Characterization of Damaged Materials

- 格式:pdf

- 大小:523.16 KB

- 文档页数:12

Advanced Materials CharacterizationAdvanced materials characterization plays a crucial role in various scientific and engineering fields, providing valuable insights into the properties and behavior of materials at the atomic and molecular levels. This multidisciplinary field encompasses a wide range of techniques and methods aimed at understanding the structure, composition, and performance of advanced materials. From nanomaterials to biomaterials, the characterization of these advanced materials is essential for the development of innovative technologies and applications. In this discussion, we will explore the significance of advanced materialscharacterization from different perspectives, highlighting its impact on research, industry, and society. From a scientific standpoint, advanced materials characterization enables researchers to gain a deeper understanding of the fundamental properties of materials. Techniques such as X-ray diffraction, electron microscopy, and spectroscopy provide detailed information about the crystal structure, morphology, and chemical composition of materials. This knowledge is invaluable for elucidating the underlying principles governing the behavior of materials, paving the way for the design and synthesis of new materials with tailored properties. Moreover, advanced materials characterization plays a pivotal role in advancing our knowledge of nanomaterials, metamaterials, and other cutting-edge materials, driving the frontiers of scientific discovery. In the realm of engineering, advanced materials characterization is indispensable for the development and optimization of materials for various applications. Whether in the aerospace, automotive, or electronics industry, the ability to characterize materials at the micro and nanoscale is essential for ensuring their reliability and performance. For instance, the characterization of composite materials used in aircraft structures allows engineers to assess their mechanical properties, fatigue resistance, and damage tolerance. This, in turn, contributes to the enhancement of safety standards and the development of lightweight, high-strength materials for advanced aerospace applications. Furthermore, advanced materials characterization has significant implications for the medical and healthcare sectors. Biomaterials play a critical role in various medical devices, implants, and tissue engineering applications. Characterization techniques such asscanning electron microscopy and atomic force microscopy are employed to analyzethe surface topography and mechanical properties of biomaterials, therebyinfluencing their biocompatibility and functionality. Additionally, the characterization of drug delivery systems and nanomedicines is essential for understanding their release kinetics, stability, and interactions with biological systems, ultimately impacting the efficacy and safety of therapeutic interventions. In the context of environmental and energy-related applications, advancedmaterials characterization contributes to the development of sustainable technologies. The characterization of materials for energy storage and conversion, such as batteries, fuel cells, and photovoltaic devices, is essential forimproving their efficiency, durability, and cost-effectiveness. Moreover, thestudy of advanced materials for environmental remediation, pollution control, and sustainable infrastructure relies on advanced characterization techniques toassess their performance under different environmental conditions. By gaining insights into the degradation mechanisms and long-term behavior of materials, researchers and engineers can contribute to the development of eco-friendly and resilient materials for addressing global challenges. From a societal perspective, the impact of advanced materials characterization is far-reaching. The advancements in materials science and characterization techniques have led to the development of innovative consumer products, from high-performance electronics to advanced medical devices, improving the quality of life for individuals worldwide. Moreover, the integration of advanced materials in various industries has the potential to drive economic growth and create new opportunities for employment and entrepreneurship. By fostering collaboration between academia, industry, and government agencies, the field of advanced materials characterization plays apivotal role in translating research discoveries into practical solutions that benefit society as a whole. In conclusion, advanced materials characterization isa multidisciplinary field that holds immense significance for scientific research, technological innovation, and societal advancement. By enabling a comprehensive understanding of the structure-property relationships of materials, advanced characterization techniques empower researchers, engineers, and industries to develop materials with tailored functionalities and enhanced performance. As thefrontiers of materials science continue to expand, the continued advancement of advanced materials characterization will undoubtedly shape the future of diverse fields, from healthcare and energy to environmental sustainability and beyond.。

