D45 1528-B-1997

- 格式:pdf

- 大小:109.07 KB

- 文档页数:11

第 2 期李再琴等.全钢载重子午线轮胎胎面混炼胶停放时间对挤出效果的影响111全钢载重子午线轮胎胎面混炼胶停放时间对挤出效果的影响李再琴,刘 强,焦清伟(八亿橡胶有限责任公司,山东枣庄 277800)摘要:研究全钢载重子午线轮胎胎面混炼胶停放时间对挤出效果影响。

结果表明:胎面混炼胶停放时间与挤出部件的气孔率、质量和尺寸有密切关系;胎面混炼胶需要停放一定时间,但停放时间不宜太长,一般控制在96 h内,以降低混炼胶停放时间对挤出半成品的影响,提升产品质量。

关键词:胎面胶;停放时间;质量;气孔率;尺寸中图分类号:U463.341+.3/.6;TQ336.1 文章编号:1006-8171(2019)02-0111-03文献标志码:B DOI:10.12135/j.issn.1006-8171.2019.02.0111随着轮胎市场竞争的愈演愈烈以及客户对轮胎品质的要求越来越高,高端、高品质轮胎将成为未来市场竞争的焦点,各企业都在提升产品内在质量,针对每个生产环节进行细节研究。

我公司在试验中发现胎面混炼胶停放时间与挤出工艺有着密切的关系,对半成品稳定性影响显著。

在混炼胶加工结束后,混炼胶被送到胶料停放场进行停放,这个过程并非单纯的静态过程,也非投入使用前的暂时储存,混炼胶停放时间过长对后续加工会造成不利影响[1-3]。

本工作主要研究全钢载重子午线轮胎胎面混炼胶停放时间对挤出效果的影响。

1 实验1.1 主要原材料天然橡胶(NR),STR20#,新远大橡胶(泰国)有限公司产品;炭黑N134,上海卡博特化工有限公司产品;白炭黑,山东金能科技股份有限公司产品;氧化锌,大连氧化锌厂产品;防老剂4020,江苏圣奥化学科技有限公司产品。

1.2 配方NR 100,炭黑N134/白炭黑 54,硬脂酸/氧化锌 6,硫黄/促进剂 2.6,其他 5。

1.3 主要设备和仪器XJD250型销钉冷喂料挤出机和双复合热喂料挤出机,中国化学工业桂林工程有限公司产品;Φ660开炼机,青岛双星机械股份有限公司产品;GT-7080-S2型门尼粘度仪,高铁检测仪器(东莞)有限公司产品。

ICS75.180.10E 92 Q/ 无锡双马钻探工具有限公司企业标准Q/320206 QMGN01—2015 非开挖(定向)钻杆文稿版次选择2015-03-20发布2015-03-25实施前言本标准依据GB/T 1.1—2009《标准化工作导则第1部分:标准的结构和编写》的有关规定编制。

本标准由无锡双马钻探工具有限公司提出。

本标准起草单位:无锡双马钻探工具有限公司技术部门。

本标准主要起草人:周中吉、刘道喜。

本标准为首次发布。

非开挖(定向)钻杆1 范围本标准规定了非开挖(定向)钻杆的术语和定义、分类和基本参数、要求、试验方法、检验规则、标志、包装、运输和贮存。

本标准适用于两端具有端部加厚的整体或焊接的钢制非开挖(定向)钻杆(以下简称钻杆)。

钻杆用于非开挖钻探过程。

2 规范性引用文件下列文件对于本文件的应用是必不可少的。

凡是注日期的引用文件,仅所注日期的版本适用于本文件。

凡是不注日期的引用文件,其最新版本(包括所有的修改单)适用于本文件。

GB/T 230.1 金属材料洛氏硬度试验第1部分:试验方法(A、B、C、D、E、F、G、H、K、N、T标尺) GB/T 4340.1 金属材料维氏硬度试验第1部分:试验方法GB/T 5777 无缝钢管超声波探伤检验方法GB/T 7735 钢管涡流探伤检验方法GB/T 10610 产品几何技术规范(GPS).表面结构.轮廓法.评定表面结构的规则和方法GB/T 11336 直线度误差检测GB/T 22512.2 石油天然气工业.旋转钻井设备第2部分:旋转台肩式螺纹连接的加工与测量GB/T 29166 石油天然气工业钢制钻杆3 术语和定义GB/T 29166所确立的术语和定义适用于本文件。

4 分类和基本参数4.1 分类钻杆分焊接钻杆和整体钻杆二类。

4.2 结构焊接钻杆的结构见图1;整体钻杆的结构见图2。

1—钻杆内螺纹接头;2—内螺纹接头过渡带;3—钻杆焊颈;4—钻杆加厚端;5—钻杆管体;6—钻杆管体;7—摩焊焊缝;8—外螺纹接头过渡带;9—钻杆外螺纹接头;10—旋转台肩式连接。

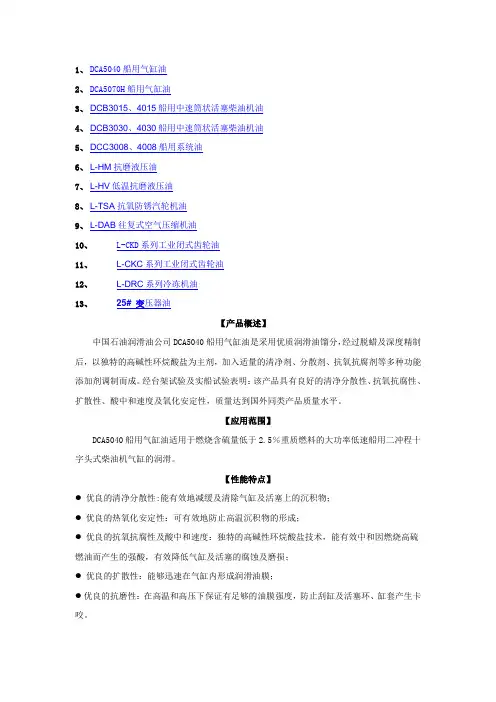

1、DCA5040船用气缸油2、DCA5070H船用气缸油3、DCB3015、4015船用中速筒状活塞柴油机油4、DCB3030、4030船用中速筒状活塞柴油机油5、DCC3008、4008船用系统油6、L-HM抗磨液压油7、L-HV低温抗磨液压油8、L-TSA抗氧防锈汽轮机油9、L-DAB往复式空气压缩机油10、L-CKD系列工业闭式齿轮油11、L-CKC系列工业闭式齿轮油12、L-DRC系列冷冻机油13、25# 变压器油【产品概述】中国石油润滑油公司DCA5040船用气缸油是采用优质润滑油馏分,经过脱蜡及深度精制后,以独特的高碱性环烷酸盐为主剂,加入适量的清净剂、分散剂、抗氧抗腐剂等多种功能添加剂调制而成。

经台架试验及实船试验表明:该产品具有良好的清净分散性、抗氧抗腐性、扩散性、酸中和速度及氧化安定性,质量达到国外同类产品质量水平。

【应用范围】DCA5040船用气缸油适用于燃烧含硫量低于2.5%重质燃料的大功率低速船用二冲程十字头式柴油机气缸的润滑。

【性能特点】●优良的清净分散性:能有效地减缓及清除气缸及活塞上的沉积物;●优良的热氧化安定性:可有效地防止高温沉积物的形成;●优良的抗氧抗腐性及酸中和速度:独特的高碱性环烷酸盐技术,能有效中和因燃烧高硫燃油而产生的强酸,有效降低气缸及活塞的腐蚀及磨损;●优良的扩散性:能够迅速在气缸内形成润滑油膜;●优良的抗磨性:在高温和高压下保证有足够的油膜强度,防止刮缸及活塞环、缸套产生卡咬。

