A20825xls

- 格式:xls

- 大小:639.00 KB

- 文档页数:48

Large Commercial Split SystemSSA5-PRC003-ENProduct CatalogueSeptember 2006Split System 23-55 TonsRAUP/TTV Models 50 HzContentsModel Number Description4 General Data 20-55 Ton Condensing Units6 General Data Blower Coil Units7 System Performance Matrix8 Features Summary8 Outdoor Unit Application Considerations9 Outdoor Unit Selection10 Indoor Unit Fan Performance Data11 Dimensional Data Condensing Unit RAUP 25013 Dimensional Data Condensing Unit RAUP 30014 Dimensional Data Condensing Unit RAUP 40015 Dimensional Data Condensing Unit RAUP 50016 Dimensional Data Condensing Unit RAUP 60017 Dimensional Data DX Air Handling unit TTV 25018 Dimensional Data DX Air Handling unit TTV 30020 Dimensional Data DX Air Handling unit TTV 40022 Dimensional Data DX Air Handling unit TTV 50024 Dimensional Data DX Air Handling unit TTV 60026 Mechanical Specifications Outdoor Unit28 Mechanical Specifications Indoor Unit29Model Number DescriptionUnit Model Number DescriptionThe product is identified by a multiple-character model number that precisely identifies a particular type of unit. An explanation is shown below. It will enable the owner or Service Engineer to define operation, components and applicable accessories for a specific unit.R A U P 250D1B0A123456789101112Digit No. 1 = Product TypeR = Remote Condensing UnitDigit No. 2 = Product TypeA = Air CooledDigit No. 3 = Product TypeU = Unit Airflow-UpflowDigit No. 4 = Development SequenceDigit No. 5, 6 and No. 7 = Nominal Gross Capacity (MBH)(Note: The Alphabetic Letter “O” is not used in Digit 6 or 7, Only the Number “0” is used.) 250=250 MBH300=300 MBH400=400 MBH500=500 MBH600=600 MBHDigit No. 8 = Electrical Rating/Utilization RangeD = 380-415V/3ph/50HzDigit No. 9 = Motor/Compressor Controls(Note: The Alphabetic Letter “O” is not used in Digit 9, Only the Number “0” is used.)0 = None1 = DOL ( 3 wire ) StarterDigit No. 10 = Minor Design SequenceDigit No. 11 = Factory Installed/Shipped Options(Note: The Alphabetic Letter “O” is not used in Digit 11, Only the Number “0” is used.)0 = None1 = Blue fin2 = Suction/Liquid shut off valve3 = Crankcase Heater4 = Copper finS = SpecialDigit No. 12 = Service IndicatorModel Number DescriptionT T V250A D01A0A A0D 12345678910111213141516Digit No 1, 2, 3 = Airflow ConfigurationV = Vertical DischargeDigit No 4, 5, 6 = Nominal Gross Capacity (MBH)Digit No 7 = Major Design SequenceDigit No 8 = Electrical Rating / Utilization RangeD = 380-415V/3Ph/50HzDigit No 9 = Motor Control0 = None1 = DOL 4 wireDigit No 10 = Factory Installed Options0 = No Motor and Drive1 = 3.7 Supply Fan Motor kW2 = 5.5 Supply Fan Motor kW3 = 7.5 Supply Fan Motor kW4 = 11 Supply Fan Motor kW5 = 15 Supply Fan Motor kWDigit No 11 = Minor Design SequenceDigit No 120 = No Discharge Plenum1 = With Discharge Plenum (For TTV250&300)Digit No 13A = Internal Filter Rack ; 1" FilterB = External Filter Rack ; 2" FilterC = Internal Filter Rack ; 1" Filter with Decorative Return Air GrilleDigit No 14 = ArrangementA = Arrangement 1B = Arrangement 2C = Arrangement 3D = Arrangement 4Digit No 15 = Future UseDigit No 16 = ServiceGeneral Data 20-55 Ton Condensing UnitsTable 11 MCA - Minimum Circuit Ampacity is 125% of the largest compressor RLA plus 100% of the other compressor RLA plus the sum of the motor RLA.2 At 7 deg C SST and 35 deg C Ambient, Subcooling 8.3 K, Superheat 11.1 K.3 Nominal Airflow is rated wiht standard air-dry coil.General Data Blower Coil UnitsTable 2MCA - Minimum Circuit Ampacity ; calculated as follow : 125% of heater R.L Amps plus the fan motor R.L Amps.CFM is rated with standard air-dry coil.System Performance MatrixTable 3•Scroll Compressors•High compressor EERs.•Less vibration and a Quieter Operation •Durability / Extended LifeBuilt in dirt separator to prevent dirt reaching the bearings High volume oil sump prevents excessive oil loss.•Compressor ProtectionInternal motor temperature sensor.Current overloadsExternal high and low pressure switches •T andem CapabilityAchieves high part load efficiencies and additional part load control.•Sight glass & oil charging valves•DOL Starter, minimizing field installation.•Micro Controller with labled and numbered wiring.•Helps in troubleshooting and reduces service time.•Detailed two digits troubleshooting diagnostics.•Higher Controller reliability than traditional hard wired systems •Robust Casing•Stainless Steel & Corrosion Resistant Coated external screws.•Corrossion resistant coated coils as an option.•High efficiency Trane slit fin coils.•Weather resisant baked matt polyester powder painted GI panels.Heavy gauge welded steel base with mounting holes.•IP 55 condenser fan motors with built in thermal overloads.•Aluminium Blade propeller fans.•Fully factory leak and pressure, tested.•Factory Packaged•DOL Starters, Filter driers, controller •Pre Matched Compact Air Handlers•Small foot print•Multiple fan arrangements. Vertical or horizontal discharge configurations.•Up to 2.5“ (625Pa) ESP•Baked Polyester Powder Painted GI panels•25 mm Aluminium foil faced fiberglass insulation.•Double Inlet Width Forward curved fans •Standard 25 mm washable air filters.•Oversized motor options for higher static operation.*Some items are optional and not standard.Features SummaryCapacities based on ambient temperature of 95O F (35O C) Coil on coil temperature of 80/67O F (26/19O C) EDB/EWB.Capacities are gross and do not include the evaporator fan motor heat deductionCertain application constraints should be considered when sizing, selecting and installing Trane air-cooled condensing units. Unit reliability is dependent upon these considerations. Where your application varies from the guidelines presented, it should be reviewed with the local Trane sales engineer.Unit SizingIntentionally oversizing a unit to assure adequate capacity is not recommended. Erratic system operation and excessive compressor cycling are often a direct result of an oversized condensing unit. In addition, an oversized units usually more expensive to purchase, install and operate. If oversizing is desired, consider using two units.Unit PlacementA base or foundation is not required if the selected unit location is level and strong enough to support the unit’s operating weight.Isolation and Sound Emission The most effective from of isolation is to locate the unit away from any sound sensitive area. Structurally transmitted sound can be reduced by using spring or rubber isolators. The isolators are effective in reducing the low frequency sound generated by compressors and, therefore are recommended for sound sensitive installations. An acoustical engineer should always be consulted on critical applications. For maximum isolation effect, the refrigeration lines and electrical conduct should also be isolated. Use flexible electrical conduit. State and local codes on sound emissions should always be considered. Since the environment in which a sound source is located affects sound pressure, unit placement must be carefully evaluated.Unit LocationUnobstructed flow of condenser air isessential for maintaining condensingunit capacity and operation efficiency.When determining unit placement,careful consideration must be given toassure proper air flow across thecondenser heat transfer surface. Failureto heed these considerations will resultin warm air recirculation and coil air flowstarvation, resulting in a high pressurecompressor cutoff.Warm air recirculation occurs whendischarge air from the condenser fansis recycled back at the condenser coilinlet. Coil starvation occurs when freeair flow to the condenser is restricted.Both warm air recirculation and coilstarvation cause reductions in unitefficiency and capacity. In addition,in more severe cases, nuisance unitshutdowns will result from excessivehead pressures. Accurate estimates ofthe degree of efficiency and capacityreduction are not possible due to theunpredictable effect of varying winds,temperatures and coil conditions.In addition, wind tends to further reducehead pressure. Therefore, it is advisableto protect the air-cooled condensingunit from continuous direct windsexceeding 10 miles per hour.Debris, trash, supplies, etc., should notbe allowed to accumulate in the vicinityof the air-cooled condensing unit. Supplyair movement may draw debris betweencoil fins and cause coil starvation. Specialconsideration should be given to unitsoperating in low ambient temperatures.Condenser coils and fan dischargemust be kept free of snow and otherobstructions to permit adequate air flowfor satisfactory unit operation.Effect of Altitude On CapacityCondensing unit capacities given in theperformance data tables. At elevationssubstantially above sea level, thedecreased air density will decreasecondenser air density will decreasecondenser capacity and efficiency.Ambient ConsiderationsStart up and operation at lowerambients requires sufficient headpressure be maintained for properexpansion valve operation.At higher ambients, excessive headpressure may result. Standard operatingambients are 7-45O C. With a low ambientkit comprising crank case heaters andfrequency inverters, operation below7O C is achievable. Minimum ambientcondition are based on still conditions.Refrigerant PipingSpecial consideration must always begiven to oil retum. Minimum suction