20TH INTERNATIONAL SYMPOSIUM ON BALLISTICSORLANDO, FL, 23–27 SEPTEMBER 2002NUMERICAL SIMULATION OF THE PENETRATIONPROCESS OF GEOPENETRATORS INTO PREDAMAGEDCONCRETE TARGETSN. Heider11Ernst-Mach-Institut, Eckerstr. 4, 79104 Freiburg, GermanyTandem warhead systems consist of two components: a precursor shaped charge and a following kinetic energy (KE) projectile containing a high explosive filling. They are designed to penetrate hardened structures especially targets with concrete layers. The performance of the KE projectile depends strongly on the target damage due to the shaped charge jet penetration. At the moment there are no detailed reliable data about the damage available. This paper therefore analyses in a parametric way the influence of target damage (formation of crater hole as well as concrete material damage) on the achievable KE penetration performance. The simulations are based on an explicit modeling of the shaped charge jet crater with the crater profile deduced from experimental results. The crater shape and the damage level (reduced compressive strength of the concrete afterloading from the shaped charge jet) are varied parametrically. The numerical model is validated with experiments of KE projectiles intoplain concrete targets without pre damage. INTRODUCTIONA principal sketch of a tandem warhead system is shown in fig.1. The sequence of events during the impact of the tandem warhead is as follows:∙ Initiation of precursor shaped charge with jet formation∙ Interaction of jet with target (crater formation and damage of concrete around the crater)∙ Penetration of the following KE projectile into the pre damaged concrete target.A complete simulation of the tandem warhead function including the shaped charge jetpenetration is given in [1]. The theoretical description of the performance of the two tandem warhead components as a single weapon is already very good (within numerical as well as analytical modeling). Some uncertainties still exist for the tandem system especially concerning the interaction of the KE projectile with the damaged target. The analytical and empirical modeling of the tandem system therefore requires some better understanding of the target damage and its influence on the time history of the KE projectile penetration process. Due to the lack of detailed experimental and theoretical data on the damage distribution within the target it seems a reasonable approach to analyze the penetration process with the help of parametric variations of the relevant parameters describing the crater and the degree of damage in the concrete target material. This method allows the separate investigation of the influence of these physical parameters on the penetration depth of the KE projectile and a detailed understanding of the involved processes.Fig.1 Components of tandem warhead system Fig.2 Parameterization of carter ProfileEXPERIMENTAL BASISThe simulation model is based on experimental results of concrete penetration with shaped charge jets and KE projectiles.The explicit modeling of the damaged concrete target requires information about typical crater profiles created by the impact of the shaped charge jet. The crater profiles are taken from experiments where shaped charges were fired against concrete targets at a stand off of 3 calibers. The crater profiles are not very sensitive to stand off as soon as the maximum penetration depth as a function of stand off is reached. Even at high stand off values of 20calibers the crater profiles are still similar to the corresponding ones at 3 calibers. The tests have been performed with 80 mm caliber charges with aluminum liners and point initiation. Typical crater profiles have the following characteristics:Biconical profile (see fig.2)Spall crater at shaped charge jet impact surfaceErosion crater reaching to the final depth.The explicitly modeled crater profiles are derived from these data.The KE projectile penetration into undamaged concrete targets was used as avalidation case for the simulation model including the concrete material description.The following penetrator design was used:Caliber 60mmLength 508mmMass 6039gThe target consisted of two concrete blocks of diameter 96cm, length 1m and a steel casing. The concrete compressive strength was 35N/mm2 . The experimental results were (see [2] and [3] for experimental details and interpretation of penetration depth within cavity expansion theory):Impactvelocity 509m/secPenetration depth 114.5cmFig.3 shows the front and rear side of the target after impact of the KE projectile.Fig.3 KE projectile impact test: front and rear side of concrete target The corresponding results from the simulation are shown in fig.4 with the configurationat the time of impact and after the penetrator came to rest. The calculated penetration depth is 119 cm and agrees very well the experimental value of 114.5cm.Fig.4 Simulation: KE penetrator at impact and at end of penetrationSIMULATION MODELThe simulation model consists of the damaged target and the KE penetrator. Theperformance of the shaped charge jet is not explicitly modeled. Instead the crater profile andthe damage area around the crater are modeled explicitly. The simulation model used forthis application is based on the erosion crater because the radius of the spall crater issignificantly bigger than the radius of the KE projectile and thus has no influence on the KEprojectile penetration. The crater used in the simulations is thus characterized by twodiameters corresponding to target surface and the final penetration depth. These twoparameters can be varied to study the influence of crater diameter on the penetration process.As no date are available about the damage produced in the concrete target due to thepenetration of the shaped charge jet, the damaged region around the crater and the amount ofstrength reduction are additional variation parameters. The damaged area was assumedcylindrical with a certain depth and radius and a constant degree of damage within this area.These are three further variation parameters.The presented model parameters are deduced from experiments if possible and in theother cases are varied in a range that seems to be reasonable and interesting for he physicalunderstanding.The simulation contains the three materials: original concrete target, damaged concretetarget and the high strength steel penetrator case. The high strength steel is described with aJohnson Cook model for the deviatoric strength behavior. Very important is the material description of concrete. For this purpose the RHT model, developed at EMI is used .Concrete has the following experimental material properties:∙ Tensile strength is 1/10 of compressive strength∙ Shear strength is pressure dependent∙ Damage development (failure surface depends on damage due to preloading)∙ Porosity and existence of micro cracks between mortar and aggregatesThe description of these phenomena requires a complex model for the characterization of concrete. The EMI RHT model includes the static as well as the dynamic range and thus can be used for the penetration processes of KE penetrators.The following gives a short summary of the main properties of the model:∙ Porous equation of state∙ Limit surfaces pressure dependent (elastic, failure and residual strength)∙ Limit surfaces depend on all 3 invariants of stress tensor∙ Strain rate effectsFig.5 shows the schematic location of the different limit surfaces in the stress space especially the change of the failure surface due to damage development. Damage occurs as soon as the failure surface in the stress space is reached during a loading process. In the uniaxial compression test damage occurs in the stress strain diagram in the region following the maximum compression stress. The material behavior is then characterized by macroscopic crack development. The following phenomena have to be described:∙ Reduction of the failure surface with increasing damage (material with a complete damage can not sustain any tensile stresses any more)∙ Reduction of elastic constantsIn the following the presented modeling parameters are varied and their influence on the KE penetration depth is analyzed.SIMULATION RESULTSThe simulation variants analyzed are shown in fig.6. The reference case is simulation 1 with the original undamaged concrete target. Varied is the crater profile (simulation 2 and 7)and the damaged area around the crater (spatial extend and damage level, simulations 3 to 6 and 8 to 12). In addition a simulation 13 was performed with a semi infinite target to get information about the influence of the target size on the penetration performance.Influence of the crater diameter: fig.7 shows the penetration depth of the KE projectile as a function of the crater radius on the impact surface. The penetration depth from the simulation in the undamaged target is 1198mm (the corresponding experimental value is 1145mm). Modeling of the eroded crater profile (without damage in the region around the crater) gives an increase to 1251mm (crater radius 11.2mm) or 1404mm (crater radius22.4mm). Small hole diameters (compared with the projectile diameter) lead only to a small increase of the performance of the penetrator. Only hole diameters approaching half of the penetrator caliber significantly increase the penetration depth.Influence of strength reduction: fig.8 shows the penetration depth as a function of time for several simulations. Here the reference configuration 1 is compared with the simulation 6 where the model shows only a strength reduction (from 35MPa for the original concrete to10MPa for damaged concrete) but no crater hole in the target. The penetration depth increases from 1198mm to 1377mm. The increase is nearly as high as for simulation 2 with the crater profile modeled (penetration depth for simulation 2 is 1404mm). The strength reduction with a spatial extension of 2 penetrator calibers around the impacting projectile thus leads already to a significant performance increase.Combination of crater profile and strength reduction: fig.8 contains the simulations 1,3 and 4. This corresponds to the situation where crater profile and strength reduction occur together. The penetration depth increases from 1198mm (reference case) to 1458mm (simulation 3 with small damage area) and finally to 1467mm (simulation 4 with bigger damage area). Comparison with the former results shows that the combined effect leads to a relatively small additional increase of penetration.Material damage or crater hole alone give already most of the achievable performance gain. The combination shows an overmatch for the simulated configuration. Variation of the damage level from 10MPa to 5MPa gives an additional penetration depth increase (simulation 4 - 1467mm compared with simulation 5 - 1490mm). It is important to note that there is no linear addition of the contributions fromdamage and crater hole to the total penetration. The whole target damage in front of the penetrator determines the performance independent by which effect it is caused. If there is already a significant damage due to eroded material an additional material damage has only minor influence. On the other hand material damage alone is sufficient to increase the penetration depth significantly.Fig.6 Simulated crater profiles and damaged target areasInfluence of spatial extension of damage zone: the radial as well as the axial extension of the damage zone is varied. For the axial extension the two values of 637mm and 1000mm were selected. The crater hole profile itself was not changed. The dependence of the penetration on the radial extension of the damaged area is shown in fig.9. There is a sort of plateau formation at a radial distance of around 2 projectile calibers with a penetration increase of around 250mm. The 2 significantly lower values at the radial distance at 50mm correspond to the axial damage extension of 637mm.This shows the importance of the radial as well as the axial extension of the damaged target regions on the penetration.Fig.5 Schematic representation of Fig.7 KE projectile penetration aslimit surfaces of concrete a function of crater radiusFig.8 Time history of KE Fig.9 KE projectile penetration asprojectile penetration a function of damage radius Influence of target dimension: a final simulation 13 was done which modeled a target with semi infinite extension (simulated with corresponding boundary conditions). The penetration is 1104mm and has to be compared with the value of 1198mm from the reference simulation 1. It gives an impression of the expected variation of performance of KE projectiles in real targets where different impact conditions are found. The decrease of penetration is due to the higher confinement and the reduced effects from the target boundaries.SUMMARYThe performance of the precursor shaped charge in a tandem warhead systems leads to a weakening of target (formation of crater hole and material damage). The development of engineering codes for the description of the tandem system requires a detailed understandingof the separated effects. Therefore a finite element model was developed that is based on experimental results and includes an explicit modeling of the crater profile and damaged region around the crater. The model allows the parametric analysis of the target weakening on the penetration of the KE projectile.Following conclusions can be drawn:∙ The penetration depth increase of the penetrator is not a linear combination of eroded crater and damage around the crater. In the analyzed parameter range both effects alone lead nearly to the final penetration depth.∙ Penetration increases slowly with crater diameter and reaches significant contributions at crater diameter larger than half of the penetrator caliber.∙ The damage area (radial and axial extend) influences the penetration depth with the effects being strongly pronounced when the damage area is significantly larger than the penetrator caliber.REFERENCES1. N. Heider, S. Hiermaier, Numerical Simulation of the Performance of Tandem Warheads,Proceedings of the 19th International Symposium on Ballistics, 807-815, 20012.N. Heider, U. Günther, Modern Geopenetrators and Relevant Revision of Concrete Penetration Models, Proceedings of the 5th International Symposium on Structures Under Shock and Impact (SUSI), 807-815, 19983.K. Kleinschnitger, C. Mayrhofer, E, Schmolinske, Modellversuche mitKE-Penetratoren gegen Betonziele, Internal EMI Report E 8/94, 19944.W. Riedel, Beton unter dynamischen Lasten Meso-und makromechanische Modelle und ihre Parameter, Dissertation Universität der Bundeswehr, 143-166, 2000。

