奈米级析出物强化热轧汽车用钢开发

- 格式:doc

- 大小:1.12 MB

- 文档页数:16

日本JFE钢铁公司战略发展趋势当前,世界钢铁工业发展面临着新的巨大挑战。

在这种形势下,世界第三大钢铁联合企业——日本JFE钢铁公司的产品发展战略定位成努力研发创新技术,开发“独创”和“领先”产品,占领高端产品市场。

近年,随着创新技术的不断开发成功,各种高端新产品也应运而生。

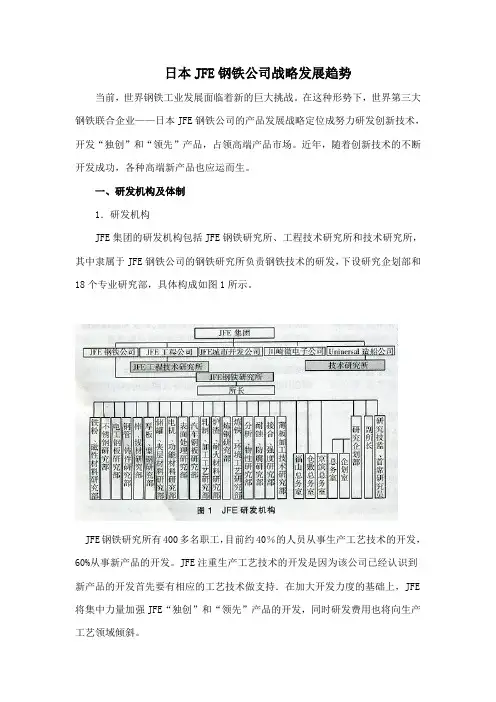

一、研发机构及体制1.研发机构JFE集团的研发机构包括JFE钢铁研究所、工程技术研究所和技术研究所,其中隶属于JFE钢铁公司的钢铁研究所负责钢铁技术的研发,下设研究企划部和18个专业研究部,具体构成如图1所示。

JFE钢铁研究所有400多名职工,目前约40%的人员从事生产工艺技术的开发,60%从事新产品的开发。

JFE注重生产工艺技术的开发是因为该公司已经认识到新产品的开发首先要有相应的工艺技术做支持.在加大开发力度的基础上,JFE 将集中力量加强JFE“独创”和“领先”产品的开发,同时研发费用也将向生产工艺领域倾斜。

2.研发体制为了促进各产品区域重点技术课题的制定和各工序间技术开发的横向推进,JFE钢铁公司采用横跨生产、研究和经营部门的研发体制——产品区域、SB U(战略经营单元)体制(见图2)。

产品区域由薄板、厚板等8部分组成,在经营计划的基础上制定技术开发战略,并制定重点技术课题,横向推进技术研发。

S BU由通用技术领域的炼铁、炼钢、炉渣、设备、环境和能源5个部门组成,各S BU要制定部门战略,横向推进技术开发。

产品区域、SBU中的各部门由专业技术会议联系在一起,专业技术会议以产品区域、SBU提出的技术战略为基础推进课题、预测中长期技术动向、强化公司的技术创造力。

二、产品研发战略1.创新技术开发战略JFE集团的开发理念是以用户需求为第一,进行自主创新产品的开发;高效率生产优质产品技术的开发;环保型产品与技术的开发。

同时,通过充分发挥集团整体的协同作用,拓展新领域,灵活应对环境的变化,确保高收益率,获得市场和社会的信赖。

在该理念指导下,近年JFE钢铁公司的技术开发都是以“独创”和“领先”为目标,在加工技术、基础技术、工艺技术、产品技术等领域开发出了许多如超速冷却技术(Super—OLAC)、在线热处理工艺(HOP)、提高焊接热影响区韧性技术(EWEL)等创新技术(如表1所示),从而大幅提高了设备生产效率,降低了生产成本。

