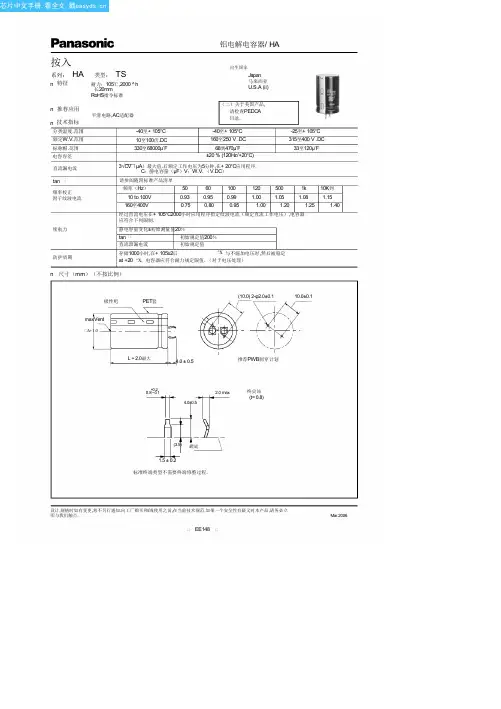

EI1808NPOSS-1中文资料

- 格式:pdf

- 大小:149.23 KB

- 文档页数:3

物料编号CC1808JKNPOEBN100参数_易容网

MLCC即是多层陶瓷电容片式,是电子信息产品不可或缺的基本组件之一。

我国MLCC的生产起步在80年代初,行业早期主要是在外资企业的带动下发展起来的,近年来国内企业在技术上实现突破,行业国产化成效显著,并推动了MLCC产量迅速增长。

目前,MLCC的应用领域已从手机、电脑、电视机等消费电子领域,逐步拓展到新能源发电、新能源汽车、节能灯具、轨道交通、直流输变电、三网融合、高清电视、机顶盒、手机电视等多个行业。

对于这个悄悄活跃在人们生活中的元件你又知道多少呢.

本次易容网为大家推荐比较常用的MLCC国巨 | Yageo品牌的料号CC1808JKNPOEBN100相关参数

易

容网是深圳市易容信息技术有限公司独自研发的全球最大的MLCC搜索采购服务网站,2014年创立于深圳市南山区,全国首家电子元器件行业电容元件的搜索引擎及o2o商务服务平台。

易容网()现已建成全球最大的MLCC电容搜索引擎数据库,包含全球25家电容生产厂商超过28万组MLCC产品数据,用户可根据行业应用、物料编号、规格参数等信息快速的找到所有相关的MLCC电容数据。

易容网在搜索服务的前提下还提供村田、TDK、国巨、太阳诱电、风华高科等常见品牌产品的o2o商务服务,让企业客户实现询价、报价、在线订单、出库、实时物流、签收、账期服务等在线一站式商务服务体验。

DS-K1808A系列读卡器用户手册法律声明版权所有©杭州海康威视数字技术股份有限公司2020。

保留一切权利。

本手册的任何部分,包括文字、图片、图形等均归属于杭州海康威视数字技术股份有限公司或其关联公司(以下简称“海康威视”)。

未经书面许可,任何单位或个人不得以任何方式摘录、复制、翻译、修改本手册的全部或部分。

除非另有约定,海康威视不对本手册提供任何明示或默示的声明或保证。

关于本产品本手册描述的产品仅供中国大陆地区销售和使用。

本产品只能在购买地所在国家或地区享受售后服务及维保方案。

关于本手册本手册仅作为相关产品的指导说明,可能与实际产品存在差异,请以实物为准。

因产品版本升级或其他需要,海康威视可能对本手册进行更新,如您需要最新版手册,请您登录海康威视官网查阅( )。

海康威视建议您在专业人员的指导下使用本手册。

商标声明• 为海康威视的注册商标。

•本手册涉及的其他商标由其所有人各自拥有。

责任声明•在法律允许的最大范围内,本手册以及所描述的产品(包含其硬件、软件、固件等)均“按照现状”提供,可能存在瑕疵或错误。

海康威视不提供任何形式的明示或默示保证,包括但不限于适销性、质量满意度、适合特定目的等保证;亦不对使用本手册或使用海康威视产品导致的任何特殊、附带、偶然或间接的损害进行赔偿,包括但不限于商业利润损失、系统故障、数据或文档丢失产生的损失。

•您知悉互联网的开放性特点,您将产品接入互联网可能存在网络攻击、黑客攻击、病毒感染等风险,海康威视不对因此造成的产品工作异常、信息泄露等问题承担责任,但海康威视将及时为您提供产品相关技术支持。