1.3.2.2“不用说I”才能出现的句式“不用说。

”可用于强调句式“是……的”中,“别说l”不能用于该强调句式中。

例如:(41)艾莉眼睛一红,她说:“宝珠欺负我,那是不用说的了,现在,连天培也欺负我。

”(42)我争得这个信任和权利,欢喜是不用说的,更重要的是,每月二十几元,一个人如何用得完?其中,“是”和“的”可同时省略。

两例中的“不用说l”都不能替换成“别说l”。

1.3.2.3“别说1”才能出现的句式“别说l”可用于“别说[有]多X”中,表示程度深,不用细说。

“不用说1”没有这种用法。

例如:(43)过去我们只能在电视里看到这些演员,现在这些真人就在我们面前演出,别说多高兴了。

”(44)平时为人别说多谦和,但认死理,敢说真话,敢同村里、乡里的头头脑脑平等地说话。

例(43)中的“别说多高兴”夸张地表达了“高兴”的程度之深,例(44)中的“别说多谦和”夸张地表达了“谦和”的程度之深。

两例中的“别说l”不能替换成“不用说】”。

另外,“别说l”还可以用于“x让/求/请/NY别说了”中。

例如:(45)例如,我在说件什么事的时候,他让我别说了,他告诉我女人不要唠叨。

(46)“别说了!”她哀求的喊:“求求你别说了吧!”(47)辛楣道:“请你别说了。

我想一个人打鼾不打鼾,相貌上看得出来。

”以上三例中的“别说1”不能替换成“不用况1”。

1.4小结综合本章分析可知,“不用说。

”作为动词短语使用。

意义上,“不用说,”可表示“不要说(话)”,表示“不需要说”;句法卜,“不用说l”可以单独成旬、充当句法成分,还可以用于强调句式“是……的”之中。

“不用说,”与同类短语“别说。

”,在使用上存在诸多共同之处。

语义方面,“不用说1”和“别说1”都可用于对话语境的祈伎句中,表示“不要说(话)”,劝阻或禁止对方的言说行为:“不用说1”和“别说1”与“更”合用,都可用来16第3章连词“不用说。

"的考察分析3.1汉语连词及其类别《现代汉语通沦(第二版)》指出,“连词的语法作用是把两个词、短语、分句或句子连接起来,以显示两者之问的逻辑关系”。

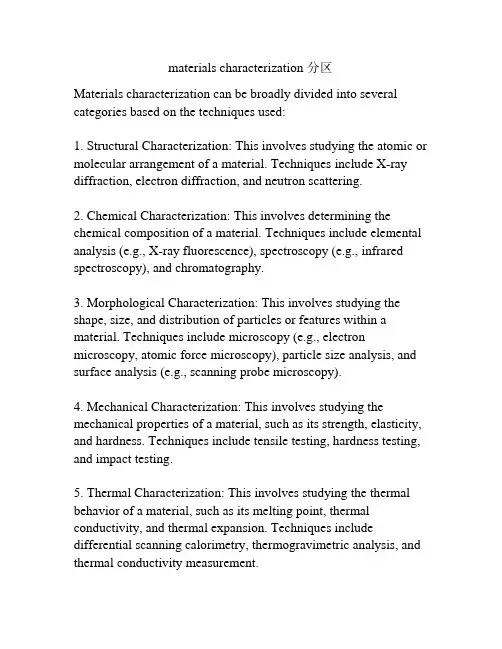

materials characterization 分区Materials characterization can be broadly divided into several categories based on the techniques used:1. Structural Characterization: This involves studying the atomic or molecular arrangement of a material. Techniques include X-ray diffraction, electron diffraction, and neutron scattering.2. Chemical Characterization: This involves determining the chemical composition of a material. Techniques include elemental analysis (e.g., X-ray fluorescence), spectroscopy (e.g., infrared spectroscopy), and chromatography.3. Morphological Characterization: This involves studying the shape, size, and distribution of particles or features within a material. Techniques include microscopy (e.g., electron microscopy, atomic force microscopy), particle size analysis, and surface analysis (e.g., scanning probe microscopy).4. Mechanical Characterization: This involves studying the mechanical properties of a material, such as its strength, elasticity, and hardness. Techniques include tensile testing, hardness testing, and impact testing.5. Thermal Characterization: This involves studying the thermal behavior of a material, such as its melting point, thermal conductivity, and thermal expansion. Techniques include differential scanning calorimetry, thermogravimetric analysis, and thermal conductivity measurement.6. Electrical Characterization: This involves studying the electrical properties of a material, such as its conductivity, resistivity, and dielectric constant. Techniques include electrical conductivity measurement, impedance spectroscopy, and dielectric spectroscopy.7. Magnetic Characterization: This involves studying the magnetic properties of a material, such as its magnetization, magnetic susceptibility, and coercivity. Techniques include magnetic susceptibility measurement, magnetometry, and Mössbauer spectroscopy.These are just some of the main categories of materials characterization, and there can be overlap between different techniques and methods depending on the specific material and property of interest.。