【实船试验及混对试验】●DCA5040船用气缸油在B&W8K84EF机型上进行实船试验,试验时间3962小时。

●活塞环的磨损率正常,活塞环无粘结卡咬、气缸内壁光滑、无拉痕,活塞表面、气口积炭均较少。

其质量达到国外同类产品质量水平,可以满足远洋运输船舶的要求。

●DCA5040船用气缸油与各种国外同类船用气缸油混对,无沉淀、悬浮物、分层等现象发生,可以任意比例混对使用。

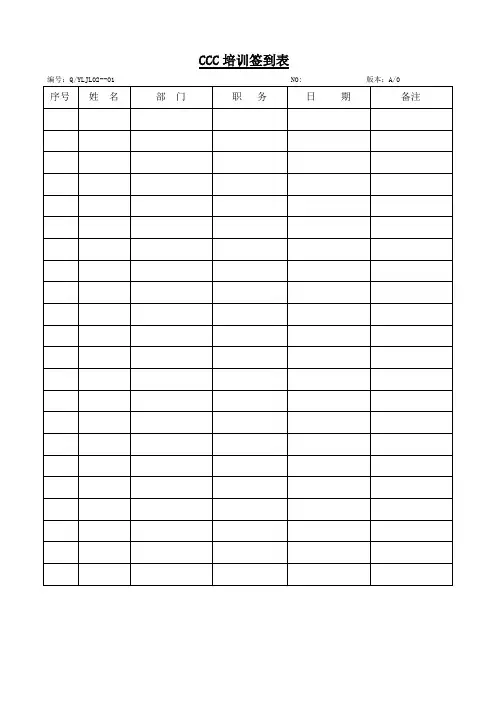

编号:Q/YLJL02--01 NO: 版本:A/0编号:Q/YLJL02--02 NO: 版本:A/0编号:Q/YLJL02--03 NO: 版本:A/0年度培训计划编号:Q/YLJL02--04 NO: 版本:A/0编制/日期:审核/日期:批准/日期:职工培训档案卡编号:Q/YLJL02--05 NO: 版本:A/0员工登记表编号:Q/YLJL02--06 NO: 版本:A/0培训有效性评价表编号: Q/YLJL02--07 NO: 版本:A/0编号:Q/YLJL03--01 NO: 版本:A/0编号:Q/YLJL03—02 NO: 版本:A/0使用部门设备状态申请单编号:Q/YLJL03—02 NO: 版本:A/0设备台帐编号:Q/YLJL03--03 NO:版本:A/0编号:Q/YLJL03--04 NO:版本:A/0编号:Q/YLJL03--05 NO:版本:A/0设备检修计划及记录设备保养记录注:保养后:用”∨”表示日保,“⊿”表示周保,“О”表示月保,“X”表示有异常情况,应在“异常情况记录”栏予以记录设备保养记录注:保养后:用”∨”表示日保,“⊿”表示周保,“О”表示月保,“X”表示有异常情况,应在“异常情况记录”栏予以记录受控文件发放/回收记录表编号:Q/YLJL04--01 NO:版次:A/0非受控文件发放申请表编号:Q/YLJL04--03 NO:版次:A/0文件资料清单编号:Q/YLJL04--02 NO:版次:A/0文件更改申请及记录表编号:Q/YLJL04--05 NO:版次:A/0文件借阅/复制记录□借阅□复制编号:Q/YLJL04--06 NO:版次:A/0文件销毁记录表编号:Q/YLJL04--08 NO:版次:A/0外来文件清单编号:Q/YLJL04--07 NO:版次:A/0质量记录清单编号:Q/YLJL05--01 NO:版次:A/0制表:日期:编号:Q/YLJL06--05 NO: 版本:A/0编号:Q/YLJL06--01 NO: 版本:A/0合格供方名单编号:Q/YLJL06--02 NO: 版本:A/0供方业绩评定表编号:Q/YLJL06--03 NO: 版本:A/0采购计划编号:Q/YLJL06--04 NO:版本:A/0 供方名称:编号:Q/YLJL08--01 NO: 版本:A/0编制/日期:审核/日期:批准/日期:编号:Q/YLJL08--02 NO: 版本:A/0模具履历表编号:Q/YLJL09--01 No:版次:A/0模具名称:规格:模具台账编号:Q/YLJL09--02 NO:版次:A/0模具检验记录模具收发记录编号:Q/YLJL09—04 NO: 版本:A/0模具维修/报废记录编号:Q/YLJL09—05 NO: 版本:A/0 □维修□报废模具维修/报废记录编号:Q/YLJL09—05 NO: 版本:A/0原辅料检验记录编号:Q/YLJL11--01 NO: 版本:A/0原辅料检验记录编号:Q/YLJL11--01 NO: 版本:A/0周期校准计划计量器报废(失效)通知单编号:Q/YLJL12--03 NO:版本:A/0量具档案编号:Q/YLJL12—04 NO:版本:A/0计量器具台帐编号:Q/YLJL12--01 NO:版本:A/0运行检查记录NO:版本:A/0量具重复性和再现性分析报告(均值和极差法)编号:Q/YLJL13--02 No:版本:A/0计数型测量系统分析报告(小样法)编号: Q/YLJL13--03 NO: 版本:A/0测量系统分析计划编号:Q/YLJL13--05 NO: 版本:A/0量具重复性和再现性数据表编号:Q/YLJL13--01 NO: 版本:A/0 零件号和名称:测量参数:规格要求:量具名称:量具编号:量具规格:返工产品检验记录编号:Q/YLJL14—02 NO:版本:A/0返工产品检验记录编号:Q/YLJL14—02 NO:版本:A/0返工产品检验记录编号:Q/YLJL14—02 NO:版本:A/0返工产品检验记录编号:Q/YLJL14—02 NO:版本:A/0编号:Q/YLJL15--01 NO:版次:A/0编号:Q/YLJL15--02 NO:版次:A/0制表:邱阔批准人:年月日内部审核检查记录表编号:Q/YLJL15--03 NO:版次:A/0审核组长/日期:审核员/日期:于奎堂 /2009/03/03 部门负责人/日期:内部审核报告编号:Q/YLJL15--04 NO:版次:A/0。

固定钻套规格表机床夹具零件及部件 固定钻套国标GB/T 8045.1-1999 机床夹具零件及部件 固定钻套国标GB/T 8045.1-1999 1.本标准规定了0-85mm 的固定钻套 2.引用标准:GB/T 699-1988 优质碳素结构钢的技术条件 GB/T 1298-1986 碳素工具钢技术条件GB/T 8044-19999 机床夹具零件及部件技术条件 JB/T 8045.5-1999 机床夹具零件及部件钻套螺钉 3.图示4.尺寸表dDD1 H t基本尺寸 极限偏差F7基本尺寸极限偏差D6>0~1 +0.016 +0.006 3 +0.010 +0.004 6 69 --0.008>1~1.8 4 +0.016 +0.0087 >1.8~2.6 5 8 >2.6~3 69 8 12 16>3~3.3 +0.022 +0.010>3.3~4 7 +0.019 +0.010 10 >4~5 8 11 >5~6 10 13 10 16 20 >6~8 +0.028 +0.013 12 +0.023 +0.012 15 >8~10 15 18 12 20 25 >10~12 +0.034 +0.016 18 22 >12~15 22 +0.028 +0.015 26 16 28 36 >15~18 26 30 0.012>18~22 +0.041 +0. 30 34 20 36 45 >22~26 35 +0.033 +0.017 39 >26~30 42 46 25 45 56 >30~35 +0.050 +0.025 48 52 >35~42 55 +0.039 +0.59 30 5667>42~4862665.技术条件材料:d≤26mm T10A按GB/T 1298的规定d>26mm 20钢按GB/T 699的规定热处理:T10A为58~6HRC;20钢渗碳深度为0.8~1.2mm,58~64HRC广州宏富精密五金配件厂为您提供各类非标钻套、固定钻套、可换钻套、合金钻套、钨钢钻套、变径套、莫氏钻套锥套等加工。

Remove the specimen,cover,and cool in a desiccator for 1h.Weigh the cooled specimen to the nearest 0.1mg.12.Calculation12.1The volatile material is given by the following equa-tion:V 5~S o !2~S h !/S o 3100(1)where:V 5volatiles,%,S o 5original specimen mass,andS h 5heated specimen mass.13.Report13.1Report results obtained from two individual determi-nations and their average to the nearest 0.01%.14.Precision and Bias 314.1This precision and bias section has been prepared inaccordance with Practice D 4483.Refer to Practice D 4483forterminology and other statistical details.14.2The precision results in this precision and bias sectiongive an estimate of the precision of this test method with thematerials (rubbers)used in the particular interlaboratory pro-grams as described below.The precision parameters should notbe used for acceptance/rejection testing of any group ofmaterials without documentation that they are applicable tothose particular materials and the specific testing protocols thatinclude this test method.14.3A Type 1(interlaboratory)precision was evaluated in1986.Both repeatability and reproducibility are short term.Aperiod of a few days separates replicate test results.A test resultis the mean value,as specified by this test method,obtained ontwo determinations or measurements of the property or param-eter in question.14.4Three different materials were used in the interlabora-tory program.These were tested in seven laboratories on twodifferent days.14.5The results of the precision calculations for repeatabil-ity and reproducibility are given in Table 1,in ascending orderof material average or level,for each of the materials evalu-ated.14.6The precision of this test method may be expressed in the format of the following statements which use an “appro-priate value”of r,R ,(r )or (R ),that is,that value to be used in decisions about test results (obtained with the test method).The appropriate value is that value of r or R associated with a mean level in Table 1closest to the mean level under consideration at any given time,for any given material in routine testing operations.14.7Repeatability —The repeatability,r ,of this test method has been established as the appropriate value tabulated in Table 1.Two single test results,obtained under normal test method procedures,that differ by more than this tabulated r (for any given level)must be considered as derived from different sample populations.14.8Reproducibility —The reproducibility,R ,of this test method has been established as the appropriate value tabulated in Table 1.Two single test results obtained in two different laboratories,under normal test method procedures,that differ by more than the tabulated R (for any given level)must be considered to have come from different or nonidentical sample populations.N OTE 1—The values of r and R are relatively large,whereas the average or mean test level is small (close to zero).This is typical for this type of precision measurement process.This should be kept in mind whenever use is made of r and R .14.9The relative repeatability (r )and reproducibility (R )have been omitted from Table 1since the level of values tested was extremely low and approached the limits of sensitivity of the test method.Under these circumstances the relative values become trivial.14.10Bias —In test method terminology,bias is the differ-ence between an average test value and the reference (or true)test property value.Reference values have not been evaluated for this test method.Bias,therefore,cannot be determined.p -PHENYLENEDIAMINE ANTIDEGRADANT 15.Scope 15.1This test method describes the determination of vola-tile materials in p -phenylenediamine antidegradants and is based on the mass loss upon heating at 70°C.15.2The measured loss on heating represents volatile or-ganics plus