•使用本产品时,请您严格遵循适用的法律法规,避免侵犯第三方权利,包括但不限于公开权、知识产权、数据权利或其他隐私权。

您亦不得将本产品用于大规模杀伤性武器、生化武器、核爆炸或任何不安全的核能利用或侵犯人权的用途。

•如本手册内容与适用的法律相冲突,则以法律规定为准。

数据安全声明•您在使用产品的过程中,将收集、存储与使用个人数据。

HCPL-0601中⽂资料CAUTION: The small device geometries inherent to the design of this bipolar component increase the component's susceptibility to damage from electrostatic discharge (ESD). It is advised that normal static precautions be taken in handling and assembly of this component to prevent damage and/or degradation which may be induced by ESD.Small Outline, 5 Lead, High CMR, High Speed, Logic Gate Optocouplers Technical DataHCPL-M600HCPL-M601HCPL-M611DescriptionThese small outline high CMR,high speed, logic gate optocoup-lers are single channel devices in a five lead miniature footprint.They are electrically equivalent to the following Agilentoptocouplers (except there is no output enable feature):SO-5 Package Standard DIP SO-8 Package HCPL-M6006N137HCPL-0600HCPL-M601HCPL-2601HCPL-0601HCPL-M611HCPL-2611HCPL-0611The SO-5 JEDEC registered (MO-155) package outline does not require “through holes” in a PCB.This package occupies approximately one fourth the footprint area of the standard dual-in-line package. The lead profile is designed to be com-patible with standard surface mount processes.The HCPL-M600/01/11 optically coupled gates combine a GaAsP light emitting diode and an integrated high gain photon detector. The output of thedetector I.C. is an Open-collectorSchottky-clamped transistor. The internal shield provides a guaranteed common modetransient immunity specification of 5,000 V/µs for the HCPL-M601,and 10,000 V/µs for the HCPL-M611.This unique design provides maximum ac and dc circuit isolation while achieving TTL compatibility. The optocoupler ac and dc operational parameters are guaranteed from -40°C to 85°C allowing trouble free system performance.FeaturesSurface MountableVery Small, Low Profile JEDEC Registered Package OutlineCompatible with Infrared Vapor Phase Reflow and Wave Soldering Processes Internal Shield for High Common Mode Rejection (CMR)HCPL-M601: 10,000 V/µs at V CM = 50 VHCPL-M611: 15,000 V/µs at V CM = 1000 VHigh Speed: 10 Mbd LSTTL/TTL Compatible Low Input Current Capability: 5 mAGuaranteed ac and dc Performance overTemperature: -40°C to 85°C ? Recognized under theComponent Program of U.L.(File No. E55361) forDielectric Withstand Proof Test Voltage of 2500 Vac, 1MinuteThe HCPL-M600/01/11 are suitable for high speed logic interfacing, input/outputbuffering, as line receivers in environments that conventionalline receivers cannot tolerate, and are recommended for use inextremely high ground or induced noise environments.Outline Drawing (JEDEC MO-155)ApplicationsIsolated Line Receiver Simplex/Multiplex Data TransmissionComputer-Peripheral InterfaceMicroprocessor System InterfaceDigital Isolation for A/D, D/A ConversionSwitching Power Supply Instrument Input/Output IsolationGround Loop Elimination Pulse Transformer ReplacementPin Location (for reference only)SchematicUSE OF A 0.1 µF BYPASS CAPACITOR MUST BE CONNECTED BETWEEN PINS 6 AND 4 (SEE NOTE 1). V CC V OGNDTRUTH TABLE (POSITIVE LOGIC)LEDONOFFOUTPUT L H65431V CCV OUT GNDANODE 0.71 (0.028)UNDERSIDE OF THE PACKAGEDIMENSIONS IN MILLIMETERS (INCHES) * MAXIMUM MOLD FLASH ON EACH SIDE IS 0.15 mm (0.006) Recommended Operating ConditionsParameterSymbol Min.Max.Units Input Current, Low Level I FL *0250µA Input Current, High Level I FH 515m A Supply Voltage, Output V CC 4.55.5V Fan Out (R L = 1 k ?)N 5TTLLoads Output Pull-Up Resistor R L 3304,000?Operating TemperatureT A-4085°C* The off condition can also be guaranteed by ensuring that V F (off) ≤ 0.8 volts.Absolute Maximum Ratings(No Derating Required up to 85°C)Storage Temperature....................................................-55°C to +125°C Operating Temperature ..................................................-40°C to +85°C Forward Input Current - I F (see Note 2).......................................20 mA Reverse Input Voltage - V R .................................................................5 V Supply Voltage - V CC (1 Minute Maximum)........................................7 V Output Collector Current - I O ........................................................50 mA Output Collector Power Dissipation .. (85)mW Output Collector Voltage - V O ............................................................7 V (Selection for higher output voltages up to 20 V is available)Infrared and Vapor Phase Reflow Temperature.......................see belowMaximum Solder Reflow Thermal Profile.(Note: Use of Non-Chlorine Activated Fluxes is Recommended.)240TIME – MINUTEST E M P E R A T U R E – °C220200180160140120100806040200260Insulation Related SpecificationsParameter Symbol Value Units ConditionsMin. External Air Gap L(IO1)≥5mm Measured from input terminals (Clearance)to output terminalsMin. External Tracking Path L(IO2)≥5mm Measured from input terminals (Creepage)to output terminalsMin. Internal Plastic Gap0.08mm Through insulation distance (Clearance)conductor to conductor Tracking Resistance CTI175V DIN IEC 112/VDE 0303 Part 1 Isolation Group (per DIN VDE 0109)IIIa Material Group DIN VDE 0109 Electrical SpecificationsOver recommended temperature (T A = -40°C to 85°C) unless otherwise specified. (See note 1.)*All typicals at T A = 25°C, V CC = 5 V.Switching SpecificationsOver recommended temperature (T A = -40°C to 85°C), V CC = 5 V, I F = 7.5 mA unless otherwise specified.*All typicals at T A = 25°C, V CC = 5 V.Notes:1. Bypassing of the power supply line is required with a 0.1 µF ceramic disc capacitor adjacent to each optocoupler. The total leadlength between both ends of the capacitor and the isolator pins should not exceed 10mm.2. Peaking circuits may produce transient input currents up to 50 mA, 50 ns maximum pulse width, provided average current does not exceed 20mA.3. Device considered a two terminal device: pins 1 and 3 shorted together, and pins 4, 5 and 6 shorted together.4. In accordance with UL 1577, each optocoupler is proof tested by applying an insulation test voltage ≥3000 V RMS for 1 second(Leakage detection current limit, I I-O≤ 5 µA).5. The t PLH propagation delay is measured from 3.75 mA point on the falling edge of the input pulse to the 1.5 V point on the rising edge of the output pulse.6. The t PHL propagation delay is measured from 3.75 mA point on the rising edge of the input pulse to the 1.5 V point on the falling edge of the output pulse.7. CM