool the jars for at least 30 min.10.3 Remove the fabric and baskets, or other support, from the jars. Recap the jars and shake them to mix any condensa-tion formed on the jar sides.10.4 Pipette 5 mL of Nash reagent into a suitable number of test tubes, small (50mL) Erlenmeyer flasks, or other suitable flasks (colorimeter or spectrophotometer tubes can be used directly, see 13.2) and pipette 5 mL of the reagent into at least one additional tube for a reagent blank.Add 5 mL aliquots from each of the sam-ple incubation jars to the tubes and 5 mL of distilled water to the tube which is used as a reagent blank.10.5 Mix and place the tubes in a 58 ±1°C water bath for 6 min. Remove and cool.10.6 Read the absorbance in the colo-rimeter or spectrophotometer against the reagent blank using a blue filter or a wavelength of 412 nm. Caution: Expo-sure of the developed yellow color to di-rect sunlight for a period of time will cause some fading. If there is appreciable delay in reading the tubes after color de-velopment and strong sunlight is present,care should be exercised to protect the tubes such as by covering them with a cardboard box or by similar means. Oth-erwise the color is stable for considerable time (at least overnight) and reading may be delayed.10.7 Determine the µg/mL formalde-hyde (HCHO) in the sample solutions us-ing the prepared calibration curve (see 8.3 and 13.3).11. Calculation 11.1 Calculate the amount of formalde-hyde released for each specimen to the nearest µg/g using the following equation:F = (C ) (50)/WCopyright The American Association of Textile Chemists and ColoristsProvided by IHS under license with AATCCLicensee=Hong Kong Polytechnic Univ/9976803100 Not for Resale, 03/24/2007 04:07:53 MDT No reproduction or networking permitted without license from IHSCopyright © 2006 American Association of Textile Chemists and Colorists 176TM 112-2003AATCC Technical Manual/2007where:F concentration of formaldehyde (µg/g),C =concentration of formaldehyde in solution as read from the calibra-tion curve, and W =weight of the test specimen, g.12. Precision and Bias 12.1 Precision.12.1.1 Interlaboratory tests. Two inter-laboratory studies (ILS) of AATCC Method 112 were conducted in 1990 and 1991, with a 20 h incubation at 49°C and a 5/5 sample to Nash solution ratio. Sin-gle operators in each participating labora-tory ran triplicate determinations on each fabric. In the first ILS, results from nine laboratories testing one fabric each at three low formaldehyde levels in the range of 100-400 µg/g were analyzed by analysis of variance (ANOV A). In the second ILS, results from eight laborato-ries testing ten fabrics of nominal 0 µg/g were analyzed by ANOV A. The analyses have been deposited for reference in the RA68 committee files.12.1.2 Critical differences were calcu-lated for zero-formaldehyde fabrics,shown in Table I, and for low level-form-aldehyde fabrics shown in Table II.12.1.3 When two or more laboratories wish to compare test results, it is recom-mended that laboratory level be estab-lished between them prior to beginning test comparisons.12.1.4 If comparisons are made be-tween laboratories on a single fabric level of formaldehyde release, the critical dif-ferences in the column, single level, in Table II should be used.12.1.5 If comparisons are made be-tween laboratories on a series of fabrics of a range of formaldehyde levels, the critical differences in the column, multi-ple levels, in Table II should be used.12.1.6 The number of determinations per laboratory average (det/avg) also de-termines the critical difference.12.2 Bias.12.2.1 The formaldehyde release of a fabric can be defined only in terms of a test method. There is no independent method for determining the true value. As a means of estimating formaldehyde re-leased from a fabric under the conditions of accelerated storage in AATCC Method 112, the method has no known bias.12.2.2 AATCC Method 112 generallyis accepted by the textile and apparel in-dustries as a referee method.13. Notes 13.1 A simple cloth support for insertion in the mason jars can be constructed as follows:A piece of aluminum wire screening 15.2 ×14.0 cm (6.0 × 5.5 in.) is bent around a length of wood 3.8 cm (1.5 in.) square and fastened together to form a rectangular, open-endedcage. One side is cut at the corners about half-way up the side and the cut section folded in-ward and fastened. This folded piece forms the bottom of the wire basket while the other three sides form the support legs. Fastening can be accomplished by twisting short lengths of wire through or around the appropriate part.13.2 The ratio of reagent to sample solu-tions can be adjusted, within limits, to suit the individual absorbance range and optical pathlength of the sampling tubes or cuvettes of the particular photometric instrument being used.For example, although 5 mL reagent to 5 mLsample solution has been found convenient for several types of instruments, other 1:1 ratios,such as a ratio of 2 mL reagent to 2 mL sam-ple may be more suitable for others. The same ratio should be used with the standards as with the sample. The use of colorimeter or spectro-photometer tubes directly for color develop-ments avoids the transfer step, test tubes to spectrophotometer cells, and may save consid-erable time when many determinations are to be made. Repipettes or similar devices can be used for reagent dispensing, and Oxford or Eppendorf disposable tip automatic pipettes can be used for the sample solutions.13.3 The procedure in Section 10 has been set up to cover the range from about 0 µg/g on the weight of the fabric to about 500 µg/g. In fabrics containing releasable formaldehyde in the range from 500 µg/g on the weight of the fabric to about 3500 µg/g, it is recommended that a ratio of 10 mL Nash reagent to 1 mL sample be used. If this is done, it is necessary to prepare an additional calibration chart with 10:1 ratios of standard solutions to Nash re-agent by diluting 5, 10, 15 and 20 µg/mL, re-spectively, of the approximately 1500 µg/mL standardized stock solution of formaldehyde to the mark with distilled water in 500 mL vol-umetric flasks. Formaldehyde solutions con-taining approximately 15, 30, 45 and 60 µg/mL respectively will be obtained (see 8.3).13.4 The chromotropic acid colorimetricmethod can be used as an alternate to the Nash reagent for the determination of the formalde-hyde content of the sample jars after oven in-cubation. It should be noted that the Precision and Bias Statement was not developed usingthe chromotropic acid method. A suitable pro-cedure is given in J. Frederick Walker, Form-aldehyde, 3rd Edition, Reinhold Publishing Co., NY, 1964, p470. When using this methoda change may be necessary in the size of both the aliquots taken from the sample jars (see10.2) and the standard formaldehyde solutions used in preparing the calibration curve (see 8.3).Caution! Since concentrated sulfuric acid is used with the chromotropic acid method, adequate care should be exercised to protect operating personnel and spectrophoto-metric equipment.13.5 Incubation conditions of 65 ± 1°C (149 ± 4°F) for 4 h can be used as an alternate to the incubation conditions of 49 ± 1°C (120± 2°F) for 20 h (see 5.3 and 10.1). The incuba-tion conditions of time and temperature mustbe reported. Upon completion of the 4-h incu-bation period, remove and cool the jars for at least 30 min and remove the fabric from the jars. Recap the jars and shake them to mix any condensation formed on the jar sides. Proce-dures for sample preparation and color devel-opment following the incubation period are performed as outlined in 10.4-10.7.13.6 Standardization of Formaldehyde Stock Solution. General: The stock solution containing approximately 1500 µg/mL of formaldehyde must be accurately standardized in order to make precise calculations from the calibration curve used in colorimetric analysis.An aliquot of the stock solution is reacted with an excess of sodium sulfite followed by a back-titration with standard acid solution in the presence of thymolphthalein as indicator.Apparatus: 10-mL volumetric pipette, 50-mL volumetric pipette, 50-mL burette, 150-mL Erlenmeyer flask.Reagents: 1 M sodium sulfite (126 g Anhy-drous Na 2SO 3/L), 0.1% Thymolphthalein Indi-cator in ethanol, 0.02 N sulfuric acid (can bepurchased in standardized form from chemical supply companies or must be standardizedfrom standard NaOH solution). Do not usecommercial standardized sulfuric acid that has been stabilized with formaldehyde. If there isa doubt, check with the chemical supplier.Procedure: A. Pipette 50 mL of 1 M Na 2SO 3 into the Erlenmeyer flask. B. Add 2drops of thymolphthalein indicator. C. Add a few drops of standard acid until blue color dis-appears (if necessary). D. Pipette 10 mL of thestock formaldehyde solution to the flask.(Blue color will reappear.) E. Titrate the solu-tion with the standard 0.02N H 2SO 4 until theblue color is discharged. Record the volume of acid used. (The volume of acid should be in the range of 25 mL for 0.02N acid.)Calculations:C = (30,030) (A ) (N )/10where:C =Wt/Vol concentration of formalde-hyde (µg/mL)A =V ol of acid used (mL)N =Normality of acid Perform the standardization in duplicates.Average the results and use the accurate con-centration in preparing the calibration curve for the colorimetric analysis.13.7 Available from Publications Office,ACGIH, Kemper Woods Center, 1330Kemper Meadow Dr., Cincinnati OH 45240;tel: 513/742-2020.Table I—Critical Differences for Zero Formaldehyde Det/Avg Critical Differences for Averages 95% Probability, µg/g Within Lab Single Fabric Between Labs Multiple Fabric Between Labs 17.712.013.82 5.510.612.73 4.510.212.3Table II—Critical Differences for Low Level Formaldehyde Det/Avg Critical Differences for Averages 95% Probability, µg/g Within Lab Single Fabric Between Labs Multiple Fabric Between Labs 121.680.3116.0215.278.9115.0312.478.4114.7Copyright The American Association of Textile Chemists and ColoristsProvided by IHS under license with AATCC Licensee=Hong Kong Polytechnic Univ/9976803100Not for Resale, 03/24/2007 04:07:53 MDT No reproduction or networking permitted without license from IHS。

