兰州交通大学毕业设计

- 格式:doc

- 大小:35.50 KB

- 文档页数:2

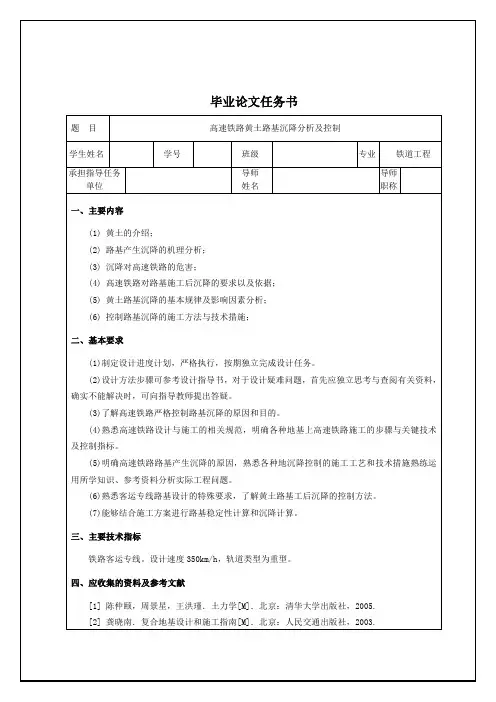

毕业论文任务书题目高速铁路黄土路基沉降分析及控制学生姓名学号班级专业铁道工程承担指导任务单位导师姓名导师职称一、主要内容(1)黄土的介绍;(2)路基产生沉降的机理分析;(3)沉降对高速铁路的危害;(4)高速铁路对路基施工后沉降的要求以及依据;(5)黄土路基沉降的基本规律及影响因素分析;(6)控制路基沉降的施工方法与技术措施;二、基本要求(1)制定设计进度计划,严格执行,按期独立完成设计任务。

(2)设计方法步骤可参考设计指导书,对于设计疑难问题,首先应独立思考与查阅有关资料,确实不能解决时,可向指导教师提出答疑。

(3)了解高速铁路严格控制路基沉降的原因和目的。

(4)熟悉高速铁路设计与施工的相关规范,明确各种地基上高速铁路施工的步骤与关键技术及控制指标。

(5)明确高速铁路路基产生沉降的原因,熟悉各种地沉降控制的施工工艺和技术措施熟练运用所学知识、参考资料分析实际工程问题。

(6)熟悉客运专线路基设计的特殊要求,了解黄土路基工后沉降的控制方法。

(7)能够结合施工方案进行路基稳定性计算和沉降计算。

三、主要技术指标铁路客运专线。

设计速度350km/h,轨道类型为重型。

四、应收集的资料及参考文献[1]陈仲颐,周景星,王洪瑾.土力学[M].北京:清华大学出版社,2005.[2]龚晓南.复合地基设计和施工指南[M].北京:人民交通出版社,2003.[3]池淑兰,孔书祥.路基工程[M].北京:中国铁道出版社,2002.[4]中华人民共和国铁道部.铁路路基设计规范TB10001—2005[S].2005.[5]范云.地基加固技术[M].石家庄:石家庄铁道学院,1999.五、进度计划第1-4周开题报告。

路基沉降机理及其危害分析,熟悉各种控制沉降的施工方法与技术措施;第5-8周控制沉降施工方法与技术措施经济技术比较,沉降监测方案设计。

撰写设计说明。

第9周整理、装订教研室主任签字时间年月日毕业论文开题报告题目高速铁路黄土路基沉降分析及控制学生姓名学号班级专业一、课题研究背景及国内外研究现状我国人口众多,随着中国经济的迅猛发展,城市化进程加快,我国铁路呈现客流量大、集中、行程长的特点。

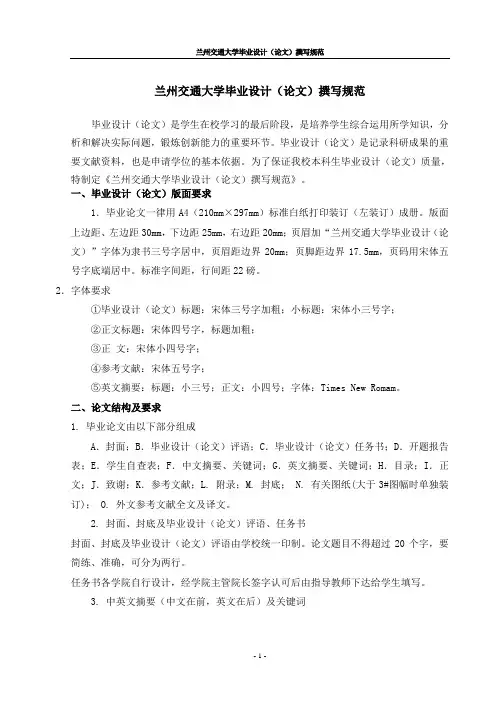

兰州交通大学毕业设计(论文)撰写规范兰州交通大学毕业设计(论文)撰写规范毕业设计(论文)是学生在校学习的最后阶段,是培养学生综合运用所学知识,分析和解决实际问题,锻炼创新能力的重要环节。

毕业设计(论文)是记录科研成果的重要文献资料,也是申请学位的基本依据。

为了保证我校本科生毕业设计(论文)质量,特制定《兰州交通大学毕业设计(论文)撰写规范》。

一、毕业设计(论文)版面要求1.毕业论文一律用A4(210mm×297mm)标准白纸打印装订(左装订)成册。

版面上边距、左边距30mm,下边距25mm,右边距20mm;页眉加“兰州交通大学毕业设计(论文)”字体为隶书三号字居中,页眉距边界20mm;页脚距边界17.5mm,页码用宋体五号字底端居中。

标准字间距,行间距22磅。

2.字体要求①毕业设计(论文)标题:宋体三号字加粗;小标题:宋体小三号字;②正文标题:宋体四号字,标题加粗;③正文:宋体小四号字;④参考文献:宋体五号字;⑤英文摘要:标题:小三号;正文:小四号;字体:Times New Romam。

二、论文结构及要求1. 毕业论文由以下部分组成A.封面;B.毕业设计(论文)评语;C.毕业设计(论文)任务书;D.开题报告表;E.学生自查表;F.中文摘要、关键词;G.英文摘要、关键词;H.目录;I.正文;J.致谢;K.参考文献;L. 附录;M. 封底; N. 有关图纸(大于3#图幅时单独装订); O. 外文参考文献全文及译文。

2. 封面、封底及毕业设计(论文)评语、任务书封面、封底及毕业设计(论文)评语由学校统一印制。

论文题目不得超过20个字,要简练、准确,可分为两行。

任务书各学院自行设计,经学院主管院长签字认可后由指导教师下达给学生填写。

3. 中英文摘要(中文在前,英文在后)及关键词兰州交通大学毕业设计(论文)撰写规范第一层次(章)和第二层次(节)题序和标题用宋体四号字加粗,题序和标题之间空两个字。