gasvelocities must always be maintainedfor proper oil retum. Outdoor Unit Application ConsiderationsOutdoor Unit SelectionSYSTEM PERFORMANCE DATAEWB=Entering Wet Bulb, deg. FTC=Total Capacity, MBHSHC=Sensible Heat Capacity, MBHPI=Power Input, kW CompressorsAll capacities are gross and do not include a deduction for evaporator fan motor heat.Interpolation is allowed. Do not extrapolate.Correction FactorsCooling Capacity Correction Factor for CFM/CMH, other than standard%CFM.CMH Variation From Rated-20-10Rated+10+20 Total Cooling Capacity Multiplier0.960.98 1.00 1.02 1.03 Sensible Heat Multaiplier0.910.96 1.00 1.04 1.08Note : Calculate total and sensible capacities in MBH and multiply by above factors to determine revised capacitiesEvaporator Fan Performance - TTV 250English UnitsIndoor Unit Fan Performance DataNotes: 1.Standard motor is 7.5 hp (5.5 kW), 1st option high static motor is 10 hp (7.5 kW), 2nd option high static motor is 15 hp (11 kW)2.To determine the power of the motor to be installed, the following correction factors to the fan Shaft Absorbed hp.Fan motor hp = Absorbed Fan Shaft hp x Correction FactorCorrection Factor = 1.2 for Absorbed Fan Shaft < 10 kW (13.4 hp)Correction Factor = 1.15 for Absorbed Fan Shaft > 10 kW (13.4 hp)Fan Motor Heat (MBH) = 2.55 x BHP Data Includes wet coil pressure dropIndoor Unit Fan Performance DateEvaporator Fan Performance - TTV 500English UnitsFAN ARRANGEMENT 1SIDE VIEW FAN ARRANGEMENT 2SIDE VIEWFAN ARRANGEMENT 3FAN ARRANGEMENT 4SIDE VIEWSIDE VIEWFAN ARRANGEMENT 1FAN ARRANGEMENT 2SIDE VIEWSIDE VIEWFAN ARRANGEMENT 3FAN ARRANGEMENT 4SIDE VIEWFAN ARRANGEMENT 1FAN ARRANGEMENT 2SIDE VIEWFAN ARRANGEMENT 3FAN ARRANGEMENT 4SIDE VIEWFAN ARRANGEMENT 1FAN ARRANGEMENT 2SIDE VIEWFAN ARRANGEMENT 3FAN ARRANGEMENT 4SIDE VIEWFAN ARRANGEMENT 1FAN ARRANGEMENT 2SIDE VIEWFAN ARRANGEMENT 3FAN ARRANGEMENT 4SIDE VIEWCASINGThe unit shall be designed for outdoor installation with completely factory assembled panels. Unit panels shall be constructed of 0.9 mm galvanized steel held in place by Allen key arrangements for easy removal. Exterior panels shall be cleaned, chemically treated and finished with a weather resistant oven-baked polyester powder paint. The entire unit shall be mounted on a galvanized sheet steel base for ease of shipment and handing. COMPRESSORThe unit shall have hermetic, welded shell Trane designed scroll compressors. Scroll compressors shall be heavy-duty suction gas cooled type complete with suction screen centrifugal oil pump with dirt separator, oil sight glass, protective device for low and high pressure and compressor motor winding thermostat. Two manifold compressors on unit sizes RAUP 150 to RAUP 300, four compressors on two independent manifolded circuits on unit sizes RAUP 400 to RAUP 600.CONDENSING COILOne vertical air-cooled condenser coil for RAUP 150 to RAUP 300, two vertical coils for RAUP 400 to RAUP 600.The coil shall be made of 3/8” seamless copper tubes mechanically bonded to aluminium plate fins. The coils shall be leak and proof tested to 300 and 450 psig respectively, and dehydrated and charged with nitrogen Optional corrosion resistant condenser coils are available for corrosive environments. CONTROLSProtective devices for low pressure, high pressure, motor winding temperature thermostat current overload for compressors and time delay protection shall be provided. DOL starter shall be provided as a standard. Shutoff valves shall be and option. Micro Control Processors shall be standard on a RAUP’s. Micro Controllers shall have diagnostics.FANDirect drive propeller fans shall be provided. Fan motors shall be protected with current overload protection. SHIPMENTAll units shall be shipped on a wooden skid with the compressor oil operating charge and a R22 holding charge.Mechanical Specifications Outdoor UnitUNIT CASINGThe unit framework shall be 3 mm ga.GI steel. Exterior panels shall be fabricated from 1.2 mm ga. galvanized steel. All panels shall be cleaned and coated with a baked polyester powder paint. The base frame shall be welded 3mm galvanized steel.All panels in contact with air stream shall be insulated with 1 inch 2 pound density fibre glass insulation covered with aluminium foils to prevent contact of moving air with insulation. All panels shall be removable to ensure proper access for servicing and maintenance.Removable panels shall be secured with bolts.FOOTPRINTTo save building space all models shall be placed against wall with return air from the front and general service from the sides.COOLING COILThe evaporator coil shall be one-half inch or three-eight inch OD seamless copper tubes mechanically expanded into aluminium fins.Coils shall have at least two independent circuits for good part load capability.Coils shall be proof tested at 375 psig and leak tested at 250 psig. Thermal expansion device shall be of direct expansion type with external equalizers,(Capillary tubes shall not be acceptable).The drain pan shall be fabricated of galvanized steel, insulated to prevent any condensation, and mastic coated to pervert corrosion.REFRIGERANT CIRCUITRefrigerant circuits shall be independent or manifolded and shall include pressure access ports (high and low pressure)filter driers, and charging valves. The circuits shall be lead tested and factory charged with N2.FANSSupply fans shall be of double width double inlet forward curved centrifugal fans statically and dynamically balanced. The drive components shall included fixed pitch drives and multiple V-belts. The drives shall be factory run tested and balanced. The supply fan motor shall be totally enclosed fan cooled.STARTERSUnit mounted DOL fan motor starters are available as a standard feature.HI-STATIC MOTOR (OPTIONAL)Optional factory mounted oversized fan motor for high external static pressureapplication.Mechanical Specifications Indoor UnitLiterature Order Number SSA5-PRC 003-EN Supersedes Sep 2006Stocking LocationSoft Copy OnlyTrane Thailand7th Floor, Ploenchit Center Building 2 Sukhumvit Road, Klongtoey Bangkok 10110。

![表3.0.5 [变压器(油浸电抗器)名称编号]变压器(油浸电抗器)检查(隐蔽)签证](https://uimg.taocdn.com/a69e7d2524c52cc58bd63186bceb19e8b9f6ec61.webp)

Rev. 0.2 9/06Copyright © 2006 by Silicon LaboratoriesAN208AN208S E N S O R L E S S B R U S H L E S S DC M O T O R R E F E R E N C E D E S I G N1. IntroductionThis reference design provides a hardware and software solution for Sensorless Brushless dc motors. This document includes complete schematics, printed circuit board layout, and firmware. The Sensorless Brushless dc motor reference design may be used as a starting point for motor control system designers using Silicon Laboratories MCUs, significantly reducing the design time and time to market.Brushless dc motors consist of a permanent magnet rotor with a three-phase stator winding. Brushless dc motors evolved from conventional dc motors where the function of the brushes is replaced by electronics. Brushless dc motors offer longer life and less maintenance than conventional brushed dc motors.Most Brushless dc motor designs historically use Hall effect sensors to measure the position of the rotor. Hall effect sensors provide absolute position information required to commutate the motor. Using Hall effect sensors provides simple, robust commutation and performance roughly comparable to brushed dc motors. One of the major barriers limiting the market penetration of Brushless dc motors has been the cost of using Hall effect sensors. The Hall effect sensors themselves are not particularly expensive. However, the Hall effect assembly adds significant expense to the cost of manufacturing the motor. Hall effect sensors also typically require 5 additional wires, adding to the installation costs.A “Sensorless” Brushless dc motor does not have Hall effect sensors. Sensorless Brushless dc motors employ more sophisticated electronics using some alternative scheme to control the commutation of the motor. The most common scheme involves measuring the back EMF of the motor and using this information to control the commutation of the motor.Most computer hard disc drives use a sensorless brushless dc motor. However, these small motor drives use a linear regulator to control the voltage applied to the motor. This works well for small motors, but is too inefficient to use for motors greater than a few watts. Larger motors require PWM control for efficient operation. Using PWM control makes the task ofmeasuring the back EMF of the motor more difficult, due to noise coupled from the active windings.Sensorless Brushless dc motors are well suited for fans and rotary pumps from a few watts up to about 1 kW. Fans and pumps’ loads are predictable and fairly well behaved. Most Sensorless Brushless dc motors do notprovide the same level of dynamic speed control available from Hall effect controlled BLDC motors or dc motors. While it is theoretically possible to achieve high-performance from a sensorless BLDC motor using sophisticated vector control, most practical sensorless BLDC implementations address the much simpler fan and pump applications. This reference design is targeted for simple fan applications.Sensorless BLDC motor drives often compete against ac induction motors for certain applications. A system designer must consider the power level, efficiency requirements, and