Materials Characterization是一个涉及多个学科领域的综合性研究领域,其目的是通过各种实验手段和理论分析,深入了解材料的组成、结构、性能和变化规律。

在Materials Characterization领域,根据不同的研究目的和实验方法,可以将该领域分为多个分区。

一、显微结构分析分区显微结构分析是Materials Characterization领域中最为基础和重要的一个分区。

该分区主要涉及光学显微镜、扫描电子显微镜(SEM)、透射电子显微镜(TEM)等实验方法,用于观察材料的微观结构和形貌。

通过这些实验方法,可以获得材料表面的形貌、相结构、晶体结构、化学成分等信息,从而对材料的基本性能和变化规律进行深入了解。

二、物理性能测试分区物理性能测试是Materials Characterization领域中最为常用的一个分区。

该分区主要涉及硬度、韧性、弹性、导电性、热学性能等实验方法,用于评估材料的各种物理性能。

通过这些实验方法,可以获得材料的基本物理性能数据,为材料的设计、开发和应用提供重要依据。

三、化学分析分区化学分析是Materials Characterization领域中不可或缺的一个分区。

该分区主要涉及元素分析、化学键分析、表面分析等实验方法,用于确定材料的化学组成和化学键结构。

通过这些实验方法,可以获得材料的化学成分、化学键结构和表面化学信息,为材料的合成、改性和应用提供重要指导。

四、光谱分析分区光谱分析是Materials Characterization领域中一个重要的分支领域。

该分区主要涉及红外光谱、拉曼光谱、紫外-可见光谱等实验方法,用于研究材料的分子结构和分子振动模式。

通过这些实验方法,可以获得材料分子的结构和振动信息,为材料的设计和开发提供重要依据。

五、热学分析分区热学分析是Materials Characterization领域中一个重要的分支领域。

Materials Characterization审稿意见IntroductionMaterials characterization is an essential aspect of scientific research and industrial applications. In this article, we will discuss the importance of materials characterization and explore various techniques used in the field. Additionally, we will address the key considerations for reviewers when evaluating materials characterization studies.Importance of Materials CharacterizationMaterials characterization plays a crucial role in understanding the properties and behavior of various materials. It involves the analysis and evaluation of the structure, composition, and physical properties of materials. By characterizing materials, scientists and engineers can make informed decisions about their applications and optimize their performance.Techniques used in Materials Characterization1. Scanning Electron Microscopy (SEM)SEM is a widely used technique for characterizing materials at high resolution. It uses a focused beam of electrons to scan the surface of a sample, providing detailed information about its topography, composition, and elemental analysis. SEM is particularly useful for studying microstructures, surface morphology, and particle distribution.2. X-ray Diffraction (XRD)XRD is a technique that analyzes the crystal structure of materials. It works by shining X-rays onto a sample and measuring the diffraction pattern produced. This pattern contains information about the arrangement of atoms in the material, allowing researchers to determineits crystal structure, lattice parameters, and phase composition. XRD is commonly used to identify crystalline phases and study phase transformations in materials.3. Fourier Transform Infrared Spectroscopy (FTIR)FTIR is a spectroscopic technique used to identify functional groups and chemical bonds in organic and inorganic materials. It measures the absorption of infrared radiation by the sample, providing a unique fingerprint that can be used for identification. FTIR is widely used in materials characterization to determine the presence of specificchemical groups, analyze molecular structures, and investigate surface properties.4. Thermal AnalysisThermal analysis techniques, such as differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA), are used to study thethermal behavior of materials. DSC measures the heat flow in a sample as a function of temperature, providing information about phase transitions, thermal stability, and thermal properties. TGA measures the weight loss of a sample as it is heated, allowing for the analysis of composition, decomposition, and moisture content.Key Considerations for ReviewersWhen evaluating materials characterization studies, reviewers should consider several key aspects to assess the quality and significance of the research. These considerations include:1.Sample Preparation: Reviewers should evaluate the adequacy of thesample preparation techniques used in the study. Proper samplepreparation is vital to obtain accurate and representative results.2.Characterization Techniques: Reviewers should assess thesuitability and reliability of the characterization techniquesemployed. The chosen techniques should be appropriate for theresearch objectives and should provide sufficient evidence tosupport the conclusions.3.Data Analysis: Thorough data analysis is essential for materialscharacterization studies. Reviewers should evaluate thestatistical methods, data interpretation, and conclusions drawnfrom the analysis. It is important to ensure that the conclusions are supported by the data presented.4.Reproducibility: Reviewers should consider the reproducibility ofthe results presented in the study. Materials characterizationstudies should provide sufficient information to allow otherresearchers to reproduce the experiments and obtain similarresults.5.Limitations and Future Directions: It is important for authors toacknowledge the limitations of their study and propose futuredirections for research. Reviewers should assess whether theseaspects are adequately addressed and if the study contributes tothe existing knowledge in the field.ConclusionMaterials characterization is an integral part of scientific research and technological advancements. By employing various characterization techniques, researchers gain insights into the properties and behavior of materials, leading to the development of new materials with enhanced functionalities. Reviewers play a crucial role in ensuring the quality and validity of materials characterization studies by thoroughly evaluating the sample preparation, characterization techniques, data analysis, reproducibility, and future directions of the research.。

ANDREW S. TANENBAUM 秒,约533 msec.----- COMPUTER NETWORKS FOURTH EDITION PROBLEM SOLUTIONS 8. A collection of five routers is to be conn ected in a poi nt-to-poi nt sub net.Collected and Modified By Yan Zhe nXing, Mail To: Betwee n each pair of routers, the desig ners may put a high-speed line, aClassify: E aEasy, M ^Middle, H Hard , DaDeleteGree n: Importa nt Red: Master Blue: VI Others:Know Grey:—Unnecessary ----------------------------------------------------------------------------------------------ML V Chapter 1 In troductio nProblems2. An alter native to a LAN is simply a big timeshari ng system with termi nals forall users. Give two adva ntages of a clie nt-server system using a LAN.(M)使用局域网模型可以容易地增加节点。