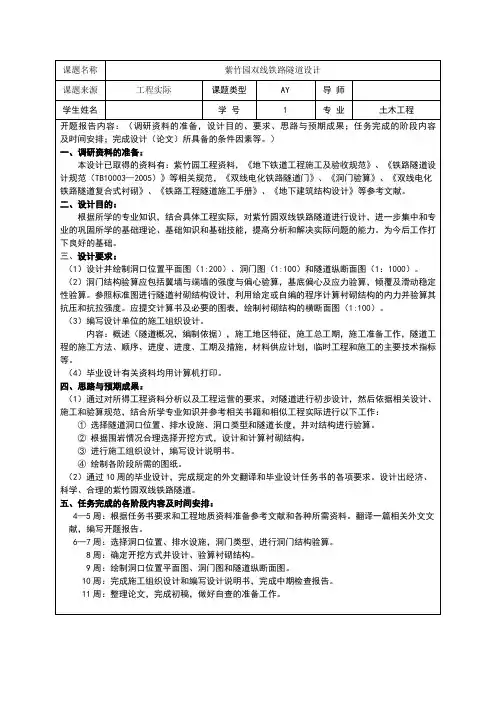

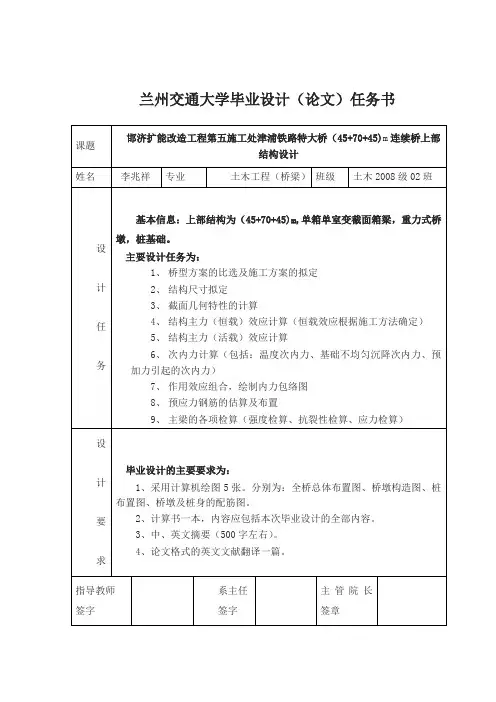

兰州交通大学毕业设计(论文)任务书兰州交通大学毕业设计(论文)学生自查表(中期教学检查用)指导教师签字:年月日兰州交通大学毕业设计(论文)开题报告表课题类型:(1)A—工程设计;B—技术开发;C—软件工程;D—理论研究;(2)X—真实课题;Y—模拟课题;Z—虚拟课题(1)、(2)均要填,如AY、BX等.摘要预应力混凝土连续梁是现在广泛使用的一种体系,主要适用于大跨度梁桥。

它具有变形小,结构刚度好,行车平顺舒适,伸缩缝少,养护简易,抗震能力强等优点。

而且采用了预应力筋,增加预应力筋能充分发挥高强材料的特性,具有可靠的强度、刚度和抗裂性能,耐久性强,材料可塑性强,便于建筑艺术处理,也容易满足桥梁曲线和坡度的要求。

当桥跨增大时,在荷载作用下,连续梁桥的中间节点截面处将承受较大的负弯矩,从绝对值来看,支点负弯矩远大于跨中正弯矩。

采用变截面梁(支点处梁高增大,跨中梁高减小,其间按曲线或折线过渡)更能适用结构的内力分布规律。

常采用悬臂法施工,变截面梁的受力状态与其施工时的内力状态基本吻合,更适用于大跨度预应力混凝土连续梁桥,其外形和谐,节省材料并可增大桥下净空,是大跨度桥梁的优选方案。

本设计包括上部结构尺寸的拟定、内力计算、配筋、验算、施工问题的研究等。

本设计题目为:三跨(45+70+45m)预应力混凝土变截面箱型连续梁桥。

它具有变形小,结构刚度好,行车平顺舒适,伸缩缝少,养护简易,抗震能力强等优点。

而且采用了预应力筋,增加预应力筋能充分发挥高强材料的特性,具有可靠的强度、刚度和抗裂性能,耐久性强,材料可塑性强,便于建筑艺术处理,也容易满足桥梁曲线和坡度的要求。

关键词:预应力、连续梁、上部结构、内力计算、配筋、验算、施工abstractPrestressed concrete continuous beam is now widely used a system, mainly is suitable for the large span bridge. It has little deformation, structure stiffness, driving smooth and comfortable, less expansion joints, easy maintenance, seismic ability, etc. And the tendons, increase tendons that can give full play to the characteristics of the high strength materials with reliable strength, stiffness and crack resistance, durability strong, material plasticity, facilitate architectural art processing, also easy to meet the requirements of the bridge curve and slope. When the bridge spans increases, the under load of continuous girder bridge for middle section of the node will bear larger in the negative moment, from absolute value perspective, the fulcrum in the negative moment far outweigh the cross CKS bending moment. The variable beam can be applied to the internal structure more distribution rule. Often the cantilever construction method, become beam's stress state and its construction of internal force of the state results, more suitable to the large span prestressed concrete continuous girder bridge, its appearance is harmonious, save material and can increase the obstacle clearance under the bridge, is the large span bridge optimization.This design including the upper structure size of the recommended, internal force calculation, reinforcement, checking and construction problems of the research, etc.This design topic for: three cross (45+70+45m) prestressed concrete continuous girder bridge variable cross-section of the box. It has little deformation, structure stiffness, driving smooth and comfortable, less expansion joints, easy maintenance, seismic ability, etc. And the tendons, increase tendons that can give full play to the characteristics of the high strength materials with reliable strength, stiffness and crack resistance, durability strong, material plasticity, facilitate architectural art processing, also easy to meet the requirements of the bridge curve and slope.Key words: prestress, continuous beam, the upper structure and internal force calculation, reinforcement, checking and construction目录第一章绪论 (1)一、桥的概念 (1)二、桥的意义与特点 (1)三、桥的产生与发展 (1)第二章桥梁方案比选 (4)一、拟定方案并进行方案比选 (4)1.比选原则 (4)2.方案 (4)3.方案比选及结果 (6)二、尺寸拟定 (8)1.横截面 (8)2.梁高与细部尺寸 (9)3.本桥主要材料 (11)4.悬臂浇筑施工程序 (12)5.设计计算依据 (15)6.基本设计数据 (15)第三章预应力混凝土连续刚构桥主梁内力计算 (17)一、建立有限元模型 (17)二、最大悬臂时内力计算结果 (18)1.恒载内力计算 (18)2.中跨合龙后的内力计算 (21)三、活载内力计算 (26)1.中活载max (26)2.中活载min (30)四、活载组合 (40)1.主力组合 (40)第四章预应力钢束的估算及布置 (50)一、钢筋的估算 (50)1.基本公式 (50)二、计算结果 (53)三、钢束布置 (55)1.布置原则 (55)四、钢束布置图 (56)1.钢束布置图 (56)2.张拉之后的内力组合 (58)第五章截面验算 (70)一、强度检算 (70)1.基本理论 (70)二、应力检算 (72)1.预应力损失所考虑的因素: (72)2.未扣除混凝土收缩徐变引起的损失时 (73)3.对不允许开裂的构件 (73)4.对边跨1/4截面验算: (73)5.对跨中截面 (74)结束语 (75)致谢 (76)参考文献 (77)第一章绪论一、桥的概念桥是一种架空的人造通道。

兰州交通大学毕业设计(论文)规范要求1、毕业论文组成论文由封面、毕业设计(论文)成绩评议表、毕业设计(论文)任务书、开题报告、中期检查、结题验收、中文摘要、英文摘要、目录、正文、参考文献、附录十二部分组成。

各种部分的格式详见附录;(1)封面:封面包括论文题目、学生姓名、班级等,格式详见附1;(2)成绩评议表:包括论文评语、论文成绩,由答辩委员会填写,格式详见附2;(3)任务书:由指导教师填写,在布置毕业设计时发给学生,格式详见附3;(4)开题报告:学生认真书写后交指导教师检查,经指导教师签字有效,格式详见附4;(5)中期报告:由学生认真书写,指导教师签字后有效,格式详见附5;(6)结题验收:由学生认真书写,指导教师签字后有效,格式详见附6;(7)目录:按三级标题编写,要求层次清晰,主要包括摘要、正文主要层次标题、参考文献、附录等;(8)摘要:中文摘要应在400 字左右,包括论文题目、论文摘要、关键词(3至5个),英文要与中文摘要内容要对应;(9)正文:论文正文包括绪论(或前言、概述等)、论文主体、结论。