《析出强化对Ni2CrFeAl0.3高熵合金力学性能的影响》一、引言随着高熵合金的发展,析出强化作为一种重要的强化手段,在提高合金力学性能方面发挥着重要作用。

本文以Ni2CrFeAl0.3高熵合金为研究对象,通过析出强化处理,探讨其对合金力学性能的影响。

二、Ni2CrFeAl0.3高熵合金的组成与性质Ni2CrFeAl0.3高熵合金是一种由镍、铬、铁、铝等元素组成的多组元合金。

由于其独特的组成,该合金具有优异的耐腐蚀性、高温稳定性和良好的力学性能。

然而,为了进一步提高其力学性能,我们采用了析出强化处理。

三、析出强化处理析出强化是一种通过在合金中引入第二相粒子,从而提高合金力学性能的方法。

在Ni2CrFeAl0.3高熵合金中,我们通过控制热处理工艺,使合金中的元素在特定温度下发生相变,从而形成细小的第二相粒子。

这些粒子能够有效地阻碍位错运动,提高合金的强度和硬度。

四、析出强化对Ni2CrFeAl0.3高熵合金力学性能的影响1. 强度与硬度经过析出强化处理的Ni2CrFeAl0.3高熵合金,其强度和硬度得到了显著提高。

这是由于第二相粒子的形成,有效地阻碍了位错运动,使得合金在受力时能够更好地抵抗变形。

2. 韧性虽然析出强化提高了合金的强度和硬度,但并未降低其韧性。

相反,适当的析出强化处理可以提高合金的韧性和抗冲击性能。

这是因为第二相粒子的分布和尺寸得到了优化,使得合金在受到外力时能够更好地吸收能量。

3. 疲劳性能析出强化处理还可以提高Ni2CrFeAl0.3高熵合金的疲劳性能。

由于第二相粒子的存在,合金在循环载荷作用下能够更好地抵抗疲劳裂纹的扩展,从而提高合金的疲劳寿命。

五、结论本文通过对Ni2CrFeAl0.3高熵合金进行析出强化处理,探讨了其对合金力学性能的影响。

结果表明,析出强化可以显著提高合金的强度、硬度和韧性,同时还可以提高合金的疲劳性能。

因此,析出强化是一种有效的提高Ni2CrFeAl0.3高熵合金力学性能的方法。

A12时效温度对HSLA-100高强船体钢组织性能的影响罗小兵苏航杨才福柴锋钢铁研究总院结构材料研究所北京 100081摘要:采用固溶+时效的热处理方法研究了时效温度对HSLA-100含铜高强船体钢组织性能的影响。

结果表明,试验钢在450℃处出现强度峰值,这是由大量纳米级的Cu析出物(<5nm)和少量Nb(C,N)第二相粒子的析出强化造成的。

过时效状态下,Cu析出粒子尺寸显著增大(10 nm~30 nm),其形状由球状变为杆状或短棒状,晶体结构也由bcc转变为fcc结构,并与基体失去共格关系,沉淀强化作用也逐渐减弱。

时效过程中基体软化和第二相粒子沉淀强化的共同作用决定了含铜高强船体钢的性能变化规律。

关键词:时效温度 HSLA-100 Cu 沉淀强化船体钢Effect of aging temperature on microstructure and properties of HSLA-100 highstrength ship hull steelsLUO Xiaobing, SU Hang , YANG Caifu, CHAI FengCentral Iron and Steel Research Institute, Institute for structural materials, Beijing 100081, China Abstract:Processing of quenching and aging was applied in this paper to research the effect of aging temperature on microstructure and properties of HSLA-100 copper-bearing high strength ship-hull steels. The results indicated that t he strength of tested steels were peaked while aging at 450℃ which attributed to the large amount of fine Cu particles( less than 5nm)and a small number of Nb(C,N) precipitates. The size of Cu particles happened to coarsen(10 nm~30 nm)in the condition of over aging, and it grew to rod-like from spherical in the particle shape, and lost the relationship of coherency to matrix , finally its precipitation strengthening is weakened. In addition, competition between the soften of matrix and the strengthen by second phase determined the aging regularity of copper-bearing high strength ship-hull steels.Keywords:Aging Temperature HSLA-100 Cu Precipitation Strengthening Ship-Hull steels0 前言随着国内外对铜在钢中作用研究的不断深入,Cu的沉淀强化技术被人们广泛应用于船舶、桥梁、汽车、石油化工、压力容器等领域。