AATCC标准测试完整版干洗色牢度-AATCC 1321.仪器及材料1.1 水洗色牢度实验机1.2不锈钢洗杯:直径为75mm~高为125mm~容量为500ml。

1.3 不锈钢珠1.4 未染色斜纹棉布:克重为270+70g/m2~未经整理过的~切割成尺寸为120mm x120mm的布片1.5 全氯乙烯,干洗级1.6 AATCC变色灰卡~AATCC沾色灰卡1.7 分光光度计1.8 摩擦附布1.9 洗涤剂~Perk-Sheen2.测试样品2.1 如果被测试物为织物~每种样布取3块样品~每块样品尺寸为10x5cm。

长边方向平行于经向或纬向。

2.2 如果被测试物为纱线~将其织成尺寸为10x 5cm的织片~长边方向平行于经向或纬向。

2.3 样品准备2.3.13.测试程序3.1 将两块未染色的正方形棉斜纹布沿三边缝合~制成一个内尺寸为100mmx100mm的布袋~将一块试样和12片不锈钢圆片放入袋中~用任何方便的形式缝住袋口。

3.2 把装有试样和钢片的布袋放在容器内~在30C+2加入200ml全氯乙烯~如用其它溶剂~需在报告中说明。

在规定的装臵中~30C+2C处理试样30min。

3.3 从溶剂中拿出布袋~取出试样~夹于吸水袋或布之间~挤压或离心去除多余的溶剂~将试样悬挂在温度为60+5的热空气中烘干。

3.4 用灰卡评定试样的变色3.5 实验结束后~用滤纸过滤留在容器中的溶剂。

将过滤后的溶剂和空白溶剂到入臵于白卡前的比色管~采用透射光~用评定沾色用灰卡比较两者的染色。

汗渍色牢度-AATCC151(设备~材料和试剂1.1 AATCC 汗渍实验器或等同装臵,带有塑料~玻璃压片,1.2 烘箱—对流式1.3 天平~精确度到0.0011.4 多纤维附布NO.10或FA1.5 pH计~精确度到0.01。

1.6 5步或9步AATCCA彩色沾色灰卡或沾色灰卡。

1.7 变色灰卡1.8 轧车1.9 白色吸水纸1 / 231.10 酸性人工汗液。

aatcc防水结果解读

AATCC是指美国纺织化学会(American Association of Textile Chemists and Colorists),该协会制定了一系列用于测试纺织品性能的标准。

其中,AATCC 22是用于测试纺织品防水性能的标准。

在进行AATCC 22测试后,会得到一系列数据,需要进行解读。

首先,AATCC 22测试通常会得出两个主要结果,防水等级和防水持久性。

防水等级通常用于描述材料对液体的防护能力,等级越高代表防水性能越好。

而防水持久性则描述了材料在经历一定数量的洗涤或使用后,防水性能的持久程度。

在解读AATCC 22测试结果时,需要考虑以下几个方面:

1. 防水等级,根据测试结果得出的防水等级,可以判断材料对液体的防护能力。

通常,防水等级分为1至100,等级越高代表防水性能越好。

需要根据具体的应用需求来判断防水等级是否符合要求。

2. 防水持久性,除了防水等级外,还需要关注材料的防水持久

性。

通过测试结果可以了解材料在经过一定数量的洗涤或使用后,防水性能是否有所下降。

这对于一些需要长期使用的产品来说尤为重要。

3. 结合实际应用,除了纯粹的测试数据,还需要结合实际应用情况来综合评估防水性能。

比如,考虑材料在不同环境条件下的表现,以及使用过程中可能遇到的各种情况。

总的来说,解读AATCC 22测试结果需要综合考虑防水等级、防水持久性以及实际应用情况,以便全面评估材料的防水性能。

这样才能更准确地判断材料是否符合预期的防水要求,从而在实际应用中发挥最佳效果。

AATCC检测AATCC 6-2001 耐酸碱色牢度AATCC 8-2001 耐摩擦色牢度:AATCC耐摩擦色牢度测定器AATCC 15-2002 耐汗渍色牢度AATCC 16-2003 耐光色牢度AATCC 17-1999 湿润剂,评定AATCC 20-2002 纤维分析:质量AATCC 20A-2000 纤维分析:数量AATCC 22-2001 排水:喷雾试验AATCC 23-1999 耐烟熏色牢度AATCC 24-1999 昆虫,纺织品耐AATCC 26-1999 硫染纺织品用剂:加速AATCC 27-1999 湿润剂:再湿润剂评定AATCC 28-1999 纺织品防昆虫、害虫AATCC 30-1999 耐真菌活性,纺织品材料的评定:纺织品材料耐霉菌防腐烂AATCC 35-2000 耐水渍:雨水试验AATCC 42-2000 耐水渍:冲击穿透试验AATCC 43-1999 丝光处理湿润剂AATCC 61-2003 耐家庭、商业洗涤色牢度:加速AATCC 66-2003 机织物折痕回复:回复角AATCC 70-2000 排水:滚筒水击动态吸收试验AATCC 76-2000 纤维表面电阻AATCC 79-2000 漂白纺织品的吸收性AATCC 81-2001 湿加工时纺织品水萃取PH值AATCC 82-2001 漂白棉布中纤维素分散质的流度AATCC 84-2000 纱线电阻AATCC 86-2000 干洗:应用设计和整理的耐久性AATCC 88B-2003 多次家洗后织物缝线处的平滑性AATCC 88C-2003 织物多次家洗后留下的折痕AATCC 89-2003 棉的丝光处理AATCC 92-1999 氯,存留的,张力损耗:单个取样法AATCC 93-1999 织物耐磨:加速剂方法AATCC 94-2002 织物整理:鉴别AATCC 96-2001 机织和针织物(毛织物除外)商业洗涤后尺寸变化AATCC 97-1999 原纱和/或已处理纺织品的可提取成分AATCC 98-2002 含过氧化氢的漂白槽中的碱AATCC 99-2000 机织或针织毛纺织品尺寸变化:松弛、收缩和毡合AATCC 100-1999 纺织品材料上耐细菌整理:评定AATCC 101-1999 过氧化氢漂白色牢度AATCC 102-2002 过氧化氢漂白,高锰酸钾滴定法:测定AATCC 103-1999 用于退浆的细菌性α淀粉酶,化验AATCC 104-1999 耐水滴色牢度AATCC 106-2002 耐水浸色牢度:海水AATCC 107-2002 耐水浸色牢度AATCC 109-2002 耐低湿度大气臭氧色牢度AATCC 110-2000 纺织品的白度AATCC 111-2003 纺织品耐气候性AATCC 112-2003 织物挥发甲醛,测定:封罐法AATCC 114-1999 氯,存留的,张力损耗:多次取样法AATCC 115-2000 织物静电依附:织物—金属试验AATCC 116-2001 耐摩擦色牢度:旋转垂直耐摩擦色牢度测定器法AATCC 117-1999 耐高温色牢度:干燥(不包括熨烫)AATCC 118-2002 排油:耐烃试验AATCC 119-1999 平面磨蚀引起的色变(消光):屏蔽电线方法AATCC 120-1999 平面磨蚀引起的色变(消光):金刚砂方法AATCC 121-2000 地毯玷污:可视评定法AATCC 122-2000 地毯沾污:使用沾污法AATCC 123-2000 地毯沾污:加速沾污法AATCC 124-2001 织物多次家洗后外形AATCC 125-1991 耐水耐光色牢度:交替暴露AATCC 127-2003 耐水性:流体静压试验AATCC 128-1999 织物折痕回复:外形AATCC 129-2001 耐高湿度大气臭氧色牢度AATCC 130-2000 排除污垢:油污排除法AATCC 131-2000 耐褶裥色牢度:蒸汽褶裥AATCC 132-2003 耐干洗色牢度AATCC 133-1999 耐高温色牢度:热压AATCC 134-2001 地毯的静电性AATCC 135-2003 机织和针织物自动家洗时尺寸变化AATCC 136-2003 黏合或层压织物的黏合强度AATCC 137-2002 瓷砖上小地毯背面沾污AATCC 138-2000 清洁:铺地织物的清洗AATCC 139-2000 耐光色牢度:致光色变现象的观察AATCC 140-2001 轧-烘处理过程中染料和涂剂泳移AATCC 141-1999 碱性染料与丙烯酸纤维的相容性AATCC 142-2000 植绒织物经多次家洗和/或在投币自动干洗后外形AATCC 143-2001 衣服和其他纺织成品多次家洗后的外形AATCC 144-2002 湿处理织物所含碱:整体AATCC 146-2001 分散染料的分散性:过滤试验AATCC 147-1998 织物材料抗菌活性测定:平行条纹法AATCC 149-2002 螯合剂:氨基聚羧酸螯合作用值及其盐分;草酸钙法AATCC 150-2003 服装自动家洗时尺寸的变化AATCC 151-2003 污物再沉积AATCC 154-2001 分散染料的热固定性AATCC 157-2000 耐溶剂滴色牢度:全氯乙烯AATCC 158-2000 全氯乙烯干洗后尺寸变化:机械法AATCC 159-1999 尼龙上酸和金属络合酸性染料的转移AATCC 161-2002 螯合剂:金属引起的分散染料色度阴暗;控制AATCC 162-2002 耐水浸色牢度:氯化水池AATCC 163-2002 色牢度:留存染料转印;织物对织物AATCC 164-2001 耐高湿度大气中氧化氮色牢度AATCC 165-1999 耐摩擦色牢度:铺地织物-AATCC耐摩擦色牢度测定器AATCC 167-2003 分散染料的起泡性AATCC 168-2002 螯合剂:聚氨基聚羧酸的活性成分含量极其盐分;铜硝酸过氧化乙酰法(PAN)AATCC 169-2003 织物的耐气候性:氙灯暴露AATCC 170-2001 粉状染料的喷撒性:评定AATCC 171-2000 地毯:热水萃取法AATCC 172-2003 家洗耐无氯漂白色牢度AATCC 173-1998 CMC:小色差合格率计算AATCC 174-1998 地毯耐微生物活性测定AATCC 175-2003 耐脏:绒毛铺地材料AATCC 176-2001 染料剂分散质斑点:评定AATCC 178-1999 纬向染疵:可视测定和渐次调和AATCC 179-2001 自动家洗时缠绕引起织物和衣服变形AATCC 180-1997 高温下耐光色牢度:受装置控制的天然光温度AATCC 181-1997 高温下耐光色牢度:受装置控制的天然光温度和湿度AATCC 182-2000 溶液中染料颜色的相对强度AATCC 183-2000 紫外线穿透织物强度AATCC 184-2000 染料喷撒性能:测定AATCC 185-2000 螯合剂:过氧化氢漂白槽中的百分含量:铜硝酸过氧化乙酰(PAN)指示剂方法;AATCC 186-2001 耐气候性:紫外线和湿度暴露AATCC 187-2002 织物的尺寸变化:加速的AATCC 188-2003 家洗耐钠、次氯盐酸漂白色牢度AATCC 189-2002 地毯纤维含氟量AATCC 190-2003 耐活性氧漂白洗涤剂家洗的色牢度:加速酸性纤维素酶,作用于:最大负荷量洗涤器AATCC 191-2003 木纤维质酵酶酸一洗衣机顶部装载的影响AATCC 192-2003 织物的耐久性:有水或者无水情况暴露于电孤光下。