工科论文要求符合科技论文格式,正文文字应在15000字以上;(10)参考文献:必须是学生本人真正阅读过的,以近期发表的杂志类文献为主,图书类文献不能过多,且要与论文内容直接相关;(11)附录:含外文复印件及外文译文、有关图纸、计算机源程序,如果有毕业实习,需提供毕业实习报告等。

2、毕业论文的格式要求(1)毕业论文要统一用a4(210mm×197mm)标准纸打印装订(左装订)成册,正文用宋或楷体小四号字,版面上空 2.5 cm,下空 2 cm,左右空2 cm(靠装订纸一侧增加0.5 cm空白用于装订)。

题目用三号(分两行书写时用小三号)黑体字;题序和标题用四号黑体字。

(2)论文中所涉及到的全部附图,不论计算机绘制还是手工绘制,都应规范化,符号符合国颁标准。

(3)学生完成毕业设计(论文)后,打印一份在xx年9月15日以前交指导教师评阅,进行结题验收。

兰州交通大学继续教育学院关于毕业设计(论文)若干问题的规定一、毕业设计(论文)的目的和任务毕业设计(论文)是教学计划规定的最后一个教学环节。

通过这一实践教学过程,帮助学生巩固所学知识,培养独立分析、解决实际问题的能力,全面提高学生的综合素质。

通过毕业设计(论文)教学过程(包括题目的选择、资料的查询、方案的制定、研究过程的总结、论文的撰写和答辩表述等)的综合训练,全面提高学生的专业理论水平和工程素质,培养学生独立解决现场实际问题的能力,为搞好本职工作和今后继续学习打下良好的基础。

二、毕业设计(论文)的选题1、毕业设计选题原则:⑴选题应符合专业培养目标和教学要求,使学生能够综合运用所学知识,受到比较全面的训练。

⑵紧密结合学生的本职工作,选择与生产、实际相结合的题目,以解决生产中存在的问题。

⑶题目类型可根据专业特点及指导教师与学生的不同条件选择。

可以是科研课题,工程设计、技术革新、设备调试、专题论述等形式。

⑷题目的难度和工作量要适合学生知识、能力和毕业设计所规定的时间,既要具有一定的水平,又要使学生在规定的期限内经过努力能按时完成。

⑸选题应考虑到学生综合能力的培养和训练,给学生充分发挥和施展才华的空间。

原则上一个学生一个题目,大课题也可以分成若干个子课题,由若干学生分担完成,但每个学生要对整个课题有全面的了解,且要明确每个学生应独立完成的任务,各有侧重,并有一定的工作量。

几个学生不得合搞完全相同且无法分工完成的题目。

2、毕业设计选题程序:学校公布指导教师提供的选题目录;学生根据自己的实际情况,选择适当题目或自荐论文题目根据学生志愿和教师意见,确定学生的毕业设计题目;报主管院长批准后向学生公布。

三、毕业设计(论文)的指导1.应选派教学水平较高、有一定实践经验的讲师或工程师及以上技术职称的教师或工程技术人员担任毕业设计(论文)的指导工作。

2.教师对指导的每位学生认真填写毕业设计(论文)任务书。

任务书的内容包括课题内容、基本要求、重点研究的问题、主要技术指标及其他要说明的问题(如进度要求、应达到的技术经济指标、参考资料等)。

文档编号:0000 115

优秀毕业设计

LANZHOU JIAOTONG UNIVERSITY

兰州交通大学毕业论文任务书

目录

目录. (2)

兰州交通大学(设计)论文任务书(模板一) (2)

兰州交通大学(设计)论文任务书(模板二) (6)

兰州交通大学(设计)论文任务书(模板三) (9)

兰州交通大学(设计)论文任务书(模板四) (10)

兰州交通大学(设计)论文任务书(模板五) (12)

兰州交通大学(设计)论文任务书(模板六) (14)

兰州交通大学(设计)论文任务书(模板七) (15)

兰州交通大学(设计)论文任务书(模板八) (17)

兰州交通大学(设计)论文任务书(模板九) (19)

兰州交通大学(设计)论文任务书(模板十) (21)

本文精选了兰州交通大学各个学院毕业(设计)论文任务书,总共10 个不同类别的任务书模板范文,都选自兰州交通大学同学的优秀毕业论文,包含各个专业类别的任务书,适合各个学院同学们撰写毕业设计论文时参考和研究。

撰写毕业论文是检验学生在校学习成果的重要措施,也是提高教学质量的重要环节。

大学生在毕业前都必须完成毕业论文的撰写任务。

申请学位必须提交相应的学位论文,经答辩通过后,方可取得学位。

愿此文能助毕业班同学们一臂之力,欢迎下载。

兰州交通大学(设计)论文任务书(模板一)

(包括原始数据、技术要求、工作要求)

5月20日:论文答辩

九、主要参考文献

主要参考文献

兰州交通大学(设计)论文任务书(模板二)

3•对本毕业设计(论文)课题成果的要求〔包括毕业设计论文、图表、实物样品等〕:。

摘要 (2)Abstract (3)第一章绪论 (4)§1.1 问题的提出 (4)§1.2 电力机车设备诊断系统研究的可行性 (4)§1.3 和国内外同类技术比较 (4)§1.4 作者所做的工作 (5)第二章总体方案设计 (6)§2.1 系统总体结构 (6)§2.2 系统总体功能 (7)§2.3 微处理器的选取 (8)§2.4 相关理论研究 (12)第三章数据采集单元硬件及软件设计 (26)§3.1 数据采集单元的总体设计 (26)§3.2 数据采集单元系统的电路设计 (27)§3.2 数据采集单元系统的软件设计 (43)第四章显示、通讯单元硬件及软件设计 (47)§4.1 显示、通讯单元的总体设计 (47)§3.1 显示、通讯单元的主要电路设计 (47)§3.3 显示、通讯单元的软件设计 (58)第五章电力机车设备诊断系统的使用 (62)§5.1 车载微机系统采集、处理的信号 (62)§5.2 电力机车设备诊断系统的使用 (63)§5.3 车载系统的人机接口 (66)第六章结论 (69)致谢 (70)参考文献 (71)附录作者简历 (73)摘要铁路大幅度提速对设备可靠性提出了更高的要求,相应的要求机务部门在机车的维修、维护上有更高的水平。

“电力机车设备诊断系统”的研制,就是使机务部门对机车上各设备的当前工作状态和未来发展趋势有充分的掌握,克服以往机车定修、大修存在的“易磨损部件不能及时更换,耐用部件更换过早”的问题,从真正意义上提高机车的维修质量。

“电力机车设备诊断系统”分为车载微机系统和地面计算机处理系统两个子系统。

车载微机系统应用最新的计算机及电子技术,实时检测机车各主要设备的状态参数,对参数做定时记录并实时显示各状态参数值;当检测到某设备工作不正常时语音报警,并根据系统自带的小型知识库,通过LCD显示故障的应急处理办法。

兰州交通大学毕业设计(论文)任务书课题大唐西固热电厂脱硫废水硫化物的测定及方法不确定度评价姓名任士明专业环境工程班级环工092设计任务随着兰州市城市化步伐的加快及社会经济的发展,原兰州市大唐西固热电厂脱硫废水硫化物的测定及方法不确定度评价已不能满足现有测定精度的要求,对硫化物的测定有对氨基苯胺分光光度法、碘量法、间接火焰原子吸收法、气相分子吸收光谱法等,目前《污水综合排放标准》(GB8978—1996)中规定我国国标规定硫化物测定方法有碘量法、对氨基苯胺分光光度法。

大唐西固热电厂脱硫废水具有一些特殊的性质,需要对其进行预处理,并在国标测定方法基础上进行改进,以期能够准确快捷的测定硫化物的含量,并对实验方法不确定度进行评价,给出方法的精确度灵敏度等。

设计进度:第一周—第三周(1.27~2.27):查阅文献,熟悉资料,了解水质监测实验的一般程序和步骤,查阅一篇与本毕业设计论文和相关的外文参考文献并翻译。

(不少于5000字符)。

第五周(2.28~3.28):做实验前期准备工作,配制相关实验试剂;并按照毕业设计任务书的有关要求和规定,完成“开题报告”,经教师严格检查合格后,方可实施毕业设计(论文)工作。