moisture.16.Summary of Test Method 16.1The p -phenylenediamine test unit is weighed before and after heating for 3h at 70°C.The measured difference in mass is the volatile material.17.Significance and Use 17.1The quantity of volatile material in p -phenylenediamines can affect performance of these anti-degradants in rubber if they exceed critical levels.17.2Since the loss on heating is an empirical and nonspe-cific method,it is essential that the prescribed analysis condi-tions (sample container,oven temperature,oven air flow,cooling conditions,etc.)be controlled so that results are meaningful.17.3Prolonged heating or overheating of the sample or the3Supporting data are available from ASTM Headquarters.Request RR:D11-1047.TABLE 1Type 1Precision Results—Volatile Materials,PercentMaterial Aver-age Within Laboratory A Between Laboratory AS r r S R RGeneral Purpose Ground Sulfur0.070.0180.0530.0450.127Oil Treated,90%Insolule Sulfur—A0.260.0250.0730.1300.368Oil Treated,90%Insoluble Sulfur—B0.320.0420.1190.1510.427Pooled Values B 0.220.0300.0870.1190.338A S r 5repeatability standard deviation.r 5repeatability 52.833the square root of the repeatability variance.S R 5reproducibility standard deviation.R 5reproducibility 52.833the square root of the reproducibility variance.B No valuesomitted.test unit can result in high heat loss values due to oxidative generation of volatile degradation products.18.Apparatus18.1See Section6.19.Sampling19.1To ensure homogeneity,at least250g of the“lot”sample should be well blended prior to removing the test unit.20.Procedure20.1Dry a clean weighing bottle and stopper(stopper removed)for30min in the specified oven set at70°C.Place the bottle and stopper in the desiccator and allow them to cool to room temperature.Weigh the bottle with a stopper to the nearest0.1mg.20.2Weigh a nominal20-g test unit into the weighing bottle to the nearest0.1mg.20.3Place the weighing bottle containing the test unit and the stopper(with the stopper removed)in the specified oven, which has equilibrated at70°C,for3h.20.4After the heating period,replace the stopper and transfer the bottle to the desiccator for a period of time sufficient for the assembly to equilibrate at room temperature. Reweigh the bottle to the nearest0.1mg.20.5Repeat the procedure on a second test unit.21.Calculation21.1Calculate the percent heating loss to the nearest0.1% as follows:H5@~B2C!/~B2A!#3100(2) where:H5heating loss,%,A5mass of weighing bottle and stopper,g,B5mass of weighing bottle,stopper,and test unit before heating,g,andC5mass of weighing bottle,stopper,and test unit after heating,g.22.Report22.1Report the following information:22.1.1Proper identification of the sample,and22.1.2Results obtained from two individual determinations and their average,reported to the nearest0.01%.23.Precision and Bias323.1This precision and bias section has been prepared in accordance with Practice D4483.Refer to Practice D4483for terminology and other statistical details.23.2A Type1(interlaboratory)precision was evaluated in 1987.Both repeatability and reproducibility are short term.A period of a few days separates replicate test results.A test result is the mean value,as specified by this test method,obtained on two determinations or measurements of the property or param-eter in question.23.3Four different materials were used in the interlabora-tory program.These were tested in six laboratories on two different days.23.4The results of the precision calculations for repeatabil-ity and reproducibility are given in Table2,in ascending order of material average or level,for each of the materials evalu-ated.23.5The precision of this test method may be expressed in the format of the following statements which use an“appro-priate value”of r,R,(r),or(R),that is,that value to be used in decisions about test results(obtained with the test method). The appropriate value is that value of r or R associated with a mean level in Table2closest to the mean level under consideration at any given time,for any given material in routine testing operations.23.6Repeatability—The repeatability,r,of this test method has been established as the appropriate value tabulated in Table2.Two single test results,obtained under normal test method procedures,that differ by more than this tabulated r (for any given level)must be considered as derived from different or nonidentical sample populations.23.7Reproducibility—The reproducibility,R,of this test method has been established as the appropriate value tabulated in Table2.Two single test results obtained in two different laboratories,under normal test method procedures,that differ by more than the tabulated R(for any given level)must be considered to have come from different or nonidentical sample populations.23.8The relative repeatability(r)and reproducibility(R) have been omitted from Table2since the level of values tested was extremely low and approached the limits of sensitivity of the test method.Under these circumstances the relative values become trivial.23.9Bias—In test method terminology,bias is the differ-ence between an average test value and the reference(or true) test property value.Reference values have not been evaluated for this test method.Bias,therefore,cannot be determined.24.Keywords24.1antidegradants;rubber chemicals;sulfur;volatile con-tentTABLE2Volatile Materials of p-Phenylenediamine,PercentMaterialAver-ageWithin Laboratory A Between Laboratory AS r r S R RM1-6PPD0.060.0220.0620.0290.083M2-IPPD0.080.0040.0110.0260.075M3-BMPPD0.190.0340.0980.0730.026M4-DTPD0.040.0020.0050.0190.055 Pooled Values B0.090.0210.0610.0450.129A Sr5repeatability standard deviation.r5repeatability52.833the square root of the repeatability variance.S R5reproducibility standard deviation.R5reproducibility52.833the square root of the reproducibility variance.B No valuesomitted.The American Society for Testing and Materials takes no position respecting the validity of any patent rights asserted in connection with any item mentioned in this ers of this standard are expressly advised that determination of the validity of any such patent rights,and the risk of infringement of such rights,are entirely their own responsibility.This standard is subject to revision at any time by the responsible technical committee and must be reviewed everyfive years and if not revised,either reapproved or withdrawn.Your comments are invited either for revision of this standard or for additional standards and should be addressed to ASTM Headquarters.Your comments will receive careful consideration at a meeting of the responsible technical committee,which you may attend.If you feel that your comments have not received a fair hearing you should make your views known to the ASTM Committee on Standards,100Barr Harbor Drive,West Conshohocken,PA19428.。