如果局域网只是一条长的电缆,且不会因个别的失效而崩溃(例如采用镜像服务-------------------------------------------器)的情况下,使用局域网模型会更便宜。

materials characterization分区-回复材料表征是研究材料性质和结构的一种关键技术。

它主要通过实验手段来分析材料的成分、结构、形态、性质和性能等方面的信息,并通过对实验数据的处理和分析,为材料设计、选择和应用提供重要依据。

本文将从材料表征的定义、分类和主要技术方法等方面一步一步回答。

一、材料表征的定义材料表征是指通过一系列实验手段来研究材料的基本性质和结构的过程。

它可以帮助科学家和工程师了解材料的组成、形态、微观结构以及相互作用等,从而揭示材料的性能和性质等方面的信息。

二、材料表征的分类根据材料表征的目的和研究对象,可以将其分为多个分类。

常见的分类方法包括:1. 成分分析:通过对材料中元素的定性、定量分析,确定材料的成分。

2. 结构表征:通过对材料的晶体结构、纳米结构、晶粒大小等方面进行观察和分析。

3. 形态表征:对材料的形貌、尺寸、孔隙结构等进行表征,了解材料的形态特征。

4. 物性测试:通过对材料的力学性能、电磁性能、热学性能等方面进行测试,揭示材料的性质特征。

三、材料表征的主要技术方法材料表征涉及多种实验手段和技术方法。

下面将介绍一些主要的技术方法:1. X射线衍射(XRD):用于分析材料的晶体结构和相组成。

2. 扫描电子显微镜(SEM):通过扫描样品表面,并利用电子束与样品相互作用产生的信号来观察样品形貌和表面特征。

3. 透射电子显微镜(TEM):用来观察材料的微观结构和纳米尺度的特征。

4. 能谱分析:如能量散射X射线光谱(EDX)和电子能谱(ESCA),用于分析材料的化学成分。

5. 热分析技术:如差示扫描量热法(DSC)和热重分析(TGA),用于研究材料的热性能和热稳定性。

6. 核磁共振(NMR):用来研究材料中的原子核和其周围的化学环境。

7. 红外光谱(IR):用于研究材料的分子结构和化学键等方面的信息。

8. 拉曼光谱:用于研究材料的晶格振动和分子振动等。

以上只是一些常见的材料表征技术方法,随着科学技术的发展,新的材料表征方法也在不断涌现。

聚酰亚胺复合材料的防辐射性能设计聚酰亚胺复合材料的防辐射性能设计王铎(陕西理工学院材料学院,汉中723001)文摘以聚酰亚胺,氧化锆及金属铅粉为主要原材料,制备了聚酰亚胺基复合材料,并进行了x一射线衍射,紫外射线分析.结果表明,聚酰亚胺/氧化锆+金属铅复合材料比纯聚酰亚胺具有更好的x一射线防护性能.耐热性能仍然很好.关键词金属铅粉末,耐热,X一射线衍射DesignofPolyimideofCompositeMaterialsforRadiationProtectionWangDuo(MaterialsCollege,ShaanxiUniversityofTechnology,Hanzhong723001) AbstractPolyimidecompositewasmadebyusingpolyimide,zirconia,asrawmaterialsandth esecompositewerestudiedbyX—raydiffractionanalysis&UV.Theresultsshowthatpolyimide/zirconia+leadhasbetter X-raypro-tectionperformancethanthepurepolyimide,anditsheatresistanceisalsoverygood. KeywordsLeadmetalpowder,Heat,X—raydiffraction0引言聚酰亚胺(PI)具有优良的热稳定性,耐化学腐蚀性,抗湿性,耐辐射性,机械性和介电性,在航天航空,电器,微电子工业,低温超导,气体分离,感光刻蚀中有广泛的应用¨.由于其结构和功能的特殊性,常被制成特殊材料而应用于以上领域各种苛刻的工作环境中,如:在HT一7U超导托卡马克核聚变实验装置国家"九五"重大科学工程项目和目前国际热核试验反应堆(ITER)等项目的超导磁体绝缘系统中都使用了大量的PI样品作为绝缘料.现代工业的发展对聚酰亚胺性能提出了更高的要求:既要有良好的热导率,线胀系数,介电常数,又要具有较高的力学性能及热稳定性.因此需对其改性.研究表明,PI在高温状态下,除能保持自身的优异性能外,其大分子自身的多孔结构有助于稳定纳米甚至是微米尺寸分散的颗粒,使其不易聚集成为可能,对合成复合材料十分有利.因此,将无机组分引入PI基体树脂中达到有机一无机性能的复合,成为目前以PI为有机体复合材料研究的一个热点[5-.ZrO化学性质稳定,具有良好的热化学稳定性,高温导电性和较高的高温强度及韧性,更具有良好的机械,热学,电学,光学性质,在受到温度梯度作用时能发生晶型转变,对提高材料韧性有较大的贡献,常被广泛地应用到冶金,电子,机械,航天航空,日化等领域j.铅尽管可引起人体中毒,但却可以很好地阻挡X一射线.本文将铅与ZrO同时与聚合物形成复合材料,以期研制出一种耐热型的防x射线的材料.1实验1.1主要原材料4,4'一二氨基二苯醚(ODA),化学纯,国药集团化学试剂有限公司生产;均苯四甲酸二酐(PMDA),化学纯,国药集团化学试剂有限公司生产;N,N一二甲基乙酰胺(DMAc),分析纯,成都科龙化工试剂厂生产;铅粉末(Pb)99.5%,200目,灰色粉末,北京怡天惠金属材料有限公司;ZrO,单斜晶系,分析纯,天津市耀华化学试剂有限责任公司生产.1.2原料的处理用铬酸洗液将研钵和棒杵浸泡,然后用大量清水冲洗,最后用蒸馏水清洗若干次,置于烘箱中烘干;将PMDA置于研钵中,用棒杵均匀研细后,放人称量瓶中置于220℃的烘箱中烘干4h,密封备用;将ODA放人经处理的研钵中研细后放人称量瓶中,置于80℃下烘干3h密封备用;向溶剂N,N'一二甲基乙收稿日期:201l一03—07作者简介:王铎,1971年出生,副教授,主要从事高分子材料方面的教学与研究工作.E—mail:********************宇航材料工艺http://www.yhclgy.tom2011年第5期酰胺中先加人金属镁粉,在20~(2的温度下反应2h后,静置,分层,将清液层移入磨口蒸馏瓶中进行蒸馏,馏分保存在洁净,干燥的容器中供下面实验用;将铅粉末与ZrO放人85~C的烘箱中加热6h后,放人干燥器中备用.1.3主要仪器设备红外光谱分析仪,VERTEX70型,德国布鲁克公司;紫外分光光度计,Cary50紫外分光光度计,美国瓦里安中国有限公司;X射线衍射仪,DX一2500,丹东方圆仪器有限公司:电子分析天平,GR200,日本;强力机械搅拌机,6511型,转速200~4000r/rain,上海标本模型厂;电热鼓风干燥箱,北京科伟永兴仪器有限公司101型.1.4材料的合成将一定量的ODA加入100mLDMAc中,制成溶液,并在强力搅拌下10min内分数次逐渐加入PM-DA,按摩尔比二酐:二胺=1.02:1,溶液黏度逐渐增大,继续搅拌12h,合成聚酰胺酸(简称PAA)胶体溶液.称取等量PAA若干份,分别按不加入物质,加入ZrO2,加入Pb,加入"ZrO2+Pb"后,强力搅拌2h,得到PI,PI+ZrO2,PI+Pb,PI+ZrO2+Pb等复合树脂,采用涂覆,流涎法在玻璃板上涂覆一定厚度的液膜,并置于室温下2h,再在电热鼓风机恒温箱中由20~C开始,以20℃/30min升温速率,在设定的每个温度下保持30min,直至200~C为止,使这些复合树脂固化成型,制得PI及复合材料样品,1为PI+Pb粉末;2为PI+2%ZrO2;3为PI+2%ZrO2+2%Pb粉末;4为PI.待冷却后,取出密封,待用.1.5测试与表征采用x射线衍射仪分析基体及复合材料的辐射吸收情况,测试条件:0[轴转动范围为一45.~90.