第六周—第七周(3.29~4.6):掌握实验相关仪器的使用方法。

在条件允许的情况下,进行现场调查,查阅基础资料了解项目所在地总体环境特征及经济发展现状。

第九周—第十周(4.6~6.15):对废水水样进行实验研究,开始撰写论文的框架体系和论文初稿;并认真填写“兰州交通大学毕业设计(论文)自查表”。

设计任务第十一周(4.30-5. 6):探讨实验中遇到的各种问题。

第十二周-第十三周(5.7-5.20):在实验的基础上,分析实验整体数据,进行必要的数据处理,认真撰写论文第十四周-第十五周(5.21-6.3):按照兰州交通大学毕业设计(论文)撰写规范,经补充修改后,论文整理定稿。

第十六周(6.4-6.10):积极认真准备,完成毕业答辩。

摘要本设计为预应力混凝土连续梁桥的设计,桥式布置为4 20m、连续空心板梁,梁高90cm,桥面宽度12。

5m;双柱式桥墩,桩基础。

本设计对该桥的上部结构做了设计与检算。

根据线路情况,全桥共设为4跨,有3个桥墩,两个桥台。

在上部结构设计中,根据设计要求进行拟定截面尺寸,分别计算结构恒载、活载内力,并进行荷载组合,确定出主梁的最不利荷载,进行预应力钢束的估算和布置并考虑各阶段的预应力损失,最后对控制截面进行强度、应力、抗裂性和挠度检算。

以上各项检算均满足相关规范要求。

本次设计所选方案合理,设计方法正确,设计和检算均采用Excel列表计算,并利用AutoCAD软件绘制了全桥总体布置图、主梁构造图、预应力筋布置图及桥墩构造图. 关键词:预应力;连续梁;空心板;荷载组合AbstractThis paper is the design of the PC continuous beam。

which is located at Jiuquan ,the4 20m spans and simply-continuous hollow slab —beams is laid to the form of the bridge, the height of the beam is 90 cm,the width of the pavement is 12.5 m, the pile foundation。

The upper rpart of the bridge are calculated in this design,basing on the condition of the line, there are four spans,three piers and two abutments on the bridge。

The dimension of the section is referred to the demand of the design,then the structure's dead load,live load and internal force is calculated, at the same time, the load is assembled,so the main girder’s most disadvantaged load can be decided, considering the each phase’s PC loosing,the PC Steels are generally calculated and arranged. Lastly, the control section’s strengthen,stress, crack resistance, deformation is calculated。