AATCC技术手册-2008标准全套(英文版)AATCC 6-2006(2008) RR1 Colorfastness to Acids and Alkalis 16 AATCC 8-2007(2008) RA38 Colorfastness to Crocking: AATCC Crockmeter Method 17AATCC 15-2007(2008) RR52 Colorfastness to Perspiration 20 AATCC 16-2004(2008) RA50 Colorfastness to Light 23AATCC 17-2005(2008) RA63 Wetting Agents, Evaluation of 35 AATCC 20-2007(2008) RA24 Fiber Analysis: Qualitative 38 AATCC 20A-2007(2008) RA24 Fiber Analysis: Quantitative 57 AATCC 22-2005(2008) RA63 Water Repellency: Spray Test 65 AATCC 23-2005(2008) RA33 Colorfastness to Burnt Gas Fumes 68AATCC 26-2004(2008) RR9 Ageing of Sulfur-Dyed Textiles: Accelerated 71AATCC 27-2004(2008) RA63 Wetting Agents: Evaluation of Rewetting Agents 73AATCC 28-2004(2008) RA49 Insect Pest Deterrents on Textiles 74 AATCC 30-2004(2008) RA31 Antifungal Activity, Assessment on Textile Materials:Mildew and Rot Resistance of Textile Materials AATCC 35-2006(2008) RA63 Water Resistance: RAin Test 80 AATCC 42-2007(2008) RA63 Water Resistance: Impact Penetration Test 82AATCC 43-2004(2008) RA63 Wetting Agents for Mercerization 84 AATCC 61-2007(2008) RA60 Colorfastness to Laundering: Accelerated 86AATCC 66-2003(2008) RA61 Wrinkle Recovery of Woven Fabrics: Recovery Angle 91AATCC 70-2005(2008) RA63 Water Repellency: Tumble Jar Dynamic Absorption Test 95AATCC 76-2005(2008) RA32 Electrical Surface Resistivity of Fabrics 97AATCC 79-2007(2008) RA63 Absorbency of Textiles 99AATCC 81-2006(2008) RA34 pH of the Water-Extract from Wet Processed Textiles 101AATCC 82-2007(2008) RA34 Fluidity of Dispersions of Cellulose from Bleached Cotton Cloth 103AATCC 84-2005(2008) RA32 Electrical Resistance of Yarns 106 AATCC 86-2005(2008) RA43 Drycleaning: Durability of Applied Designs and Finishes 108AATCC 88B-2006(2008) RA61 Smoothness of Seams in Fabrics after Repeated Home Laundering110AATCC 88C-2006(2008) RA61 Retention of Creases in Fabrics after Repeated Home Laundering114AATCC 89-2003(2008) RA66 Mercerization in Cotton118AATCC 92-2004(2008) RR35 Chlorine, Retained, Tensile Loss: Single Sample Method 120AATCC 93-2005(2008) RA29 Abrasion Resistance of Fabrics: Accelerotor Method 123AATCC 94-2007(2008) RR45 Finishes in Textiles: Identification 126AATCC 96-2004(2008) RA42 Dimensional Changes in Commercial Laundering of Woven and Knitted Fabrics Except Wool 133 AATCC 97-1999(2008) RA34 Extractable Content of Greige and/or Prepared Textiles 137AATCC 98-2007(2008) RA34 Alkali in Bleach Baths Containing Hydrogen Peroxide 139AATCC 99-2004(2008) RA42 Dimensional Changes of Woven or Knitted Wool Textiles: Relaxation, Consolidation and Felting 141 AATCC 100-2004(2008) RA31 Antibacterial Finishes on Textile Materials: Assessment of 145AATCC 101-2004(2008) RA34 Colorfastness to Bleaching with Hydrogen Peroxide 148AATCC 102-2007(2008) RA34 Hydrogen Peroxide by Potassium Permanganate Titration: Determination of 151AATCC 103-2004(2008) RA34 Bacterial Alpha-Amylase Enzymes used in Desizing, Assay of 153AATCC 104-2004(2008) RA23 Colorfastness to Water Spotting 156AATCC 106-2007(2008) RA23 Colorfastness to Water: Sea 157 AATCC 107-2007(2008) RA23 Colorfastness to Water 159 AATCC 109-2005(2008) RA33 Colorfastness to Ozone in the Atmosphere under Low Humidities 161AATCC 110-2005(2008) RA36 Whiteness of Textiles 163AATCC 111-2003(2008) RA50 Weather Resistance of Textiles: Exposure to Daylight and Weather 165AATCC 112-2003(2008) RR68 Formaldehyde Release from Fabric, Determination of: Sealed Jar Method 174AATCC 114-2005(2008) RR35 Chlorine, Retained, Tensile Loss: Multiple Sample Method 177AATCC 115-2005(2008) RA32 Electrostatic Clinging of Fabrics: Fabric-to-Metal Test 179AATCC 116-2005(2008) RA38 Colorfastness to Crocking: Rotary Vertical Crockmeter Method 183AATCC 117-2004(2008) RR54 Colorfastness to Heat: Dry (Excluding Pressing) 185AATCC 118-2007(2008) RA56 Oil Repellency: Hydrocarbon Resistance Test 187AATCC 119-2004(2008) RA29 Color Change Due to Flat Abrasion (Frosting): Screen Wire Method 190AATCC 120-2004(2008) RA29 Color Change Due to Flat Abrasion (Frosting): Emery Method 193AATCC 121-2005(2008) RA57 Carpet Soiling: Visual RAting Method 195AATCC 122-2000(2008) RA57 Carpet Soiling: Service Soiling Method 197AATCC 123-2000(2008) RA57 Carpet Soiling: Accelerated Soiling Method 199AATCC 124-2006(2008) RA61 Appearance of Fabrics after Repeated Home Laundering 201AATCC 127-2003(2008) RA63 Water Resistance: Hydrostatic Pressure Test 207AATCC 128-2004(2008) RA61 Wrinkle Recovery of Fabrics: Appearance Method 209AATCC 129-2005(2008) RA33 Colorfastness to Ozone in the Atmosphere under High Humidities211AATCC 130-2000(2008) RA56 Soil Release: Oily Stain Release Method 213AATCC 131-2005(2008) RR53 Colorfastness to Pleating: Steam Pleating 216AATCC 132-2004(2008) RA43 Colorfastness to Drycleaning 218 AATCC 133-2004(2008) RR54 Colorfastness to Heat: Hot Pressing 221AATCC 134-2006(2008) RA57 Electrostatic Propensity of Carpets 223AATCC 135-2004(2008) RA42 Dimensional Changes of Fabrics after Home Laundering 227AATCC 136-2003(2008) RA79 Bond Strength of Bonded and Laminated Fabrics 231AATCC 137-2007(2008) RA57 Rug Back Staining on Vinyl Tile 234 AATCC 138-2005(2008) RA57 Cleaning: Washing of Textile Floor Coverings 236AATCC 139-2005(2008) RA50 Colorfastness to Light: Detection of Photochromism 238AATCC 140-2006(2008) RA87 Dye and Pigment Migration in a Pad-Dry Process: Evaluation of 240AATCC 141-2004(2008) RA87 Compatibility of Basic Dyes for Acrylic Fibers 243AATCC 142-2005(2008) RR81 Appearance of Flocked Fabrics after Repeated Home Laundering and/or Coin-Op Drycleaning 245 AATCC 143-2006(2008) RA61 Appearance of Apparel and Other Textile End Products after Repeated Home Laundering 248AATCC 144-2007(2008) RA34 Alkali in Wet Processed Textiles: Total 254AATCC 146-2006(2008) RA87 Dispersibility of Disperse Dyes: Filter Test 256AATCC 147-2004(2008) RA31 Antibacterial Activity Assessment of Textile Materials: Parallel Streak Method 259AATCC 149-2007(2008) RA90 Chelating Agents: Chelation Value of Aminopolycarboxylic Acids and Their Salts; Calcium Oxalate Method 261AATCC 150-2003(2008) RA42 Dimensional Changes of Garments after Home Laundering 263AATCC 151-2003(2008) RA56 Soil Redeposition: Launder-Ometer Method 267AATCC 154-2006(2008) RA87 Thermal Fixation Properties of Disperse Dyes 269AATCC 157-2005(2008) RR92 Colorfastness to Solvent Spotting: Perchloroethylene 271AATCC 158-2005(2008) RA43 Dimensional Changes on Drycleaning in Perchloroethylene: Machine Method 273AATCC 159-2006(2008) RA87 Transfer of Acid and Premetallized Acid Dyes on Nylon 276AATCC 161-2007(2008) RA90 Chelating Agents: Disperse Dye Shade Change Caused by Metals; Control of 278AATCC 162-2002(2008) RA23 Colorfastness to Water: Chlorinated Pool 281AATCC 163-2007(2008) RR92 Colorfastness: Dye Transfer in Storage; Fabric-to-Fabric 283AATCC 164-2006(2008) RA33 Colorfastness to Oxides of Nitrogen in the Atmosphere under High Humidities 285AATCC 165-1999(2008) RA57 Colorfastness to Crocking: Textile Floor Coverings—AATCC Crockmeter Method 287AATCC 167-2003(2008) RA87 Foaming Propensity of Disperse Dyes 290AATCC 168-2007(2008) RA90 Chelating Agents: Active Ingredient Content of Polyaminopolycarboxylic Acids and Their Salts; Copper PAN Method 292AATCC 169-2003(2008) RA50 Weather Resistance of Textiles: Xenon Lamp Exposure 294AATCC 170-2006(2008) RA87 Dusting Propensity of Powder Dyes: Evaluation of 300AATCC 171-2005(2008) RA57 Carpets: Cleaning of; Hot Water Extraction Method 302AATCC 172-2007(2008) RA60 Colorfastness to PowderedNon-Chlorine Bleach in Home Laundering 304AATCC 173-2005(2008) RA36 CMC: Calculation of Small Color Differences for Acceptability 307AATCC 174-2007(2008) RA31 Antimicrobial Activity Assessmentof Carpets 312AATCC 175-2003(2008) RA57 Stain Resistance: Pile Floor Coverings 315AATCC 176-2006(2008) RA87 Speckiness of Colorant Dispersions: Evaluation of 318AATCC 178-2004(2008) RR97 Barré: Visual Assessment and Grading 320AATCC 179-2004(2008) RA42 Skewness Change in Fabric and Garment Twist Resulting from Automatic Home Laundering 323 AATCC 181-2005(2008) RA50 Colorfastness to Light at High Temperatures: Daylight Temperature and Humidity Controlled Apparatus 327AATCC 182-2005(2008) RA36 Relative Color Strength of Dyes in Solutions 331AATCC 183-2004(2008) RA106 Transmittance or Blocking of Erythemally Weighted Ultraviolet(2008) RAdiation through Fabrics 334AATCC 184-2005(2008) RA87 Dusting Behavior of Dyes: Determination of 338AATCC 185-2006(2008) RA90 Chelating Agents: Percent Content in Hydrogen Peroxide Bleach Baths; Copper PAN Indicator Method 342AATCC 186-2006(2008) RA50 Weather Resistance: UV Light and Moisture Exposure 344AATCC 187-2004(2008) RA42 Dimensional Changes of Fabrics: Accelerated 349AATCC 188-2003(2008) RA60 Colorfastness to Sodium Hypochlorite Bleach in Home Laundering 352AATCC 189-2007(2008) RA57 Fluorine Content of Carpet Fibers 355AATCC 190-2003(2008) RA60 Colorfastness to Home Laundering with Activated Oxygen Bleach Detergent: Accelerated 358 AATCC 191-2004(2008) RA41 Acid Cellulase Enzymes, Effect of: Top Loading Washer 361AATCC 192-2005(2008) RA50 Weather Resistance of Textiles: Sunshine-Arc Lamp Exposure With and Without Wetting 363 AATCC 193-2007(2008) RA56 Aqueous Liquid Repellency:Water/Alcohol Solution Resistance Test 372AATCC 194-2007(2008) RA49 Assessment of the Anti-House Dust Mite Properties of Textiles under Long-Term Test Conditions 375 AATCC Evaluation ProceduresAATCC 1-2007 RA36 Gray Scale for Color Change 377AATCC 2-2007 RA36 Gray Scale for Staining 379AATCC 4-2007 RA36 Standard Depth Scales for Depth Determination 381AATCC 5-2006 RA89 Fabric Hand: Guidelines for the Subjective Evaluation of 382AATCC 6-2003 RA36 Instrumental Color Measurement 384 AATCC 7-2003 RA36 Instrumental Assessment of the Change in Color of a Test Specimen 390AATCC 8-2007 RA36 AATCC 9-Step Chromatic Transference Scale 392AATCC 9-2007 RA36 Visual Assessment of Color Difference of Textiles 394AATCC 10-2007 RA59 Multifiber Adjacent Fabrics: Evaluation of 397AATCC 11-2007 RA36 Spectrophotometer UV Energy Calibration Procedure for Optically Brightened Textiles 400。