最小转动步距0.001./步;轴转动范围:360.,最小转动步距0.005./步;轴转动范围为±8mm水平45.方向摆动;轴转动范围为10mm最小移动步距5p,m/ 步.利用Cary50紫外分光光度计对基体及复合材料进行测试分析,测试条件为,UV—VIS谱带宽度:<1.5 nm,杂散光:220nm(10LNalASTM法)<0.05%.波长范围:190—1100nm,波长准确度:±0.5nm (541.9nm),波长重复性:±0.1nm.2结果与讨论2.1X一衍射分析将PI及复合材料四种样品置于x射线衍射仪上进行测试实验,结果见图1所示.一38一图1PI及其复合材料样品的XRDFig.1XRDofPIanditscomposite由图1可见,4样品的X一射线衍射强度最强,3样品最弱,表明,无论从任何角度照射纯PI,X射线都能较好地从样品内部的晶格中衍射绕过而射出,但是在PI中掺入氧化锆和金属铅粉末后的样品(3样品)对x一射线有极差的衍射效果,即X一射线不能绕过样品晶格而出射,这是由于ZrO与影响了PI晶体的晶格排列及金属铅具有吸收X射线的特点双重原因所致.2及3样品表明,单靠ZrO或者铅在PI中均不能较好的阻止x一射线衍射而出射.2.2紫外测试分析样品在紫外光谱分析仪上的测试结果如图2所示.图2样品的UV测试Fig.2UVteatofthesamples图2表明,4样品对紫外吸收很差,不具有抗紫外辐射,掺人了ZrO与Pb的复合材料3样品的紫外吸收峰最大,对紫外线能很强地吸收,很显然1样品与2样品没有ZrO与Pb共同存在时对紫外线的吸收能力强.2.3耐热性能测试取相同大小的l~4样品各一块,置于热重分析仪上进行测试(图3).PI+2%ZRO2+2%Pb复合材料分解推迟于PI基体,即使Pb受热会氧化,还会增重,Pb/PI复合材料分解温度似乎会更高,热失重会更慢些,但因Pb仅为2%(很少)引起的分解温度滞后极小,不能成为分解滞后的主要因素,可见,该样品材料具有较好耐热性能,而PI+2%ZrO2及PI+2%Pb样品同未掺杂的基体宇航材料工艺http://www.yhclgy.corn2011年第5期样品相比较,杂化复合材料的耐热性能好,热分解温度有所提高,这是由于无机粒子与PI相互作用,使分子主链运动受阻,柔性减少,从而提高了耐热性能,但二者耐热性能均低于PI+2%ZrO+2%Pb材料,这是由于ZrO:与Pb双重作用原因引起的.340202003004005006o07008009oolOOO£,℃图3样品的TG测试Fig.3TGtestofthesamples3结论(1)利用化学合成法与选定的原料配比成功制出了PI及PI+ZrO+Pb等复合材料.(2)ZrO:与Pb能够成功的改进PI晶格结构,使得这种复合材料1能够限制x一射线而衍射出来,能够起到保护对象受x一射线的辐射作用.(3)"PI+ZrO+Pb"复合材料对紫外线具有较强的.址(上接第17页)3结论对复合材料飞机结构在设计和合格审定中涉及的材料许用值和设计许用值的确定原则和方法进行了全面,系统的讨论,给出了复合材料结构材料许用值和设计许用值的确定方法,阐述了材料许用值的表征和应用,试验以及试验数据的统计分析方法,并对静强度,疲劳强度,损伤容限和修理设计许用值的确定方法进行了分析.参考文献[1]沈真.复合材料飞机结构设计许用值及其确定原则[J].航空,1998,19(4):385[2]沈真,柴亚南,杨胜春,等.复合材料飞机结构强度规范要点概述[J].航空,2006,27(5):784[3]沈真,陈普会,唐啸东,等.复合材料结构设计值和冲击损伤容限许用值[J].航空,1993,14(12):B575[4]沈真,陈普会,杨胜春,等.复合材料结构设计许用值和韧性树脂评定技术[J].结构强度,2001(4):1[5]沈真,杨胜春,陈普会,等.复合材料抗冲击性能和结构压缩设计许用值[J].航空,2007,28(3):561[6]WangJT,PoeCC,AmburDR,eta1.Residual strengthpredictionofdamagedcompositefuselagepanelwithR—curvemethod[J].CompositesScienceandTechnology,2006,66(14):2557宇航材料工艺2011年第5期吸收能力,从而因防止紫外线辐射而起到保护作用.参考文献[1]张亚丽,沈孝洪.聚酰亚胺/硝酸铅辐射防护材料的制备和性能研究[J].工程塑料应用,2010,38(2):7-11[2]吴小军,刘西强,占克军,等.聚酰亚胺共混和复合改性的研究进展[J].工程塑料应用,2009,37(2):19—21[3]张保坦,李茹,陈修宁,等.有机硅一聚酰亚胺类耐高温材料合成方法及应用述评[J].工程塑料应用,2010,38(2):11—14[4]王铎.聚酰亚胺/纳米碳化硅复合样品的制备及性能研究[J].绝缘材料,2007,40(2):7-9[5]刘秋萍,等.聚酰亚胺/硅石一钛酸钡纳米复合材料的制备与表征[J].陕西师范大学(自然科学版),2007,35(2):65—68[6]QiuwL,LuoYJ,ChenFT,eta1.Morphologyandsize—controlofinorganicparticlesinpolyimidehybridsbyusingSiO2一TiO2mixedo~de[J].ChineseJournalofPolymerScience,2003,44 (19):5821-5826[7]ChengBei,DingBeidao,ChengChuan,eta1.Microstruc—tureandcrystalorientationrelationshipofZrO2laminatedceramics [J].ActaMateriaeCompositaeSinica,2005,22(1):59—63[8]全仁夫,杨迪生,吴晓春,等.二氧化锆梯度复合羟基磷灰石生物材料的制备及其生物相容性[J].复合材料学报,2006,23(3):114—122(编辑任涛)『71AtaderoRA,KarbhariVM.Sourcesofuncertaintyand designvaluesforfield—manufacturedFRP『positeStruc—tures,2009,89(1):83[8]沈真,杨胜春,陈普会,等.复合材料抗冲击性能和结构压缩设计许用值[J].航空,2007,28(3):561[9]沈真,张子龙,王进,等.复合材料损伤阻抗和损伤容限的性能表征[J].复合材料,2004,21(5):140『10]positematerialsstrengthdetermi—nationwithinthecurrentcertificationmethodologyforaircraft structures[J].JournalofAircraft,2009,46(4):1365[11]中国航空研究院.复合材料飞机结构耐久性/损伤容限设计指南[M].北京:航空工业出版社,1995[12]DepartmentofDefense.Polymermatrixcomposite guidelinesforcharacterizationofstructuralmaterials[S].MIL- HDBK-17-3FCompositeMaterialsHandbook,2002,1 [13]中国航空研究院.复合材料结构设计手册[M].北京:航空工业出版社,2001r14]JeanRouchon.Certiticationofcompositeaircraft8true—tures:achievementsandchallenges『C]//The1International SymposiumOilAircraftAirworthiness.Beijing,2009 [15]赵渠森,杨国章,等编着.复合材料飞机构件制造技术[M].北京:国防工业出版社,1989(编辑任涛)一39—。