( 1. Faculty of Civil Engineering & Geosciences, Delft University of Technology , P. O. Box 5048,2600 GA Delft, t he Nether lands; 2. Key Laboratory of Silicate Materials Science and Engineering of the Ministry of Education, Wuhan University of Technology, Wuhan 430070, China)Abstract: Coal tar, a by- product from the destructive distillation of coal in co king oven, is widely used in road engineering for its excellent adhesion and fuel resistance properties, especially for pavement surface treatments in gas stations and airports.However, coal tar has a high Poly cyclic Aromatic Hydro carbons ( or PAHs) content, which makes it toxic.I n 1985, the International Agency for Research on Cancer ( IARC) has proved that coal tar is carcinogenic to humans. Research showed that Coal Tar- based Sealers ( CTS) contribute to the majority of PAHs pollution in the water environment. Because of this environmental concern, CT S are not allowed in many dev eloped countries in the USA and Europe. In contrast, coal tar is still used for road engineering in China and is even used increasingly .This paper gives a literature review on the general information and research about environmental concern of using coal tar in road engineering. Based on the review , some possible alternatives to replace coal tar are described. These alternatives include nanoclay/ epoxy modified bitumen/ bitumen emulsion and waterborne polyuret hane/ epoxy resin, which are environmental friendly. They have the potential to perform as w ell as CTS, and even better in some special applications.Key words:coal tar; pavement surface treatment; adhesion property; poly cyclic aromatic hydrocarbons; modified bitumen emulsionCLC number: U 416 Document code: A Article ID: 1671- 4431( 2010) 17- 0001- 07Received date: 2010- 05- 07.Biography : Xiao Y( 1986- ) , Ph D Candidate. E-mail: yue. xiao@1 introductionTwo basic types of binders are currently used in the pavement surface treatment market: coal tar-based and bitumen-based. At some places like g as stat ions and airports, coal tar-based surface sealers performed much better than bitumen-based sealers with regards to adhesion properties and chemical resistance. Coal tar-based have better resistance to petroleum oils and inorganic acids, and have better moisture resistance[ Austin, 2005] .Because of these out standing properties, CTS are widely used in road engineering for pavement surfacetreatment for many years. However, coal tar is a complex hydrocarbon mixture consisting of hundred of PAH[SCHER, 2008] . These PAHs are toxic and considered human carcinogens. Because of it s environmental unfriendly properties, coal tar is not allowed in most of the developed counties like the Netherlands. In the Netherlands,use of tar containing product s is not allowed since 20 years, with one temporary except ion for antiskid runways in airfields [ van Leest , 2005] . But after 2010, it w ill not be allowed for airport pavement application anymore. Compared to these bans, coal tar is still used for road engineering in China. China Coal Tar Industry Report mentioned that the coal tar consumption w ill be on the upward t rend [CCTIR, 2008] .Based on new technologies like nano technology and two-component technology, other materials are developed for pavement surface treatment and they perform w ell. Modified bitumen emulsions, which can be applied at low temperatures, were successfully used in South Africa, Australia and many other countries. Additives such as polymers ( SBS, SBR and EVA ) , clays ( illite, kaolinite and montmorillonite ) are known to improve the properties of bitumen emulsions in special road applications [ TRB-EC102, 2006;Xiao, 2010] . With the waterborne two-component technology, coating manufacturers can producehigh-performance sealers and achieve the same or better properties than solvent-based sealers. Furthermore, waterborne resins for coating s usually do not contain or just contain a small amounts of other solvent s, indicating that waterborne two component systems are environmental friendly. Epoxy modified bitumen w as originally developed in the late 1950s by Shell Oil Company as a material designed to withstand fuel exposure [ Thom, 2006] . After full curing , epoxy modified bitumen mixture has high temperature stability and strength, excellent fatigue, superior adhesion and rutting resistance.In this paper, a short literature review is given on the use and properties of CTS for pavement surface treatment and its environmental concern. After that several possible alternatives are discussed, such as nanoclay modified bitumen emulsion, epoxy modified bitumen, waterborne polyurethane/ epoxy resin. These alternatives may have good properties and are environmental friendly.2 Use and Advantages of Coal Tar Based SealersCoal tar-based products are used in many industries, for example pavement engineering, the building industry and medical treatment s. In pavement engineering , one of the largest applications is CTS.Coal tar can be used as a binder and filler in surface treatment formulations, and as a modifier for epoxyresin surface coating s. T he streets of Baghdad w ere the first to be paved with tar from the 8th century AD. Tar was a vital component of the first sealed, or tarmac roads. The first tar macadam road with a tar-bound surface was placed in 1848 out side Nottingham, England. In Washington D. C. some of thetar-bound surface courses have a service life of about 30 years.Coal tar is a very complex mixture of chemicals. It s molecular structure is quite different from bitumen.Some of the constituents are described as PAHs. Being stable in molecular structure, these chemicals are incompatible with oil and gas, and provide a barrier coat to protect asphalt surfaces against the destructive effects of petroleum based products and chemicals [Aust in, 2005] . CTS have a better chemical resistance than bitumen based, extremely low permeability to moisture and a high resistance to ultraviolet radiation. These properties make it ideally suited for parking areas w here concentrations of oil and gasoline leaks are prevalent, like gas stations, truck and bus terminals and airport s. CTS are used to extend the life and reduce maintenance cost associated with asphalt pavements, primarily in asphalt road pavement. They are typically used at airports for aprons, taxiways and runways. The Federal Aviation Administration Advisory Circular 150/ 5370-10A Standards for Specifying Construction of Airports include a requirement for pavement sealers that they should contain at least 35% coal tar in runway asphalt pavement.The reason for this requirement is that CTS have a much better resistance to jet fuel than bitumen-based sealers [Austin, 2005].3 Environmental ConcernGenerally, coal tars consist of a mixture of many organic compounds, like benzene, toluene, phenol, naphthalene, anthracite , and others. The risk assessment of coal tar is largely based on PAHs, especially on Benzo (a) pyrene . PAHs are the most relevant component s in terms of toxicity in coal tarproducts[ SCHER, 2008] .3. 1 Polycyclic aromatic hydrocarbonsPolycyclic aromatic hydrocarbons are also known as polycyclic aromatic compounds, polyaromatic hydrocarbons or as polynuclear aromatics. PAHs are a group of over 100 different chemicals consisting of carbon and hydrogen in fused-ring structures. T able 1 shows several typical chemical structures of PAHs. PAHs are highly toxic and harmful to human and ecosystem health [Austin, 2005] . The content of PAHs in coal tar increases as the carbonization temperature increases.3.2 Environmental riskIn 1985, IARC has pointed out that coal tar pitches are carcinogenic in humans [IARC, 1985] . In 2008,three scientific commit tees ( SCCP, the Scientific Commit -tee on Consumer Products; SCHER, the Scientific Committee on Health and Environmental Risks; SCEN IHR, the Scientific Commit tee on Emerging and NewlyIdentified Health Risks) concluded that cancer risk was the most serious point of coal tar s risk characterizations [ SCHER, 2008] . Occupational exposure to coal tar increases the risk of developing skin cancer and other tissue sites , like lung, bladder, kidney and digestive tract . According to the IARC, products that include more than 5 percent of crude coal tar are Group 1 carcinogen which has sufficient evidence of carcinogenicity in humans. So, many countries all over the world have eliminated it s usage.In 2003, scientist s from the city of Austin ( USA ) identified CTS as a significant source of PAHs contamination. The United States Geological Survey and Austin City have conducted additional research that corroborates this finding, concluding that coal tar sealants are responsible for the majority of PAHs pollution in water environment in the Austin area. Coal tar-based pavement sealers are considered as a source of urban water pollution. These are long-lasting substances that can build up in the food chain to harmful levels to humans. Based on their investigations, Austin became the first city in the USA to ban the use of CTS for pavements [ Austin,2005; Mahler, 2005] .As a precaution, in Germany, manufacturers have voluntarily agreed to ban coal tar from their product s. In the Netherlands, coal tar containing products did not meet the Dutch Environmental Standards and w ill not be allowed for airport pavement after 2010.4 Possible AlternativesAccording to these environmental concerns, alternatives are required. These alternatives should have atleast comparable or better properties than CTS. At the same time, they should be environmental friendly. In this section, the possible use of modified bitumen emulsions, epoxy modified bitumen and waterborne resins are discussed.4. 1 Modified bitumen emulsionsBitumen emulsions are heterogeneous systems with two or more liquid phases, consisting of a continuous liquid phase ( water ) and at least one second liquid phase ( bitumen) dispersed in the former as fine droplets [ TRB-EC102, 2006] . Standard bitumen emulsions are normally considered to be of the oil in water type and contain from 40% to 75% bitumen, 0. 1% to 2. 5% emulsifier, 25% to 60% water plus some minor components. The bitumen droplets rang e from 0. 1 to 20 micron in diameter.4. 1. 1 Properties of modified bitumen emulsionsUnlike bitumen, bitumen emulsions do not need to be heated at high temperatures before application. Temperature storage and application at ambient temperature can avoid the use of energy and emissions associated with heating and drying [Kennedy, 1997]. This makes bitumen emulsions more economic and environmental friendl , compared to coal tar-based products.Additives are used to improve the properties of bitumen emulsions in special road applications. Polymer( SBS, SBR and EVA) , clay illite , kaolinite and montmorillonite and epoxy modified bitumen/ bitumen emulsions were successfully used in South Africa and Australia [ TRB-EC102, 2006; Xiao, 2010] .During the application of bitumen emulsion, the water must be separated from the bitumen phase and evaporate.This separation is called breaking. After complete evaporation of the water, the bitumen particles will coalesce and bond together to develop mechanical properties. This strength development is curing.4. 