耐摩擦色牢度:AATCC摩擦测试仪法AATCC RA38技术委员会于1936年制定:1937年、1952年、1957年、1961年、1969年、1972年、1985年、1988年、1996年、2004年、2005年、2007年修订;1945年、1989年重新审定;1968年、1974年、1977年、1981年、1995年、2001年编辑修订并重新审定;1986年、2002年编辑修订;部分等效于ISO105-X12。

1.目的和范围1.1本测试方法用来评定有色纺织品表面因摩擦颜色转移到其他表面的程度。

适用于各种纤维的、各种类型的有色纱线和织物,包括染色织物、印花织物和其他有色织物。

不推荐用于地毯和面积太小的印花纺织品。

1.2测试方法使用摩擦白布,包含干的和已用水湿润的。

1.3因水洗、干洗、收缩、熨烫、整理等等可能影响颜色的转移程度,所以可在整理前、整理后或一并进行试验。

2.原理2.1在规定条件下,有色试样与摩擦白布进行摩擦2.2沾色摩擦白布与沾色灰卡或沾色彩卡比较,对沾色摩擦白布评价并确定级数。

3.术语3.1色牢度:材料暴露在加工、测试、储存或使用种可能遇到的环境下的耐颜色变化,或染料向贴衬材料转移的能力。

3.2摩擦脱色:通过摩擦,颜色从色纱或者有色织物表面转移到另一个表面或同一织物的邻近区域。

4.安全预防措施本安全各预防措施仅供参考。

这些措施有助于测试过程,但未包含所有的内容。

在本测试方法中,使用者有责任在处理材料时采用安全各正确的技术;须向制造商咨询有关材料的详尽信息,如材料的安全参数和其他建议;须向“美国职业安全卫生管理局”(OSHA)咨询并完全遵守其标准和规定。

4.1应遵守良好的实验室规范,在所有实验场所要佩戴防护镜。

5.仪器和材料5.1 AATCC耐摩擦色牢度测试仪或者类似的供替换的仪器(见13.2、13.3和图1)5.2摩擦白布,剪成50mm正方(见13.4)5.3 AATCC沾色彩卡(见13.5)5.4 沾色灰卡(见13.5)。