materials characterization分区-回复在材料科学和工程领域中,材料表征是一个关键的研究领域,它涉及到对材料进行详细的分析和评估,以了解其性质、结构和性能。

材料表征的目的是为了帮助工程师和科学家们更好地理解材料,并为材料设计和制备提供必要的依据。

在本篇文章中,我们将逐步回答关于材料表征的问题,从概念和方法到技术和应用。

第一步:什么是材料表征?材料表征是指通过各种技术和方法对材料进行分析和评估的过程。

这些技术和方法可以用来观察、测量和描述材料的结构、形貌、成分、物理性质和化学性质等。

它们可以揭示材料的微观和宏观特性,从而帮助我们理解材料的性能和行为。

第二步:为什么需要进行材料表征?材料表征对于材料科学和工程的发展至关重要。

了解材料的性质和行为有助于我们设计和制备更好的材料,并优化其性能。

通过材料表征,我们可以确定材料的物理性质、力学性能、热性能、电学性能、光学性能等,从而指导我们在各种应用领域中的材料选择和设计。

第三步:材料表征的方法和技术有哪些?材料表征涉及各种不同的方法和技术,以下是一些常用的材料表征技术:1. 光学显微镜和电子显微镜:用于观察材料的微观结构和形貌。

2. X射线衍射:用于分析材料的晶体结构和晶格参数。

3. 扫描电子显微镜(SEM)和透射电子显微镜(TEM):用于观察材料的结构和形貌,并提供高分辨率的图像。

4. 能量散射X射线光谱(EDX)和电子能谱(ESCA):用于分析材料的化学成分和元素分布。

5. X射线荧光光谱:用于定量分析材料中的元素含量。

6. 红外光谱(IR)和拉曼光谱:用于分析材料的分子结构和化学键。

7. 热重分析(TGA)和差示扫描量热分析(DSC):用于研究材料的热性能和热稳定性。

8. 磁性测试和电性测试:用于评估材料的磁性和电性能。

第四步:材料表征在哪些领域中有应用?材料表征在许多不同的领域中都有广泛的应用,包括但不限于以下几个方面:1. 材料研究和开发:通过材料表征,研究人员可以了解材料的结构和性能,指导新材料的设计和开发。

Classification of Materials(材料分类)Solid materials have been conveniently grouped into three basic classifications: metals, ceramics, and polymers. This scheme is based primarily on chemical makeup and atomic structure, and most materials fall into one distinct grouping or another, although there are some intermediates. In addition, there are three other groups of important engineering materials—composites, semiconductors, and biomaterials.译文:固体材料被便利的分为三个基本的类型:金属,陶瓷和聚合物。

这个分类是首先基于化学组成和原子结构来分的,大多数材料落在明显的一个类别里面,尽管有许多中间品。

除此之外,有三类其他重要的工程材料-复合材料,半导体材料和生物材料。

Composites consist of combinations of two or more different materials, whereas semiconductors are utilized because of their unusual electrical characteristics; biomaterials are implanted into the human body. A brief explanation of the material types and representative characteristics is offered next.译文:复合材料由两种或者两种以上不同的材料组成,然而半导体由于它们非同寻常的电学性质而得到使用;生物材料被移植进入人类的身体中。

Materials Characterization Materials Characterization Materials characterization is an essential process in the field of materials science and engineering. It involves the use of various techniques to study and understand the properties and behavior of different materials. In this essay, we will explore the importance of materials characterization, the techniques involved, and its applications in various industries. To begin with, materials characterization plays a crucial role in understanding the structure and properties of materials. By analyzing the composition, microstructure, and mechanical properties of materials, researchers can gain valuable insights into their behavior under different conditions. This knowledge is essential for developing new materials with improved properties and performance. There are several techniques used for materials characterization, including microscopy, spectroscopy, diffraction, and thermal analysis. Microscopy allows researchers to study the microstructure of materials at a microscopic level, while spectroscopy is used to analyze the interaction of materials with electromagnetic radiation. Diffraction techniques, such as X-ray diffraction, provide information about the crystal structure of materials, and thermal analysis helps in understanding the thermal properties of materials. The applications of materials characterization are diverse and far-reaching. In the field of manufacturing, materials characterization is used to ensure the quality and reliability of materials used in various products. For example, in the automotive industry, materials characterization is essential for developing lightweight and high-strength materials for vehicle components. In the aerospace industry, materials characterization is crucial for ensuring the structural integrity and performance of aircraft materials. Moreover, materials characterization is also important in the field of nanotechnology, where the properties of materials at the nanoscale are of great interest. By using advanced characterization techniques, researchers can study the behavior of nanomaterials and develop new applicationsin electronics, medicine, and energy. In addition, materials characterization plays a vital role in the field of biomaterials, where the interaction ofmaterials with biological systems is of utmost importance. By characterizing the surface properties and biocompatibility of materials, researchers can developimplantable materials for medical applications, such as orthopedic implants and tissue engineering scaffolds. In conclusion, materials characterization is an indispensable process in materials science and engineering. It provides valuable insights into the properties and behavior of materials, and its applications are diverse, ranging from manufacturing to nanotechnology and biomedical engineering. With the continuous advancement of characterization techniques, the future holds great potential for the development of new and innovative materials with superior properties and performance.。