H is the maximum tolerable rate of rise of the common mode voltage to assure that the output will remain in a high logicstate (i.e., V OUT > 2.0V).8. CM L is the maximum tolerable rate of fall of the common mode voltage to assure that the output will remain in a low logic state (i.e., V OUT > 0.8 V).9. For sinusoidal voltages, (|dV CM|/dt)max = πf CM V CM(p-p).10. See application section; “Propagation Delay, Pulse-Width Distortion and Propagation Delay Skew” for more information.11. t PSK is equal to the worst case difference in t PHL and/or t PLH that will be seen between units at any given temperature withinthe worst case operating condition range.Figure 5. Low Level Output Current vs. Temperature.Figure 4. Output Voltage vs.Forward Input current.Figure 1. High Level Output Current vs. Temperature.Figure 2. Low Level Output Voltage vs. Temperature.Figure 3. Input Diode Forward Characteristic.Figure 6. Test Circuit for t PHL and t PLH .I O H – H I G H L E V E L O U T P U T C U R R E N T – µAT A – TEMPERATURE – °C101550.4T A – TEMPERATURE – °C 0.30.1V O L – L O W L E V E L O U T P U T V O L T A G E – V0.2V F – FORWARD VOLTAGE – VOLTS10I F – F O R W A R D C U R R E N T – m A100I F – FORWARD INPUT CURRENT – mAV O – O U T P U TV O L T A G E – VI O L – L O W L E V E L O U T P U T C U R R E N T – m A T A – TEMPERATURE – °C60802040OUTPUT V O MONITORING NODEI FV F = 7.5 mAF = 3.75 mAFigure 12. Temperature Coefficient for Forward Voltage vs. Input Current.Figure 10. Rise and Fall Time vs.Temperature.Figure 9. Pulse Width Distortion vs.Temperature.Figure 8. Propagation Delay vs.Pulse Input Current.Figure 7. Propagation Delay vs.Temperature.Figure 11. Test Circuit for Common Mode Transient Immunity and Typical Waveforms.10080T A – TEMPERATURE – °C 600t P – P R O P A G A T I O N D E L A Y – n s402010590I F – PULSE INPUT CURRENT – mA7530t P – P R O P A G A T I O N D E L A Y – n s60454030T A – TEMPERATURE – °C20P W D – P U L S E W I D T H D I S T O R T I O N – n s10-10t r , t f– R I S E , F A L L T I M E – n sT A – TEMPERATURE – °Cd V F /d T – F O R W A R D V O L T A G E T E M P E R A T U R E C O E F F I C I E N T – m V /°C0.1110100I F – PULSE INPUT CURRENT – mA-1.4-2.2-2.0-1.8-1.6-1.2-2.4V O 0.5 VV O (MIN.)5 V0 V SWITCH AT A: I F = 0 mA SWITCH AT B: I F = 7.5 mAV CMCM HCM LV O (MAX.)V CM (PEAK)V O+5 VO GENERATOR Z O = 50 ?Propagation Delay, Pulse-Width Distortion and Propagation Delay Skew Propagation delay is a figure of merit which describes how quickly a logic signal propagates through a system. The propaga-tion delay from low to high (t PLH) is the amount of time required for an input signal to propagate to the output, causing the output to change from low to high. Similarly, the propagation delay from high to low (t PHL) is the amount of time required for the input signal to propagate to the output, causing the output to change from high to low (see Figure 7).Pulse-width distortion (PWD) results when t PLH and t PHL d iffer in value. PWD is defined as the difference between t PLH and t PHL and often determines the maxi-mum data rate capability of a transmission system. PWD can be expressed in percent by dividing the PWD (in ns) by the minimum pulse width (in ns) being transmitted. Typically, PWD on the order of 20-30% of the minimum pulse width is tolerable; the exact figure depends on the particular application (RS232,RS422, T-1, etc.).Propagation delay skew, t PSK, is an important parameter to consider in parallel data appli-cations where synchronization of signals on parallel data lines is a concern. If the parallel data is being sent through a group ofoptocouplers, differences inpropagation delays will cause thedata to arrive at the outputs of theoptocouplers at different times. Ifthis difference in propagationdelays is large enough, it willdetermine the maximum rate atwhich parallel data can be sentthrough the optocouplers.Propagation delay skew is definedas the difference between theminimum and maximumpropagation delays, either t PLH ort PHL, for any given group ofoptocouplers which are operatingunder the same conditions (i.e.,the same drive current, supplyvoltage, output load, andoperating temperature). Asillustrated in Figure 15, if theinputs of a group of optocouplers are switched either ON or OFF at the same time, t PSK is the difference between the shortest propagation delay, either t PLH or t PHL, and the longest propagation delay, either t PLH or t PHL.As mentioned earlier, t PSK can determine the maximum parallel data transmission rate. Figure 11 is the timing diagram of a typical parallel data application with both the clock and the data lines being sent through optocouplers. The figure shows data and clock signals at the inputs and outputs of the optocouplers. To obtain the maximum data transmission rate, both edges of the clock signal are being used to clock the data; if only one edge were used, the clock signal would need to be twice as fast.Propagation delay skew represents the uncertainty of where an edge might be after being sent through an optocoupler. Figure 16 shows that there will be uncertainty in both the data and the clock lines. It is important that these two areas of uncertainty not overlap, otherwise the clock signal might arrive before all of the data outputs have settled, or some ofthe data outputs may start tochange before the clock signalhas arrived. From theseconsiderations, the absoluteminimum pulse width that can besent through optocouplers in aparallel application is twice t PSK. Acautious design should use aslightly longer pulse width toensure that any additionaluncertainty in the rest of thecircuit does not cause a problem.The t PSK specified optocouplersoffer the advantages ofguaranteed specifications forpropagation delays, pulse-widthdistortion and propagation delayskew over the recommendedtemperature, and input current,and power supply ranges.Figure 15. Illustration ofPropagation Delay Skew – t PSK .Figure 13. Input Threshold Current vs. Temperature.Figure 14. Recommended TTL/LSTTL to TTL/LSTTL Interface Circuit. Figure 16. Parallel Data Transmission Example.I T H – I N P U T T H R E S H O L D C U R R E N T – m AT A – TEMPERATURE – °C452316V* DIODE D1 (1N916 OR EQUIVALENT) IS NOT REQUIRED FOR UNITS WITH OPEN COLLECTOR OUTPUT. CC 2I FV OI FV ODATAINPUTS CLOCKDATAOUTPUTSCLOCK/doc/9b0bff6d783e0912a2162a2e.html Data subject to change.Copyright ? 1999 Agilent Technologies Obsoletes 5091-9635E (10/93)5966-4942E (11/99)。