starting requirements when choosing between BLDC motors and ac induction motors. BLDC motors are most often used for small motors rangingfrom 1 watt to 1 kW. AC induction motors are readily available from 250 W to 10 kW or more. BLDC motors offer potentially higher efficiency than ac induction motors. This is due to the fact that ac motors have high rotor losses while BLDC motors do not waste energy in magnetizing the rotor. AC induction motors are much easier to start than sensorless BLDC motors. Thecomplexity of starting a fully loaded BLDC motor often makes the ac induction motor a better choice, particularly for piston pumps and compressors.AN2082Rev. 0.22. Theory of OperationBrushless dc motors have a dual personality. To fully understand Sensorless Brushless dc motor control it is necessary to understand both dc motor characteristics and Stepper motor characteristics. When commutated using Hall effect sensors, the torque speed characteristics of the Brushless dc motor are virtually identical to a conventional dc motor. The ideal no load speed is a linear function of the applied voltage. The torque and motor current are at a maximum at zero speed and decrease to zero at the maximum speed. The torque-speed characteristics of a dc motor are shown in Figure 1. Under ideal conditions, the characteristics of a sensorless BLDC motor are similar.The characteristics of a stepper motor are quite different. The motor current in a stepper motor is not proportional to the load torque. The motor winding resistance typically limits the current in a stepper motor. The motor winding resistance of a stepper motor is normally an order of magnitude higher than a BLDC motor. An ideal model for a stepper motor is shown in Figure 2.Figure 2. Stepper Motor ModelThe motor is driven with a constant voltage. When the motor is at a standstill, the back EMF is zero and the current is at its maximum value. As the motor speed increases the back EMF will increase, reducing the voltage across the motor resistance, and the motorcurrent will decrease. The available torque for a stepper motor is proportional to the current forced through themotor windings. The available torque is at its maximum value when the motor is at a standstill. The available torque decreases as the motor speed increases. If the load torque ever exceeds the available torque the motor will stall. Figure 3. Stepper Motor CharacteristicsThe performance of the stepper motor may be improved using a variable voltage drive. By increasing the voltageapplied to the stepper motor in proportion to the velocity,the available torque will remain constant and the fancan be driven to a higher velocity before stalling as shown in Figure 3.A BLDC motor can also be considered as an unusual stepper motor. A 4-pole 12 V BLDC motor is functionally equivalent to a 12-step per revolution stepper motor with a voltage rating of about 1 V. A typical Stepper motor has a much higher step count, higher voltage, and higher resistance. A typical hybrid permanent-magnet stepper motor has a step angle of 1.8º, or 200 steps per revolution. A 12 V stepper motor might have a resistance of 30 Ω, compared to less than 1 Ω for a similar size BLDC motor. The stepper motor is optimized for precise angular positioning and constant voltage drive. The BLDC motor is optimized for Hall effect commutation and variable voltage drive.2.1. PWM SchemeMost Hall effect BLDC motors use a three-phase bridge to drive the motor windings. A Three-Phase bridge isshown in Figure 4.AN208Rev. 0.23Figure 4. Three-Phase BridgeThe most common drive method is to use blockcommutation and apply a PWM signal to only thebottom transistors as shown in Table 1. Depending onthe position of the motor and the Hall effect code, theappropriate step pattern is applied to the motor. As themotor rotates, the step pattern will increment throughthe table entries. Using this method, at any point in timethere is only one top transistor in the continuous ONstate and only one bottom transistor being driven by thePWM signal.Considering the motor phases, one phase is drivenhigh, one phase is being pulse-width modulated, andone phase is open. The open phase is noted in thetable. However, there is a problem using the open-phase to sense the back EMF when pulse-widthmodulating only the bottom transistors.Figure 5. Low-Side PWM Back EMFConsider the BLDC motor winding shown in Figure 5. Inthis case the motor is at the first state of thecommutation table. A pulse-width modulated signal isapplied to phase A, phase B is driven high, andphase C is open. The back EMF that we are interestedin is actually the voltage from phase C to the centerconnection labeled point Y. The problem is that thecenter of the Y connection is not a constant dc voltage.Assuming that the resistance and inductance ofwindings A and windings B are the same, the voltage atpoint Y will be halfway between phase A and phase B.The voltage at point Y will be approximately half thesupply voltage when phase A is driven low. Whenphase A is high, the center point Y will be approximatelyequal to the upper supply voltage. The voltage on theopen phase C is now the voltage at center-point Y plusthe back EMF of the motor. The voltage at phase C isalso clamped to the upper rail by the MOSFET bodydiodes in the inverter bridge. The result is a pulse widthmodulated waveform where the minimum voltage levelis equal to the back EMF of the motor. While it ispossible to filter out the PWM signal or sample thevoltage during the PWM on-time, working with thiswaveform is problematic.A better approach is to use a symmetric PWM scheme.A symmetric PWM scheme is any PWM scheme wherethe active top and bottom transistors are turned on andoff together. The simplest method is to apply identicalPWM signals to the top and bottom transistorsaccording to Table 2. This commutation table is similarto the low side PWM commutation table except that thehigh side transistors are pulse-width modulated insteadof just being turned on.Table 1. Low-Side PWM CommutationTop Bottom OpenA B C A B C Phase0ON PWM C1ON PWM B2ON PWM A3ON PWM C4ON PWM B5ON PWM AAN2084Rev. 0.2During the first state of Table 2, an identical PWM signal is applied to both the A bottom transistor and the B top transistor. The result is that Phase A will go low when Phase B goes high and visa versa. If the A and B windings are balanced, the center point Y will remain mid-rail even though phase A and phase B are being pulse-width modulated. The voltage on phase C is now roughly equal to the back EMF voltage. There may be some residual PWM noise due to the second order effects of unbalanced windings and capacitive coupling. However, the unwanted PWM signal is reduced by at least an order of magnitude, as shown in Figure 6.Figure 6. Symmetric PWM Back EMF3. Back EMF WaveformsMost sensorless BLDC control systems use the back EMF zero crossing time as a control variable for a phase locked loop. Instead of using the zero-crossing time, this reference design measures the back EMF voltage at middle of the commutation period using the ADC and uses the voltage measurement to control the commutation. This method provides higher resolution and always provides a robust feedback signal even asthe motor approaches a stall condition. When using the zero-crossing time as a feedback signal, special measures must be taken when a zero crossing does not fall within the measurement window.The back EMF voltage for three different cases is shown in Table 3. If the voltage and speed are just right the voltage ramp will be centered within the commutation period and the midpoint voltage will measure half of the supply rail. If the voltage is too low or the speed is too fast the voltage ramp will be shifted up and to the right. If the voltage is too high or the speed is too slow, the voltage ramp will be shifted down and to the left. The feedback loop should work to keep the mid-point voltage at mid-rail.3.1. Safe Operating RangeWhen driving a Sensorless BLDC motor from a MCU there are two output variables, the motor Voltage V and the motor speed ω. Figure 7 shows the output voltage verses speed characteristics for a sensorless BLDC motor. Three lines are labeled in Figure 7. The middle line is the ideal “no load” line with V equal to ω times the motor constant K E . This line represents the optimum voltage for a perfect motor with no friction.Table 2. Symmetric PWM CommutationTop Bottom Open A B CA BCPhase 0PWMPWMC 1PWM PWM B 2PWMPWM A 3PWM PWMC 4PWM PWM B 5PWM PWMATable 3. Back EMF ControlAN208Rev. 0.25 Figure 7. Output Voltage and SpeedThe maximum current is normally limited by thecapability of the power transistors. The maximum boostvoltage is then the maximum inverter current times thewinding resistance. The upper line in Figure 7 is theideal voltage plus the maximum boost voltage. This linedefines the maximum bounds for safe operation. Thelower line is the ideal voltage minus the maximum boostvoltage. This line defines the minimum bounds for safeoperation. While not intuitive, it is quite possible to getan over-current condition by driving the motor with avoltage that is too low for a particular speed.Figure 8. Safe Operating AreaThe Safe Operating Area for the Sensorless BLDCmotor is shown in Figure 8. Above the maximum line thevoltage is