1.2 nanoclay modified bitumen emulsionThe most preferred and widely used nanoclays are organically modified smectite clays with a 2: 1-type layey structure such as montmorillonite, saponite, etc [ Ammala , 2007] . All these layered silicates have the same crystalline structure and normally have a thickness of about 1 nanometer and a length of about 50 ~ 1 000 nanometers.In nanoclay modified bitumen emulsion, three possible particle dispersions can be distinguished as Fig. 1 shows [Xiao, 2010]. In the case of type one (see Fig. 1( a) ) , all the nanoclay particles are dispersed in the bitumen droplets. In this case, after breaking and curing the particles are dispersed in the binder between the aggregates. In the second type (see Fig. 1( b) ) , all of the nanoclay particles are dispersed in the water phase. After breaking and full curing, the particles are surrounding at the boundaries of the bitumen droplet s. The third type( see Fig. 1( c) ) is a combination of the first two types. Some of the particles are dispersed in the bitumen droplets while the others are dispersed in the water phase. In this condition, after breaking and curing the nanoclay particles both occur in the binder and between the bitumen droplets.These dispersion types have a significant influence on the properties of bitumen residues. Further investigations need to be carried on for checking these dispersions.Fig . 2 shows the possible outstanding properties of nanoclay modified bitumen emulsion on outside chemical resistance [Xiao, 2010] . With the unmodified bitumen emulsion after curing on the pavement surface, fuel, moisture and ultraviolet radiation can affect the binder directly. These can decrease the performance and cause raveling and ageing problems. When nanoclay modified bitumen emulsions are used for surface treatment, four steps can be dist inguished during breaking and curing. First, nanoclay modified bitumen emulsion consist s mainly of water, bitumen drop and nanoclay layers. Second, the water phase evaporates during the breaking and curing process. Then, bitumen droplets adhere to nanoclay particles, causing clusters to form the binder. At the last, binder is formed with nanoclay layers inside.The dispersed nanoclay particles can decrease surface damages due to fuel, moisture, air, etc. to a certain extent, resulting in better chemical and ageing resistance.4.2 Epoxy modified bitumensThe epoxy modified bitumen binder is a two phase chemical system in which the continuous phase is an acid cured epoxy and the discontinuous phase is a mixture of specialized bitumens, which makes the mixture performdifferent from a traditional asphalt mixture.4. 2. 1 Properties of epoxy modified bitumensEpoxy modified bitumen was used for pavement treatment long time ago and has achieved better properties than unmodified bitumen. In 1967, it was used to strengthen the surface of San Francisco Bay smile-long San Mateo-Hay ward Bridge. After more than 40 years, the bridge surface is reported to be in excellent condition.The special structure of epoxy modified bitumen makes it perform different from traditional bitumen. It does not become brittle at low temperature and does not melt at high temperature. Epoxy modified bitumen is a flexible material that can be applied in thin surface layers. When used on roads, it sets quickly enough to allow early traffic even before full curing, which enables the road to be reopened withintwo hours [ Xiao, 2010] .Epoxy modified bitumen is reported to be extremely durable as w ell as flexible. Surfaces with epoxy modified bitumen obtained better skid resistance and produce less noise than bitumen based sealers. Epoxy modified bitumen has extremely high temperature stability and strength, superior rutting resistance, excellent adhesion properties, high resistance to surface abrasion and is sufficiently fuel resistance [ Elliot t, 2008; Xiao, 2010] .4.2.2 Two-component epoxy modifiedbitumenTwo-component epoxy modified bitumen is acold mix application material. It is a two componentreactive material based on two components. One is amix of bitumen, bitumen-compatible epoxides andadditives. The other one is a mix of hardeners. After mixing of these two component s, there will be a fast react ion leading to epoxy resin within a bitumen based matrix.The tensile strength of Esha Seal 2C, which is a kind of two-component epoxy modified bitumen, obtained from ICOPAL BV, was evaluated using the Direct T ensile Test . Fig. 3 shows the tensile strengthafter different curing times and temperatures.Results indicate that the curing rate of epoxy modified bitumen emulsion depends on the curing temperature. The tensile strength increases with increasing curing time temperature . The tensile strength after full curing is higher than thetensile strength of bitumen, which implies that roads can be reopened for traffic very quickly w hen epoxy modified bitumens are applied in the surface layer.4. 3 Waterborne resinsWaterborne resins use water as the main volatile liquid component . It always shows good adhesion and the resistance to fuel, water and chemical is good. New technologies in waterborne systems provide unique technical solutions to get good properties, such as good adhesion to concrete and acidic resistance. With the waterborne two-component technology, coating manufacturers can formulate high-performance coatings without a cosolvent and achieve the same or better properties. Here waterborne polyurethane and epoxy resins will be discussed.4. 3. 1 Waterborne polyurethane resinsPolyurethane is a polymer consisting of a chain of organic units joined by urethane carbamate links. Polyurethane resins are formed from the reaction of an isocyanate with compounds containing active hydrogen, as Fig.4 shows. When the two components are mixed the hydroxyl groups ( - OH) in the resin react with the isocyanate groups ( N=C=O) in the hardener and a three dimensional molecular structure is produced[Weiss, 1997] .Because only one isocyanate group can react with one hydroxyl group, it is possible to vary the ratio of hydroxyl groups and isocyanate groups slightly either w ay in order to modify the mechanical properties of the system.Basically, waterbornepolyurethanes can be described asreactive or non-reactive polymerscontaining urethane and urea groupswhich are stabilized in water byinternal or external emulsifiers. Thesedifferent hydrophilic modify cationsallow the production of stablewaterborne polyurethanes with average particle sizes between 10 nm and 200 nm. Waterborne polyurethane resin is a water-based aliphatic polyurethane emulsion.Waterborne polyurethanes are environmental friendly. They provide a tough, durable and highly flexible binder. The advantages associated with polyurethane coatings are their high tensile strength, excellent adhesion properties and chemical/ mechanical resistance. Properties of waterborne polyurethanes can be improved by adding modifiers, such as organoclay layers [ Kim, 2003; Xiao, 2010] .Addagrip 1000 System resin is a two-component polyurethane resin designed by Addagrip Surface Treatments UK Ltd. It can be used for sealing to protect asphalt surfaces from erosion caused by frostdamage, chemical at tack and aviation fuel spillage. Areas treated over the last twenty years at military and civil air fields have prevented further deterioration and increased the service life of the concrete pavement by an estimated 10~ 15 years. Table 2 show s the properties of the samples before and after surface treatment with Addagrip 1000 System resin. 10 cm x 10 cmx10 cm blocks w ere used. The sample surfaces w ere heated and dried by a hot compressedair system before the resin w as sprayed onto the surface [Addagrip Ltd. ] . After surface reatment with this kind of polyurethane resin, the water and fuel resistance can be improved significantly.4. 3. 2 Waterborne epoxy resinsEpoxy is a copolymer. It is formed from two different chemicals, the resin and the hardener. Most common epoxy resins are produced from a reaction between Epichlorhydrin and bispheno-l A, see Fig.5[Weiss,1997] .Waterborne epoxy resin, with excellent adhesion properties, is another possible alternative. Waterborne epoxy resin is a stable resin material prepared by dispersing epoxy resin in the form of particles or droplet s into the dispersion medium based on water as a continuous phase.Application ofwaterborne epoxy resinsis not onlyconvenient but alsocauses no pollution tothe environmentand no harm to thehuman body. Afteradding a properamount of curing/ solidifying agent, advantages like high strength ,high-temperature resistance, chemical resistance, fatigue resistance, and high antiaging ability can be achieved [ Xiao, 2010; Weiss, 1997]5 ConclusionCTS are widely used for pavement surface treatments because of their excellent adhesion properties and good fuel resistance. How ever, because of their high PAHs content s, which are considered as human carcinogens, CTS are not allowed anymore in some of the developed counties. In order to eliminate the significant threat of pollution to our environment, w e should stop using CTS. Instead, modified bitumen emulsions, epoxy modified bitumen, waterborne polyurethanes and waterborne epoxy resins could achievecomparable or better properties than CTS. All of them have good adhesion, excellent chemical and ageing resistance. Epoxy modified bitumen has extremely high temperature stability and strength. Application of waterborne resins is convenient and the curing rate can be easily adjusted by changing the ratio of chemical components. And, the most important, these alternatives are environmental friendly.AcknowledgementsThe scholarship from the China Scholarship Council is acknowledged. T he authors would like to express thanks to ICOPAL BV for their materials and technical supports.References[1] AddagripLtd.www .adda grip [2] Ammala A, Hill A J.Poly( M-Xylene Adipamide)-Kaolinite and Poly( M-XyleneAdipamide)-Montmorillonite Nanocomposites [J] . Journal of Applied Polymer Science, 2007(104):1377- 1381.[3] Austin. http: / /www .ci. austin. tx . us/ watershed/ coaltar- ban. htm. Austin Bans Use of Coal Tar Sealants-first in Nation,2005.[4] CCTIR.China Coal Tar Industry Report 2006-2010.[R],2008.[5] Elliott R. 2008. Epoxy Asphalt: Concept and Properties. Workshop of TRB 2008.[6] IARC. Polynuclear Aromatic 4 Bitumens , Coal Tars and Der ived Products,Shale Oils and Soots. IARC Monographs on the Evaluation of Carcinogenic Risk of Chemicals to Humans,Vol. 35. Lyon, France:International Agency for Research on Cancer,1985.[7] Kennedy J. Alter native Materials and Techniques for Road Pavement Construction[R] . London: DOE Energy Efficiency Office,1997.[8] Kim B K, Seo J W, Jeong H M. Morphology and Properties of Waterborne Polyurethane/ clay Nanocomposite [J]. European[9] SCHER. Scientific Committee on Health and Environmental Risks. Coal tar pitch, high temperature Human Health Part. CAS No: 65996- 93- 2. EINECS No: 266- 028-2.[10] Thom N H. Asphalt Cracking: A Nottingham Perspective [J].Engenaria Civil/ Civil Engineering, 2006(26) : 75- 84.[11] TRB-EC102. Asphalt Emulsion Technology. Transportation Research Board[S], 2006.[12] Van Leest A J, Gaar keuken G. The F O D. Resistance of Sur face Layers on Airfields in the Netherlands; in Situ and Laboratory Testing [R] . 2005 European Airport Pavement Workshop, 2005. [13] Van Metre P C, Mahler B J. Trends in Hydrophobic Organic Contaminants in Urban and Reference Lake Sediments Across the United States, 1970- 2001[J]. Environmental Science and Technology,2005, 39( 15) : 5567- 5574.[14] Weiss K D. Paint and Coatings: A Mature Industry in Transition [J].Progress in Polymer Science, 1997, 22(2):203- 245.[15] Xiao Y. Literature Review on Possible Alternatives to Tar for Antiskid Layers . Delft University o f Technology, Road and Railway Engineering Section[R] . Report No.7-10-185-1,the Nether lands.。