Designation:D1578–93(Reapproved2000)Standard Test Method forBreaking Strength of Yarn in Skein Form1This standard is issued under thefixed designation D1578;the number immediately following the designation indicates the year of original adoption or,in the case of revision,the year of last revision.A number in parentheses indicates the year of last reapproval.A superscript epsilon(e)indicates an editorial change since the last revision or reapproval.1.Scope1.1This test method covers the determination of the break-ing strength of yarn in skein form.The observed breaking strength is expressed in units of force,and equations are provided to convert breaking strength to skein breaking tenac-ity and to skein break factor.N OTE1—For the determination of the breaking strength and elongation of yarn by the single strand method,refer to Test Method D2256.1.2This test method is applicable to spun yarns,either single or plied,composed of anyfiber or blend offibers,but is not suitable for yarns which stretch more than5%when the tension is increased from2.5to7.5mN/tex or0.03to0.08 gf/denier.1.3This test method provides three options based on the perimeter of the reel,the number of wraps in the skein,and the machine speed or time-to-break.1.3.1Option1—Eighty,forty,or twenty turns on a1.50-m or1.5-yd reel,broken at300mm/min or12in./min.1.3.2Option2—Fifty turns on a1.00-m or1-yd reel,broken at300mm/min or12in./min.1.3.3Option3—Fifty turns on a1-m reel,broken in20s. N OTE2—Option1is in general use in the United States,Option2is used for woolen yarns,and Option3has been proposed in the Interna-tional Standards Organization(ISO)for international use.N OTE3—Metric reels are available with1and1.125-m circumferences. Data from the two reels will be about1%different(see5.6).ISO uses a 1-m circumference reel.1.4This test method is frequently combined with the determination of linear density carried out on the same skeins. Special precautions for reeling such skeins are noted.1.5Where appropriate,this test method states all require-ments in SI units.The traditional units are inch-pound and are exact values.1.6This standard does not purport to address all of the safety problems,if any,associated with its use.It is the responsibility of the user of this standard to establish appro-priate safety and health practices and determine the applica-bility of regulatory limitations prior to use.2.Referenced Documents2.1ASTM Standards:D76Specification for Tensile Testing Machines for Tex-tiles2D123Terminology Relating to Textiles2D1776Practice for Conditioning Textiles for Testing2D1907Test Method for Yarn Number by the Skein Method2D2256Test Method for Tensile Properties of Yarns by the Single-Strand Method2D2258Practice for Sampling Yarn for Testing2D2904Practice for Interlaboratory Testing of a Textile Test Method that Produces Normally Distributed Data23.Terminology3.1Definitions:3.1.1breaking force,n—the maximum force applied to a material in a tensile test carried to rupture.3.1.1.1Discussion—Force is commonly expressed as mil-linewtons(mN),newtons(N),grams-force(gf),or pounds-force(lbf).3.1.2force,n—a physical influence exerted by one body on another which produces acceleration of bodies that are free to move and deformation of bodies that are not free to move. (Compare strength).3.1.3skein break factor,n—the comparative breaking strength of a skein of yarn adjusted for the linear density of the yarn expressed in an indirect system;the product of the breaking strength of the skein and the yarn number expressed in an indirect system.(Syn.count-strength product)3.1.3.1Discussion—A statement of the break factor of the skein must indicate the number of wraps in the skein if this is not otherwise apparent;without information on the number of wraps,a statement of the break factor is meaningless.Break factor is frequently given other designations such as lea count constant,lea product,and breaking ratio.3.1.4skein,n—a continuous strand of yarn in the form of a flexible coil having a large circumference in proportion to its thickness.3.1.5skein breaking tenacity,n—the skein breaking strength divided by the product of the yarn number in a direct1This test method is under the jurisdiction of ASTM Committee D13on Textilesand is the direct responsibility of Subcommittee D13.58on Yarn Test Methods,General.Current edition approved July15,1993.Published September1993.Originallypublished as D1578–st previous edition D1578–88.2Annual Book of ASTM Standards,V ol07.01.1Copyright©ASTM International,100Barr Harbor Drive,PO Box C700,West Conshohocken,PA19428-2959,United States.numbering system and the number of strands placed under tension.3.1.5.1Discussion—Observed breaking strength can be converted to breaking tenacity by dividing the breaking strength by the product of the yarn number measured in a direct numbering system and the number of strands placed under tension(twice the number of wraps in the skein(see Eq7)).3.1.6skein strength,n—the force required to rupture a skein of yarn,expressed in units of force,as breaking strength. 3.1.7strength,n—the property of a material that resists deformation induced by external forces.(Compare force).3.1.8For definitions of other textile terms used in this test method,refer to Terminology D123.4.Summary of Test Method4.1A skein of yarn,prepared by winding the prescribed number of turns on a reel,is broken on a tensile testing machine.N OTE4—If the yarn number is also required for the determination of skein breaking tenacity or break factor,the broken skein may be weighed and the yarn number calculated as directed in Test Method D1907. 5.Significance and Use5.1Test Method D1578for testing any spun yarn for breaking strength is considered satisfactory for acceptance testing of commercial shipments since the method has been used extensively in the trade.5.1.1In case of a dispute arising from differences in reported test results when using Test Method D1578for acceptance testing of commercial shipments,the purchaser and the supplier should conduct comparative tests to determine if there is a statistical bias between their petent statistical assistance is recommended for the investigation of bias.As a minimum,the two parties should take a group of test specimens which are as homogeneous as possible and which are from a lot of material of the type in question.The test specimens should then be randomly assigned in equal numbers to each laboratory for testing.The average results from the two laboratories should be compared using Student’s t-test for unpaired data and an acceptable probability level chosen by the two parties before testing is begun.If a bias is found,either its cause must be found and corrected or the purchaser and the supplier must agree to interpret future test results in the light of the known bias.5.2This test method is not suitable for yarns that stretch more than5%when the force is increased from2.5to7.5 mN/tex or0.03to0.08gf/denier,because(a)they require special precautions as to tension in reeling,and(b)users of such yarns are more interested in their elastic behavior at low forces than in their ultimate breaking strength.5.3For Option1,it is advisable to use a tensile testing machine of the proper capacity to break skeins with80turns. If it is necessary to break skeins having only40or20turns, convert the observed results to an80-turn basis by multiplying by factors of2or4,respectively.(The available literature does not show that any significant error is introduced by the use of these factors.)5.4The circumference of the skeins used to determine the breaking load is not critical,and as a consequence,close control of the tension at which the skeins are wound is not necessary.If,however,the same skeins are to be used to determine yarn number for any purpose,the skeins must be reeled under controlled tension on a reel meeting the require-ments given in Test Method D1907.5.5For some purposes it may be advisable to convert the skein breaking strength observed for yarn of one number to the estimated skein breaking strength of a different yarn number. Factors for making such a conversion for cotton yarns are given in11.2.No corresponding factors have been developed for yarns spun from otherfibers.5.6The results obtained from different options are not fully comparable because the breaking force per wrap increases slightly as the perimeter of the skein is reduced.The skein breaking tenacity observed for1-m skeins may be as much as 4%higher,and from1-yd skeins5%higher,than that observed for1.5-yd skeins.These relationships may vary with the type of yarn or with yarn unevenness and should not be used as conversion factors.With a reasonable number of specimens,this method provides a useful index that combines the effects of unevenness and single strand strength.5.7This method is rarely,if ever,used forfilament yarns because their uniformity makes it possible to obtain reliable results economically by the single-strand method.6.Apparatus6.1Reel—A hand or motor-driven reel having a perimeter of1.50m or1.5yd for Option1,1.0m or1yd for Option2 (see Note3),or1m for Option3.The reel shall befitted with a traversing mechanism that will minimize bunching the yarn on the reel and with an indicator of the length wound.A warning bell or an automatic cutoff that will operate at a specified number of turns is advisable.It is also recommended that the reel have a collapsible arm for relaxing the tension on the skeins to facilitate their removal from the reel.If yarn number is to be determined from the same skeins,refer to Test Method D1907for additional reel specifications.6.2Package Holders—Vertical spindles for bobbins or cones if not provided as an integral part of the reel,shafts on which tubes orflanged spools can turn freely.6.3Tensile Testing Machine—A constant-rate-of-traverse (CRT type)or constant-rate-of-extension(CRE type)tensile testing machine of suitable capacity as prescribed in Specifi-cation D76,capable of operating the moving clamp(spool)at a uniform speed of300610mm/min or1260.5in./min(for Options1and2)or capable of operating at a rate that will break the skein broken in an average time of2063s from the start of application of tension to the skein(for Option3).The machine shall be equipped with spools not less than25mm or 1in.nor more than30mm or1.25in.in both diameter and length,and supported with at least one spool free to turn on its axis.The distance between the spools shall be sufficient to permit placing the skeins on the spools in a wide,flat band.6.4Skein Holder or Rack,having parallel pegs or bars placed a sufficient distance apart to hold the skeins extended to nearly their full length without either stretching,kinking,or entangling theyarn.7.Sampling7.1Lot Sample—Take a lot sample as directed in an applicable specification,or as agreed upon between the pur-chaser and the supplier.In the absence of an applicable specification or agreement,take a lot sample as directed in Practice D2258.N OTE5—An adequate specification or other agreement between the purchaser and the supplier requires taking into account variability between shipping units,between packages or ends within a shipping unit,and between specimens from a single package so as to provide a sampling plan with a meaningful producer’s risk,consumer’s risk,acceptable quality level,and limited quality level.7.2Laboratory Sample—As a laboratory sample for accep-tance testing,take a total of ten packages for yarn spun on the cotton or worsted systems and a total of20packages for yarns spun on the woolen system.Select the packages randomly from all the packages in the lot sampling units.7.3Number of Specimens—Test one skein from each pack-age in the laboratory sample.8.Conditioning8.1Preconditioning—Yarns for testing should be wound into skeins for preconditioning and conditioning(see Section 9).Reel one or more extra skeins for use in determining when moisture equilibrium has been reached(see8.2.1).8.1.1Precondition the skeins at a temperature no higher than50°C or120°F in an atmosphere having a relative humidity between5and25%.Skeins will usually reach approximate moisture equilibrium in4h especially in moving air.Crowding skeins too close together on the rack,or anything that obstructs the circulation of air,may lengthen the time appreciably.8.2Conditioning—Condition the skeins in the standard atmosphere for testing textiles,which is2161°C or7062°F and6562%relative humidity,until moisture equilibrium has been reached.8.2.1For cotton yarns,a minimum conditioning time of4h is specified.Yarns made from otherfibers or blends may require other lengths of time.When testing additional samples of the same type of yarn,it may be assumed that moisture equilibrium has been reached after exposure for a time25% longer than that found by test to be sufficient.8.2.1.1If necessary use the extra skein(s)to determine that moisture equilibrium has been reached when successive weigh-ings at intervals of not less than15min do not differ by more than0.1%.Do not use the skeins that are to be tested for strength for determining moisture equilibrium.9.Preparation of Specimens9.1Mounting of Packages:9.1.1For yarns on bobbins,cops,cones,or similar pack-ages,draw the yarn off over the end of the package at a speed between100and300rpm of the reel.9.1.2For yarns onflanged spools or other packages nor-mally unwound from the side,mount the packages to turn freely and draw the yarn from the side of the package at a speed of20to30rpm of the reel.9.1.3When several ends are wound parallel on a single package,draw each end through a separate guide and reel a skein from each end,unwinding from the side of the package.9.1.4If the yarn is received in skein form,mount it on an umbrella reel or swift and reel at a speed of20to30rpm. 9.2Reeling—Draw each end of yarn through a separate guide and attach the yarn to the reel.Turn the reel at a uniform speed and maintain sufficient tension to lay the yarn smoothly on the reel.When the required number of turns have been reeled,tie the ends of the yarn together loosely but securely with a nonslipping knot.For easier separation of skeins on the rack,a loose loop may be made about the skein cross section, and the yarns once again knotted.If skein breaking tenacity or skein break factor is to be calculated,the method of reeling must comply with the additional requirements in Test Method D1907.9.2.1For Option1,reel80turns on