热轧工艺参数优化在钢材的晶粒细化和析出相控制中的应用与研究热轧工艺参数优化在钢材的晶粒细化和析出相控制中的应用与研究随着工业发展的进步与科技的不断创新,钢材作为重要的工程材料,在各个领域发挥着重要的作用。

然而,钢材在使用中也面临着一系列的问题,如晶粒粗化、硬度不足等。

因此,如何通过适当的工艺参数控制,对钢材进行晶粒细化和析出相控制的研究成为了科学家和工程师们的研究重点。

热轧工艺是钢材加工中重要的一个环节,通过加热和轧制的过程,可以改变钢材内部的组织结构和力学性能。

合理的工艺参数设计和优化,对于晶粒细化和析出相控制起着至关重要的作用。

在新的材料分析和工艺实验的基础上,科学家们通过应用数值模拟和统计分析等方法,对热轧工艺参数进行优化,以实现对钢材晶粒细化和析出相的有效控制。

首先,在热轧过程中,温度是一个重要的工艺参数。

合适的温度可以促使晶粒的形成和生长,从而达到晶粒细化的目的。

研究发现,当热轧温度较高时,晶粒尺寸会变大,晶界的运动和晶粒的再结晶会受到抑制;而当温度较低时,晶粒尺寸会变小,晶界能量的积累和晶粒的再结晶会增强。

因此,通过合理调节热轧温度,可以有效控制钢材的晶粒尺寸。

其次,轧制速度也是一个重要的工艺参数。

合适的轧制速度可以影响钢材的变形行为和转变轧制过程中的成分和组织结构。

研究发现,当轧制速度较低时,晶粒会发生细化,晶界的移动和晶粒的完全再结晶会减缓;而当速度较高时,晶粒会变大,晶界的运动和晶粒的再结晶会增强。

因此,通过合理调节轧制速度,可以实现对钢材晶粒细化和析出相的控制。

此外,轧制力和压下量也是影响钢材晶粒细化和析出相控制的重要工艺参数。

较大的轧制力可以增加晶粒的变形和阻碍晶界的移动;而较小的轧制力则有利于晶粒的再结晶和晶界的移动。

适当的压下量可以促进晶粒细化和控制析出相的分布。

通过合理调节轧制力和压下量,可以实现对钢材晶粒细化和析出相的精确控制。

总之,热轧工艺参数的优化在钢材的晶粒细化和析出相控制中起着至关重要的作用。

奈米级析出物强化热轧汽车用钢开发 黄 庆 渊1 ■ 颜 鸿 威2 ■ 潘 永 村1 ■ 杨 哲 人2 1. 中国钢铁股份有限公司钢铁铝品研究发展处 2. 国立台湾大学材料科学与工程学研究所