EPL-6200L产品基本介绍A U K L E T愛普生(中国)有限公司技術支援課 2003年10月Rev.A1概要 (4)1.1 上市时间 (4)1.2 市场参考价 (4)1.3 产品定位 (4)1.4 不同地区的名字 (4)2产品特点 (4)2.1 基本描述 (4)2.2 主要特点 (4)3产品比较 (4)3.1 与EPSON EPL-6100L的比较 (4)3.2 与EPSON EPL-6200的比较 (5)4基本规格 (6)4.1 纸张规格 (6)4.2 信赖性,可靠性和维护性 (6)4.2.1 信赖性 (6)4.2.2 可靠性 (6)4.2.3 维护性 (7)4.3 使用环境规格 (7)4.4 控制器基本规格 (7)5状态页说明 (8)6故障信息 (9)7特殊操作 (9)7.1 EEPROM初始化 (9)7.2 打印机调整(隐藏功能) (11)8耗材 (12)9维修信息 (12)9.1 维修服务 (12)9.2 保修期 (12)版本信息版本页项目描述原因---A ALL 首次发行 ---1 概要1.1 上市时间2003年9月1.2 市场参考价约RMB 2100 元1.3 产品定位经济型小型办公室A4幅面黑白激光打印机1.4 不同地区的名字名字地区EPL-6200L 日本之外的国家LP-1400 日本2 产品特点2.1 基本描述简洁轻巧的经济型A4幅面黑白激光打印机,适合小型办公或家庭使用。