a1.50-m(1.5-yd)reel. If the breaking strength of such a skein is greater than the capacity of the available testing machine,try40or20turns.9.2.2For Option2,reel50turns on a1-m or a1-yd reel.9.2.3For Option3,reel50turns on a1-m(1.09–yd)reel. Include extra skeins for adjustment of the tester for time to break.9.3Conditioning—Transfer the skeins to the rack carefully with as little disturbance of the yarn as possible.Keep the yarns parallel and the skeinflat,with no bunching or twisting.Do not stretch or jerk the yarn and do not allow it to kink.If more than one skein is to be stored on each pair of pegs,the skeins may be transferred one at a time to the rack,with rings or washers placed between them for easier separation.Precondition(if not done before reeling)and condition as prescribed in Section8. Do not remove the skeins from the rack until time of test. 10.Procedure10.1Perform all tests in the standard atmosphere for testing textiles,which is2161°C or7062°F and6562%relative humidity.10.2Select the appropriate capacity range of the testing machine as follows:10.2.1For Options1and2,a range within which(1)the calibration of the tensile testing machine is accurate within 61.0%and(2)the breaking force can be read with a precision of62.0%.10.2.2For Option3,select the capacity and speed of the testing machine to reach the breaking force in an average time of2063s or a testing speed agreed upon by purchaser and supplier.Break one or more preliminary skeins,and adjust the speed as necessary until the time-to-break conforms to the specified limits.If the time-to-break for the preliminary skeins is within the specified limits and no adjustment is required,the observed values for the preliminary skeins may be included in the test report data.10.3Handle each skein carefully as directed in9.3and transfer it to the testing machine as directed as follows: 10.3.1Place the skein over the top spool with the yarns lyingflat and parallel over the spool.10.3.2Then place the lower part of the skein under the lower spool.10.3.3Move the skein around the spools,maintaining a gentle tension,to ensure that the yarns are lyingflat and parallel with no bunching ortwisting.10.4Start the machine and maintain the tension on the skein by gentle pressure of the hand(not by gripping or pinching the yarn)until the machine takes up the slack.Keep hands well away from the spools.10.5Stop the machine when the scale indicator reaches the maximum force.10.6Record the breaking force to the nearest2N or0.5lbf if under450N or100lbf,or to the nearest5N or1.0lbf if450 N or100lbf or more.10.7Continue as directed in10.3-10.6until the required number of skeins have been tested.10.8If the skein breaking tenacity or break factor is to be calculated,or if skein breaking strength is to be corrected for yarn number,weigh the broken skeins and determine the average yarn number as directed in Test Method D1907. 11.Calculation of Results11.1Skein Breaking Strength:11.1.1Calculate the average breaking force from the values observed for all specimens in a laboratory sample,and record this as the breaking strength for that sample.11.1.2Calculate the average breaking strength for the lot.11.2Breaking Strength Adjusted to Specified Yarn Number: 11.2.1If the average observed yarn number does not differ from the specified yarn number by more than10%,an approximate adjusted breaking strength can be calculated using Eq1or Eq2:S25~T2/T1!S1(1) orS25~N1/N2!S1(2) where:S1=observed average breaking strength,S2=adjusted breaking strength,T1=observed yarn number in a direct system,T2=specified yarn number in a direct system,N1=observed yarn number in an indirect system,andN2=specified yarn number in an indirect system.N OTE6—For plied yarns,the yarn numbers used throughout these calculations are the resultant yarn numbers,that is,the yarn number of the plied yarn,calculated from the mass of a given length,in the same manner as for single yarns.11.2.2For cotton yarns a more accurate adjustment can be made over a wide range of yarn numbers by use of Eq3or Eq 4:S25~T2/T1!S11K@~T2/T1!21#(3) orS25~N1/N2!S11K@~N1/N2!21#(4) where:K=a constant,to be selected from experience with the particular type of cotton,usually18for strengthexpressed in lbf.3N OTE7—In publications of the U.S.Dept.of Agriculture,4Eq3aboveis given in the form shown in Eq5.S25@N1S12K~N22N1!#/N2(5) There are indications that K varies with staple length and possibly with otherfiber properties.Since N1S1is usually between1800and2400,the use of a value of K between18and24results in an additional adjustmentof breaking strength of approximately1%per unit difference between N1 and N2,beyond that obtained by the simple proportional conversion given in11.2.1.Hence,an error of10%in selecting a value for K will make a difference of about0.1%in the resulting adjusted skein breaking strengthper unit difference between N1and N2.For breaking strengths in kilograms-force,K is0.454times the K for breaking strengths in pounds-force.This may be rounded to the nearest whole number.No information is available on values of K for yarns of otherfibers than cotton.11.3Skein Breaking Tenacity:11.3.1Calculate the average skein breaking tenacity using Eq6or Eq7:Skein breaking tenacity,mN/tex5L/~23W3T!(6) or54448S/~23W3T!52224S/~W3T!(7) where:L=breaking strength,mN,S=breaking strength,lbf,W=number of wraps in skein,andT=average yarn number,tex.N OTE8—Breaking tenacity in grams-force per denier is equal to breaking tenacity in millinewtons per tex divided by88.3.Example1—Breaking strength=55lbf,average yarn number=40.2 cotton count(14.7tex),and number of wraps=80.Skein breaking tenacity=(2224355)/(80314.7)=104mN/tex 11.3.2Calculate the average for the lot.11.4Skein Break Factor(Count-Strength Product):11.4.1Calculate the break factor using Eq8:Skein break factor5~803S3N!/W(8) where:S=average breaking load,lbf,N=average yarn number in an indirect system,andW=number of wraps in skein.11.4.1.1For skeins of80wraps the equation becomes:Break factor5S3N(9)Example2—Skein breaking strength=55lbf,average yarn number =40.2cotton count,and number of wraps=80.Break factor555340.252211N OTE9—The skein break factor equals the breaking tenacity in grams-force per denier multiplied by1877or the breaking tenacity in millinewtons per tex multiplied by21.26.11.4.2Calculate the average for the lot.11.5Calculate the coefficient of variation if requested.12.Report12.1State that the specimens were tested as directed in Test Method D1578.Describe the product or material being3Webb and Richardson,“An Evaluation of the Significance and Use of the K Factor of Yarn Strength,”U.S.Dept.of Agriculture,June1953.4Circular413,U.S.Dept.ofAgriculture.sampled and the method of sampling used.12.2Report the following information:12.2.1Skein breaking strength and the average for the lot.12.2.2Coefficient of variation,if determined.12.2.3Average yarn number,and the numbering systems,if determined.12.2.4Any derived values,such as skein breaking strength adjusted to specified yarn number (including method of calcu-lation),skein breaking tenacity,or skein break factor.12.2.5Number of packages or ends tested,12.2.6Circumference of reel and number of wraps per skein,12.2.7Type of testing machine,and12.2.8Capacity and rate of operation of testing machine (Option 1or 2)or average time-to-break (Option 3).13.Precision and Bias13.1Summary —Interlaboratory test data have shown that the variation in breaking force test data is dependent upon the material being tested;therefore,no general statement can be made about critical differences.A user can get a general idea from the data in 13.1.1and 13.1.2of the critical differences associated with typical yarns.If more nearly exact information is needed or if other materials are involved,a single laboratory test on the specific yarn is recommended.Sections 13.2-13.4explain the basis of this summary and evaluations made under other conditions.13.1.1Cotton System —In comparing two averages of ten observations each for yarns spun on the cotton system,the differences should not exceed the following critical differencesin 95cases out of 100when all of the observations are taken by the same well-trained operator using the same piece of test equipment and specimens randomly drawn from the same sample of material:10/1c.c.,100%cotton,open-end spun4.4lb 10/1c.c.,65/35polyester/cotton,open end spun 4.2lb 40/1c.c.,100%cotton,ring-spun1.4lb 37.5/1c.c.,65/35polyester/cotton,ring spun 0.9lb 19.5/1c.c.,100%rayon,ring spun4.4lbLarger differences are likely to occur under all other circum-stances.13.1.2Worsted and Woolen Systems —In comparing two averages of ten observations each for yarns spun on the worsted or woolen systems,the differences should not exceed the following critical differences in 95cases out of 100when all of the observations are taken by the same well-trained operator using the same piece of test equipment and specimens randomly drawn from the same sample of material.Yarns spun on worsted system 4.7%of the grand average Yarns spun on woolen system6.9%of the grand averageLarger differences are likely to occur under all other circum-stances.TABLE 1Components of Variance as Coefficients of Variation,%of AverageName of the PropertySingle-Operator ComponentWithin Laboratory ComponentBetween LaboratoryComponentSkein Breaking Strength (lb),Cotton System 10/1c.c.-100%cotton,open end2.603.510/1c.c.-65/35polyester/cotton,open end 1.8 1.4 5.340/1c.c.-100%cotton,ring spun2.807.937.5/1c.c.-65/35polyester/cotton ring spun 1.5 2.23.819.5/1c.c.-100%rayon,ring spun2.72.15.1Yarn Count,Cotton System10/1c.c.-100%cotton,open end2.40010/1c.c.-65/35polyester/cotton,open end 2.30040/1c.c.-100%cotton,ring spun1.40 1.237.5/1c.c.-65/35polyester/cotton,ring spun 0.70 1.719.5/1c.c.-100%rayon,ring spun2.20 6.1Skein Break Factor10/1c.c.-100%cotton,open end1.60 3.410/1c.c.-65/35polyester/cotton,open end 1.5 1.2 3.340/1c.c.-100%cotton,ring spun2.507.437.5/1c.c.-65/35polyester/cotton,ring spun 2.7 1.7 4.919.5/1c.c.-100%rayon,ring spun2.5 1.4 5.0TABLE 2Components of Variance as Coefficients of Variation,%of Average ANames of the PropertiesSingle-Operator ComponentSkein breaking strength,worsted system 5.4Skein breaking strength,woolen system7.9AComparable estimates of precision have been in use since 1967.TABLE 3Critical Differences A ,B %of Grand Average,forConditions NotedNames of the PropertiesNumber of Observations in Each AverageSingle-Operator Precision Skein breaking strength,worsted system5 6.710 4.720 3.340 2.4Skein breaking strength,woolen system59.710 6.920 4.9403.4AThe critical differences were calculated using z =1.960.BTo convert the tabulated values of the critical differences to units of measure,multiply the average of the two specific sets of data being compared by the critical differences expressed as decimalfractions.TABLE4Critical Differences for Conditions NotedName of the Property Number of Observationsin Each AverageSingle OperatorPrecisionWithin LaboratoryPrecisionBetween LaboratoryPrecisionSkein Breaking Strength(lb)10/1c.c.-100%cotton,open end113.613.623.029.69.621.04 6.8 6.819.88 4.8 4.819.210 4.4 4.419.116 3.4 3.418.920 3.1 3.118.8 10/1c.c.-65/35polyester/cotton,open end113.316.942.529.414.041.54 6.612.341.08 4.711.440.710 4.211.140.416 3.310.940.320 2.910.740.3 40/1c.c.-100%cotton,ring spun1 4.3 4.312.82 3.0 3.012.44 2.1 2.112.38 1.5 1.512.210 1.4 1.412.116 1.1 1.112.1200.60.612.0 37.5/1c.c.-65/35polyester/cotton,ring spun1 2.9 5.29.12 2.0 4.88.94 1.4 4.68.88 1.0 4.58.7100.9 4.48.7160.7 4.48.7200.7 4.48.7 19.5/1c.c.-100%rayon,ring spun114.017.731.629.914.730.047.012.929.18 5.011.928.710 4.411.628.716 3.511.428.520 3.111.228.5 Yarn Count,Cotton System10/1c.c.-100%cotton,open end10.70.70.720.50.50.540.30.30.380.20.20.2100.20.20.2160.20.20.2200.10.10.1 10/1c.c.-65/35polyester/cotton,open end10.70.70.720.50.50.540.30.30.380.20.20.2100.20.20.2160.20.20.2200.10.10.1 40/1c.c.-100%cotton,ring spun1 1.5 1.5 2.02 1.1 1.1 1.740.80.8 1.680.50.5 1.5100.50.5 1.4160.40.4 1.4200.30.3 1.4 37.5/1c.c.-65/35polyester/cotton,ring spun10.80.8 2.020.50.5 1.940.40.4 1.980.30.3 1.9TABLE 4ContinuedName of the PropertyNumber of Observationsin Each AverageSingle Operator PrecisionWithin LaboratoryPrecisionBetween LaboratoryPrecision100.20.2 1.9160.20.2 1.9200.20.2 1.819.5/1c.c.-100%rayon,ring spun1 1.1 1.1 3.320.80.8 3.240.60.6 3.280.40.4 3.2100.40.4 3.2160.30.3 3.2200.30.33.1Skein Break Factor10/1c.c.-100%cotton,open end1808019225757184440401818282817910262617816202017720191917710/1c.c.-65/35polyester/cotton,open end11121442872791202764561062708409826710369726716289426620259426640/1c.c.-100%cotton,ring spun11521524742107107462476764568545445310484845316383845220343445237.5/1c.c.-65/35polyester/cotton,ring spun12002374362142190412410016140087114539810641433961650138394204613639419.5/1c.c.-100%rayon,ring spun12402765452169218518412018250488516149910751524981660145496205314349513.2Interlaboratory Test Data 5—An interlaboratory test was run in 1986in which randomly drawn specimens of five materials spun on the cotton system were tested in eight laboratories as directed in Practice D 2904.Each laboratory used two operators,each of whom tested three specimens of each material on different days.The components of variance expressed as coefficients of variation are listed in Table 1.13.2.1Only yarns spun on the cotton system were used in the interlaboratory test because yarns spun on the woolen and worsted systems were not readily available.The data quoted in 13.1.2are based on the estimates of the single-operatorcomponent of variance expressed as coefficients of variation listed in Table 3.13.3Precision —For the components of variance reported in Table 1,the averages of two observed values should be considered significantly different at the 95%probability level if the difference equals or exceeds the critical differences listed in Table 4.N OTE 10—The tabulated values of the critical differences should be considered to be a general statement,particularly with respect to between-laboratory precision.Before a meaningful statement can be made about two specific laboratories,the amount of statistical bias,if any,between them must be established,with each comparison being based on recent data obtained on randomized specimens from one sample of the material to be tested.5Supporting data are available from ASTM Headquarters,100Barr Harbor Drive,West Conshohocken,PA 19428.Request RR:D13–1076.。