为了节省能源消耗与兼顾乘车安全性,汽车用钢材使用的强度等级愈来愈高。过去高强度钢通常采用麻田散铁或变韧铁为主要显微组织的相变态强化设计,然而此类钢材加工成形性不够好。 为了得到优良强度与加工性组合,本研究采用高钛(>0.08wt%)复合添加钒之合金设计配合热轧轧延参数之精致控制,利用肥粒铁晶粒细化及奈米析出复合强化机构来产制高强度热轧汽车用钢。其冶金机制是利用高温时非常稳定之TiN来抑制热轧制程再加热时沃斯田铁晶粒成长,并于热轧制程上控制完轧温度尽可能接近Ar3来大幅增加肥粒铁成核位置,配合采用快速冷却模式来防止于高温产生肥粒铁相变化,以避免肥粒铁晶粒粗化。另外再藉由热轧盘卷温度的适当控制,使奈米尺寸的(Ti,V)C界面析出物(<10nm)持续于肥粒铁相变化过程中析出,而得到大量均匀散布于肥粒铁晶粒中之析出物,充分发挥良好的析出强化效果。本研究藉由微米级(<3μm)细晶肥粒铁中奈米级析出物之大量产生,使得热轧后之钢材不需再经过任何热处理,其抗拉强度可以稳定达到>780MPa的超高强度,而且伸长率还可达到18%的水平。此钢材超高强度与良好加工成形性,已经被广泛应用于卡车大梁及汽车之防撞钢梁、安全汽囊零件等汽车部件上。 To save the energy and increase the passenger safety, the required strength level of automobile steels has become higher and higher. Traditionally, the microstructure of the high strength steels is mainly composed of martensite or bainite for getting the transformation strengthening effect, but these steels usually exhibit poor formability. To reach the demand of high strength and formability balance, the steels with composition of high Ti content (>0.08wt%) and minor V addition undergoing careful control of hot rolling parameters are used to get the grain refinement and nanoprecipitation coupled strengthening mechanisms for the production of high strength automobile steel. The stable TiN precipitates inhibit the grain growth during reheating treatment. In addition, the proper control of the finish rolling temperature nearby the Ar3 temperature promotes a lot of ferrite nucleation sites on the prior austenite grain boundaries. During the subsequent cooling stage, fast cooling is applied to further prevent the occurrence of ferrite transformation and corresponding coarsening of ferrite grain size. Additionally, by controlling the coiling temperature of the strip, lots of nano-sized (<10nm) (Ti,V)C interface precipitates are consecutively appeared during the slow cooling period. The ultra fine grained refinement and nano-precipitation technologies ensure the strength of steel higher than 780 MPa, and the elongation of the steel better than 18%, sparing the common strengthening by heat treatment. This steel has been applied in several parts of automobile, such as truck frame, door impact beam, and container of safety steam capsule etc.

壹、前 言 随着地球暖化问题日益严重,降低车体重量以减少汽车行驶当中的二氧化碳排放,已经是刻不容缓的核心议题。汽车车体重量约有 70% 为钢铁材料所构成,所以高强度汽车用钢的开发与运用是降低车体重量最有效的方法,同时也已被证实对汽车之节能减碳有相当之帮助。由于汽车用钢材在使用的过程中,均可能比一般高强度钢材经过更繁复的成形加工,因此汽车用钢除了强度的要求外,其加工性要求亦较严格,所以高强度汽车用钢材在开发的过程中,均将比其它高强度钢材面临更大的挑战,全球各大先进钢厂也均将热轧汽车用钢产品之可生产等级,做为评鉴各钢厂技术能力的重要指标。过去国内超过 60 公斤级以上的热轧汽车用钢均由国外进口,包括 HT620 (SAE J1392 80XLF, SAE J2340 080XF, ASTM1011/1018 Gr.80)、HT690 与 HT780(JSH780) 三种等级之钢材,其中 HT780 只有极少数先进钢厂具备生产能力,而且日本对于 780MPa 等级钢片的出口有所管制,国内汽车零组件加工业者往往因无法取得原料而失去订单。因此为了因应国内汽车工业需求,提升国内业者在国际市场之竞争力,本研究将投入开发 HT620、HT690 与 HT780 三种强度等级高于 60 公斤之热轧汽车用钢,此三种等级热轧钢材之机械性质要求如表-1 所示。