第26卷第10期 岩 土 力 学 V ol.26 No.10 2005年10月 Rock and Soil Mechanics Oct. 2005收稿日期:2004-02-05 修改稿收到日期:2004-12-05 基金项目:国家自然科学基金资助项目(No.50379005);水利部科技创新基金资助项目(No.SCX2000-56)。

作者简介:曹茂森,男,1971年生,博士后,副教授,主要从事土木工程健康诊断与损伤机理研究。

E-mail:cmszhy@文章编号:1000-7598-(2005) 10―1570―05混凝土结构损伤的分形特征实验分析曹茂森1,2,任青文1,翟爱良2,张 静3(1.河海大学 土木工程学院,南京 210098;2.山东农业大学 水利土木工程学院,山东 泰安 271018;3.山东省引黄济青工程管理局,山东 济南 250013)摘 要:在物理模型试验中分析了混凝土结构损伤演化中的分形行为,揭示了混凝土结构的裂缝生长及表面裂缝分布具有分形特性,表明分形维可以定量描述表面裂缝分布。

利用分形几何学研究混凝土结构的损伤演化过程,证明了结构表面裂缝分布分形维与结构力学性能之间存在良好线性相关性,认为表面裂缝分形维可作为度量混凝土损伤程度的损伤特征因子。

与基于振动理论的损伤特征因子相比,这一新特征因子具有自己的一些特色和优势,为创建新的混凝土结构健康诊断和安全性评价方法体系提供了一条新途径。

关 键 词:混凝土结构;损伤;表面裂缝分布;分形特征 中图分类号:TV 554 文献标识码:AExperimental study on fractal characterization indamages of concrete structuresCAO Mao-sen 1,2, REN Qing-wen 1, ZHAI Ai-liang 2, ZHANG Jing 3(1.College of Civil Engineering, Hohai University, Nanjing 210098, China;2.College of Water Conservancy and Civil Engineering, Shandong Agricultural University, Tai’an 271018, China;3.Management Bureau of Water Diversion from the Yellow River into Qingdao of Shandong Province, Jinan 250013, China)Abstract: The fractal characterization in the evolving damages of concrete structures is studied based on physical model experiments. It is revealed that the surface-crack distribution of the damaged concrete structures takes on fractal behavior. This shows that fractal dimension is able to characterize the surface-crack distribution quantitatively. Then fractal geometry is employed to investigate the crack evolving process of concrete structures; and the relationships between the fractal dimension of surface-crack distribution and the mechanical properties of the damaged structures are discussed in detail. It is found that there exists a good linear correlation between the fractal dimension and the natural frequency, which shows that the fractal dimension of surface-crack distribution is able to act as a damage feature index to reflect the damage degree of concrete structures effectively. Compared with the conventional damage feature indices generated from vibration testing; this novel damage feature index is of some advantages and distinguishing features. It provides a promising approach to develop new technologies for structural health monitoring and safety evaluation. Key words: concrete structure; damage; surface-crack distribution; fractal characterization1 引 言现有土木工程安全性方面的工作多半属于结构可靠性评估,而结构损伤检测方面的研究还不够深入。

祖国正发展材料英语作文素材China's Flourishing Advancements in Material Science and Technology.China, the world's most populous nation, has emerged as a global powerhouse in scientific research and technological innovation. Among its numerous accomplishments, the nation's remarkable progress in the field of material science and technology stands out as a testament to its unwavering commitment to fostering scientific excellence.A Legacy of Innovation.China's journey in material science began in the ancient times, with the development of materials such as bronze, iron, and porcelain. These materials were instrumental in shaping China's history and culture, and they laid the groundwork for the country's future advancements in this field.In the modern era, China has continued to invest heavily in material science research. The country has established numerous state-of-the-art research facilities and universities, attracting some of the world's leading scientists and engineers. This investment has yielded impressive results: China is now a global leader in the development and application of a wide range of materials, including composites, nanomaterials, and biomaterials.Composite Materials.Composites are materials made from two or more constituent materials that combine to create a material with properties superior to those of its individual components. China has made significant contributions to the development of composite materials, particularly in the areas of carbon fiber and graphene composites.Carbon fiber composites are renowned for their exceptional strength-to-weight ratio and are widely used in aerospace, automotive, and sports equipment industries.China is now a major producer and exporter of carbon fiber composites, and its companies are actively developing new applications for these materials.Graphene composites, derived from the two-dimensional carbon material graphene, have attracted tremendousinterest due to their unique electrical, thermal, and mechanical properties. Chinese researchers have made significant breakthroughs in the synthesis and characterization of graphene composites, and they are actively exploring their potential applications in energy storage, electronics, and biomedicine.Nanomaterials.Nanomaterials are materials with at least one dimension measuring less than 100 nanometers. These materials exhibit novel properties that are not found in their bulk counterparts, making them promising candidates for a wide range of applications.China has emerged as a leading player in the field ofnanomaterial research. Chinese scientists have developed novel synthesis methods and characterization techniques for a variety of nanomaterials, including carbon nanotubes, metal oxides, and quantum dots. These materials are being explored for applications in optics, electronics, catalysis, and drug delivery.Biomaterials.Biomaterials are materials that are compatible withliving tissues and can be used for medical and dental applications. China has a strong track record inbiomaterial research, with a focus on developing materials for tissue engineering, regenerative medicine, and drug delivery.Chinese scientists have developed advanced biomaterials such as biodegradable polymers, bioactive ceramics, andbio-inspired materials. These materials are being used to create artificial organs, repair damaged tissues, anddeliver drugs directly to target sites.Environmental Sustainability.In addition to its focus on developing advanced materials, China is also committed to promoting environmental sustainability. The country has invested in research on green materials, such as biodegradable plastics and recycled materials. These materials help reduce waste and pollution, contributing to a more sustainable future.International Collaboration.China actively collaborates with international partners on material science research. The country has established joint research centers and partnerships with leading universities and research institutions around the world. These collaborations foster knowledge sharing and innovation, enabling China to remain at the forefront of material science advancements.Conclusion.China's remarkable progress in material science andtechnology is a testament to the country's commitment to innovation and scientific excellence. With its strong foundation in research and development, China is poised to continue making significant contributions to the field. The country's focus on advanced materials, environmental sustainability, and international collaboration will undoubtedly lead to even greater breakthroughs in the years to come, shaping the future of science and technology.。