一、烟煤、无烟煤与粘结指数专用无烟煤国家标准物质1.烟煤、无烟煤国家标准物质(50g/瓶)2. 粘结指数专用无烟煤国家标准物质(Kg/瓶、500g/瓶)3. 烟煤、无烟煤标准样品(含量以证书为准)二、焦炭系列国家与行业标准样品1.焦炭物理特性和化学成分分析国家与行业标准样品(50g/瓶)2.焦炭物理特性和化学成分分析国家标准物质(50g/瓶)化学成分含量%国家编号样品编号Std Ad Vd Qgrd SiO2Al2O3CaO MgO Fe2O3TiO2Na2O GBW11133a JN 0.46 12.69 1.33 28.61 5.99 4.54 0.45 0.13 0.61 0.18 0.13 GBW11134a JG 0.67 11.62 1.42 28.95 5.48 4.08 0.45 0.10 0.58 0.18 0.078 GBW11135 JN07-3 0.76 14.42 1.78 28.26 6.52 4.95 0.52 0.15 1.22 0.22 0.050 GBW11136 JN07-4 0.80 12.29 1.22 29.04 6.08 4.61 0.38 0.046 0.40 0.19 0.038 GBW11137 JN07-5 0.81 11.90 1.68 29.10 5.63 3.98 0.55 0.16 0.63 0.18 0.084 GBW11138 JN07-6 1.44 16.20 1.80 27.56 8.17 5.28 0.57 0.097 0.96 0.20 0.067 国家编号样品编号K2O MnO SrO P Cr Ni Cu V Pb As Cl GBW11133a JN 0.067 0.0031 0.011 0.020 0.0018 0.0012 0.0021 0.0033 0.0006 0.00011 0.034 GBW11134a JG 0.057 0.0055 0.0095 0.027 0.0017 0.0009 0.0019 0.0028 0.0007 0.00012 0.026 GBW11135 JN07-3 0.079 0.0052 0.017 0.037 0.0022 0.0008 0.0027 0.0038 0.0011 0.00014 0.020 GBW11136 JN07-4 0.062 0.0028 0.010 0.031 0.0013 0.0007 0.0014 0.0021 0.0009 0.00010 0.022 GBW11137 JN07-5 0.069 0.013 0.011 0.018 0.0022 0.0008 0.0020 0.0032 0.0008 0.00020 0.049 GBW11138 JN07-6 0.11 0.0044 0.0084 0.018 0.0021 0.0010 0.0018 0.0037 0.0008 0.00024 0.022三、水溶液成分分析国家标准物质1.单元素标准溶液(50mL/瓶)2.单元素标准溶液(50mL/瓶)3.多元素相同浓度标准溶液(50mL/瓶)名称及国家编号元素质量浓度(mg/ml)不确定度(mg/ml)介质多元素标准溶液Ⅰ GBW(E)130268 Al、Cd、Co、Pb、Cr、Cu、Fe、V、Mg、Mn、Ni、Zn 0.100 0.001 5%HNO3多元素标准溶液Ⅱ GBW(E)130269 Al、Cd、Co、Cr、Cu、Fe、Mg、Mn、Ni、Pb、V、Zn 0.0500 0.0003 5%HNO3多元素标准溶液Ⅲ GBW(E)130270 Al、Cd、Co、Cr、Cu、Fe、Mg、Mn、Ni、Pb、V、Zn 0.0100 0.0002 5%HNO3四、金属助熔剂及纯金属名 称编 号 C S 性质 纯铁助熔剂C 型 821D0.0005 0.0008 A 型 821G小于0.001 小于0.001 821E0.0004 0.0012 纯铜助熔剂 0.0013 0.0012 纯锡助熔剂 C <0.0009 S <0.0003 粒度20-60目 钨助熔剂 C <0.0008S <0.0005粒度20-40目 硅钼粉纯度>99.8%纯 金 属名 称 含 量 % 名 称 含 量 % 名 称 含 量 % 纯铜20g/瓶 99.95 纯镍10g/瓶 99.9 纯锰20g/瓶99.9 纯锡20g/瓶 99.99 纯锑10g/瓶 99.99 纯硅20g/瓶 99.99 纯铅20g/瓶 99.99 纯镉10g/瓶 99.999 纯钴20g/瓶 99.98 纯锌20g/瓶 99.99 纯钛10g/瓶 99.99 纯铋20g/瓶99.99 纯铝20g/瓶99.99纯镁20g/瓶99.99纯 铁 国 家 标 准 样 品五、矿石类系列标准样品1.铁矿石系列标准样品标样编号名称TFe FeO SiO2Al2O3CaO MgO K2O Na2O TiO2MnO S P As YSBC28739-95 贫铁矿38.08 7.40YSBC28740-95 赤铁矿66.15 4.30 0.0060YSBC28741-95 赤铁矿56.16 6.26 0.0135YSBC28742b-2011 铁矿石49.53 0.05 7.44 7.45 0.032 0.107 0.370 3.39 0.029 0.083 C:0.071 YSBC28746-95 磁铁矿16#47.5113.09 0.587YSBC28747-95 磁铁矿17#47.3813.76 0.624YSBC28747b-2011 铁矿石48.00 0.05 12.74 3.44 0.15 0.268 Pb:0.283 Zn:0.49 0.146 3.40 0.111 0.076 C:0.072 YSBC28748-95 磁铁矿18#12.61 0.728YSBC28749b-2011 铁矿石50.98 8.92 9.40 5.03 3.44 1.05 0.125 0.306 0.113 0.963 C:0.89 YSBC28756-2008 赤铁矿55.81 1.86 13.00 1.93 1.10 0.36 0.433 0.33 0.083 0.026 0.469 0.011 0.23 YSBC28757-2008 褐铁矿57.41 1.89 7.31 5.11 0.34 0.142 0.150 0.045 0.230 0.228 0.018 0.054 0.00142.磁铁矿系列标准样品3.进口铁矿石和铁精矿国家标准样品4.球团矿、烧结矿与高炉渣系列标准样品5.锰矿石系列标准样品标样编号样品名称TMn MnO2TFe SiO2Al2O3CaO MgO TiO2BaO K2O GSB03-2586-2010 锰矿石1# 14.45 20.70 0.85 56.03 8.25 2.07 0.60 0.177 0.064 3.74 GSB03-2587-2010 锰矿石2# 22.18 18.40 10.62 24.73 2.80 6.20 3.14 0.123 0.164 0.83 GSB03-2588-2010 锰矿石3# 30.99 45.62 10.68 17.30 6.40 1.15 0.70 0.215 1.11 0.65 GSB03-2589-2010 锰矿石4# 36.31 45.02 6.90 17.70 2.08 3.30 1.29 0.085 0.410 0.49 GSB03-2590-2010 锰矿石5# 44.97 67.67 2.75 16.00 2.35 0.195 0.182 0.105 0.058 1.48 标样编号样品名称Na2O Cr Ni Cu V P Pb As Zn S GSB03-2586-2010 锰矿石1# 0.48 0.011 0.0025 0.013 0.015 0.012 GSB03-2587-2010 锰矿石2# 0.049 0.0023 0.0044 0.0071 0.0044 0.074 0.0066 0.032 0.012 0.044 GSB03-2588-2010 锰矿石3# 0.058 0.013 0.083 0.015 0.019 0.171 0.110 0.089 0.235 0.100 GSB03-2589-2010 锰矿石4# 0.076 0.0018 0.010 0.0086 0.0075 0.105 0.0083 0.039 0.027 0.021 GSB03-2590-2010 锰矿石5# 0.034 0.038 0.079 0.022 0.018 0.230 0.011 0.042 0.070 0.0086 6.高铬镍铁矿石、烧结矿系列标准样品7.铝矾土系列标准样品标样编号样品名称AlO3CaO MgO P2O5Fe2O3TiO2MnO SiO2K2O Na2O LOI C2YSS064-2013矾土(Al2O3-46)46.52 0.69 0.37 0.35 14.01 1.36 0.13 22.96 0.25 0.10 12.75 0.20 YSS065-2013 矾土(AlO3-60)60.41 0.51 0.26 0.30 9.69 2.22 0.082 17.82 0.22 0.070 7.96 0.142YSS066-2013 矾土(AlO3-70)70.28 0.37 0.18 0.25 6.64 2.85 0.053 14.20 0.20 0.051 4.57 0.0992YSS067-2013 矾土(AlO3-83)83.07 0.22 0.088 0.18 2.71 3.64 0.011 9.69 0.17 0.022 0.15 0.0502YSS068-2013 矾土(Al2O3-88)88.55 0.15 0.073 0.23 1.75 3.69 4.88 0.11 0.017 0.018 8.硅石列标准样品标样编号名称SiO2CaO MgO Fe2O3Al2O3MnO P TiO2K2O Na2O YSBC28761—95 硅石1#99.42 0.045 0.0083 0.050 0.250 0.00074 0.0015 0.0073 0.077 0.055 YSBC28763—95 硅石3#98.50 0.102 0.171 0.188 0.593 0.0029 0.004 0.012 0.140 0.128 YSBC28764—95 硅石4#94.92 0.043 0.042 0.37 2.42 0.0050 0.0045 0.0083 1.41 0.32 9.保护渣标准样品10.石灰石、白云石、菱镁石系列标准样品11.石灰石、白云石标准样品编号名称SiO2CaO MgO Fe2O3Al2O3MnO P TiO2K2O Na2O SrO S 灼减YSBC28701-93 石灰石1#0.195 55.48 0.31 0.048 0.120 0.0040 0.0006 0.0065 0.040 <0.01 0.017 0.008 43.60 YSBC28703-93 石灰石3#0.78 54.89 0.42 0.078 0.215 0.0034 0.0014 0.012 0.105 <0.01 0.017 0.011 43.10 YSBC28704-93 石灰石4#0.97 51.70 3.47 0.094 0.240 0.0045 0.0016 0.013 0.090 0.011 0.024 0.070 43.16 YSBC28706-93 石灰石6# 1.43 51.05 3.88 0.111 0.208 0.0052 0.0016 0.0145 0.065 <0.010.032 0.043 42.76 YSBC28707-93 石灰石7# 1.46 46.16 7.72 0.130 0.285 0.0054 0.0020 0.016 0.125 0.014 0.021 0.087 42.90 YSBC28711-93 石灰石11# 3.40 45.07 8.31 0.160 0.330 0.0067 0.0030 0.018 0.130 0.015 0.020 0.077 41.75 YSBC28712-93 石灰石12# 5.20 42.56 10.25 0.200 0.380 0.0081 0.0041 0.023 0.120 0.013 0.022 0.065 40.27 YSBC28713-93 石灰石13#7.80 42.54 9.82 0.220 0.400 0.0093 0.0042 0.021 0.140 0.017 0.017 0.048 38.10 YSBC28721-93 白云石1# 1.51 34.80 17.75 0.185 0.310 0.0070 0.0027 0.019 0.025 <0.010.031 0.030 44.70 YSBC28722-93 白云石2# 2.09 29.80 21.06 0.209 0.285 0.011 0.0024 0.016 0.160 <0.010.004 0.022 45.46 YSBC28723-93 白云石3# 5.20 29.36 20.79 0.247 0.350 0.012 0.0040 0.017 0.160 <0.010.005 0.021 42.45 YSBC28724-93 白云石4# 5.20 29.20 20.78 0.210 0.310 0.011 0.0023 0.011 0.160 <0.010.004 0.015 43.02六、铁合金类标准样品1.硅铁、稀土镁与硅铁中间合金系列标准样品2.工业硅系列标准样品标样编号化学成分含量Fe Al Ca Mn P Cr Ni Cu Co V Ti Mg Cd工业硅新1# 0.345 0.113 0.044 0.0083 0.0062 0.0046 0.013 0.0066 0.00077 0.060 0.023 0.0025 0.00003 工业硅2# 0.465 0.507 0.310 0.014 0.0076 0.0054 0.011 0.0086 0.00038 0.0017 0.037 0.0064 0.00004 工业硅3# 0.662 0.375 0.111 0.020 0.0086 0.010 0.0055 0.0070 0.00033 0.00083 0.029 0.0093 0.00005 工业硅4# 0.705 0.310 0.140 0.015 0.0078 0.0076 0.0036 0.0059 0.00025 0.00070 0.025 0.0066 0.00006 工业硅5# 0.955 0.072 0.023 0.014 0.011 0.013 0.0060 0.027 0.00039 0.00084 0.025 0.0025 0.00008 工业硅6# 0.870 0.705 0.145 0.028 0.0050 0.014 0.0094 0.0028 0.00055 0.0014 0.087 0.0067 0.00008 工业硅7# 1.20 0.790 0.790 0.013 0.0057 0.017 0.026 0.047 0.0011 0.0027 0.042 0.0076 0.000103.