2.2 主要特点1) 简洁轻巧的A4幅面黑白激光打印机。

2) 基于主机的打印机技术。

3) 数据压缩技术。

4) 20ppm高速打印。

5) 标配USB1.1接口。

6) 标配IEEE1284双向并行接口。

7) 硒鼓和碳粉既可分开又可以组装为一个整体的设计,既充分利用耗材又便于操作。

8) 碳粉盒有CSIC可自动识别碳粉容量和新碳粉。

9) 最高可达600dpi高清晰度。

10) 无分辨率增强模式。

11) 无300dpi模式。

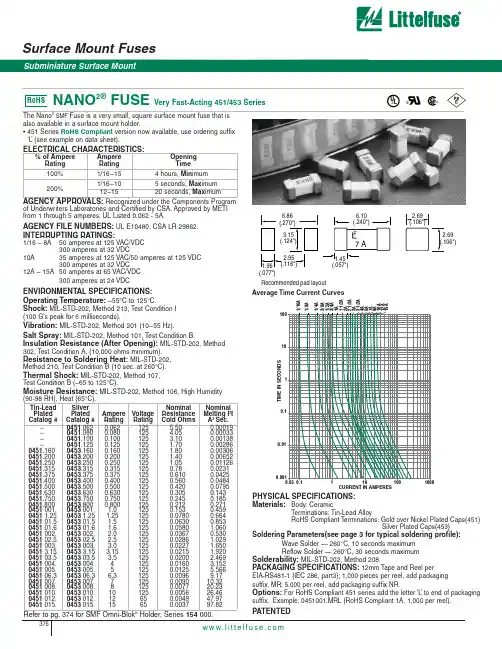

376Surface Mount Fusesw w w.l i t t e l f u s e.c o mNANO 2®FUSE Very Fast-Acting 451/453 SeriesThe Nano 2SMF Fuse is a very small, square surface mount fuse that isalso available in a surface mount holder.• 451 Series RoHS Compliant version now available, use ordering suffix ‘L ’(see example on data sheet).ELECTRICAL CHARACTERISTICS:% of AmpereAmpereOpening Rating Rating Time 100%1/16–15 4 hours, Min imum 200%1/16–10 5 seconds, Max imum12–1520 seconds, Max imumAGENCY APPROVALS:Recognized under the Components Program of Underwriters Laboratories and Certified by CSA.Approved by METI from 1 through 5 amperes.UL Listed 0.062 - 5A.AGENCY FILE NUMBERS:UL E10480, CSA LR 29862.INTERRUPTING RATINGS:1/16 – 8A50 amperes at 125 VAC/VDC 300 amperes at 32 VDC10A 35 amperes at 125 VAC/50 amperes at 125 VDC300 amperes at 32 VDC12A – 15A 50 amperes at 65 VAC/VDC300 amperes at 24 VDCENVIRONMENTAL SPECIFICATIONS:Operating Temperature:–55°C to 125°C.Shock:MIL-STD-202, Method 213, Test Condition I(100 G’s peak for 6 milliseconds).Vibration:MIL-STD-202, Method 201 (10–55 Hz).Salt Spray:MIL-STD-202, Method 101, T est Condition B.Insulation Resistance (After Opening):MIL-STD-202, Method 302, Test Condition A, (10,000 ohms minimum).Resistance to Soldering Heat:MIL-STD-202, Method 210, Test Condition B (10 sec.at 260°C).Thermal Shock:MIL-STD-202, Method 107, T est Condition B (–65 to 125°C).Moisture Resistance:MIL-STD-202, Method 106, High Humidity (90-98 RH), Heat (65°C).(.077")(.057")Recommended pad layoutTin-LeadSilver Nominal Nominal Plated Plated Ampere Voltage Resistance Melting I 2t Catalog #Catalog #Rating Rating Cold Ohms A 2Sec.–0451.0620.062125 5.500.00019–0451.0800.080125 4.050.00033–0451.1000.100125 3.100.00138–0451.1250.125125 1.700.002860451.1600453.1600.160125 1.800.003060451.2000453.2000.200125 1.400.006520451.2500453.2500.250125 1.050.011260451.3150453.3150.3151250.780.02310451.3750453.3750.3751250.6100.04250451.4000453.4000.4001250.5600.04840451.5000453.5000.5001250.4200.07950451.6300453.6300.6301250.3050.1430451.7500453.7500.7501250.2450.1850451.8000453.8000.8001250.2120.2710451001.0453001. 1.01250.1530.45904511.2504531.25 1.251250.07800.664045101.5045301.5 1.51250.06300.853045101.6045301.6 1.61250.0580 1.0600451002.0453002.2.01250.03670.530045102.5045302.5 2.51250.0286 1.0290451003.0453003.3.01250.0227 1.65004513.1504533.15 3.151250.0215 1.920045103.5045303.53.51250.0200 2.4690451004.0453004.41250.0160 3.1520451005.0453005.51250.0125 5.566045106.3045306.3 6.31250.00969.170451007.0453007.71250.009010.320451008.0453008.81250.007720.230451010.0453010.101250.005626.460451012.0453012.12650.004947.970451015.0453015.15650.003797.82®Refer to pg.374 for SMF Omni-Blok ®Holder, Series 154 000.RoHSAverage Time Current CurvesMaterials:Body:CeramicTerminations:Tin-Lead AlloyRoHS Compliant Terminations:Gold over Nickel Plated Caps(451)Silver Plated Caps(453)Soldering Parameters(see page 3 for typical soldering profile):Wave Solder — 260°C, 10 seconds maximum Reflow Solder — 260°C, 30 seconds maximumSolderability:MIL-STD-202, Method 208.PACKAGING SPECIFICATIONS:12mm Tape and Reel perEIA-RS481-1 (IEC 286, part3);1,000 pieces per reel, add packaging suffix, MR;5,000 per reel, add packaging suffix NR.Options:For RoHS Compliant 451 series add the letter ‘L ’to end of packaging suffix.Example:0451001.MRL (RoHS Compliant 1A, 1,000 per reel).PATENTEDU L。

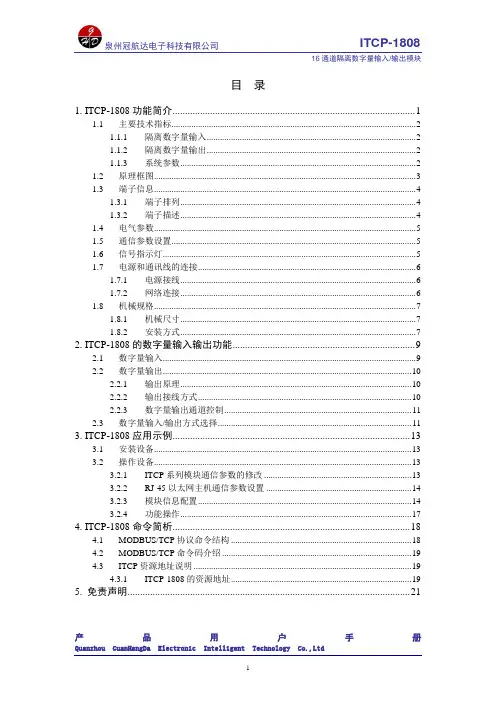

目录1. ITCP-1808功能简介 (1)1.1 主要技术指标 (2)1.1.1 隔离数字量输入 (2)1.1.2 隔离数字量输出 (2)1.1.3 系统参数 (2)1.2 原理框图 (3)1.3 端子信息 (4)1.3.1 端子排列 (4)1.3.2 端子描述 (4)1.4 电气参数 (5)1.5 通信参数设置 (5)1.6 信号指示灯 (5)1.7 电源和通讯线的连接 (6)1.7.1 电源接线 (6)1.7.2 网络连接 (6)1.8 机械规格 (7)1.8.1 机械尺寸 (7)1.8.2 安装方式 (7)2. ITCP-1808的数字量输入输出功能 (9)2.1 数字量输入 (9)2.2 数字量输出 (10)2.2.1 输出原理 (10)2.2.2 输出接线方式 (10)2.2.3 数字量输出通道控制 (11)2.3 数字量输入/输出方式选择 (11)3. ITCP-1808应用示例 (13)3.1 安装设备 (13)3.2 操作设备 (13)3.2.1 ITCP系列模块通信参数的修改 (13)3.2.2 RJ-45以太网主机通信参数设置 (14)3.2.3 模块信息配置 (14)3.2.4 功能操作 (17)4. ITCP-1808命令简析 (18)4.1 MODBUS/TCP协议命令结构 (18)4.2 MODBUS/TCP命令码介绍 (19)4.3 ITCP资源地址说明 (19)4.3.1 ITCP-1808的资源地址 (19)5. 免责声明 (21)1. ITCP-1808功能简介ITCP-1808是隔离数字量输入输出模块,支持16路数字量隔离通道,每个通道可以独立配置为输入或者输出;数字量输入支持开关触点信号和电平信号。

适用于采集工业现场的各种数字量信号,以及控制继电器等开关设备。

ITCP-1808模块的外观如图1.1所示。

图 1.1 ITCP-1808外观示意图1.1 主要技术指标1.1.1 隔离数字量输入♦输入路数:16路♦输入类型:开关触点信号或电平信号♦输入范围:高电平(数字1):+3.5 V~+50V低电平(数字0):≤+1V♦开关触点有效输入阻抗:≤1kΩ♦隔离耐压:2500 V DC1.1.2 隔离数字量输出♦输出路数:16路♦输出类型:集电极输出♦最大负载电压:50V♦最大负载电流:50mA♦隔离耐压:2500 V DC1.1.3 系统参数♦CPU:32位RISC ARM♦操作系统:实时操作系统♦供电电压:+10~+30V DC,电源反接保护♦工作温度范围:-20℃~+85℃♦工业级塑料外壳,标准DIN导轨安装♦通讯接口:隔离2500 V DC,ESD、过压、过流保护1.2 原理框图ITCP-1808模块的原理框图如图1.2所示。

PEX1000系列工业型条形码打印机使用者手册系列型号:PEX1120/ PEX1130/ PEX1160 PEX1220/ PEX1230/ PEX1260⏹ 热转式 ⏹ 热敏式版权声明©©2021 TSC Auto ID Technology Co., Ltd,本手册和手册中所述之条形码打印机软件和固件版权均归TSC Auto ID Technology Co., Ltd所有。