dangerously too high. Below the minimum linethe voltage is dangerously too low. The area betweenthe ideal line and the max line is labeled the positivetorque region. In normal steady state operation, theoutput variables will operate in the positive torqueregion.The area below the ideal line is labeled the negativetorque region. While most simple fan and pumpapplications do not require negative torque, operation inthe negative area is permitted. If the motor speedcommand is decreased, the control system will outputvalues in the negative torque region until the operatingpoint is re-stabilized. While it is possible to prohibitoperation in the negative torque region, this mayadversely affect the stability of the control system.The safe operating area is important because it is veryeasy to exceed the limit using conventional controltechniques. If we ignore the safe operating area anduse a simple PI controller to regulate the output voltage,the control loop will output excessive voltage and thepower transistors may be damaged.If we drive the motor with a voltage corresponding to themaximum line, we are forcing maximum current into themotor at all times. This will provide the maximumavailable torque at all times and it is unlikely that themotor will stall. However, the no load efficiency will bevery low and cogging torque may be a problem.Cogging torque is the variation in torque caused by apulsating electromotive force. Stepper motors aredesigned to operate on the max line with low coggingtorque. Most BLDC motors are not designed for thiskind of operation. Excessive cogging torque can causevibration, noise, and stability problems.This reference design uses a novel control techniqueentitled “Constant Voltage Control with SpeedDependent Limiting”. The goal of this controlmethodology is to provide a simple and robust controlalgorithm using a single control loop while keeping theoutput speed and voltage within the Safe OperatingArea.The control technique is illustrated in Figure 9. Theinput speed control potentiometer controls the targetoperating point indicated by the dot on the ideal line. Ifthe error signal is zero, the output voltage and speedare set according to the speed potentiometer. As thespeed control is varied, the target operating point willvary along the ideal line.The bold line indicates variation in the output voltageand speed due to the error signal. A small positive errorsignal from the feedback control system will result in adecrease in speed while the voltage remains constant.The voltage will remain constant until the speed reachesthe limit set by the maximum line. If the error signal islarge enough to exceed the limit, both voltage andspeed are reduced according to the maximum limit.In a similar fashion, a small negative error signal willresult in an increase in speed. If the negative error isincreased beyond the bounds set by the minimum line,the voltage will be increased.The resulting control loop is very stable. The motor isdriven with a constant voltage, as long as the loadAN2086Rev. 0.2torque and acceleration are within the bounds set by the minimum and max limits. In this region the motor behaves like a dc motor with a constant voltage drive. A small increase in load torque will result in a small decrease in speed.For large positive errors signals, the motor voltage is reduced to keep the current below the maximum limits. In this region the motor behaves as a constant current or constant torque drive.Figure 9. Constant-Voltage with Limiting3.2. Starting One major problem with using the back EMF to control the commutation of a sensorless BLDC motor is that the back EMF is not present or is too small to be useful until the motor is rotating at some minimum speed. Thecommon solution is to drive the BLDC motor like astepper motor to align the motor and accelerate themotor up to some nominal speed. This requires that the control system have multiple modes of operation. While it is generally undesirable to have a control system withmultiple modes of operation, it is unavoidable in thiscase. A common pitfall of systems with multiple modesof operation is instability during the transition from one control mode to another. Special considerations are required in the running stage to ensure system stabilityduring the transitions.The motor state diagram is shown in Figure 10. The system is initially in the STOP state. Pressing the Start button will advance to the ALIGN state. The motor willthen advance automatically to the START and RUNstates. An over-current error will reset the motor to the STOP state. Figure 10. SBLDC State Diagram3.3. AlignmentThe alignment state consists of two stages—the Alignment Ramp and the Alignment Delay. During the Alignment Ramp, one of the motor windings is excited by PWMing the top of one phase and the bottom of another phase. The PWM duty cycle is initially at zero percent and is ramped up to 50% plus the starting boost voltage. The voltage is increased using a linear ramp with a fixed delay time between voltage increments. The current in the motor winding will depend on the motor inductance and winding resistance. For duty cyclesbelow 50% the current will be discontinuous. The current will increase while the transistors are on and decrease to zero after the transistors turn off as shown in Figure 11. The peak and average dc current for duty cycles equal to or less than 50% can be calculated using Equation 1.The PWM duty cycle will always be above 50% while running.I avg I peak VL---d×==AN208Rev. 0.27Equation 1. Peak and Average CurrentFor duty cycles above 50% the current will be continuous. Usually a higher current is desired for alignment. Above 50%, a small change in duty cycle will result in a much large change in average dc current. The starting boost voltage is typically a very small number.The second part of the alignment phase consists of asimple delay. The voltage is held constant for a period oftime. The alignment delay time should be long enough to allow the motor to align to the excited pole position. A one second ramp time and a two second delay time works well for the test motor with no fan. When using a large fan, a time of several seconds may be required. Finding the optimal delay time requires some experimentation.The alignment stage ensures that the motor starts froma known position. Without the alignment stage the motormight miss the first several critical commutations in the starting acceleration ramp. If the motor does not align during this stage a motor stall is more likely in the starting phase.During the alignment stage the system is in a relativelybenign state. The dc current is predictable and wellregulated. The power dissipated in the motor can becalculated from the motor winding resistance. A currentmeasurement is only needed to protect against wiringerrors.Most BLDC motors are optimized for high-speedoperation and have very limited torque in the alignmentphase. This is not too much of a problem for small fans,but it does preclude the use of sensorless control insome other applications. The torque is limited by theinverter current and motor design. Over-sizing the inverter or using a lower speed motor can increase the starting torque.3.4. Starting During the starting phase the BLDC motor is driven like a stepper motor. The motor is commutated at first very slowly and then velocity is increased linearly using a linear velocity ramp table. The voltage is also increasedin proportion to the velocity with additional boost voltageto keep the current at a constant value. The motor winding resistance normally limits the boost voltage.The acceleration ramp table ramps the motor speedover a 30:1 range from 25 to 750 rpm. The maximumvalue of 750 rpm was chosen to be one tenth of the maximum speed of the motor. The closed loop sensorless control will then operate over a 10:1 range from 750 to 7500 rpm. The back EMF at 750 rpm will be one tenth of the rated voltage.The key to getting the motor up to 750 rpm is to use alarge enough acceleration ramp table with a sufficiently large ratio of minimum to maximum. A ratio of 30:1 can be achieved using a table with only 192 bytes of data. This also permits the efficient use of an 8-bit table index. Experimental results using a smaller 16-byte table withan 8:1 range proved unsatisfactory. If the table is too small, the initial velocity will be too fast or the finalvelocity will be too slow.The voltage of the motor is also ramped during the acceleration phase. If the voltage were held constant at the alignment value, the current would decrease during the motor acceleration. Initially the current is only limited by the motor resistance. As the motor starts turning, the back EMF of the motor will subtract from the voltageacross the motor resistance. This results in a decrease in motor current and a corresponding decrease in theamount of available torque.Assuming the motor will accelerate in step with the commutation period, the back EMF will be proportional to the motor velocity and inversely proportional to themotor period. The motor voltage ramp may be calculated by dividing a constant by the value in theramp table. By increasing the voltage during theacceleration phase the motor current can be held at aconstant value. This ensures maximum available torqueduring the