OLED技术毕业设计摘要OLED 具有全固态、主动发光、高对比度、超薄、低功耗、无视角限制、响应速度快、低电压直流驱动、工作温度范围宽、易于实现柔性显示和3D 显示等诸多优点,将成为未来20 年最具“钱景”的新型显示技术。

同时,由于OLED 具有可大面积成膜、功耗低以及其它优良特性,因此还是一种理想的平面光源,在未来的节能环保型照明领域也具有广泛的应用前景。

本文将系统介绍OLED的发展背景、发展史、制备及应用,介绍了有机电致发光器件(OLED) 的结构和发光机理。

典型的传统OLED是生长在透明的阳极例如ITO玻璃上的,发射出来的光是由最底层衬底透出,这使得它与其他电子元件如硅基显示驱动器的集成变得非常复杂。

因此,理想的做法是研发一种OLED,其光的发射由器件顶部的透明电极透出。

重点介绍一种具有阴极作为底层接触层,阳极ITO薄膜作为顶部电极的表面发射型或者说有机“反转”的LED(OILED)。

介绍了该器件的制备工艺,对该OILED的I一V特性及EL谱进行了测试,发现与传统的OLED相类似,而工作电压有所升高,效率一定程度上降低。

为了进一步改善器件性能,我们对器件增加了保护层(PL),研究了PL对OILED器件性能的影响。

最后概述了器件的技术进展和应用前景, 并展望了未来OLED 发展的方向。

关键词:有机电致发光器件,有机反转电致发光器件,发光机理,保护层(PL),阳极ITO 薄膜AbstractOLED has a solid state, self-luminous, high contrast, ultra-thin, low power consumption, viewing angle, fast response, low-voltage DC drive, the operating temperature range, easy to implement many of the advantages of flexible displays and 3D displays will the future20 years of the most "moneylow power consumption, and other fine features, so an ideal plane light source, also has broad application prospects in the future of energy saving lighting in the area. In this paper, the systematic introduction of OLED development background, history of the development, preparation and application, the structure of the organic electroluminescent devices (OLED) and the luminescence mechanism.Typical traditional OLED is growth in transparent anode ITO glass, for example, the light is emitted by bottom gives fully substrate, this makes it and other electronic components such as that the integration of the silica based drive become very complex. Therefore, the ideal way is developing a OLED, its light emission from the top of the device gives fully transparent electrodes. Focuses on a cathode as the bottom contact layer, the anode of ITO films as the top electrode surface emission or organic LED of the "reverse" (OILED). Of the device preparation process, the OILED I-V characteristics and EL spectra of the test, found that similar to the conventional OLED, the working voltage was increased efficiency to a certain extent on the lower. To further improve the device performance of the device to increase the protective layer (PL), PL OILED device performance. Finally an overview of the technical progress and prospects of the device, and looked to the future OLED, the direction of development.Keywords:Organic Electroluminescent Devices,Organic reverse electroluminescent devices, Luminescence mechanism,Protective layer (PL), the anode of ITO films.目录摘要 (II)Abstract (III)目录 (IV)1.绪论 (1)1.1课题背景 (1)1.2 OLED技术的发展概况 (2)1.2.1 全球OLED发展史 (4)1.2.2 中国OLED发展状况 (5)1.2.3 OLED的应用 (6)1.2.3 OLED的制备 (6)2.有机电致发光器件 (8)2.1 引言 (8)2.2 有机电致发光器件 (8)2.3 有机电致发光器件的结构 (9)2.4 OLED发光机理 (10)2.5 我国发展OLED产业存在的问题及发展趋势 (13)2.5.1 存在的问题 (13)2.5.2 发展趋势 (14)2.6 结论及建议 (14)3.有机反转电致发光器件 (16)3.1 引言 (16)3.2 器件制备工艺 (17)3.2.1 基片的清洗及表面处理 (17)3.2.2 阴极的蒸镀 (17)3.2.3 有机层的成膜 (18)3.2.4 阳极的溅射 (18)/ PVK:TPD/PTCDA/ITO结构的有机反转电致发光器件的3.3 Si/Al/Alq3研究 (19)3.3.1 OILED的I一V特性及亮度测试 (19)3.4 保护层(PL)对器件性能的影响 (27)3.4.1 PL厚度对器件j一V特性的影响 (27)的影响 (29)3.4.2 PL对器件的最大驱动电流Im ax的影响 (30)3.4.3 PL对器件外量子效率qe3.4.4 PL对EL发射谱的影响 (30)3.4.5 顶电极(阳极)面积对载流子注入效率的影响 (31)3.4.6 PL层对器件最表面状态的影响 (32)4.OLED与OILED的特性及存在的问题 (34)4.1 与目前占主流地位的CRT及LCD技术相比,OLED与OILED具有以下更多的优点: (34)4.2 与OLED相比OILED的不同 (36)4.3 OLED与OILED 急待解决的问题和未来发展趋势 (36)结论 (39)5.致谢 (40)6.参考文献: (41)1.绪论1.1课题背景信息显示是信息产业的核心技术之一, 而信息显示技术及显示器件多种多样, 到目前为止,有四种发光物理机制完全不同的固态场致发光形式。

摘要随着我国铁路运输向高速和重载方向发展,转向架摇枕的运用条件日趋苛刻。

因此,研究重载运输条件下的摇枕结构及其性能变得尤为重要。

本文通过国内外重载运输的发展现状的了解,分析了国内外现有重载货车转向架的结构特点和性能。

首先对我国30t轴重转向架进行了结构选型,初步确定了适应我国国情的30t轴重货车转向架的基本结构型式。

重点对该转向架的摇枕的结构进行自主设计与分析。

运用SolidWorks建立30t轴重货车转向架摇枕的三维模型,并且详细介绍了该转向架摇枕的结构特点及设计步骤,其中包括了外壁和内部筋板厚度、排水口、漏沙孔等工艺孔、摇枕斜楔、15旁承台座、16弹簧承台、心盘部位、摇枕吊耳。

然后对该摇枕进行了有限元应力分析,然后根据分析结果确定摇枕的薄弱地方并进行改进,最终设计得到满足强度要求,并有足够抗疲劳性能的转向架摇枕。

关键词:重载货车;转向架;摇枕;设计;有限元分析AbstractWith the development of railway transportation in China to high speed and heavy, truck bolster conditions using the increasingly harsh.Therefore, studying under heavy haul bolster structure and performance has become particularly important. The current development status at home and abroad through the heavy haul transportation understanding, analysis of the structure characteristics and performance of the existing heavy truck frame at home and abroad to .The first of China's 30t axle load bogie structure selection, initially identified the basic structure frame of the axle load 30t China steering. The focus of the steering structure bolster frame of independent design and analysis.Use SolidWorks to set up 30t axle load truck steering frame bolster 3D model, and introduces the structure characteristics and design steps of steering frame bolster, including the outer and inner rib plate thickness, drains, drain sand hole technology of hole, bolster wedge, a side bearing pedestal, spring seat, center plate position, swing hanger lug. Then the bolster the finite element stress analysis, then bolster weak place and determined according to the analysis results, the final design can meet the strength requirements, and has enough fatigue performance of the bogie bolster.Key words: heavy-duty freight car; Bogie;Bogie Bolster; Design;The finite element analysis目录1 绪论------------------------------------------------------------------------------------------------- 11.1 选题背景---------------------------------------------------------------------------------- 11.2 国外重载车辆的现状------------------------------------------------------------------- 11.3 我国近年来重载车辆现状------------------------------------------------------------- 21.4 本文主要工作---------------------------------------------------------------------------- 22 国内外大轴重转向架的现状------------------------------------------------------------------- 32.1 国外大轴重转向架---------------------------------------------------------------------- 32.2 我国国内及出口大轴重转向架 ------------------------------------------------------ 53 转向架的结构选型------------------------------------------------------------------------------- 83.1 转向架选型原则------------------------------------------------------------------------- 83.2 转向架结构特点------------------------------------------------------------------------- 84 转向架摇枕的设计------------------------------------------------------------------------------104.1 大轴重转向架载重分析和损伤部位探究 -----------------------------------------104.2 转向架摇枕的三维结构设计 --------------------------------------------------------124.2.1 总体结构设计------------------------------------------------------------------124.2.2 外壁和内部筋板厚度的设计 -----------------------------------------------134.2.3 排水口、漏沙孔等工艺孔的设计 -----------------------------------------144.2.4 摇枕斜楔的设计---------------------------------------------------------------154.2.5 旁承台座的设计---------------------------------------------------------------164.2.6 弹簧承台的设计---------------------------------------------------------------174.2.7 心盘部位的设计---------------------------------------------------------------174.2.8 摇枕吊耳的设计---------------------------------------------------------------184.2.9 棱角的圆弧过渡设计 --------------------------------------------------------195 转向架摇枕的有限元分析---------------------------------------------------------------------215.1.1 有限元求解问题的思路及方法 --------------------------------------------215.1.2 转向架摇枕承受载荷情况分析 --------------------------------------------225.1.3 转向架摇枕使用Simulation进行有限元分析---------------------------235.1.4 转向架改进措施---------------------------------------------------------------275.1.5 本章小结------------------------------------------------------------------------27结论 ---------------------------------------------------------------------------------------------------28 致谢 ---------------------------------------------------------------------------------------------------29 参考文献---------------------------------------------------------------------------------------------301 绪论1.1 选题背景我们国家自从改革开放到现在,随着国民经济的一直深入的发展和人民生活水平的显著提高,我们对货物运输效率的要求也是越来越高了。