本手册提供购买设备的操作者参考和使用,未经明确的书面许可,不得为了其他目的使用、复制。

所有其他品牌名称、产品名称或商标,隶属于其他个别拥有者。

因持续产品的改进,故手册中所述的机种规格、配件、零件、设计及程序内容应以实机为主,如有变更,恕不另行通知。

TSC尽力确保手册内容正确无误,但错误在所难免。

TSC保留更正任何这类错误的权利,并声明不对因此所造成的后果负责。

I目录1. 打印机简介 (1)1.1 产品规格 (2)1.1.1 标准配备 (2)1.1.2 选购配备 (4)1.2 一般规格 (4)1.3 打印规格 (5)1.4 碳带规格 (6)1.5 纸张规格 (6)2. 产品介绍 (7)2.1 拆封与检查 (7)2.2 打印机方向 (8)2.3 检查安装空间 (9)2.4 打印机组件 (13)2.4.1 外观 (13)2.4.2 内部 (14)2.2.3 后部 (15)2.5.1 LED辅助警示灯和操作按键 (17)3. 安装 (19)3.1 安装打印机 (19)3.2 安装碳带 (20)3.3 安装标签纸 (24)3.4 剥纸模式装纸 (28)4. 调整钮 (32)4.1 碳带张力调整旋钮 (33)4.2 皱折解说及排除 (34)4.3 碳带张力调整建议 (37)5. TSC Console (39)5.1 启动TSC Console (39)5.2 新增以太网络接口 (41)5.3 设置Wi-Fi并新增至TSC Console接口 (43)5.4 初始化打印机的Wi-Fi模块(选配) (46)5.6 设置打印后动作 (48)6. 打印机内键功能(Menu) (49)6.1进入选单 (49)6.2 选单简介 (50)6.3 Setting (51)6.3.1 TSPL (52)6.3.2 ZPL (55)6.4 Sensor(传感器设置) (58)6.5 Interface(通讯接口) (59)6.5.1 Serial Comm(串行端口设置) (60)6.5.2 Ethernet(以太网络设置) (61)6.5.3 Wi-Fi (62)6.5.4 Bluetooth(蓝牙) (63)6.5.5 GPIO (64)6.6 Advanced(高级设置) (69)6.7 File Manager(档案管理) (71)6.8 Diagnostic(打印机诊断) (72)7. 故障排除 (78)8. 保养办法 (81)9. 安规认证 (83)10. 历史纪录 (89)1. 打印机简介感谢您对本公司所出品的条形码打印机的支持。

门禁产品系列(带"※"的产品有中性面盖)产品名称产品型号产品图片产品简介经济型单门门禁机CHD802A CHD802A无内置读头,可外接一个标准维根读头;不支持密码输入功能;CHD802B CHD802B内置EM读头,可外接一个标准维根读头;不支持密码输入功能;CHD802M CHD802M内置MIFARE读头,可外接一个标准维根读头;不支持密码输入功能;尺寸:L150mm×W100m×H28mm米白无键盘,仅指示灯提示工作状态;通讯地址通过8位拨码开关设定;※支持RS485/RS232/RS422等多种组网方式标准版单门门禁机CHD805AE CHD805AE无内置读头,可外接两个标准维根读头;不支持密码输入;CHD805BE CHD805BE内置EM读头,可外接一个标准维根读头;不支持密码输入;CHD805M CHD805M内置MIFARE读头,可外接一个标准维根读头;不支持密码输入;CHD805SCY CHD805SCY无内置读头,可外接两个标准维根读头;可外接密码键盘读头,支持ID+密码,刷卡加密码功能;尺寸:L150mm×W100mm×H28mm有键盘,6位LED数码显示,提示工作状态和操作步骤米白支持门磁、红外、手动、紧急输入,OC门报警输出;支持脱机增删卡、参数以及通讯设置(通过键盘)功能,可登记1700个不同用户,可保留最新记录6144条;※支持RS485总线方式通讯;标准版单门门禁机CHD806AE CHD806AE无内置读头,可外接两个标准维根读头;不支持密码输入;CHD806BE CHD806BE内置EM读头,可外接一个标准维根读头;不支持密码输入;尺寸:L167mm×W94mm×H25mm18键轻触键盘,拉盖隐藏设计,LED数码显示,提示工作状态和操作步骤米白/铁灰/黑支持门磁、红外、手动、紧急输入,OC门报警输出;支持脱机增删卡、参数以及通讯设置(通过键盘)功能,可登记1700个不同用户,可保留最新记录6144条;不支持中文显示功能;※支持RS485总线方式通讯中文显示单门门禁机CHD806ACE CHD806ACE无内置读头,可外接两个标准维根读头;不支持密码输入;CHD806BCE CHD806BCE内置EM读头,可外接一个标准维根读头;不支持密码输入;CHD806MCE CHD806MCE内置MIFARE读头,可外接一个标准维根读头;不支持密码输入;尺寸:L167mm×W94mm×H25mm米白/铁灰/黑18键轻触键盘,拉盖隐藏设计,LCD中文液晶显示,显示姓名和工作状态※支持RS485总线方式通讯中文显示单门门禁机CHD806BS内置EM读头,还可外接一个标准维根读头;不支持密码输入;(公模)尺寸:L120mm×W88mm×H18mm无键盘,有LCD中文带姓名显示,提示工作状态支持门磁、红外、手动、紧急输入,OC门报警输出;可登记3000多个不同用户,可保留最新记录近9000条(软件设置)标准RS485联网通信8位拨码开关SW1:用于选择门禁的通信地址码增强版单门门禁机CHD805AT无内置读头,可外接两个标准维根读头;不支持密码输入;尺寸:L250mm×W160mm×H44.5mm铁盒型,自带DC12V/3A电源※支持门磁、红外、手动、紧急输入,开关量(继电器)报警输出,可登记1700个不同用户,可保留最新记录6144条;支持脱机增删卡功能(增删卡按钮)支持RS485/RS422/RS232三种联网方式经济版单门门禁机CHD806AT 无内置读头,可外接两个标准维根读头;可外接密码键盘读头,支持ID+密码,刷卡加密码功能;尺寸:L178mm×W118mm×H50mm铁盒型,自带DC12V/3A电源小金属盒/小铁盒支持门磁、红外、手动输入,OC门报警输出;可登记445个不同用户,可保留最新记录2368条标准RS485联网通信8位拨码开关SW1:前七位用于选择门禁的通信地址码;第8位用于硬件增卡功能;经济版单门门禁机CHD8028BK CHD8028BK内置EM读头,可外接一个标准维根读头;可外接密码键盘读头,支持ID+密码,刷卡加密码功能;4为拨码开关设置通讯地址1-15;超过ID15可通过软件分配地址;CHD8028MK CHD8028MK内置MIFARE读头,支持ID+密码,刷卡加密码功能;不支持外接读卡器功能;设备地址通过软件分配;外形尺寸:128mm(长)X 84mm(宽)X 28mm(厚)彩色指示灯提示工作状态,自带防水键盘;支持门磁、红外、手动、紧急输入,OC门报警输出;可登记445个不同用户,可保留最新记录2368条标准RS485联网通信经济版单门门禁机CHD802AT CHD802AT无内置读头,可外接两个标准维根读头;可外接密码键盘读头,支持ID+密码,刷卡加密码功能;标准RS485通讯;CHD802A-E CHD802A-E无内置读头,可外接两个标准维根读头;可外接密码键盘读头,支持ID+密码,刷卡加密码功能;10M以太网通讯;尺寸:L150mm×W100m×H29mm支持门磁、红外、手动输入,OC门报警输出;可登记445个不同用户,可保留最新记录2368条;8位拨码开关SW1:前七位用于选择门禁的通信地址码;第8位用于硬件增卡功能;标准版双门门禁机CHD805DM2双门控制器,每门支持外接一标准维根读卡器(每门并接我司CHD601A读卡器,可实现进出刷卡),能控制两扇完全独立的门;不支持密码输入;尺寸:L150mm×W100mm×H28mm6位LED数码显示,提示工作状态和操作步骤米白可登记1700个不同用户,可保留最新记录6144条※支持独立门磁、红外、手动输入,公共紧急输入,独立OC报警输出;标准RS485组网通讯方式以太网双门门禁机CHD806D2双门控制器,每门支持外接两标准维根读卡器;能控制两扇完全独立的门;可外接密码键盘读头,支持ID+密码,刷卡加密码功能;支持RS485\RS422\RS232三种通讯方式;CHD806D2-E 双门控制器,每门支持外接两标准维根读卡器 ;能控制两扇完全独立的门;可外接密码键盘读头,支持ID+密码,刷卡加密码功能;支持10M TCP/IP、RS485\RS422\RS232四种通讯方式;尺寸:L200mm×W150mm×H19.5mm(可外配铁盒装)每门支持独立门磁、红外、手动输入,公共紧急输入,独立开关报警输出;用户注册卡数量:8000多张,记录存储量:30000多条;脱机支持"增删"(按钮)卡功能;CHD806D4四门控制器,每门支持外接一标准维根读卡器 (可通过并接CHD601A读卡器来实现进出刷卡);能控制四扇完全独立的门;可外接密码键盘读头,支持ID+密码,刷卡加密码功能;支持RS485\RS422两种通讯方式;CHD806D4-E 四门控制器,每门支持外接两一标准维根读卡器 (可通过并接CHD601A读卡器来实现进出刷卡);能控制四扇完全独立的门;可外接密码键盘读头,支持ID+密码,刷卡加密码功能;支持10M TCP/IP、RS485\RS422三种通讯方式;尺寸:L200mm×W150mm×H19.5mm(可外配铁盒装)每门支持独立门磁、红外、手动输入,公共紧急输入,独立开关报警输出;用户注册卡数量:30000多张,记录存储量:30000多条;脱机支持"增删"(按钮)卡功能;CHD805DM8CHD805DM8外接门口机可控制八个完全独立的门尺寸:L250mm×W160mm×H44.5mm实际硬件为8口RS485HUB(黄板)铁盒型,多组指示灯提示工作状态,自配DV12V/1A电源标准RS485通讯,两边都有防雷保护;多门门口一体机CHD601BS配合四门/八门门禁控制器使用,不能单独使用;内置EM读卡器,可外接一标准维根读卡器;CHD601MS配合四门/八门门禁控制器使用,不能单独使用;内置MIFARE读卡器,可外接一标准维根读卡器;尺寸:L75mm×W115mm×H20mm 有四种颜色可选:米白、米黄、铁灰、黑色米白/米黄/铁灰/黑打卡记录均有进/出标识,灌胶防水最新黄板支持门磁、红外、手动输入,OC门报警输出;可登记1536个不同用户,可保留最新记录2550条;601BS/MS上刷卡固定不需要密码。