常用的122个美标AATCC标准常用的122个美标AATCC标准1、 AATCC估计步骤一《颜色变化的灰度》2、 AATCC估计步骤二《着色的灰度色标》3、 AATCC估计步骤三《织物色差的视觉评估》4、 AATCC估计步骤四《深度测试的标准深度级别》5、 AATCC估计步骤五《织物手感:主观故测指南》6、 AATCC估计步骤六《工具性颜色检测》7、 AATCC估计步骤七《测试样品颜色变化的仪器评估》8、 AATCC估计步骤八《-步色级转移尺》9、 AATCC6-2001《耐酸碱色牢度》10、 AATCC8-2001(2004)《耐摩擦色牢度标准》11、 AATCC15-2002《耐汗色牢度》12、 AATCC16-2003(2004)《耐光色牢度》13、 AATCC17-1999《润湿剂效果的表征》14、 AATCC20A-2000《纤维分析(定量)》15、 AATCC20-2002《纤维分析(定性)》16、 AATCC22-2001《防水性:(沾水、淋水试验)》17、 AATCC23-1999《抗燃气烟的不褪色性》18、 AATCC24-1999《纺织品的防蛀能力的测试》19、 AATCC26-1999《用硫磺处理的纺织品的老化:加速》20、 AATCC27-1999《润湿剂:再润湿的评估》21、 AATCC28-1999《用于纺织品上的虫害预防物》22、AATCC30-1999《纺织品的抗真菌能力的评估:纺织品的抵抗霉变和腐烂的能力》23、 AATCC35-2000《防水性:防止雨水测试》24、 AATCC42-2000《防水性:渗透作用测试》25、 AATCC43-1999《墨塞丝光处理法的润湿剂》26、 AATCC61-2003《耐洗色牢度》27、 AATCC66-2003《折痕回复角》28、 AATCC70-2000《水排斥性:摇液瓶动力学吸收测试》29、 AATCC76-2000《纺织物的表面电阻》30、 AATCC79-2000《脱色纺织物的吸收》31、 AATCC 81-2001《PH值的检测法》32、 AATCC82-2001《漂白棉布溶液中分散纤维素流度的测定》33、 AATCC84-2000《纱线电阻的测定》34、 AATCC86-2000《干洗:外加图案和涂饰漆的耐用性》35、AATCC88B-2003《纺织品经反复家庭洗涤干燥接缝外观的评定方法》36、AATCC88C-2003《经过多次的家庭洗涤后织物上折痕的持久性》37、 AATCC89-2003《棉花碱化处理度的测定》38、AATCC92-1999《氯,残留物以及拉伸损失:单一样品的测试方法》39、AATCC93-1999《纺织品的耐磨性能测试:加速型耐磨测试仪法》40、 AATCC94-2002《织物中整理剂的鉴定》41、AATCC96-2001《除了毛料衣物之外的机织织物和编织织物在商业洗涤过程中的尺寸变化》42、 AATCC97-1999《原坯布和或者精致纺织品中的可分离量》43、 AATCC98-2002《含有过氧化氢的漂白槽中的碱含量检测》44、AATCC99-2000《机织和编织毛纺织品的尺寸变化:松弛、凝固和粘连》45、 AATCC100-1999《织物材料中抗菌整理剂的鉴定》46、 AATCC101-1999《过氧化氢漂白色牢度的检测》47、AATCC102-2002《通过高锰酸钾标准溶液滴定确定过氧化氢含量》48、AATCC103-1999《对脱浆工艺中采用的细菌性a-淀粉酶的鉴定》49、 AATCC104-1999《耐水斑色牢度》50、 AATCC106-2002《耐海水色牢度》51、 AATCC107-2002《耐水色牢度》52、 AATCC109-2002《耐低湿大气中臭氧色牢度》53、 AATCC110-2000《纺织物的白度》54、AATCC111-2003《织物耐候性:暴晒于日光和气候环境下》55、 AATCC112-2003《甲醛含量检测》56、AATCC114-1999《残留氯造成的拉伸强度的降低:复合样品的试验》57、 AATCC115-2000《织物的静电吸附:织物对金属测试》58、AATCC116-2001《耐摩擦色牢度:旋转垂直摩擦牢度仪法》59、 AATCC117-1999《耐干热(热压)色牢度》60、 AATCC118-2002《疏油性:耐烃类测试》61、AATCC119-1999《表面磨损产生色变(起霜):金属丝方法》62、 AATCC122-2000《地毯去污:保养方法》63、 AATCC123-2002《地毯污染:加速污染方法》64、 AATCC124-2001《多次家庭洗烫之后织物的表面外观》65、 AATCC125-1991《耐水和光色牢度:交替作用》66、 AATCC127-2003《耐水性:流体静压测试》67、 AATCC128-1999《织物皱纹复原:外观方法》68、 AATCC129-2001《耐高湿大气中臭氧色牢度》69、 AATCC130-2000《污物消除:污物消除方法》70、AATCC131-2000《褶皱下的染色牢度:汽蒸法处理的褶皱》71、 AATCC132-2003《干洗色牢度》72、 AATCC133-1999《耐热染色牢度:热处理》73、 AATCC134-2001《地毯的静电性能》74、 AATCC135-2003《织物水洗尺寸变化检测》75、 AATCC136-2003《粘合和层压织物的粘结强度》76、 AATCC137-2002《地毯背面在乙烯树脂瓦面上的着色》77、 AATCC138-2000《纺织品类地面覆盖物的洗涤》78、 AATCC139-2000《光照下的染色牢度:光致变色的检测》79、AATCC140-2001《浸压烘干过程中染料游移和颜料泳移的评定》80、 AATCC141-1999《丙烯酸纤维碱性染料的相容性》81、AATCC142-2002《经多次水洗或投币自动干洗后织物的外观》82、AATCC143-2001《重复多次家庭洗涤后衣物及其他纺织产品的外观表现》83、 AATCC144-2002《湿法纺织中的总碱度》84、 AATCC146-2001《分散染料的分散性:过滤测试》85、AATCC147-1998《纺织材料抗菌活性的评定:平行条纹法》86、AATCC 149-2002《鳌合剂:利用草酸钙滴定的方法测量氨基聚羟基酸及其盐类形式的鳌合值》87、 AATCC150-2003《家庭洗涤后衣物的尺寸变化》88、 AATCC151-2003《污物再沉淀:旋转清洗方法》89、 AATCC154-2001《分散染料的热固化性》90、 AATCC157-2000《溶剂点染的不褪色性:全氯乙烯》91、AATCC158-2000《用全氯乙烯干洗时的尺寸变化:机械方法》92、 AATCC159-1999《酸与预金属化酸染料在尼龙中的迁移》93、AATCC 161-2002《鳌合剂:由金属导致的分散染料颜色变化标准》94、 AATCC162-2002《耐水色牢度:含氯水池》95、AATCC163-2002《色牢度:储存时的染料迁移;由织物向织物》96、 AATCC164-2001《在高湿度环境下对二氧化氮的色牢度》97、AATCC165-1999《沾色磨擦色牢度:铺地纺织品-AATCC 沾色测试仪方法》98、 AATCC167-2003《分散染料的发泡倾向》99、AATCC 168-2002《鳌合剂:聚氨基聚羟酸以其盐类的活性成分含量;铜指示剂法》100、 AATCC169-2003《纺织品的耐气候腐蚀性:氙气灯照射》101、 AATCC170-2001《粉末染料的起尘倾向评价》102、 AATCC171-2000《地毯的热水抽吸法的清洗方法》103、 AATCC172-2003《家庭洗涤中无氯漂白剂的色牢度》104、 AATCC 173-1998《CMC:小色差可接受的计算》105、 AATCC174-1998《地毯抗微生物活性的评估》106、 AATCC175-2003《圈绒地毯的耐染色性》107、 AATCC178-1999《纬向条花:视觉评估和评级》108、 AATCC176-2001《着色剂分散斑点的评估》109、 AATCC179-2001《自动家庭洗涤的织物和成衣扭斜程度的变化》110、 AATCC180-1997《高温下耐光色牢度:日光温度控制设备》111、 AATCC181-1997《高温下耐光色牢度:日光温度和湿度控制设备》112、 AATCC182-2000《溶液中染料的相对色强度》113、 AATCC183-2000《织物对红斑加权总紫外辐射的透射率或阻隔率》114、 AATCC184-2000《染料的扬尘性及其定值》115、 AATCC185-2000《铜聚丙稀睛法测定过氧化氢漂白液中鳌合剂的百分含量》116、 AATCC186-2001《耐候性:紫外线和湿气》117、 AATCC187-2002《织物尺寸变化:加速情况下》118、 AATCC188-2003《在家用洗涤中次氯酸钠漂白作用不褪色性研究》119、 AATCC189-2003《地毯织物中的氟含量》120、 AATCC190-2003《在家庭洗涤中采用含活性氧漂白清洁剂的不褪色性:加速作用的研究》121、 AATCC191-2003《木纤维质酵素酶酸-洗衣机顶部装卸的影响》122、 AATCC192-2003《织物的耐久性:有水或者无水情况暴露于电弧光下》。