过去一般钢材在抗拉强度超过600MPa以上时,所采用的强化机构是相变态强化,如图-1所示[1],也就是控制钢材内显微组织为变韧铁或麻田散铁,藉由这些组织相变化时所产生的大量差排,以达到强化钢材的目的。不过以变韧铁或麻田散铁为基地的钢材,其拉伸的伸长率低,因此加工成形性不佳,所以并不适合做为需加工成形的汽车用钢。具备较良好加工成形性的热轧钢材,则均以肥粒铁为主要组织,过去国内所能生产之可加工成形热轧汽车用钢强度等级最高的是SPFH590 (抗拉强度590MPa),其所采用的主要强化方法是藉由添加铌所产生的肥粒铁晶粒细化与碳化铌析出强化。不过此种标榜晶粒细化与析出强化的热轧钢材,若严谨地探讨钢材中显微组织与其机械性质之对应关系时,可发现析出强化对其强度贡献是微乎其微,因为其内部的 NbCN 尺寸大多大于 20nm,而且数量相当稀少。此种型态的 NbCN 是于高温的沃斯田铁相就已经析出,其在钢材中的主要作用是延迟轧延时的再结晶[2,3],以得到未再结晶之扁平沃斯田铁晶粒,使随后相变化能得到细晶肥粒铁,所以添加铌的 SPFH590,其主要的强化均是来自于晶粒细化。所谓晶粒细化强化指的是利用晶 界来阻止差排移动达到强化的目的,所以晶粒尺寸愈小,晶界数目愈多,阻止差排移动的效果愈好。根据 Hall-Petch 方程式:

其中 d 为平均晶粒直径,σy 为其降伏强度,σi 为差排在晶粒内滑移的晶粒内磨耗力以及 ky 为材料之正比常数。材料之强度随晶粒尺寸降低而提高。晶粒细化之强化机构过去已经广泛应用于钢铁工业,对现有的制程设备而言,肥粒铁钢材的晶粒细化强化机构应用几乎已经接近极限,很难再藉由晶粒细化再大幅提升钢材强度。相对而言,析出强化则还有很大发展空间,所以肥粒铁晶粒细化再加上析出强化效用的发挥,是超高强度热轧汽车用钢发展的重要方向。 根据Orowan-Ashby析出强化机构[4,5],析出强化的效果主要是受析出物尺寸与析出物的体积分率所影响,析出物的尺寸愈小与析出体积分率愈高,则其强化效果愈好,当添加适当的合金产生一定的体积分率的析出物时,如果析出物的尺寸是奈米级 (<10nm),则其所贡献的强化效果可超过 200MPa,如图-2 所示[5]。钢材中要产生大量具备强化效果的奈米级析出物,这些析出物必须是在沃斯田铁相变化到肥粒铁过程中或者是在更低温肥粒铁中生成,1970 年代著名的冶金学者 Honeycombe 所提出的界面析出(Interphase Precipitation)[6-8] 是目前最具有析出强化效率的方法,如图-3 所示。由于过去受观察设备限制与分析方法未完整建立,对于奈米级界面析出物之特性与析出行为仍未完全厘清,所以一般认为奈米级界面析出物只能在恒温相变化中产生[9,10]。因为过去所了解的奈米级界面析出物产生的模式与一般钢材量产制程的连续冷却是无法符合,因此即使奈米级界面析出物在 1970 年代就已经被发现,不过直到上个世纪结束,此种具备相当良好强化效果的机构,都仅止于实验室的研究,而无法落实到大量生产之钢材上。不过,由于界面析出可以贡献相当好的强化效果,所以将其落实到大量生产钢材上的努力,一直没有间断过,也是许多钢铁研究人员长久以来追求的终极目标。 综合以上所述,先进的超高强度热轧汽车用钢的显微组织必须以细晶肥粒铁为基地,并且避免变韧铁的生成,在肥粒铁中必须存在大量的奈米析出物,如此的组织才可具备超高强度与良好成形性。不过这些优良的组织要在热轧制程中产生,是一个相当严厉的挑战,因为热轧生产线是一条连续式制程产线,如图-4 所示,250 ㎜ 厚的钢胚从出加热炉经轧延至所设定之厚度并且盘卷成钢卷,整个热轧制程全程约耗时 2.5~3 分钟,在如此的短暂时间中除了必须精确的控制产品的尺寸精度外,另外为了产生细晶肥粒铁与奈米析出物的冶金效应也都必须同时完成。为了使这些优良的组织在热轧制程中于钢带内产生,因此本研究将藉由实验室分析设备厘清奈米级界面析出物之结构与析出行为特性,并进而建立超高强度奈米析出强化热轧汽车用钢的量产技术,使国内生产的热轧汽车用钢等级由 590MPa (SPFH590) 大幅推升至780MPa。