铬铁系列标准样品标样编号名称Cr C Si Mn P S Ti V Ni Cu As Pb Zn Ca Fe YSBC28621-2010 高碳铬铁1# 56.76 7.28 4.25 0.300 0.023 0.024 0.412 0.203 30.22 YSBC28622-2010 高碳铬铁2# 55.77 7.60 3.95 0.382 0.022 0.031 0.423 0.175 31.41 YSBC28623-2010 高碳铬铁3# 62.54 7.78 1.45 0.307 0.026 0.033 0.166 0.138 27.09 YSBC28624-2010 高碳铬铁4# 60.00 7.72 2.43 0.340 0.025 0.033 0.261 0.153 28.65 YSBC28626-2011 中碳铬铁58.65 0.45 1.43 0.35 0.030 0.0015 0.154 0.242 0.0200.0027 0.0001 0.010 0.00124.铌铁铁、钛铁标准样品5.硅锰合金、钼铁标准样品标样编号名称Mn Si P C S Cr Ni Cu Ti V Co As Sb Pb Fe YSBC28611-2010 锰硅合金1# 62.53 14.33 0.205 2.28 0.020 0.060 0.167 0.080 0.222 0.095 0.048 0.015 0.0025 0.0012 20.00 YSBC28612-2010 锰硅合金2# 64.97 17.59 0.127 1.57 0.018 0.055 0.092 0.096 0.221 0.060 0.035 0.010 0.00095 0.0005 15.16 YSBC28613-2010 锰硅合金3# 67.40 19.34 0.107 1.05 0.017 0.045 0.036 0.051 0.255 0.063 0.017 0.0099 0.0004 0.0007 11.65 YSBC28614-2013 锰硅合金4# 56.68 11.78 0.455 2.95 0.037 0.044 0.218 0.062 0.267 0.117 0.063 0.023 0.0042 0.0015 26.93 标样编号名称Mo C Si Mn P S Cr Ni Cu W Sn As Sb Pb Fe YSBC28631-2010 钼铁1# 60.61 0.032 0.275 0.185 0.031 0.047 0.011 0.033 0.368 0.034 0.0007 0.016 0.0043 0.0006 38.48 YSBC28632-2010 钼铁2# 61.00 0.019 0.367 0.039 0.044 0.078 0.052 0.144 1.07 0.047 0.0026 0.0078 0.0059 0.0022 37.22 6.锰铁系列标准样品7.五氧化二钒标准样品8.硅钙、硅钡铝、钒铁、硼铁系列标准样品标样编号名称Si Ca C Mn P S Al Mg Sr Cr Ni Cu Fe Ba GBW01435 硅钙合金1# 58.58 28.98 0.85 0.043 0.017 0.050 1.95 0.024 0.033 0.020 7.50 GBW01436 硅钙合金2# 57.90 30.33 1.04 0.046 0.016 0.038 1.43 0.018 0.027 0.082 7.15 GBW01437 硅钙合金3# 56.60 32.40 0.51 0.037 0.017 0.038 1.14 0.011 0.030 0.020 8.12YSBC28641-2011 硅钙铝43.60 15.18 1.00 0.095 0.051 0.040 16.63 0.027 0.022 0.054 0.026 0.046 17.53 1.64 YSBC28642-2011 硅钡铝50.36 1.44 0.34 0.11 0.016 0.038 4.07 0.032 0.095 0.083 0.021 0.032 16.68 24.26 YSBC28643-2011 硅钙钡铝52.76 11.10 0.63 0.15 0.024 0.073 5.42 0.019 0.042 0.031 0.0070 0.017 10.54 15.33 标样编号名称牌号 B C Si Mn P S Cr Ni Cu Al Ti VYSBC28633-2011硼铁1# 18.920.40 0.18 0.310 0.025 0.0023 0.025 0.013 0.015 0.036 0.017 0.0090YSBC28634-2011硼铁2# 19.330.19 0.65 0.575 0.027 0.0020 0.26 0.056 0.050 0.185 0.030 0.0109.钒氮合金系列标准样品七、生铸铁化学分析用系列标准样品1.碳硫专用系列生铸铁标准样品标样编号含量%标样编号含量%标样编号含量%C S C S C SYSBC28060-94 1.59 0.0038 YSBC28070a-94 3.84 0.018 BH2040-1 3.58 0.095 YSBC28061a-94 2.19 0.016 YSBC28071a-94 3.89 0.018YSBC28062a-94 2.34 0.008 YSBC28074b-94 3.90 0.051YSBC28063a-94 2.64 0.013 YSBC28077c-94 3.82 0.056YSBC28064a-94 2.69 0.008 YSBC28079-94 3.615 0.060YSBC28067-94 3.82 0.021 YSBC28089-94 3.58 0.0955YSBC28067a-94 3.96 0.019 YSBC28090a-94 2.92 0.103YSBC28069-94 3.92 0.022 BH2022-1 3.40 0.1613.合金铸铁系列标准样品4.生铁系列标准样品5.生铁系列标准样品标样编号名称 C Si Mn P S Cu Cr V Ni Co Mo Ti BH2013-3细生铁 2.72 0.51 0.193 0.27BH2002-5B细生铁 1.15 0.545 0.060 0.068BH2010-5细生铁 1.81 0.797 0.067 0.0846BH2064-5细生铁 1.30 0.512 0.065 0.053 0.0086 0.0255 0.0145 0.0127 0.086 BH2030-5细生铁 2.67 1.12 0.144 0.075BH2003-5粗生铁 3.06 1.36 0.77 0.069 0.094 0.068 0.0325 0.0415 0.032 BH2009-5粗生铁 3.94 1.81 0.806 0.069 0.021 0.0844 0.018BH2021-5粗生铁 2.65 2.29 0.575 0.45 0.098 0.086 0.041 0.0675 0.041 BH2063-5粗生铁 3.94 1.30 0.513 0.067 0.029 0.0525 0.0086 0.0255 0.0145 0.0127 0.088 BH2027-5 生铁 3.18 2.67 0.570 0.298 0.079 0.194 0.022 0.018 0.079 YSBC280384-96 低磷生铁4# 1.04 1.40 0.128 0.055 0.0095YSBC28012-05 BH2035-5A 3.45 1.66 0.603 0.752 0.090 0.788 0.022 0.024 0.017 0.077 YSBC28020-05 BH2045-5A 3.42 1.28 0.970 0.105 0.091 0.733 0.536 0.021 0.022 0.293 0.041 YSBC28075a-05 3.75 1.90 0.705 0.277 0.051 0.048 1.68 0.030 0.259 0.341 0.071 YSBC28060-05 3.68 1.45 1.27 0.087 0.052 0.057 0.775 0.029 0.868 0.294 0.052 YSBC28073-05 BH2011-2A 3.10 1.69 0.390 0.093 0.101 0.058 0.107 0.024 0.085 0.052 0.054 YSBC28072-05 BH2013-2A 2.96 3.14 0.565 0.085 0.087 0.055 0.078 0.021 0.028 0.027 0.069 YSBC28074a-05 3.90 1.98 0.440 0.097 0.051 0.012 0.020 0.015YSBC28074b-05 3.90 1.98 0.438 0.093 0.050 0.012 0.020 0.0158.含镍生铁标准样品9.高炉生铁系列标准样品标样编号 名称牌号化 学 成 份 含 量 %C Si Mn P S Cr Ni Cu Mo V TiCo GSB03-2484-2008 高炉生铁4.32 0.361 1.42 0.032 0.154 0.034 0.015 0.018 0.013 0.530 0.024 0.0057 GSB03-2485-2008 3.90 0.656 1.38 0.057 0.128 0.021 0.013 0.021 0.0018 0.467 0.093 0.034 GSB03-2486-2008 3.61 1.27 0.882 0.218 0.101 0.041 0.050 0.036 0.020 0.361 0.131 0.010 GSB03-2487-2008 3.27 1.85 0.726 0.160 0.066 0.093 0.099 0.077 0.055 0.224 0.252 0.011 GSB03-2488-2008 3.07 2.52 0.608 0.098 0.048 0.099 0.304 0.111 0.090 0.135 0.334 0.0083 GSB03-2489-2008 2.52 3.16 0.402 0.305 0.028 0.208 0.754 0.208 0.207 0.033 0.380 0.0092 GSB03-2490-20081.76 3.79 0.247 0.468 0.0095 0.345 1.05 0.507 0.560 0.014 0.510 0.0039 标样编号 名称牌号 Als Alt As Sb Sn Pb Zn GSB03-2484-2008 高炉生铁0.033 0.035 0.023 0.0004 0.0050 0.0010 0.0009 GSB03-2485-2008 0.023 0.025 0.0025 0.0004 0.0019 0.0010 GSB03-2486-2008 0.0220.024 0.0027 0.0005 0.0012 0.0008 GSB03-2487-2008 0.00700.0092 0.0025 0.0010 0.0018 0.011 0.001 GSB03-2488-2008 0.0420.045 0.0026 0.0003 0.0010 0.0007 0.002 GSB03-2489-2008 0.0049 0.0065 0.0021 0.037 0.0088 0.014 0.0039 GSB03-2490-20080.0200.0220.0350.0520.0360.1130.004510.含镍生铁标准样品11.含五害痕量元素的钢及铸铁标准样品八、碳钢、合金钢化学分析用系列标准样品1. 碳硫专用系列钢标准样品碳钢系列标准样品3.合金钢系列标准样品合金钢系列标准样品4.低合金钢、轴承钢、模具钢、不锈钢标准样品5.锚链钢、09CuP、高速工具钢国家标准样品6.管线钢系列国家标准样品7.磷系列比色钢8.硅、锰系列比色钢9.比色钢系列标准样品10.合金结构钢标准样品11.合金钢化学分析用标准物质12.不锈钢、耐热钢化学分析用标准物质编号材质规格O N YSBC 28901-2014 碳钢球状(1g)0.0065 0.0067 YSBC 28902-2014 碳钢球状(1g)0.0035 0.0081 YSBC 28902a-2014 碳钢球状(1g)0.0043 0.0100 YSBC 28903-2014 不锈钢球状(0.5g)0.0037 0.0253九、光谱分析用标准物质/样品1.高炉生铁光谱分析用标准物质(7块/套、Φ30Х30mm)2. 球墨铸铁光谱分析用标准样品(Φ35Х30mm)国家编号样品编号 C Si Mn P S Cr Ni Cu Mo VGSB 1# 2.43 3.08 0.178 0.031 0.0037 1.98 3.70 1.35 2.06 0.450 2# 2.86 1.67 0.384 0.042 0.0068 1.54 0.985 0.987 1.55 0.395 3# 3.18 2.17 0.783 0.119 0.025 1.01 2.17 0.815 1.00 0.300 4# 3.59 1.25 1.17 0.076 0.028 0.755 0.705 0.525 0.665 0.234 5# 3.99 0.601 1.39 0.211 0.045 0.415 0.201 0.306 0.355 0.098 6# 3.48 0.275 1.69 0.554 0.052 0.164 4.18 0.068 0.076 0.055 Ti Nb Alt Mg Ce B As Sb Pb LaGSB 1# 0.057 0.054 0.007 0.110 0.171 0.051 0.0073 0.00202# 0.095 0.035 0.016 0.040 0.088 0.114 0.033 0.0062 0.0017 0.011 3# 0.074 0.020 0.041 0.033 0.0089 0.053 0.037 0.0052 0.0048 0.0017 4# 0.044 0.021 0.141 0.017 0.044 0.028 0.024 0.015 0.011 0.0074 5# 0.032 0.012 0.027 0.011 0.017 0.012 0.032 0.0071 0.0043 0.0024 6# 0.031 0.0041 0.051 0.0039 0.0077 0.081 0.0022 0.00063.合金钢光谱分析用标准物质(7块/套、Φ40Х35mm)4.不锈钢、耐热钢光谱分析用标准物质(8块/套、Φ40Х35mm)5.不锈钢光谱分析用标准样品(Φ38Х40mm)6.管线钢光谱分析用标准物质(6块/套、Φ40×40mm)7.热作模具钢光谱标准物质(Φ35×35 mm)8.碳钢、合金钢光谱分析用标准样品(Φ35Х35mm、Φ40Х40mm)9.合金钢光谱分析用标准样品(Φ40Х40mm)10.钢光谱分析用标准样品2.铅锡基合金3.铝合金。