干洗色牢度AATCC 1321.仪器及材料1.1 水洗色牢度实验机1.2不锈钢洗杯:直径为75mm,高为125mm,容量为500ml。

1.3 不锈钢珠1.4 未染色斜纹棉布:克重为270+70g/m2,未经整理过的,切割成尺寸为120mm x120mm的布片1.5 全氯乙烯,干洗级1.6 AATCC变色灰卡,AATCC沾色灰卡1.7 分光光度计1.8 摩擦附布1.9 洗涤剂,Perk-Sheen2.测试样品2.1 如果被测试物为织物,每种样布取3块样品,每块样品尺寸为10x5cm。

长边方向平行于经向或纬向。

2.2 如果被测试物为纱线,将其织成尺寸为10x 5cm的织片,长边方向平行于经向或纬向。

2.3 样品准备2.3.13.测试程序3.1 将两块未染色的正方形棉斜纹布沿三边缝合,制成一个内尺寸为100mm x100mm的布袋,将一块试样和12片不锈钢圆片放入袋中,用任何方便的形式缝住袋口。

3.2 把装有试样和钢片的布袋放在容器内,在30C+2加入200ml全氯乙烯,如用其它溶剂,需在报告中说明。

在规定的装置中,30C+2C处理试样30min。

3.3 从溶剂中拿出布袋,取出试样,夹于吸水袋或布之间,挤压或离心去除多余的溶剂,将试样悬挂在温度为60+5的热空气中烘干。

3.4 用灰卡评定试样的变色3.5 实验结束后,用滤纸过滤留在容器中的溶剂。

将过滤后的溶剂和空白溶剂到入置于白卡前的比色管,采用透射光,用评定沾色用灰卡比较两者的染色。

汗渍色牢度AATCC151.设备,材料和试剂1.1 AATCC 汗渍实验器或等同装置(带有塑料,玻璃压片)1.2 烘箱—对流式1.3 天平,精确度到0.0011.4 多纤维附布NO.10或FA1.5 pH计,精确度到0.01。

1.6 5步或9步AATCCA彩色沾色灰卡或沾色灰卡。

1.7 变色灰卡1.8 轧车1.9 白色吸水纸1.10 酸性人工汗液。

2.试剂的准备2.1 在一个容积为一升的容量瓶中装入半升蒸馏水。

常用美国AATCC纺织印染116个标准常用美国AATCC纺织印染116个标准美国纺织化学家和染色家协会(AATCC)纺织印染业标准[标准代号][标准名称]AATCC6-2001耐酸碱色牢度AATCC8-2001耐摩擦色牢度:(AATCC耐摩擦色牢度测定器)AATCC15-2002耐汗渍色牢度AATCC16-2003耐光色牢度AATCC17-1999湿润剂,评定AATCC20-2002纤维分析:质量AATCC20A-2000纤维分析:数量AATCC22-2001排水:喷雾试验AATCC23-1999耐烟熏色牢度AATCC24-1999纺织品耐昆虫,AATCC26-1999硫染纺织品用剂:加速AATCC27-1999湿润剂:再湿润剂评定AATCC28-1999纺织品防昆虫、害虫AATCC30-1999耐真菌活性,纺织品材料评定:纺织品材料耐霉菌防腐烂AATCC35-2000耐水渍:雨水试验AATCC42-2000耐水渍:冲击穿透试验AATCC43-1999丝光处理湿润剂AATCC61-2003耐家庭、商业洗涤色牢度:加速AATCC66-2003机织物折痕回复:回复角AATCC70-2000排水:滚筒水击动态吸收试验AATCC76-2000纤维表面电阻AATCC79-2000漂白纺织品的吸收性AATCC81-2001湿加工时纺织品水萃取PH值AATCC82-2001漂白棉布中纤维素分散质的流度AATCC84-2000纱线电阻AATCC86-2000干洗:应用设计和整理的耐久性AATCC88B-2003多次家洗后织物缝线处的平滑性AATCC88C-2003织物多次家洗后留下的折痕AATCC89-2003棉的丝光处理AATCC92-1999氯,存留的,张力损耗:单个取样法AATCC93-1999织物耐磨:加速剂方法AATCC94-2002织物整理:鉴别AATCC96-2001机织和针织物(毛织物除外)商业洗涤后尺寸变化AATCC97-1999原纱和/或已处理纺织品的可提取成分AATCC98-2002含过氧化氢的漂白槽中的碱AATCC99-2000机织或针织毛纺织品尺寸变化:松弛、收缩和毡合AATCC100-1999纺织品材料上耐细菌整理:评定AATCC101-1999过氧化氢漂白色牢度AATCC102-2002过氧化氢漂白,高锰酸钾滴定法:测定AATCC103-1999用于退浆的细菌性α淀粉酶,化验AATCC104-1999耐水滴色牢度AATCC106-2002耐水浸色牢度:海水AATCC107-2002耐水浸色牢度AATCC109-2002耐低湿度大气臭氧色牢度AATCC110-2000纺织品的白色AATCC111-2003纺织品耐气候性AATCC112-2003织物挥发甲醛,测定:封罐法AATCC114-1999氯,存留的,张力损耗:多次取样法AATCC115-2000织物静电依附:织物—金属试验AATCC116-2001耐摩擦色牢度:旋转垂直耐摩擦色牢度测定器法AATCC117-1999耐高温色牢度:干燥(不包括熨烫)AATCC118-2002排油:耐烃试验AATCC119-1999平面磨蚀引起的色变(消光):屏蔽电线方法AATCC120-1999平面磨蚀引起的色变(消光):金刚砂方法AATCC121-2000地毯玷污:可视评定法AATCC122-2000地毯沾污:使用沾污法AATCC123-2000地毯沾污:加速沾污法AATCC124-2001织物多次家洗后外形AATCC125-1991耐水耐光色牢度:交替暴露AATCC127-2003耐水性:流体静压试验AATCC128-1999织物折痕回复:外形AATCC129-2001耐高湿度大气臭氧色牢度AATCC130-2000排除污垢:油污排除法AATCC131-2000耐褶裥色牢度:蒸汽褶裥AATCC132-2003耐干洗色牢度AATCC133-1999耐高温色牢度:热压AATCC134-2001地毯的静电性AATCC135-2003机织和针织物自动家洗时尺寸变化AATCC136-2003黏合或层压织物的黏合强度AATCC137-2002瓷砖上小地毯背面沾污AATCC138-2000清洁:铺地织物的清洗AATCC139-2000耐光色牢度:致光色变现象的观察AATCC140-2001轧-烘处理过程中染料和涂剂泳移AATCC141-1999碱性染料与丙烯酸纤维的相容性AATCC142-2000植绒织物经多次家洗和/或在投币自动干洗后外形AATCC143-2001衣服和其他纺织成品多次家洗后的外形AATCC144-2002湿处理织物所含碱:整体AATCC146-2001分散染料的分散性:过滤试验AATCC147-1998织物材料抗菌活性测定:平行条纹法AATCC149-2002螯合剂:氨基聚羧酸螯合作用值及其盐分;草酸钙法AATCC150-2003服装自动家洗时尺寸的变化AATCC151-2003污物再沉积AATCC154-2001分散染料的热固定性AATCC157-2000耐溶剂滴色牢度:全氯乙烯AATCC158-2000全氯乙烯干洗后尺寸变化:机械法AATCC159-1999尼龙上酸和金属络合酸性染料的转移AATCC161-2002螯合剂:金属引起的分散染料色度阴暗;控制AATCC162-2002耐水浸色牢度:氯化水池AATCC163-2002色牢度:留存染料转印;织物对织物AATCC164-2001耐高湿度大气中氧化氮色牢度AATCC165-1999耐摩擦色牢度:铺地织物-AATCC耐摩擦色牢度测定器AATCC167-2003分散染料的起泡性AATCC168-2002螯合剂:聚氨基聚羧酸的活性成分含量极其盐分;铜硝酸过氧化乙酰法(PAN)AATCC169-2003织物的耐气候性:氙灯暴露AATCC170-2001粉状染料的喷撒性:评定AATCC171-2000地毯:热水萃取法AATCC172-2003家洗耐无氯漂白色牢度AATCC173-1998CMC:小色差合格率计算AATCC174-1998地毯耐微生物活性测定AATCC175-2003耐脏:绒毛铺地材料AATCC176-2001染料剂分散质斑点:评定AATCC178-1999纬向染疵:可视测定和渐次调和AATCC179-2001自动家洗时缠绕引起织物和衣服变形AATCC180-1997高温下耐光色牢度:受装置控制的天然光温度AATCC181-1997高温下耐光色牢度:受装置控制的天然光温度和湿度AATCC182-2000溶液中染料颜色的相对强度AATCC183-2000紫外线穿透织物强度AATCC184-2000染料喷撒性能:测定AATCC185-2000螯合剂:过氧化氢漂白槽中的百分含量:铜硝酸过氧化乙酰(PAN)指示剂方法;AATCC186-2001耐气候性:紫外线和湿度暴露AATCC187-2002织物的尺寸变化:加速的AATCC188-2003家洗耐钠、次氯盐酸漂白色牢度AATCC189-2002地毯纤维含氟量AATCC190-2003耐活性氧漂白洗涤剂家洗的色牢度:加速酸性纤维素酶,作用于:最大负荷量洗涤器AATCC191-2003木纤维质酵酶酸一洗衣机顶部装载的影响AATCC192-2003织物的耐久性:有水或者无水情况暴露于电孤光下。