acceleration phase.If the motor stalls at any point, the back EMF will be zero, and the assumption of motor velocity is no longervalid. The resulting motor voltage will be too high andthe current may be much higher than expected. This isproblematic for small motors and can be disastrous forlarge motors.The solution is to monitor the dc motor current during acceleration and to shut down if the motor current getstoo high. The back EMF is not sufficiently large to detect if the motor is moving. A current limit is not neededduring the starting phase if the motor voltage is limited to the maximum inverter current times the motor resistance, though this will severely limit the starting torque on all but the smallest motors.3.5. RunningThe minimum Running speed and voltage are dictatedby the starting parameters. In this example, the minimum speed is 750 rpm. The minimum voltage is10% plus the boost voltage. At the lower operatingAN2088Rev. 0.2point, the motor is being over-driven by a voltage that is intentionally higher than necessary for stable closed loop operation. Since the motor is being driven like a stepper motor, the cogging torque and motor vibration will be higher in the starting phase.3.6. Back EMF MeasurementsThe back EMF is measured at three points, as shown in Figure 12. The midpoint voltage is the primary control variable for closed loop control. The two voltage measurements at one quarter and three fourths are used for stall detection. The current measurement is used for over current detection. The time slots are discussed in further detail in the software description.Stall detection is achieved by measuring the voltage at quarter points over two cycles. The difference betweenthe minimum and maximum of these four points is anindication of the back EMF of the motor. If the back EMFis greater than a certain value, we can deduce withreasonable certainty that the motor is indeed running. Ifthe back EMF is too small to give a usefulmeasurement, we cannot know for certain if the motor isstalled or running. Thus, the stall detection operatesonly in the running phase. The example implementationilluminates an LED when a stall condition is detected.4. Hardware DescriptionThe schematic diagram for the Sensorless BLDC Motor reference design is in Appendix A. The circuit consists of the C0851F310 Microcontroller, three-phase power MOSFET bridge, three dual gate drivers, sense voltage resistive dividers, current amplifier, speed control potentiometer, two function switches, USB-UART bridge, and voltage regulator.Port P1 is configured as push-pull outputs and is connected to the three dual gate drivers. The P1 port pins are sequenced, alternating between bottom and top starting with phase A in the least significant bit. P1.0-1.5 corresponds to A bottom, A top, B bottom, B top, C bottom, and C top respectively. This sequence facilitates commutation using a simple pattern with the Crossbar pin skip register.Each of the three output phases are connected to a simple resistive divider. The resistive divider will divide the phase output voltage by six. This ratio permits accurate ADC measurements up to 19.8 volts. The 5 V tolerant port pins offer protection against phase voltages up to 30 Volts. The motor supply is 12 V nominal when loaded with the motor turning at full-speed. The unloaded voltage may climb as high as 18 V for the recommended wall mounted transformer.A capacitor across the lower resistor of each divider forms simple single-pole low-pass RC filter. Each filter is tuned approximately one decade below the PWM frequency. Three test points are provided for the scaled voltages labeled VA, VB, and VC.A forth resistive divider is used to sense the voltage of the motor supply. This resistive divider has a ratio of one to twelve. A test point is provided on the scaled motor supply voltage labeled VM. A phase voltage of 12 volts will produce voltage of 2 V on the respective ADC input, while a supply voltage of 12 V will produce a sense voltage of 1.0 V on the VM ADC input. A differential ADC voltage measurement will be used relative to the VM ADC input. The resulting ADC reading will be a signed 16-bit value with 0x0000 corresponding to mid-rail.The sensorless BLDC motor reference design boardincludes a current sense resistor R25 and currentamplifier U7A. The sense resistor is a 20 m Ω surfacemount resistor in an 1812 package. The sense resistorwas chosen for a maximum RMS current of 5 amps witha power dissipation of 500 mW. The resulting sensevoltage of only 100 mV requires amplification to achievemore than 5 bits of resolution from the 10-bit ADC.The current amplifier is a variation of the classic differential amplifier circuit. In the classic circuit configuration, the second resistors on the non-inverting input would be connected to ground. In this variation,resistor R17 is connected to a 400mV voltage reference. The 0.4V reference compensates for the variation in the input offset voltage of the op amp and also keeps the output within the recommended output voltage range. The gain of 26 was chosen to fully utilize the output voltage span of the amplifier allowing forvariation in the input offset voltage. The op amp chosen for this circuit is the LMV358. This is a low-voltage version of the industry standard LM358 dual CMOS op amp. The second op amp in the dual。

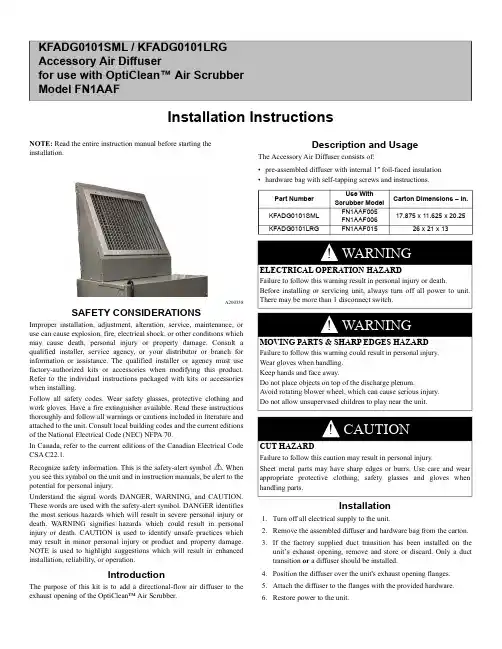

Installation InstructionsNOTE: Read the entire instruction manual before starting the installation.A200358SAFETY CONSIDERATIONSImproper installation, adjustment, alteration, service, maintenance, or use can cause explosion, fire, electrical shock, or other conditions which may cause death, personal injury or property damage. Consult a qualified installer, service agency, or your distributor or branch for information or assistance. The qualified installer or agency must use factory-authorized kits or accessories when modifying this product.Refer to the individual instructions packaged with kits or accessories when installing.Follow all safety codes. Wear safety glasses, protective clothing and work gloves. Have a fire extinguisher available. Read these instructions thoroughly and follow all warnings or cautions included in literature and attached to the unit. Consult local building codes and the current editions of the National Electrical Code (NEC) NFPA 70.In Canada, refer to the current editions of the Canadian Electrical Code CSA C22.1.Recognize safety information. This is the safety-alert symbol . When you see this symbol on the unit and in instruction manuals, be alert to the potential for personal injury.Understand the signal words DANGER, WARNING, and CAUTION.These words are used with the safety-alert symbol. DANGER identifies the most serious hazards which will result in severe personal injury or death. WARNING signifies hazards which could result in personal injury or death. CAUTION is used to identify unsafe practices which may result in minor personal injury or product and property damage.NOTE is used to highlight suggestions which will result in enhanced installation, reliability, or operation.IntroductionThe purpose of this kit is to add a directional-flow air diffuser to the exhaust opening of the OptiClean™ Air Scrubber.Description and UsageThe Accessory Air Diffuser consists of:•pre-assembled diffuser with internal 1ʺ foil-faced insulation •hardware bag with self-tapping screws and instructions.Installation1.Turn off all electrical supply to the unit.2.Remove the assembled diffuser and hardware bag from the carton.3.If the factory supplied duct transition has been installed on the unit’s exhaust opening, remove and store or discard. Only a duct transition or a diffuser should be installed.4.Position the diffuser over the unit's exhaust opening flanges.5.Attach the diffuser to the flanges with the provided hardware.6.Restore power to the unit.KFADG0101SML / KFADG0101LRGAccessory Air Diffuserfor use with OptiClean™ Air Scrubber Model FN1AAFPart Number Use With Scrubber Model Carton Dimensions – in.KFADG0101SML FN1AAF005FN1AAF00617.875 x 11.625 x 20.25KFADG0101LRGFN1AAF01526 x 21 x 13WARNING!ELECTRICAL OPERATION HAZARDFailure to follow this warning result in personal injury or death.Before installing or servicing unit, always turn off all power to unit.There may be more than 1 disconnect switch.WARNING!MOVING PARTS & SHARP EDGES HAZARDFailure to follow this warning could result in personal injury.Wear gloves when handling.Keep hands and face away.Do not place objects on top of the discharge plenum.Avoid rotating blower wheel, which can cause serious injury.Do not allow unsupervised children to play near the unit.CAUTION!CUT HAZARDFailure to follow this caution may result in personal injury.Sheet metal parts may have sharp edges or burrs. Use care and wear appropriate protective clothing, safety glasses and gloves when handling parts.© 2020 Carrier. All rights reserved.A Carrier CompanyEdition Date: 08/20Catalog No: IIK-KFADG-01Replaces: NewKFADG0101SML / KFADG0101LRG: Installation InstructionsManufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.2A200349Fig. 1 – Dimensions (KFADG0101LRG shown)Table 1 – Dimensions — in. (mm)Model A B C D E Outlet Grille Size KFADG0101SML 16.04 (407)17.44 (443) 3.50 (89)11.21 (285) 3.28 (83)12 x 8 (305 x 203)KFADG0101LRG19.56 (497)22.32 (567)4.50 (114)11.25 (286)1.06 (27)16 x 16 (406 x 406)E。