摘要猕猴桃酒是利用新鲜猕猴桃作为原料经发酵而成的果酒,Vc的含量非常高,可促进人体对铁的吸收,增强人体免疫力;富含氨基酸和肌醇,可以补充脑营养;此外它继承了猕猴桃鲜果的香甜口感,同时又增加了酒类产品特有的酒香。

猕猴桃兼有口感香甜、营养丰富、身体保健等多重功效。

目前,猕猴桃酒主要通过液体发酵生产,我国的猕猴桃市场增长快速,需求量较大。

随着猕猴桃市场的进一步发展,猕猴桃酒的需求还会进一步增加。

本设计是对年产1万吨猕猴桃酒厂的初步设计。

主要进行了猕猴桃酿造工艺的综述、工艺设计、物料衡算、设备选型和车间设计等方面的内容。

物料衡算时首先根据经验选取合理的参数,然后根据具体的工艺流程进行计算,进而对设备进行选择。

根据生产规模和工艺技术特点对工厂进行设计、对设备进行合理布局。

最后对本次设计进行初步的经济效益预估。

关键字:猕猴桃酒发酵工厂设计AbstractKiwi fruit wine is the wine that use fresh kiwi fruit as raw materials fermentation , with high content of Vc, it can promote the body's absorption ratio of iron, enhance the immunity of the human body. It rich in amino acid, inositol, can nourish the brain. in addition, it inherits the kiwi fruit sweet taste, while increasing the liquor products unique bouquet. Kiwi fruit has sweet texture, plenty of nutritious and other effects.At present, the production of kiwi wine mainly focused on liquid fermentation, the Chinese Kiwi market has rapid development, the market grow so fast and the demand is large.With the further development of the kiwi market, the demand for kiwi wine will continue increase.This design focus on the annual capacity of 10000 tons of kiwi fruit brewery. The main contents of this design are kiwi fruit brewing technology, process design, material balance, equipment selection and workshop design. Firstly, choosing reasonable design parameters and make the Material balance, then select equipment base on the process flow. According to the scale of production and technological characteristics designing factory and arranging equipment. Finally, estimate the economic performance of this design.Keyword:Kiwi wine Fermentation Factory design目录1 前言 (1)1.1 产品介绍 (1)1.1.1 产品背景 (1)1.1.2 产品概述 (2)1.1.3 果酒产品市场认知 (3)1.2 产品方案 (4)1.2.1 市场容量分析 (4)1.2.2 市场竞争地位分析 (4)1.3 生产工艺综述 (4)1.3.1 果酒类产品酿造工艺综述 (4)1.3.2猕猴桃酒的生产 (8)1.4 工厂建设 (11)1.4.1项目建设内容及建设地址选择 (11)1.4.2 主要性能指标、技术特点 (11)2 本项目采用的生产工艺 (15)2.1 工艺流程图 (15)2.2 工艺流程说明 (16)(1)原料选择 (16)(2)清洗 (16)(3)破碎 (17)(4)酶解 (17)(5)调整 (17)(6)补糖 (17)(7)接种量的控制 (17)(8)添加酵母 (17)(9)前发酵 (18)(10)榨汁 (18)(11)pH控制 (18)(12)温度的控制 (18)(13)后发酵 (19)(14)过滤 (19)(15)杀菌 (19)(16)储酿 (19)(17)调配酒液 (19)(18)下胶 (19)(19)精过滤 (20)3 全厂物料衡算及设备选型 (21)3.1 全厂物料衡算 (21)3.2 设备选型 (21)4 全厂总平面设计 (30)4.1 生产性辅助设施 (30)4.2 动力性辅助设备 (30)4.3 生活设施 (30)5 生产成本估算及成本回收 (32)5.1 生产成本估算 (32)5.2 成本回收 (33)6 本设计所存在的问题及前景 (34)6.1 本设计存在的问题 (34)6.2 本设计未来的前景 (34)结论 (35)心得体会 (36)致谢 (37)参考文献 (38)1 前言1.1 产品介绍1.1.1 产品背景(1)猕猴桃简介猕猴桃又名阳桃、奇异果、狐狸桃、藤梨等,属于猕猴桃科( Antinidiaceae)猕猴桃属( Antinidia),学名AntinidiaChinensisPlanch,原产于我国湖北省宜昌市夷陵区雾渡河镇,广泛分布于中国南方丘陵、山岭、低山区的山林中,一般多出现于高草灌丛、灌木林中。

兰州交通大学毕业设计(论文)工作管理规定毕业设计(论文)是本科各专业教学计划中最后一个重要的教学环节,是本科生获得学士学位的必备条件。

毕业设计(论文)在培养大学生探求真理、强化社会意识、进行科学研究基本训练、提高综合实践能力与素质等方面,具有不可替代的作用,是教育与生产劳动和社会实践相结合的重要体现,是培养大学生的创新精神和实践能力的重要环节。

同时,毕业设计(论文)的质量也是衡量教学水平、学生毕业与学位资格认证的重要依据。

为了进一步加强毕业设计工作,提高毕业设计的质量,提出如下意见:一、毕业设计(论文)的目的要求1. 通过毕业设计(论文)的教学过程,培养学生严肃认真的科学态度、严谨求实的作风、团结协作的品质、勇于探索和开拓创新的精神。

2. 教育学生树立科学的世界观,培养学生理论联系实际、实事求是、用实践检验理论的思想。

3. 培养学生利用文献、实验、生产实践和调查研究等方法获取知识的技能,提高学生综合运用所学知识独立分析和解决问题的能力。

4. 对学生掌握知识的广度和深度、运用知识处理问题的能力、实验能力、外语应用水平、计算机应用水平、科技写作能力、口头表达能力等进行综合考核。

二、毕业设计(论文)的组织管理全校本科生毕业设计(论文)工作在主管校长统一领导下,由校、学院、系(教研室)三级管理、组织实施。

1. 教务处职责(1)负责制定我校毕业设计(论文)管理规定,并对毕业设计(论文)工作进行统一管理、宏观指导。

(2)组织校级毕业设计(论文)督导组,对各学院毕业设计(论文)工作实行全程监控。

(3)与有关部门协调,解决经费、实验室、毕业设计场所等问题,为毕业设计(论文)工作的顺利进行提供保障。

(4)组织部署毕业设计(论文)检查和监督。

(5)组织对毕业设计(论文)工作的考核、总结、评估等。

2. 学院职责(1)贯彻执行学校毕业设计(论文)管理工作规定,根据本学院专业特点,制定毕业设计(论文)管理工作实施细则。

(2)组织有关系(教研室)根据学校统一部署,拟定本学院各专业毕业设计(论文)工作的计划和实施措施。