1I M P w w w .e x t r o n .c o m t a l l a t i o n i n s t r u c t i oo n n e c t i n g t h e e .IN1808 Series • Setup Guide4K @ 60 Hz at 4:4:4. They feature DisplayPort, HDMI, and DTP2 inputs, HDMI output and a mirrored Extron DTP2 outputextension to send video, audio, and control signals up to 330 feet (100 meters) over a shielded CATx cable. The IN1808 IPCP SA and IN1808 IPCP MA 70 models each have a built-in Extron IPCP Pro 355M IP Link Pro Control Processor, and an integrated 100 watt class D power amplifier. The IN1808 Series delivers high image quality, fast and reliable switching, Extron ProDSP audio processing, seamless video transition effects, logo keying, and HDMI loop out. The scalers can be controlled and configured over Ethernet, RS-232, or USB.This guide provides instructions for an experienced user to set up and configure the IN1808 (base model), IN1808 IPCP SA, and IN1808 IPCP MA 70 scalers. It covers how to perform basic operations using the front panel controls and selected Simple Instruction Set (SIS™) commands.NOTES:•For full installation, configuration, menus, connector wiring, and operation details, see the IN1806 and IN1808 Series User Guide at . For installation, configuration, and operation details of the embedded IPCP Pro 355M, see the IPCP Pro Series User Guide .•The IN1808 Series products can also be configured via the Extron Product Configuration Software (PCS), available at . For information on using PCS, see the IN1806 and IN1808 Series Help File.InstallationIN1808 Series Rear Panel ConnectorsFigure 1 shows the rear panel of the IN1808 IPCP SA rear panel. The IN1808 IPCP MA 70 rear panel is the same except that the embedded amplifier is mono while the SA model amplifier is stereo. The IN1808 base model rear panel does not have an embedded IPCP Pro 355M module (see figure 1, P ) or amplifier module (N ).Figure 1.Rear Panel Connectors, IN1808 IPCP SAA AC power connectorB DisplayPort input connector (input 1)C HDMI (with CEC) loop out connectorD DTP2/XTP input connectors (inputs 7 and 8)E HDMI (with CEC) output connector (1A)FDTP2/XTP/HDBaseT (with CEC) output connector (1B)G Over TP IR pass-through connectorH Analog line audio inputs 3 and 4I Analog mic/line audio inputs 1and 2 and adjacent phantom power LEDs J Analog line audio outputs 1 through 4K Remote RS-232 port L Reset LED M Reset buttonN Amplified audio output (IPCP modelsonly)o Aux mono or stereo analog lineaudio input connector P IPCP Pro 355M Control Processor (IPCP models only)Q HDMI inputs 2 through 6R LAN connector (IN1808 base modelonly, see the note and illustration below)IN1808 • Setup Guide (Continued)Mounting and CablingStep 1 — Mount the devicea. Turn off or disconnect all equipment power sources.b. Mount the IN1808 to a rack using the pre-installed side mounting brackets, or remove the brackets and use an optional19-inch rack under-desk mounting kit (see the mounting instructions provided with the kit, available at ).The IN1808 base model has a 1U high, full rack wide enclosure. The IN1808 IPCP models have 2U, full rack enclosures.Step 2 — Connect inputsMake the following input connections as needed:• Connect a DP source to the Input 1 DisplayPort connector (see figure 1, B, on the previous page).• Connect HDMI or DVI (with an appropriate adapter) sources to HDMI input connectors 2 through 6 (Q).• Connect DTP transmitters to the DTP2/XTP RJ-45 input connectors 7 and 8 (D). These connectors allow for remote powering of DTP transmitters. You can configure the TP inputs for XTP mode via SIS commands, the on-screendisplay (OSD), or PCS (see the IN1808 Series Help File). For cable wiring and recommendations, see Twisted PairRecommendations for DTP, XTP, and HDBaseT Communication on the next page.• Connect analog audio sources to:• The 5-pole captive screw line audio input connectors 3 and 4 (H) and the Aux connector (O) for balanced or unbalanced stereo audio. The Aux Line input is shared and can be associated with one or more video inputs.• Connect balanced or unbalanced mic or line level inputs to 3-pole Mic/Line captive screw connectors 1 and 2 (I).These inputs support optional +48 VDC phantom power, which is indicated by the LEDs at the left of the connectors.Step 3 — Connect outputsMake the following output connections as needed:• Connect an HDMI, or DVI with an appropriate adapter, display to HDMI/CEC output connector 1A (E).• Connect a DTP/XTP matrix switcher/HDBaseT compatible receiver to output connector 1B (F). For cable wiring and recommendations, see Twisted Pair Recommendations for DTP, XTP, and HDBaseT Communication.• To pass infrared data, connect a control device to the 3-pole IR Over DTP captive screw connector (see IR Over TP Wiring on the next page). Alternatively, insert RS-232 communication to a DTP/HDBaseT endpoint via Ethernet (see the IN1808Series User Guide for more information).• Connect balanced or unbalanced analog audio output devices to one or both 5-pole captive screw output connector pairs1 and2 or3 and4 (J). See Audio Wiring on the next page for more information.• For IPCP models, connect speakers to the amplifier module via the 5 mm 4-pole stereo (IN1808 IPCP SA) or 2-pole mono (IN1808 IPCP MA 70) Amplified Output connector (N).Step 4 — Connect control devices• To control the base model through Ethernet, connect a LAN or WAN to the LAN connector (R). To wire the RJ-45 connector to the cable, see Twisted Pair Recommendations for DTP, XTP, and HDBaseT Communication.For the IPCP models, connect a LAN or WAN to any of the AV LAN connectors on the IPCP Pro control processor (P). The default IP address of the scaler is 192.168.254.254. The default subnet mask is 255.255.255.0. The default gateway address is 0.0.0.0.• For serial RS-232 control, connect a host device to the 3-pole captive screw connector (K). The default baud rate is 9600.• For control through USB, connect a host device to the front panel USB mini-B port (see figure 2, H on page 4).Step 5 — Set up the IPCP Pro 355M control processor (IPCP models only)The Extron IPCP Pro 355M control processor (see figure 1, P) provides monitoring and control of a variety of external devices, such as projectors and lights. See the IPCP Pro Series Setup Guide, available at , for installation details.Step 6 — Connect powerConnect a 100 to 240 VAC, 50-60 Hz power source to the AC power connector (A).23Twisted Pair Recommendations for DTP , XTP , and HDBaseT CommunicationExtron recommends using the following practices to achieve full transmission distances and reduce transmission errors:•Use Extron XTP/DTP 24 SF/UTP cable for the best performance. At a minimum, Extron recommends 24 AWG, solid conductor, STP cable with a minimum bandwidth of 400 MHz.• Terminate cables with shielded connectors to the TIA/EIA-T568B standard (shown at right).•Limit the use of more than two pass-through points, which may include patch points, punch down connectors, couplers, and power injectors. If these pass-through pointsare required, use shielded couplers and punch down connectors.NOTE:When using shielded twisted pair cable in bundles or conduits, consider the following:• Do not exceed 40% fill capacity in conduits.• Do not comb the cable for the first 20 meters, where cables are straightened, aligned, and secured in tight bundles.• Loosely place cables and limit the use of tie wraps or hook-and-loop fasteners.•Separate twisted pair cables from AC power cables.Audio WiringWire the audio input and output connectors as shown at right. Use the supplied tie wrap to strap the audio cable to the extended tail of the connector. This does not apply to the amplified audio outputconnector on the SA and MA models.NOTE: The length of exposed wires is critical. The ideal length is 3/16 inch (5 mm).IR Over TP WiringTo transmit and receive IR signals, connect a control device to the three-pole Over TP IR connector (G, Tx, and Rx).NOTE: RS-232 data can be inserted via Ethernet only (see the IN1806 and IN1808 Series User Guide for details).TIA/EIA-T568B Pin Wire Color 1White-orange 2Orange 3White-green 4Blue 5White-blue 6Green 7White-brown 8BrownRJ-45ConnectorInsert Twisted Pair WiresPins:Balanced Audio OutputUnbalanced Audio OutputUnbalanced Audio InputBalanced Audio InputDo not tin the wires!Audio Inputs and Outputs 1 – 4 and AuxMic/Line Inputs 1 and 2Balanced Audio Input Unbalanced Audio Input4IN1808 • Setup Guide (Continued)Front Panel OverviewFigure 2 shows the front panel of the IN1808 IPCP SA and IPCP MA 70. The IN1808 base model is 1U high and has no IPCP Pro LEDs (H).Figure 2.Front Panel Features, IN1808 IPCP SA and IN1808 IPCP MA 70A Config portB Input selection buttons (1 through 8)C Logo buttonD Signal and Status LEDsE Menu and Enter buttonsF Navigation buttonsG Mic and Volume knobs and LEDsH IPCP Pro LEDs (IPCP models only)A Front panel configuration port — Connect a host device to the USB mini-B port for device configuration, control, and firmware upgradesB Input selection buttons (1 through 8) — Press one of these buttons to select an input. The buttons light amber for audioand video, green for video only, or red for audio only.C Logo button — Press this button to enable or disable the most recently selected logo slot. Press and hold the button toselect logo slot 1 through 8 using the input selection buttons (slots 9-16 are available via SIS commands only). See the IN1806 and IN1808 Series User Guide at for more information about logos.D Status LED indicators• Input signal LEDs — These eight LEDs light green for their corresponding inputs when active video content is detected on that input.• Output signal LEDs — Output LEDs 1A, 1B, and Loop light green when active video is being output, and blink amber when output video and sync are disabled.• Input HDCP LEDs — These eight LEDs light green for each input signal that is HDCP-encrypted. • Output HDCP LEDs — These three LEDs light green for an output when it is currently HDCP-encrypted.• DTP2 and DTP Input LEDs — These two LEDs light green if DTP or DTP2 power has been enabled on the corresponding input.•DTP2 and DTP Output LEDs — These Output LEDs light green if DTP or DTP2 power has been enabled on DTP output 1B.E Menu and Enter buttons — Press these buttons to access and navigate the on-screen display menu system.F Navigation buttons — Press these buttons to navigate through the on-screen display menu system or change settings.G Mic and Volume knobs and LED indicators — Rotate the Mic knob to adjust the microphone level. Rotate the Volumeknob to adjust the program or output volume level (configurable, see the IN1806 and IN1808 Series PCS Help File for more information). The eight LED indicators for each knob light according to the level being adjusted. The LEDs light in order from bottom to top to indicate steps from 1% (-99 dB) to 99% (-1 dB). The bottom LED blinks when the volume is muted. The top LED blinks when the volume is at 100% (12 dB).H IPCP Pro LED indicators — IPCP models only (see the IPCP Pro Series Setup Guide for details).Firmware UpdatesDownload firmware updates from the Extron website and upload them via the internal web pages or PCS.IN1808 Series Configuration Array To configure IN1808 Series, use the front panel controls, theon-screen display (OSD) menu, internal web pages, PCS, or SIScommands.On-screen Display (OSD) Menu SystemTo configure IN1808 Series using the OSD menu, connect a displayto either HDMI output 1A or to a DTP/XTP matrix switcher/HDBaseTcompatible device. The OSD menu consists of eight submenus accessedusing the front panel Menu or Enter button (see the example at right).Extron Product Configuration SoftwareTo configure IN1808 scalers using PCS, install the software (available onthe Extron website, ) to a PC connected to the scalervia Ethernet or front panel USB Config port. After the installation, start theprogram. For full instructions, press <F1> on the keyboard or click the ?button in the software and select Help File.Internal Web PagesTo configure the IN1808 Series using the factory-installed web pages in a web browser (see the example at right), connect the AV LAN connector (IPCP models) or LAN connector (base model) on the IN1808 to a LAN or WAN. The default IP address is 192.168.254.254.Basic SIS Command TableTo configure IN1808 Series with specific SIS commands via an RS-232, USB, or Ethernet connection, use the Extron DataViewer utility or a control system to send and receive SIS commands. The table below lists a selection of SIS commands. For a full list ofSIS commands and variables, see the IN1806 and IN1808 Series User Guide at .5668-3131-51 Rev. A02 19© 2019 Extron Electronics — All rights re served. All trademarks mentioned are the property of their respective owners. Worldwide Headquarters: Extron USA West, 1025 E. Ball Road, Anaheim, CA 92805, 800.633.9876For information on safety guidelines, regulatory compliances, EMI/EMF compatibility, accessibility, and related topics, see the Extron Safety and Regulatory Compliance Guide on the Extron website.。