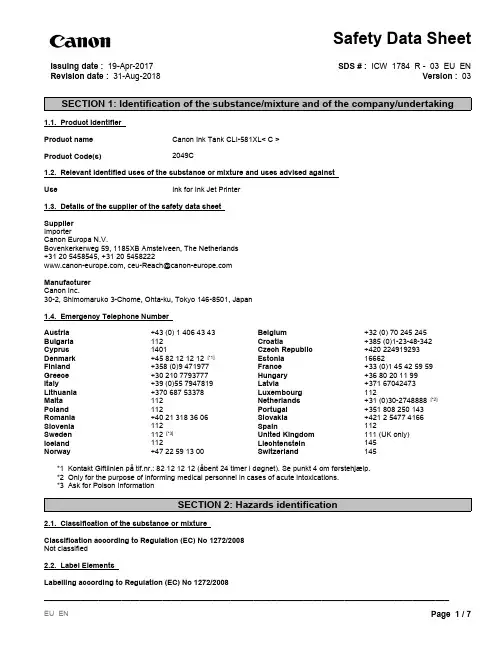

SECTION 1: Identification of the substance/mixture and of the company/undertaking1.1. Product Identifier Product name Canon Ink Tank CLI-581XL< C >Product Code(s)2049C1.2. Relevant identified uses of the substance or mixture and uses advised against UseInk for Ink Jet Printer1.3. Details of the supplier of the safety data sheet Supplier ImporterCanon Europa N.V.Bovenkerkerweg 59, 1185XB Amstelveen, The Netherlands +31 20 5458545, +31 20 5458222Manufacturer Canon Inc.30-2, Shimomaruko 3-Chome, Ohta-ku, Tokyo 146-8501, Japan 1.4. Emergency Telephone Number *1 Kontakt Giftlinien på tlf.nr.: 82 12 12 12 (åbent 24 timer i døgnet). Se punkt 4 om førstehjælp.*2 Only for the purpose of informing medical personnel in cases of acute intoxications.*3 Ask for Poison InformationSECTION 2: Hazards identification2.1. Classification of the substance or mixtureClassification according to Regulation (EC) No 1272/2008Not classified2.2. Label ElementsLabelling according to Regulation (EC) No 1272/2008112Safety Data SheetMalta 112Bulgaria Netherlands +31 (0)30-2748888 [*2]112Poland 112Version : 03Portugal +351 808 250 143CroatiaRomania +40 21 318 36 06+385 (0)1-23-48-342Slovakia +421 2 5477 4166Slovenia 112Cyprus Spain1121401Sweden 112 [*3]Issuing date : 19-Apr-2017United Kingdom 111 (UK only)Czech Republic Iceland 112+420 224919293Liechtenstein 145Norway+47 22 59 13 00Denmark Switzerland145+45 82 12 12 12 [*1]Estonia 16662SDS # : ICW 1784 R - 03 EU ENFinland +358 (0)9 471977France +33 (0)1 45 42 59 59Greece +30 210 7793777Austria Hungary +36 80 20 11 99+43 (0) 1 406 43 43Italy+39 (0)55 7947819Revision date : 31-Aug-2018Latvia+371 67042473Belgium Lithuania +370 687 53378+32 (0) 70 245 245LuxembourgHazard pictogramsNot requiredSignal wordNot requiredHazard statementsNot requiredPrecautionary statementsNot requiredOther InformationContains 1,2-benzisothiazol-3(2H)-one.May produce an allergic reaction.Contains less than 30% of components with unknown hazards to the aquatic environment.2.3. Other HazardsNoneSECTION 3: Composition/information on ingredients 3.2. MixturesChemical name CAS-No EC-No REACH registrationnumber Weight %Classification (Reg.1272/2008)Note toOtherHazardsGlycol CBI CBI CBI10 - 15NoneGlycerin56-81-5200-289-5None 5 - 10NoneUrea compound CBI CBI CBI 5 - 10Eye Irrit. 2 (H319)Substituted phthalocyanine salt CBI CBI CBI 1 - 5Eye Dam. 1 (H318)Aquatic Chronic 3 (H412) Water7732-18-5231-791-2None60 - 80NoneFull texts of Hazard statement(s) are listed in SECTION 16Note to Other Hazards : The following substance(s) is (are) marked with (1), (2) and/or (3)- (1) Substance for which EU Occupational Exposure Limit(s) is (are) established (See SECTION 8)- (2) PBT substance or vPvB substance under Regulation (EC) No 1907/2006- (3) Substance listed in Candidate List of SVHC for Authorisation under Regulation (EC) No 1907/2006In case a safety data sheet supplied under (EC) No 1907/2006 Article 31-3 is necessary, please contact us.SECTION 4: First aid measures4.1. Description of first aid measuresInhalation Move to fresh air. Get medical attention immediately if symptoms occur.Ingestion Rinse mouth. Drink 1 or 2 glasses of water. Get medical attention immediately if symptomsoccur.Skin Contact Wash off immediately with soap and plenty of water. Get medical attention immediately ifsymptoms occur.Eye Contact Flush with plenty of water. Get medical attention immediately if symptoms occur.4.2. Most important symptoms and effects, both acute and delayedInhalation None under normal use. Symptoms of overexposure are dizziness, headache, tiredness,nausea, unconsciousness, cessation of breathing.Ingestion None under normal use. Ingestion may cause gastrointestinal irritation, nausea, vomitingand diarrhea.Skin Contact None under normal use.Eye Contact None under normal use. May cause slight irritation.Chronic Effects None under normal use.4.3. Indication of any immediate medical attention and special treatment neededNoneSECTION 5: Firefighting measures5.1. Extinguishing mediaSuitable extinguishing mediaUse CO 2, water, dry chemical, or foam.Unsuitable extinguishing mediaNone5.2. Special hazards arising from the substance or mixtureSpecial HazardNoneHazardous combustion productsCarbon dioxide (CO 2), Carbon monoxide (CO)5.3. Advice for firefightersSpecial protective equipment for fire-fightersNoneSECTION 6: Accidental release measures6.1. Personal precautions, protective equipment and emergency proceduresAvoid contact with skin, eyes and clothing.6.2. Environmental PrecautionsKeep out of waterways.6.3. Methods and material for containment and cleaning upWipe up with adsorbent material (e.g. cloth, fleece).6.4. Reference to other sectionsNoneSECTION 7: Handling and storage7.1. Precautions for safe handlingAvoid contact with skin, eyes and clothing. Clean contaminated surface thoroughly. Use with adequate ventilation.7.2. Conditions for safe storage, including any incompatibilitiesKeep in a dry, cool and well-ventilated place. Keep out of the reach of children. Keep away from direct sunlight. Keep away from heat and sources of ignition.7.3. Specific end usesInk for Ink Jet Printer. Obtain special instructions before use.SECTION 8: Exposure controls/personal protection8.1. Control parameters Exposure LimitsChemical nameEU OEL Austria Belgium Bulgaria Cyprus Glycerin 56-81-5None None TWA: 10 mg/m 3None NoneChemical nameCzech Republic Denmark Finland France GermanyGlycerin 56-81-5TWA: 10 mg/m 3Ceiling: 15 mg/m 3NoneTWA: 20 mg/m 3TWA: 10 mg/m 3DFG TWA: 200 mg/m 3inhalable fraction Ceiling / Peak: 400mg/m 3 inhalablefraction Chemical nameGreece Hungary IrelandItaly NetherlandsGlycerin 56-81-5TWA: 10 mg/m 3None TWA: 10 mg/m 3 mist STEL: 30 mg/m 3 mistNone None Chemical namePoland PortugalRomania Slovakia SpainGlycerin 56-81-5TWA: 10 mg/m 3inhalable fractionTWA: 10 mg/m 3 mist NoneNone TWA: 10 mg/m 3 mistChemical nameSweden United Kingdom Norway Switzerland Turkey Glycerin 56-81-5NoneTWA: 10 mg/m 3 mistNoneTWA: 50 mg/m 3inhalable dust STEL: 100 mg/m 3inhalable dustNone8.2. Exposure controlsAppropriate engineering controlsNone under normal use conditions.Individual protection measures, such as personal protective equipmentEye/face ProtectionNot required under normal use.Skin ProtectionNot required under normal use.Respiratory ProtectionNot required under normal use.Thermal hazardsNot Applicable SECTION 9: Physical and chemical properties9.1. Information on basic physical and chemical properties AppearanceCyan ; Liquid OdorSlight odorOdor threshold No data available pH7 - 9Evaporation RateNo data availableNo data availableFlash Point (°C)> 93.0°C (Tag. Closed Cup.); estimated Melting/Freezing point (°C)No data available Boiling Point/Range (°C)Flammability (solid, gas)Not Applicable Flammability Limits in AirUpper Flammability Limit None; estimatedLower Flammability Limit None; estimatedVapor pressure No data availableVapor density No data availableRelative density 1.0 - 1.1Solubility(ies)Water; misciblePartition coefficient: n-octanol/water No data available Autoignition Temperature (°C)None; estimated Decomposition Temperature (°C)No data available Viscosity (mPa s) 1 - 5Explosive properties None; estimatedOxidizing properties None; estimated9.2. Other InformationNo data availableSECTION 10: Stability and reactivity 10.1. ReactivityNone10.2. Chemical stabilityStable10.3. Possibility of Hazardous ReactionsNone10.4. Conditions to AvoidNone10.5. Incompatible materialsAcids, Bases, Oxidizing agents, Reducing agents.10.6. Hazardous Decomposition ProductsCarbon dioxide (CO 2), Carbon monoxide (CO), and/or Ammonia.SECTION 11: Toxicological information 11.1. Information on toxicological effectsAcute toxicity No data availableSkin corrosion/irritation Non-irritant (Estimate) (OECD Guideline)Serious eye damage/eye irritation Minimal irritant (Estimate) (OECD Guideline) Sensitization Non-sensitizer (Estimate) (OECD Guideline)Germ cell mutagenicity Ames test: NegativeCarcinogenicity No data availableReproductive Toxicity No data available STOT - single exposure No data available STOT - repeated exposure No data available Aspiration hazard No data available Other InformationNo data availableSECTION 12: Ecological information12.1. Toxicity Ecotoxicity effects No data available12.2. Persistence and degradability No data available12.3. Bioaccumulative potential No data available 12.4. Mobility in soil No data available12.5. Results of PBT and vPvB assessmentThis preparation contains no substance considered to be persistent, bioaccumulating nor toxic (PBT).This preparation contains no substance considered to be very persistent nor very bioaccumulating (vPvB).12.6. Other adverse effects No data availableSECTION 13: Disposal considerations13.1. Waste treatment methodsDispose of in accordance with local regulations.SECTION 14: Transport information14.3. Transport Hazard Class 14.1. UN numberNone None 14.4. Packing Group None14.5. Environmental Hazards Not classified as environmentally hazardous under UN Model Regulations and marine pollutant under IMDG Code.14.2. UN Proper Shipping Name 14.6. Special Precautions for usersIATA: Not regulatedNoneSECTION 15: Regulatory information15.1. Safety, health and environmental regulations/legislation specific for the substance or mixture (EC) No 1907/2006 Authorisation Not regulated (EC) No 1907/2006 Restriction Not regulated (EC) No 1005/2009Not regulated (EC) No 850/2004Not regulated (EU) No 649/2012Not regulated Other InformationNone15.2. Chemical safety assessment NoneSECTION 16: Other informationFull text of H-Statements referred to under sections 2 and 3H318 - Causes serious eye damage H319 - Causes serious eye irritationH412 - Harmful to aquatic life with long lasting effectsKey literature references and sources for data- World Health Organization International Agency for Research on Cancer, IARC Monographs on the Evaluation on the Carcinogenic Risk of Chemicals to Humans- EU Regulation (EC) No 1907/2006, (EC) No 1272/2008, (EC) No 1005/2009, (EC) No 850/2004, (EU) No 649/2012Key or legend to abbreviations and acronyms used in the safety data sheet - PBT: Persistent, Bioaccumulative and Toxic - vPvB: very Persistent and very Bioaccumulative - SVHC: Substances of Very High Concern- EU OEL: Occupational exposure limits at Union level under Directive 2004/37/EC and (EU) 2017/2398, 98/24/EC, 91/322/EEC,2000/39/EC, 2006/15/EC, 2009/161/EU and (EU) 2017/164.