aatcc水洗牢度测试方法概述及解释说明1. 引言1.1 概述在纺织行业中,对于面料的颜色和图案保持稳定性的测试非常重要。

AATCC水洗牢度测试方法就是用来评估面料在水洗过程中是否会出现褪色或染料迁移现象。

本文将对AATCC水洗牢度测试方法进行全面概述和解释说明。

1.2 文章结构本文共分为五个部分,每个部分涵盖了具体的内容。

除引言外,还包括AATCC 水洗牢度测试方法的概述、解释说明、局限性与改进方向以及结论。

1.3 目的本文的目的是介绍AATCC水洗牢度测试方法,并解释其应用领域、测试步骤以及结果评定和数据分析等关键要素。

同时,我们还将探讨该方法存在的局限性,并提出改进方向和建议。

以上是引言部分内容,请根据实际情况进行修改完善。

2. AATCC水洗牢度测试方法概述2.1 AATCC水洗牢度测试的定义AATCC水洗牢度测试是一种用于评估纺织品染色牢度的标准化方法。

它主要用来检测染料在湿润状态下是否有脱色或渗漏现象,以及纺织品织物是否能够在水洗过程中保持颜色的稳定性。

该方法通过模拟纺织品在日常使用中可能遇到的各种水洗条件,并通过视觉比较或仪器分析来评估染料的固色性能。

2.2 水洗牢度测试的重要性水洗牢度是评估纺织品质量和耐久性的关键指标之一。

对于衣物、家居用品和其他纺织制品而言,经常接触到水和湿润环境,因此其颜色稳定性尤为重要。

只有具有良好的水洗牢度才能确保产品在日常使用中不会褪色或渐变,同时也符合用户对长期耐用且富有吸引力的纺织品的需求。

2.3 AATCC水洗牢度测试方法的应用领域AATCC水洗牢度测试方法广泛应用于纺织和服装行业的产品开发、质量控制和标准制定过程中。

此外,它也被用作衡量染色工艺和材料的改进效果的重要参考依据。

各种纤维材料、染料类型以及加工工艺都可以通过AATCC水洗牢度测试方法来进行评估,从而为生产商提供选择合适材料和优化工艺的依据。

以上是“2. AATCC水洗牢度测试方法概述”部分内容的解释说明。

各国纺织品中甲醛限量标准及测试方法纺织品中甲醛限量标准及测定方法甲醛作为纤维素纤维树脂整理的常用交联剂,广泛应用于纯纺或混纺产品(包括部分真丝产品),从而赋予纺织品防缩、抗皱、免烫和易去污等功能。

但是,甲醛含量超标的纺织品在穿着或使用过程中,部分未交联的或水解产生的游离甲醛会释放出来,对人体健康造成损害。

一般来说,甲醛含量较高的衣物有以下四类:一是经过防皱处理的纯棉织物;二是目前较为流行的胸前有涂料印花的T恤;三是衣物有衬布部分;四是黑色、深蓝色等颜色较深的涤纶织物。

甲醛含量的限定纺织品中甲醛含量问题日益引起业界及社会的广泛关注,同时也成为“绿色贸易壁垒”的重要内容,各国的法规或标准均对甲醛含量做了严格的限定。

⒈我国于2003 年1 月1 日起实施强制性标准GB 18401-2001《纺织品甲醛含量的限定》。

GB18401-2001《纺织品甲醛含量的限定》对纺织品(包括面料和辅料)中所含的甲醛进行了严格的限制,与目前国际通行的实际控制标准基本一致。

我国纺织品甲醛含量的限定值是根据产品最终用途而定的,其规定见表。

我国纺织品甲醛含量限定值纺织品类型甲醛含量(mg/kg)≤纺织品类型甲醛含量(mg/kg)≤婴幼儿类20 非直接接触皮肤类200直接接触皮肤类75 室内装饰类300其中:婴幼儿类包括尿布、尿裤、内衣、围嘴儿、睡衣、手套、袜子、中衣、外衣、帽子和床上用品;直接接触皮肤类包括文胸、腹带、针织内衣、衬衫、裤子、裙子、睡衣、袜子、床单和被罩;非直接接触皮肤类包括毛衫、外衣、裙子和裤子;室内装饰类包括桌布、窗帘、沙发罩、床罩和墙布。

日本相关法规和标准中甲醛含量的限定值规则纺织品类型甲醛含量(mg/kg)≤日本通产省根据日本第112 号法令(1973)颁布的《关于日用品中有害物质含量法规与皮肤直接接触的服装75与皮肤直接接触较少的服装(如衬衫) 300外衣1000 2 岁以下婴幼儿服装20日本厚生省34 号令(1974)《关于日用品中有害物质含量法规的实施规则》婴儿用品(A-Ao)值0.05其他产品75日本纺织品检查协会标准2 周岁岁内婴幼儿(A-Ao)值0.05内衣75男女衬衣300男女便裤及裙子1000注A-Ao(吸光度)是指日本标准甲醛数值,规定大于0.05 为不合格;小于或等于0.05为合格。