Specifications are subject to change without notice (20.08.01)1Proximity Sensors Inductive Stainless Steel HousingTypes EI, DC, M12, M18, M30•Stainless steel housing, cylindrical •Diameter: M12, M18, M30•Short or long versions•Sensing distance: 2 to 15 mm •Power supply:10 to 40 VDC•Output:Transistor NPN/PNP , make or break switching •Protection: Short-circuit and reverse polarity •LED-indication for output ON •2 m cable or plug M12Product Descriptiondard stainless steel hou sing.Made after Eu ronorm EN 50008.Proximity switch in hou sings ranging from M12 to M30.Short or long versions in stan-Type Selection DC Types, Cable and M12 PlugHousing Body Connec-Rated Ordering no.Ordering no.Ordering no.Ordering no.diameter style tion operating Transistor NPN Transistor NPN Transistor PNP Transistor PNP dist. (S n )Make switching Break switching Make switching Break switching M12Short Cable 2 mm 1)EI 1202 NPOSS EI 1202 NPCSS EI 1202 PPOSS EI 1202 PPCSS M12Short Plug 2 mm 1)EI 1202 NPOSS-1EI 1202 NPCSS-1EI 1202 PPOSS-1EI 1202 PPCSS-1M12Long Cable 2 mm 1)EI 1202 NPOSL EI 1202 NPCSL EI 1202 PPOSL EI 1202 PPCSL M12Long Plug 2 mm 1)EI 1202 NPOSL-1EI 1202 NPCSL-1EI 1202 PPOSL-1EI 1202 PPCSL-1M12Short Cable 4 mm 2)EI 1204 NPOSS EI 1204 NPCSS EI 1204 PPOSS EI 1204 PPCSS M12Short Plug 4 mm 2)EI 1204 NPOSS-1EI 1204 NPCSS-1EI 1204 PPOSS-1EI 1204 PPCSS-1M12Long Cable 4 mm 2)EI 1204 NPOSL EI 1204 NPCSL EI 1204 PPOSL EI 1204 PPCSL M12Long Plug 4 mm 2)EI 1204 NPOSL-1EI 1204 NPCSL-1EI 1204 PPOSL-1EI 1204 PPCSL-1M18Short Cable 5 mm 1)EI 1805 NPOSS EI 1805 NPCSS EI 1805 PPOSS EI 1805 PPCSS M18Short Plug 5 mm 1)EI 1805 NPOSS-1EI 1805 NPCSS-1EI 1805 PPOSS-1EI 1805 PPCSS-1M18Long Cable 5 mm 1)EI 1805 NPOSL EI 1805 NPCSL EI 1805 PPOSL EI 1805 PPCSL M18Long Plug 5 mm 1)EI 1805 NPOSL-1EI 1805 NPCSL-1EI 1805 PPOSL-1EI 1805 PPCSL-1M18Short Cable 8 mm 2)EI 1808 NPOSS EI 1808 NPCSS EI 1808 PPOSS EI 1808 PPCSS M18Short Plug 8 mm 2)EI 1808 NPOSS-1EI 1808 NPCSS-1EI 1808 PPOSS-1EI 1808 PPCSS-1M18Long Cable 8 mm 2)EI 1808 NPOSL EI 1808 NPCSL EI 1808 PPOSL EI 1808 PPCSL M18Long Plug 8 mm 2)EI 1808 NPOSL-1EI 1808 NPCSL-1EI 1808 PPOSL-1EI 1808 PPCSL-1M30Short Cable 10 mm 1)EI 3010 NPOSS EI 3010 NPCSS EI 3010 PPOSS EI 3010 PPCSS M30Short Plug 10 mm 1)EI 3010 NPOSS-1EI 3010 NPCSS-1EI 3010 PPOSS-1EI 3010 PPCSS-1M30Long Cable 10 mm 1)EI 3010 NPOSL EI 3010 NPCSL EI 3010 PPOSL EI 3010 PPCSL M30Long Plug 10 mm 1)EI 3010 NPOSL-1EI 3010 NPCSL-1EI 3010 PPOSL-1EI 3010 PPCSL-1M30Short Cable 15 mm 2)EI 3015 NPOSS EI 3015 NPCSS EI 3015 PPOSS EI 3015 PPCSS M30Short Plug 15 mm 2)EI 3015 NPOSS-1EI 3015 NPCSS-1EI 3015 PPOSS-1EI 3015 PPCSS-1M30Long Cable 15 mm 2)EI 3015 NPOSL EI 3015 NPCSL EI 3015 PPOSL EI 3015 PPCSL M30LongPlug15 mm 2)EI 3015 NPOSL-1EI 3015 NPCSL-1EI 3015 PPOSL-1EI 3015 PPCSL-11)For flush mounting in metal Make switching = Normally Open (NO)2)For non-flush mounting in metal Break switching = Normally Closed (NC)EI, DC, M12, M18, M30SpecificationsDimensionsType A B C D E F G H I SW K LØ mm mm mm mm mm mm mm mm mmØ mmØ mm EI 1202 XPXSS M12 x 1 x 3010.73011 5.0417EI 1202 XPXSL M12 x 1 x 5010.75011 5.0417EI 1202 XPXSS-1M12 x 1 x 3010.73012.611.9417EI 1202 XPXSL-1M12 x 1 x 5010.75012.611.9417EI 1204 XPXSS M12 x 1 x 3010.73411 5.0417EI 1204 XPXSL M12 x 1 x 5010.75411 5.0417EI 1204 XPXSS-1M12 x 1 x 3010.73412.611.9417EI 1204 XPXSL-1M12 x 1 x 5010.75412.611.9417EI 1805 XPXSS M18 x 1 x 3016.73011.615.4424EI 1805 XPXSL M18 x 1 x 5016.75011.615.4424EI 1805 XPXSS-1M18 x 1 x 3016.73013.111.9424EI 1805 XPXSL-1M18 x 1 x 5016.75013.111.9424EI 1808 XPXSS M18 x 1 x 3016.73811.615.4424EI 1808 XPXSL M18 x 1 x 5016.75811.615.4424EI 1808 XPXSS-1M18 x 1 x 3016.73813.111.9424EI 1808 XPXSL-1M18 x 1 x 5016.75813.111.9424EI 3010 XPXSS M30 x 1.5 x 30283013.615.4536EI 3010 XPXSL M30 x 1.5 x 50285013.615.4536EI 3010 XPXSS-1M30 x 1.5 x 30283013.611.9536EI 3010 XPXSL-1M30 x 1.5 x 50285013.611.9536EI 3015 XPXSS M30 x 1.5 x 30284213.615.4536EI 3015 XPXSL M30 x 1.5 x 50286213.615.4536EI 3015 XPXSS-1M30 x 1.5 x 30284213.611.9536EI 3015 XPXSL-1M30 x 1.5 x 50286213.611.95362Specifications are subject to change without notice (20.08.01)Specifications are subject to change without notice (20.08.01)3Power SuppliesPower supplies VDC:> SS 130/140.Power supplies with amplifier relays:> SV 190.Dimensions (cont.)Wiring DiagramsInstallation HintsRelief of cable strainProtection of the sensing faceSwitch mounted on mobile carrierTo avoid interference from inductive voltage/current peaks, separate the prox. switch pow-er cables from any other power cables, e.g.motor, contactor or solenoid cablesIncorrectCorrectThe cable should not be pulledA proximity switch should not serve as mechanical stopAny repetitive flexing of the cable should be avoidedEI, DC, M12, M18, M30。