- TWA: Time Weighted Average - STEL: Short Term Exposure Limit- GHS: Globally Harmonized System of Classification and Labelling of Chemicals - IARC: International Agency for Research on Cancer - IATA: International Air Transport Association - CBI: Confidential Business Information Issuing date :19-Apr-2017Revision date :31-Aug-2018Revision NoteSECTION 3 and 16 revisedThis product falls under (EC) No 1907/2006 Article 31-3.DisclaimerThe information provided on this SDS is correct to the best of our knowledge, information and belief at the date of its publication. The information given is designed only as a guide for safe handling, use, processing, storage,transportation, disposal and release and is not to be considered as a warranty or quality specification. The information relates only to the specific material designated and may not be valid for such material used in combination with any other material or in any process, unless specified in the text.14.7. Transport in bulk according to Annex II of MARPOL and the IBC CodeNot Applicable。

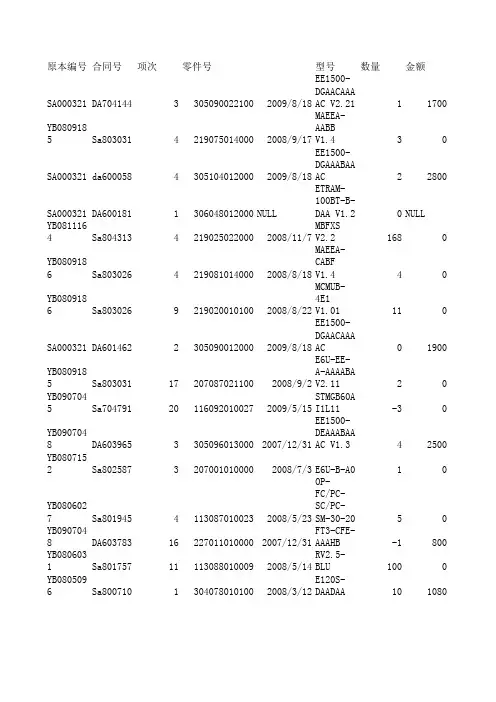

原本编号合同号项次零件号型号数量金额SA000321DA70414433050900221002009-8-18EE1500-DGAA11700 YB0809185Sa80303142190750140002008-9-17MAEEA-AABB 30 SA000321da60005843051040120002009-8-18EE1500-DGAA22800 SA000321DA6001811306048012000NULL ETRAM-100BT0NULLYB0811164Sa80431342190250220002008-11-7MBFXS V2.21680 YB0809186Sa80302642190810140002008-8-18MAEEA-CABF 40 YB0809186Sa80302692190200101002008-8-22MCMUB-4E1 V110 SA000321DA60146223050900120002009-8-18EE1500-DGAA01900 YB0809185Sa803031172070870211002008-9-2E6U-EE-A-AA20 YB0907045Sa704791201160920100272009-5-15STMGB60AI1L-30 YB0907048DA60396533050960130002007-12-31EE1500-DEAA42500 YB0807152Sa80258732070010100002008-7-3E6U-B-A010 YB0806027Sa80194541130870100232008-5-23OP-FC/PC-SC50 YB0907048DA603783162270110100002007-12-31FT3-CFE-AAA-1800 YB0806031Sa801757111130880100092008-5-14RV2.5-BLU1000 YB0805096Sa80071013040780101002008-3-12E120S-DAADA101080 YB0903099Sa90078121130870100112009-3-12OP-FC/PC-SC400 YB0907045Sa80360582270110100002008-11-4FT3-CFE-AAA-15535 YB0806067Sa80166231990999100022008-5-8171637-1120 YB0910069Sa90245562161830101002009-7-13GFA6100-PWU10 YB0811164Sa80431362190200101002008-11-7MCMUB-4E1 V60 YB0907045Sa80493453050960221002008-12-29EE1500-DEAA42380 YB0809186Sa80302611990998100722008-8-18JG-2200*60010 YB0812025Sa80417441130880100062008-10-28RV1.5-BLU1000 YB0806031Sa801757101130880100082008-5-14RV2.5-BLA1000 YB0809184Sa80302582190200101002008-8-22MCMUB-4E1 V70 YB0805123Sa80190222040010000252008-5-21BCP-079-41.10 YB0807003Sa80249941130870100232008-6-26OP-FC/PC-SC200 SA000321da60005833051040120002009-8-18EE1500-DGAA02800 YB0804019Sa800904111990998100862008-3-19BNC-75-KYK1000 SA000321DA60156551990998100442009-8-18网络设备0330 YB0806002Sa80169263080670201002008-5-9A120SV-BDDA10 YB0806067Sa80166241090580100032008-5-8172166-140 YB0809185Sa80303111990998100722008-8-18JG-2200*60010 YB0809186Sa803026102190190103002008-8-22MCMUB V1.0340 YB0811091Sa80420521130900100662008-11-4CAB-CN50M/1140 YB0909079Sa90257731990999101972009-7-22AD-FC/SC-Z400 YB0811164Sa80431332190730140002008-11-7MAEEA-AABA 60 YB0907048DA70303432270050100002007-12-31FT3-PWU40 YB0909079Sa90257741990999101972009-7-28AD-FC/SC-Z1600 YB1002028Sa10002823040890101002010-1-6E120S-DAAAB401378 YB0809184Sa803025162070090100002008-8-7E6U-PWU220-40 YB0908106Sa90187711990998100442009-6-1网络设备10 YB0809184Sa80302542190750140002008-9-17MAEEA-AABB 30 YB0907045Sa801154122160580101002008-11-11GFA-PWU48-A-3630 YB0907045Sa704791191160920100672009-5-15TWC-A-2*8-110YB0812025Sa80417413990020100002008-10-28SPS4840 YB0905052Sa90008072280030101002009-1-5E3US-NCU-A010 YB0806032Sa80184971130870100232008-5-16OP-FC/PC-SC40 YB0809185Sa803031122190240270002008-8-28MBFXO V2.72000 YB0907048DA60378323061720100002007-12-31GFT1501C-BA3800 SA000321DA60430723050900130002009-8-18EE1500-DGAA0460 YB0809184Sa803025112190220200002008-9-2MSU V2.0140 YB0907045Sa80360592270030100002008-11-4FT3-CMU-10 YB0809186Sa803026202070370211002008-8-18E6U-EE-A-AA130 YB0809184Sa80302552190730140002008-8-27MAEEA-AABA 220 YB0809184Sa803025182070370211002008-8-11E6U-EE-A-AA110 YB0809185Sa803031162070090100002008-8-7E6U-PWU220-40 YB0907045Sa704791161160920100322009-5-15DWTC-2-32-P-100 SA000321DA6001812199099810044NULL网络设备0NULLYB0809186Sa80302652190750140002008-9-17MAEEA-AABB 140 YB0907048DA60378333062070100002007-12-31GFT1501C-AA3800 SA000321DA60156541990998100442009-8-18网络设备6110 YB0809186Sa803026122190220200002008-9-2MSU V2.0230 YB0907048DA60378312270110100002007-12-31FT3-CFE-AAA8800 YB0812025Sa80417451130880100072008-10-28RV1.5-RED1000 YB1104031Sa10277123063570102002010-9-25GFT1501S-AC100250 YB0911142Sa80491242270020100002009-1-15FT3-CONT30 YB0806028Sa80173751130870100142008-5-12OP-SC/PC-SC200 YB0905017Sa901420102270030100002009-4-23FT3-CMU250 YB0809184Sa803025102190720110002008-8-22MPRUC V1.160 SA000321DA60146233050900120002009-8-18EE1500-DGAA21900 YB0809184Sa80302562190250220002008-8-22MBFXS V2.22000 YB0907048DA60378343061720100002007-12-31GFT1501C-BA-3800 YB0907045Sa80360552270030100002008-9-12FT3-CMU10 YB1103035Sa901385112281300101002009-8-17E3US-NMU-A112400 YB0907045Sa80360563062570130002008-11-4GFT1501C-BC-30545 YB0909079Sa90257731990999101972009-7-22AD-FC/SC-Z-400 YB0903054Sa80464693990020100002008-11-21SPS4820 YB0805096Sa80071013040780101002008-3-12E120S-DAADA-101080 YB0806027Sa80194551130870100232008-5-27OP-FC/PC-SC50 YB0806032Sa80184961130870100142008-5-16OP-SC/PC-SC200 YB0907048DA60378363062070100002007-12-31GFT1501C-AA-3800 YB0811164Sa80431392190220200002008-11-7MSU V2.0120 SA000321DA60430733050900130002009-8-18EE1500-DGAA1460 YB0811164Sa80431372190190103002008-11-7MCMUB V1.0320 YB0809186Sa803026112190720110002008-8-22MPRUC V1.180 YB0907045Sa704791211160920100662009-5-15TWC-A-2*16-30 YB1006196Sa10168123063500102002010-6-13GFT1501S-BA-2630 YB0907048DA60398632070080101002007-12-31E6U-PWU-A020 YB0806028Sa80173711130900100652008-5-16CAB-CN50M/150 YB0907048DA70302122270050100002007-12-31FT3-PWU20 YB0909079Sa90257741990999101972009-7-28AD-FC/SC-Z-1600YB0907048DA70302151090610100012007-12-31CC4B-K31760 YB0903040Sa804801111990999101532008-12-17PC机(笔记本10 YB0806002Sa80169243062130210002008-5-9ETRAM-V35-B10 YB0809186Sa803026143990020100002008-8-7SPS4840 YB0807152Sa80258742070080101002008-7-3E6U-PWU-A020 YB0809185Sa803031133990020100002008-8-7SPS4860 YB0809184Sa803025133990020100002008-8-7SPS4830 YB0907048DA60398611090610100012007-12-31CC4B-K3300 YB1104031Sa10277133063350102002011-2-12GFT1501S-BC-100250 YB0809186Sa803026182070770211002008-8-18E6U-EE-A-AA20 YB0907045Sa803605102270010100002008-11-4GFT2000-00-11600 YB0809186Sa803026172070090100002008-8-29E6U-PWU220-60 YB0911142Sa804912101130880100072009-1-15RV1.5-RED1000 YB0811164Sa804313163990020100002008-11-7SPS4820 YB0907045Sa80360532270010100002008-9-12GFT2000-0011600 YB0804019Sa80090461130870100062008-3-19OP-FC/PC-FC80 YB0907048DA603965873050960130002007-12-31EE1500-DEAA-22500 YB1103035sa804069172063160101002009-3-27E3U-PWU220-2850 YB0907048DA603965113061720100002007-12-31GFT1501C-BA-1800 YB0809186Sa803026162070020100002008-8-7E6U-CTL-A030 YB0806028Sa80173741130870100232008-5-12OP-FC/PC-SC10 YB0907045Sa80360523062620130002008-9-12GFT1501C-BA30545 YB0907045Sa801154132161340101002008-11-11GFA-PWU220-3630 YB0907045DA70077323061720120002007-12-31GFT1501C-BA-81160 YB0905017Sa90142093061600210002009-4-23ETRAM-10BT-20 YB0907045DA70077353061720120002007-12-31GFT1501C-BA81160 YB0907045Sa80493443050950221002008-12-29EE1500-DEAA-42380 YB0907048DA70303422270030100002007-12-31FT3-CMU20 YB0809185Sa80303182190200101002008-8-22MCMUB-4E1 V70 YB0809185Sa80303192190190103002008-8-22MCMUB V1.0330 YB0809186Sa803026132190240270002008-9-2MBFXO V2.73440 YB0809184Sa80302592190190103002008-8-22MCMUB V1.0330 YB0907045Sa803184101160920100322008-12-29DWTC-2-32-P13360 YB0805128DA60401142280020102002007-12-31E3US-OMU-A-20 SA000321DA60156531990998100442009-8-18网络设备0110 YB0911142Sa804912111130880100062009-1-15RV1.5-BLU1000 YB0806031Sa801757121130880100102008-5-14RV2.5-RED1000 YB0909079Sa90257731990999101972009-7-22AD-FC/SC-Z400 YB0907024Sa90125721990998100422009-4-16台式机10 SA000321DA70414423050900221002009-8-18EE1500-DGAA01700 YB0806045DA70458283040780101002007-12-31E120S-DAADA20 YB0907045Sa80318491160920100042008-12-29DWTC-1-2-P--13360 YB0804019Sa80090481130870100042008-3-25OP-FC/PC-FC640 SA000321DA60156561990998100442009-8-18网络设备16330 YB0907045Da7047912451160920100332007-12-31DWTC-1-32-P-10 YB0804019Sa800904101090630100012008-3-19BNC-J-2-21000 YB0907045Sa80360512270110100002008-9-12FT3-CFE-AAA15535YB0907048DA60396593061720100002007-12-31GFT1501C-BA-1800 YB0911142Sa80491272270080100002009-1-15FT3-PWU22030 YB0907045Sa704791151160920100642009-5-15TWC-A-1*2-110 YB0806031Sa801757131130900100502008-5-16CAB-SCSI68/30 YB0806027Sa80194531130900100662008-5-23CAB-CN50M/1200 YB0903099Sa90078131990999100142009-3-12AD-FC-Q-Z400 YB0907045Sa704791141160920100292009-5-15TBSG250AD1L-10 YB0907045Sa704791231160920100662009-5-15TWC-A-2*16-10 YB0907045Sa704791181160920100262009-5-15STMG280AH1L-10 YB0911142Sa80491262270050100002009-1-15FT3-PWU30 YB1103035sa804069162060140100002009-3-27E3U-PWU-A0-2850 YB0809185Sa803031182070370211002008-8-18E6U-EE-A-AA110 YB0907048DA603783182270110100002007-12-31FT3-CFE-AAA-2800 YB0809186Sa803026192070870211002008-9-2E6U-EE-A-AA70 YB0812025Sa80417431130880100052008-10-28RV1.5-BLA1000 YB0909079Sa90257741990999101972009-7-28AD-FC/SC-Z1600 YB0911142Sa80491213990020100002009-1-15SPS4860 SA000321DA70501033051370221002009-8-18EE1500-DGAA11700 YB0804019Sa80090471130870100062008-3-19OP-FC/PC-FC100 SA000321DA70501023051370221002009-8-18EE1500-DGAA01700 YB0809184Sa803025172070870211002008-9-2E6U-EE-A-AA20 YB0910069Sa90245572161840101002009-7-13GFA6100-PWU10 YB0809184Sa80302511990998100722008-8-18JG-2200*60010 YB0804019Sa800904121130870100162008-3-19OP-FC/PC-FC640 YB0809184Sa803025122190240270002008-8-22MBFXO V2.72000 SA000321DA6000581305105012000NULL EE1500-DGAA0NULLYB0811164Sa804313122070020100002008-11-7E6U-CTL-A020 YB0907048DA70316022270050100002007-12-31FT3-PWU20 YB0907045Sa80173761130900100652008-11-11CAB-CN50M/1-50 YB0809186Sa80302662190730140002008-8-27MAEEA-AABA 250 YB0907048DA603783122270110100002007-12-31FT3-CFE-AAA-4800 YB0907048DA60398642070020100002007-12-31E6U-CTL-A010 YB1103035Sa901385102280040101002009-8-17E3US-NMU-A0-12400 YB0807152Sa80258752070020100002008-7-3E6U-CTL-A010 YB0907045Sa80360542270050100002008-9-12FT3-PWU20 YB0809185Sa803031152070020100002008-8-7E6U-CTL-A020 YB0804019Sa80090491130870100042008-3-19OP-FC/PC-FC40 YB0907048DA603965823050960130002007-12-31EE1500-DEAA-22500 YB0811164Sa804313132070090100002008-11-7E6U-PWU220-40 YB0811164Sa80431382190720110002008-11-7MPRUC V1.140 YB0905052Sa90008091130870100142009-1-7OP-SC/PC-SC400 YB0907048DA603783103062070100002007-12-31GFT1501C-AA-1800 YB0809185Sa80303152190730140002008-8-27MAEEA-AABA 220 YB0907048DA603783142270110100002007-12-31FT3-CFE-AAA-1800 YB0906092Sa90061222270020100002009-3-2FT3-CONT30 YB0809186Sa80302672190250220002008-9-2MBFXS V2.23440 YB0809185Sa80303162190250220002008-8-28MBFXS V2.22000YB0809185Sa803031112190220200002008-9-2MSU V2.0140 YB0811164Sa804313152070370211002008-11-7E6U-EE-A-AA30 YB0907045Sa704791221160920100172009-5-15STMGA60AI1L-10 YB0907048DA60398622270110100002007-12-31FT3-CFE-AAA5800 YB0905052Sa90008062280680101002009-1-5E3US-OTU-PD10 YB0811164Sa804313102190240270002008-11-7MBFXO V2.71680 YB0907045Sa80360572270050100002008-11-4FT3-PWU-20 YB0806002Sa80169222280680101002008-5-8E3US-OTU-PD10 YB0907048DA60378383062070100002007-12-31GFT1501C-AA-2800 YB0911142Sa804912121130880100052009-1-15RV1.5-BLA1000 YB0907045Da7047912461160920100292007-12-31TBSG250AD1L10 YB0911142Sa80491252270030100002009-1-15FT3-CMU30 YB0905052Sa90008081130870100072009-1-7OP-FC/PC-FC300 YB0907045Sa704791171160920100652009-5-15TWC-A-2*32-100 YB0907045Sa80173771130900100662008-11-11CAB-CN50M/150 YB0809184Sa803025152070020100002008-8-7E6U-CTL-A020客户编码SA000321NULL NULL NULL NULL NULLSC000494商丘网通河南曹勇郑州办运营网通SA000321NULL NULL NULL NULL NULL北京李晨北京办经销商SA000321北京东方信电SC000494商丘网通河南曹勇郑州办运营网通SC000494商丘网通河南曹勇郑州办运营网通SC000494商丘网通河南曹勇郑州办运营网通SA000321NULL NULL NULL NULL NULLSC000494商丘网通河南曹勇郑州办运营网通SC000532NULL NULL NULL NULL NULLSC000532NULL NULL NULL NULL NULLSC000087保定网通河北裴艳峰北京办运营网通SC000532湖南网通湖南闫冬武汉办运营网通SC000532NULL NULL NULL NULL NULLSC000532湖南网通湖南闫冬武汉办运营网通SC000487浙江网通浙江刘洋上海办运营网通SC000950甘孜电信四川周勃成都办运营电信SC000532NULL NULL NULL NULL NULLSC000946福建网通福建林伟上海办运营网通SC001084NULL NULL NULL NULL NULLSC000494商丘网通河南曹勇郑州办运营网通SC000532NULL NULL NULL NULL NULLSC000494商丘网通河南曹勇郑州办运营网通SC000747贵阳联通 贵州杜敬成都办运营联通SC000532湖南网通湖南闫冬武汉办运营网通SC000494商丘网通河南曹勇郑州办运营网通SC000578泸州电信四川周勃成都办运营电信SC000532湖南网通湖南闫冬武汉办运营网通SA000321NULL NULL NULL NULL NULLSC000808廊坊网通河北张瑞生北京办运营网通SA000321NULL NULL NULL NULL NULLSC000605遵义电信贵州张岚成都办运营电信SC000946福建网通福建林伟上海办运营网通SC000494商丘网通河南曹勇郑州办运营网通SC000494商丘网通河南曹勇郑州办运营网通SC000532湖南网通湖南闫冬武汉办运营网通SC001170NULL NULL NULL NULL NULLSC000494商丘网通河南曹勇郑州办运营网通SC000532NULL NULL NULL NULL NULLSC001170NULL NULL NULL NULL NULLSC001127NULL NULL NULL NULL NULLSC000494商丘网通河南曹勇郑州办运营网通SC001138NULL NULL NULL NULL NULLSC000494商丘网通河南曹勇郑州办运营网通SC000532NULL NULL NULL NULL NULLSC000532NULL NULL NULL NULL NULLSC000747贵阳联通 贵州杜敬成都办运营联通SC000132镇江电信江苏张轲南京办运营电信SC000532湖南网通湖南闫冬武汉办运营网通SC000494商丘网通河南曹勇郑州办运营网通SC000532NULL NULL NULL NULL NULLSA000321NULL NULL NULL NULL NULLSC000494商丘网通河南曹勇郑州办运营网通SC000532NULL NULL NULL NULL NULLSC000494商丘网通河南曹勇郑州办运营网通SC000494商丘网通河南曹勇郑州办运营网通SC000494商丘网通河南曹勇郑州办运营网通SC000494商丘网通河南曹勇郑州办运营网通SC000532NULL NULL NULL NULL NULL北京李晨北京办经销商SA000321北京东方信电SC000494商丘网通河南曹勇郑州办运营网通SC000532NULL NULL NULL NULL NULLSA000321NULL NULL NULL NULL NULLSC000494商丘网通河南曹勇郑州办运营网通SC000532NULL NULL NULL NULL NULLSC000747贵阳联通 贵州杜敬成都办运营联通SC001157NULL NULL NULL NULL NULLSC000747NULL NULL NULL NULL NULLSC000532湖南网通湖南闫冬武汉办运营网通SC000377佛山电信广东李志鹏武汉办运营电信SC000494商丘网通河南曹勇郑州办运营网通SA000321NULL NULL NULL NULL NULLSC000494商丘网通河南曹勇郑州办运营网通SC000532NULL NULL NULL NULL NULLSC000532NULL NULL NULL NULL NULLSC000534NULL NULL NULL NULL NULLSC000532NULL NULL NULL NULL NULLSC001170NULL NULL NULL NULL NULLSC000451湖北网通湖北张立平武汉办运营网通SC000487浙江网通浙江刘洋上海办运营网通SC000532湖南网通湖南闫冬武汉办运营网通SC000532湖南网通湖南闫冬武汉办运营网通SC000532NULL NULL NULL NULL NULLSC000494商丘网通河南曹勇郑州办运营网通SA000321NULL NULL NULL NULL NULLSC000494商丘网通河南曹勇郑州办运营网通SC000494商丘网通河南曹勇郑州办运营网通SC000532NULL NULL NULL NULL NULLSC000132NULL NULL NULL NULL NULLSC000532NULL NULL NULL NULL NULLSC000532湖南网通湖南闫冬武汉办运营网通SC000532NULL NULL NULL NULL NULLSC001170NULL NULL NULL NULL NULLSC000451湖北网通湖北张立平武汉办运营网通SC000605遵义电信贵州张岚成都办运营电信SC000494商丘网通河南曹勇郑州办运营网通SC000087保定网通河北裴艳峰北京办运营网通SC000494商丘网通河南曹勇郑州办运营网通SC000494商丘网通河南曹勇郑州办运营网通SC000532NULL NULL NULL NULL NULLSC001157NULL NULL NULL NULL NULLSC000494商丘网通河南曹勇郑州办运营网通SC000532NULL NULL NULL NULL NULLSC000494商丘网通河南曹勇郑州办运营网通SC000747NULL NULL NULL NULL NULLSC000494商丘网通河南曹勇郑州办运营网通SC000532NULL NULL NULL NULL NULLSC000808廊坊网通河北张瑞生北京办运营网通SC000532NULL NULL NULL NULL NULLSC000534NULL NULL NULL NULL NULLSC000532NULL NULL NULL NULL NULLSC000494商丘网通河南曹勇郑州办运营网通SC000532湖南网通湖南闫冬武汉办运营网通SC000532NULL NULL NULL NULL NULLSC000532NULL NULL NULL NULL NULLSC000532NULL NULL NULL NULL NULLSC000377佛山电信广东李志鹏武汉办运营电信SC000532NULL NULL NULL NULL NULLSC000532NULL NULL NULL NULL NULLSC000532NULL NULL NULL NULL NULLSC000494商丘网通河南曹勇郑州办运营网通SC000494商丘网通河南曹勇郑州办运营网通SC000494商丘网通河南曹勇郑州办运营网通SC000494商丘网通河南曹勇郑州办运营网通SC000532NULL NULL NULL NULL NULLSC000261无锡电信江苏安钢南京办运营电信SA000321NULL NULL NULL NULL NULLSC000747NULL NULL NULL NULL NULLSC000532湖南网通湖南闫冬武汉办运营网通SC001170NULL NULL NULL NULL NULL湖北张立平武汉办运营联通SC001083湖北联通(新SA000321NULL NULL NULL NULL NULLSC000664贵州移动贵州丁少锋成都办运营移动SC000532NULL NULL NULL NULL NULLSC000808廊坊网通河北张瑞生北京办运营网通SA000321NULL NULL NULL NULL NULLSC000532NULL NULL NULL NULL NULLSC000808廊坊网通河北张瑞生北京办运营网通SC000532NULL NULL NULL NULL NULLSC000747NULL NULL NULL NULL NULLSC000532NULL NULL NULL NULL NULLSC000532湖南网通湖南闫冬武汉办运营网通SC000532湖南网通湖南闫冬武汉办运营网通SC000950甘孜电信四川周勃成都办运营电信SC000532NULL NULL NULL NULL NULLSC000532NULL NULL NULL NULL NULLSC000532NULL NULL NULL NULL NULLSC000747NULL NULL NULL NULL NULLSC000534NULL NULL NULL NULL NULLSC000494商丘网通河南曹勇郑州办运营网通SC000532NULL NULL NULL NULL NULLSC000494商丘网通河南曹勇郑州办运营网通SC000747贵阳联通 贵州杜敬成都办运营联通SC001170NULL NULL NULL NULL NULLSC000747NULL NULL NULL NULL NULLSA000321NULL NULL NULL NULL NULLSC000808廊坊网通河北张瑞生北京办运营网通SA000321NULL NULL NULL NULL NULLSC000494商丘网通河南曹勇郑州办运营网通SC001084NULL NULL NULL NULL NULLSC000494商丘网通河南曹勇郑州办运营网通SC000808廊坊网通河北张瑞生北京办运营网通SC000494商丘网通河南曹勇郑州办运营网通北京李晨北京办经销商SA000321北京东方信电SC000494商丘网通河南曹勇郑州办运营网通SC000532NULL NULL NULL NULL NULLSC000532NULL NULL NULL NULL NULLSC000494商丘网通河南曹勇郑州办运营网通SC000532NULL NULL NULL NULL NULLSC000532NULL NULL NULL NULL NULLSC000534NULL NULL NULL NULL NULLSC000087保定网通河北裴艳峰北京办运营网通SC000532NULL NULL NULL NULL NULLSC000494商丘网通河南曹勇郑州办运营网通SC000808廊坊网通河北张瑞生北京办运营网通SC000532NULL NULL NULL NULL NULLSC000494商丘网通河南曹勇郑州办运营网通SC000494商丘网通河南曹勇郑州办运营网通SC000132镇江电信江苏张轲南京办运营电信SC000532NULL NULL NULL NULL NULLSC000494商丘网通河南曹勇郑州办运营网通SC000532NULL NULL NULL NULL NULL贵州张岚成都办运营联通SC001132贵阳联通(新SC000494商丘网通河南曹勇郑州办运营网通SC000494商丘网通河南曹勇郑州办运营网通SC000494商丘网通河南曹勇郑州办运营网通SC000494商丘网通河南曹勇郑州办运营网通SC000532NULL NULL NULL NULL NULLSC000532NULL NULL NULL NULL NULLSC000132镇江电信江苏张轲南京办运营电信SC000494商丘网通河南曹勇郑州办运营网通SC000532NULL NULL NULL NULL NULLSC000605遵义电信贵州张岚成都办运营电信SC000532NULL NULL NULL NULL NULLSC000747NULL NULL NULL NULL NULLSC000532NULL NULL NULL NULL NULLSC000747NULL NULL NULL NULL NULLSC000132镇江电信江苏张轲南京办运营电信SC000532NULL NULL NULL NULL NULLSC000532NULL NULL NULL NULL NULLSC000494商丘网通河南曹勇郑州办运营网通。