36$ 3(8*(27 &,752É1'0(7+2'(6 G (66$, 0$7,(5(6&$287&+28&6 98/&$1,6(6 (7 3/$67,48(6 6283/(65,*,',7( $ %$66( 7(03(5$785(6(/21 (66$, *(+0$1Page 1/116$165(675,&7,21' 87,/,6$7,21AVANT-PROPOS&H GRFXPHQW HVW HQ FRQIRUPLWp WHFKQLTXH DYHF OD PpWKRGH G HVVDL 5(1$8/7 Q,O QH GRLW SDV rWUH PRGLILp VDQV XQH FRQVXOWDWLRQ SUpDODEOH GH 5(1$8/7,O HVW FRQIRUPH j O DFFRUG LQWHUYHQX HQWUH OHV 6HUYLFHV 1RUPDOLVDWLRQ GH 3(8*(27 6 $ HW 5(1$8/7 HQ129(0%5(2%-(7 (7 '20$,1( ' $33/,&$7,21Cette méthode a pour objet l'évaluation de l'accroissement de la rigidité aux basses températures des caoutchoucs et plastiques souples, en le caractérisant :•soit par la température (θ 10) à laquelle le module de torsion est égal à dix fois le module déterminé à 23 °C,•soit par la courbe d'évolution de ce module en fonction de la température.35,1&,3(L'essai consiste à comparer, pour chaque température définie, la rigidité en torsion d'une éprouvette du matériau examiné à celle d'un fil métallique étalon fixé en série avec l'éprouvette, en mesurant l'angle de rotation dusystème lorsqu'on lui impose un angle de torsion de 180°.Cette méthode s'inspire de la norme ASTM D 1053-85.$33$5(,//$*($33$5(,/ '( 7256,21 7<3( *(+0$1conforme à la norme ASTM D 1053-85. L'annexe 1 rappelle les principaux éléments de cet appareil qui doit êtreéquipé d'au moins trois porte-éprouvettes (I) permettant d'effectuer, à chaque température d'essai, des mesures successives sur trois éprouvettes. Ces trois porte-éprouvettes sont maintenus verticaux et équidistants les uns des autres à l'aide du support (J) dont ils sont solidaires.),/6 '( 7256,21conformes à la norme ASTM D 1053-85.Les fils portent un repère de couleur noire, jaune ou blanche correspondant aux constantes de torsion respectives de 0,01 mN.m/degré, 0,05 mN.m/degré et 0,2 mN.m/degré.Le fil de repère jaune est considéré comme fil de référence.L'étalonnage de ces fils doit être effectué périodiquement suivant les recommandations de la norme ASTMprécitée.(1&(,17( '( &21',7,211(0(17à 23 °C ± 1 °C et 50 % ± 5 % d'humidité relative.%$,1 5()5,*(5$17contenant un liquide restant fluide jusqu'à - 70 °C ± 1 °C et n'affectant pas le matériau examiné (le méthanol convient pour de nombreux caoutchoucs).La température du liquide doit être homogène à ± 0,5 °C dans toute la zone d'immersion des éprouvettes. Elle doit pouvoir être réglée de - 70 °C à la température ambiante.&+52120(75((03257( 3,(&(permettant le découpage des éprouvettes.',6326,7,) '( 5(&+$8))(0(17 '8 /,48,'( '8 %$,1permettant d'obtenir une élévation de température d'au moins 2 °C/minute.$,5 &2035,0( 35235( (7 6(&3,(' $ &28/,66((35289(77(6 ' (66$,',0(16,2164.1.1.PRELEVEMENT SUR PLAQUESLes éprouvettes doivent être prélevées à l'aide de l'emporte-pièce (3.6) dans des plaques de 2 mm ± 0,2 mmd'épaisseur perpendiculairement au sens de calandrage dans le cas des caoutchoucs. L'éprouvette d'essai doit avoir 40 mm ± 2,5 mm de long et 3 mm ± 0,2 mm de large.Mesurer à l'aide du pied à coulisse (3.9) la largeur et l'épaisseur de l'éprouvette soit, respectivement, a et b exprimés en millimètres.La différence entre les épaisseurs maximale et minimale d'une même éprouvette ne doit pas excéder 0,1 mm.4.1.2.PRELEVEMENT SUR PIECESDans ce cas, les éprouvettes ne doivent être prélevées que sur des parties planes et les résultats ne peuvent être comparés qu'à ceux d'essais effectués sur des matériaux de même épaisseur. Leurs dimensions sont déterminées comme indiqué précédemment.120%5( ' (35289(77(6Pour chaque essai, deux éprouvettes au moins doivent être utilisées.Il est souhaitable d'y adjoindre pour contrôle, une troisième éprouvette d'un matériau dont les caractéristiques en rigidité à froid sont déjà connues.35(3$5$7,21Les éprouvettes utilisées dans cette méthode et décrites aux paragraphe 4.1 et 4.2 sont généralement prélevées sur des plaques ou des pièces à l'état neuf ; il est toutefois possible de les soumettre préalablement à un vieillissement approprié (méthodes d'essai D47 1053, D47 1098 par exemple) afin d'évaluer son influence sur la rigidité à basse température du matériau examiné.02'( 23(5$72,5(9RLU DQQH[HDurant toutes les manipulations suivantes, les porte-éprouvettes (I) restent fixés sur le support (J).0217$*( '(6 (35289(77(6 685 /(6 3257( (35289(77(6 ,Insérer la cale de débattement (R) entre le sommet du porte-éprouvette (I) et la base du plot mâled'accouplement (D).Placer les mâchoires des mors de fixation (K) dans un même plan, tel que la vis (S) du plot d'accouplement (D) soit perpendiculaire à ce plan et face à l'opérateur.Insérer l'éprouvette entre les mors de fixation (K). La longueur libre (L) de l'éprouvette déterminée à l'aide du pied à coulisse (3.9) est de 25 mm ± 2,5 mm.Elle est obtenue en vissant le mors supérieur sur la tige filetée du plot mâle (D).Fixer l'éprouvette à l'aide des colliers de serrage des mors de fixation (K) et vérifier que l'éprouvette neprésente ni torsion, ni flexion.Procéder ainsi pour toutes les éprouvettes.(66$,65.2.1.ESSAI A TEMPERATURE AMBIANTE DANS L’ENCEINTE (3.3)Choisir un des fils de torsion (3.2).Adapter le support (J) sur le support (H).Fixer le fil de torsion (B) en série avec l'éprouvette.Pour cela, desserrer la vis (T), faire coulisser le fil de torsion (B) [pendant cette opération, le zéro de la tête de torsion (A) coïncide avec le repère fixe et le fil de torsion (B) ne doit subir aucun mouvement de rotation], emboîter parfaitement les plots d'accouplement mâle et femelle (D) et resserrer les vis (S) et (T).Oter la cale de débattement (R). Le fil de torsion (B) doit alors être aligné verticalement avec l'éprouvette et n'être soumis à aucune torsion.Faire pivoter le rapporteur (G) de telle sorte que sa graduation zéro coïncide avec l'indication de l'aiguille (F).Tourner rapidement mais sans-à-coup, la tête de torsion (A) de 180°, la maintenir et déclenchersimultanément le chronomètre (3.5).Effectuer la lecture de l'angle de torsion X0 au bout de 10 secondes.Ramener la tête de torsion (A) à sa position zéro. Remettre en position la cale (R), désaccoupler les plots (D) et amener le fil de torsion au-dessus de l'éprouvette suivante.1RWD7RXWHV OHV pSURXYHWWHV GRLYHQW rWUH HVVD\pHV j & ± & 6L j & O DQJOH ; Q HVW SDV FRPSULV HQWUH HW DYHF OH ILO GH WRUVLRQ GH UpIpUHQFH UHSqUH MDXQH OH ILO Q HVW SDV DGDSWp j O pSURXYHWWH FRQVLGpUpH/HV pSURXYHWWHV FRQGXLVDQW j XQ DQJOH ; VXSpULHXU j GRLYHQW rWUH HVVD\pHV DYHF XQ ILO GH UHSqUH QRLU/HV pSURXYHWWHV FRQGXLVDQW j XQ DQJOH ; LQIpULHXU j GRLYHQW rWUH HVVD\pHV DYHF XQ ILO GH UHSqUH EODQF5.2.2.ESSAI A TEMPERATURE AMBIANTE DANS LE BAIN (3.4)Prendre le même fil de torsion que celui qui a servi pour effectuer l'essai défini au paragraphe 5.2.1.Placer le support (H) muni du support (J) dans le bain réfrigérant (3.4) stabilisé à 23 °C ± 1 °C ens'assurant que le liquide circule au moins à 25 mm au-dessus du sommet des éprouvettes.Attendre 5 minutes puis procéder comme au paragraphe 5.2.1 en suivant les indications des paragraphes 5.2.1.2 à 5.2.1.7 inclus ; soit X A l'angle mesuré.Procéder ainsi pour toutes les éprouvettes.Retirer le support (J) du bain (3.4) immédiatement après la mesure des angles X A et sécher leséprouvettes à l'aide de l'air comprimé (3.8).Placer le support (J) pendant 16 h ± 1 h dans l'enceinte (3.3).5.2.3.ESSAI A BASSE TEMPERATURE DANS LE BAIN (3.4)Prendre le même fil de torsion que celui qui a servi pour effectuer l'essai défini au paragraphe 5.2.1.Ajuster la température du bain (3.4) à la valeur la plus basse désirée (en général - 50 °C) et attendre la stabilisation de cette température à ± 0,5 °C.Adapter le support (J) sur le support (H) et s'assurer que le liquide circule au moins à 25 mm au-dessus du sommet des éprouvettes.Attendre 15 minutes puis procéder comme au paragraphe 5.2.1 en suivant les indications des paragraphes 5.2.1.2 à 5.2.1.7 inclus ; soit X l'angle mesuré.Procéder ainsi pour toutes les éprouvettes.Elever la température du bain de 5 °C à la vitesse de 2 °C/min. Attendre 5 minutes après stabilisation de la température et effectuer la mesure de l'angle de torsion X en suivant les indications des paragraphes 5.2.1.2 à5.2.1.7.Procéder ainsi tous les 5 °C pour toutes les éprouvettes jusqu'à ce que l'angle de torsion X ne soit inférieur que de 5° à 10° par rapport à l'angle de torsion initial X A mesuré au paragraphe 5.2.2.A la fin de l'essai, retirer les supports (H) et (J) du bain (3.4).(;35(66,21 '(6 5(68/7$76Les paramètres suivants sont successivement déterminés :•Variation de l'angle de torsion X en fonction de la température.• Température (θ 10) à laquelle le module correspondant est égal à 10 fois le module déterminé à 23 °C.•Modules apparents de torsion à 23 °C et à θ 10.9$5,$7,21 '( / $1*/( '( 7256,21 ; (1 )21&7,21 '( /$ 7(03(5$785(Tracer la courbe X = f (θ) (voir annexe 2).7(03(5$785((θ 10) à laquelle le module correspondant est égal à 10 fois le module déterminé à 23 °C.6.2.1.COEFFICIENT MULTIPLICATEUR KLe module apparent étant proportionnel à 180−XX, pour une éprouvette donnée et à chaque température,l'augmentation du module par rapport au module à 23 °C, est caractérisée par le coefficient k défini par la formule :kXXXXAA =−−180180.dans laquelle :X = angle de torsion en degrés, mesuré à la température d'essai dans le méthanol,X A = angle de torsion en degrés, mesuré à 23 °C dans le méthanol.6.2.2.TEMPERATUREθ 10Sur la courbe X = f (θ), la température θ 10 à laquelle le module correspondant est égal à 10 fois le moduledéterminé à 23 °C (k = 10) est plus particulièrement déterminée.Il peut être intéressant de déterminer la température à laquelle le module est multiplié par 2-5 et 100 (θ 2, θ 5 et θ100).Le tableau 1 de l'annexe 3 indique, pour un angle X A donné à 23 °C, les angles correspondants pour lesquels k est égal à 2-5-10 et 100.1RWD θ HVW O DEVFLVVH G XQ SRLQW VLWXp HQ JpQpUDO VXU OD SDUWLH OLQpDLUH GH SOXV IRUWH SHQWH GH OD FRXUEH ; I θ ,O HQ UpVXOWH TX XQH HUUHXU GH OHFWXUH VXU ; GDQV FHWWH UpJLRQ QH FRQGXLW SDV j XQH HUUHXU LPSRUWDQWH VXU OD GpWHUPLQDWLRQ GH θ02'8/( $33$5(17 '( 7256,21Le module apparent de torsion G, en mégapascals, est donné par la formule :G KXXLab=−9161803().µdans laquelle :K = constante de torsion du fil en millinewtons, mètre/degré,X = angle de torsion de l'éprouvette en degrés,L = longueur de l'éprouvette libre entre mors en millimètres,a = largeur de l'éprouvette en millimètres,b = épaisseur de l'éprouvette en millimètres,µ = facteur fonction du rapport a/b et donné dans le tableau 2 de l'annexe 3.Calculer le module apparent G pour un angle X A mesuré à 23 °C et à la température pour laquelle k = 10 (θ 10).(35289(77(6 (;$0,1((6 $35(6 9,(,//,66(0(17Dans le cas d'éprouvettes examinées après vieillissement (paragraphe 4.3), la température à laquelle le module est multiplié par 10 (paragraphe 6.2) peut se calculer de deux manières :•soit par rapport au module mesuré à 23 °C après vieillissement,•soit par rapport au module mesuré à 23 °C avant vieillissement.Le choix du mode de calcul est effectué suivant les indications portées dans les documents.(66$,6 '( &21752/(Pour les essais rapides de contrôle, utiliser uniquement le fil de torsion de référence (repère jaune), puis procéder comme indiqué au paragraphe 5.0.Effectuer les mesures des angles X A (voir paragraphe 5.2.2) et X (voir paragraphe 5.2.3) à la température spécifiée dans le document. Vérifier que les valeurs mesurées pour X A et X (avec k = 10) correspondent à celles données dans le tableau 1 de l'annexe 3.352&(6 9(5%$/ ' (66$,Outre les résultats obtenus, le procès-verbal d'essai doit indiquer :•la référence de la présente méthode,•la référence de la matière,•les dimensions de l'éprouvette utilisée,•le conditionnement ou vieillissement éventuel de l'éprouvette avant essai,•le type de bain réfrigérant,•la constante du fil de torsion,•le temps de séjour dans le bain réfrigérant,•le mode de calcul choisi dans le cas d'éprouvettes examinées après vieillissement,•les détails opératoires non prévus dans la méthode d'essai ainsi que les incidents éventuels susceptibles d'avoir agi sur les résultats.'2&80(176 &,7(6'2&80(176 36$Méthodes d'essai : D47 1053, D47 1098.'2&80(17 $670 D1053-85.$QQH[H SCHEMA DE L'APPAREILLAGE$QQH[H VARIATION DE L'ANGLE DE TORSION EN FONCTION DE LA TEMPERATUREMélange NBR - méthanol$QQH[H TABLEAU 1 - ANGLES DE TORSION POUR DES VALEURS DONNEES DE kY$ÃjÃ!"à 8 qrt p 6 tyrà qrt pxÃ2Ã!6 tyrà qrt pxÃ2Ã$6 tyrà qrt pxÃ2Ã6 tyrà qrt pxÃ2Ã120 121 122 123 124 125 126 127 128 129 130 131 132 133 134 135 136 137 138 139 140 141 142 143 144 145 146 147 148 149 150 151 152 153 154 155 156 157 158 159 160 161 162 163 164 165 166 167 168 169 17090919293959697989910110210310410510710810911111211311411611711912012112312412612712913013213313413613813914014214414614714915115215415615815916151525354555657585961626364656668697071727475777880828385878890929496971001021041061081111131161181211241261301331361393031313233333435363637383940414242434546474849505153545557586062626567697173757880828588919498101105109113344444444555555556666677777788999101011111212131314151617181920222426$QQH[H TABLEAU 2 - VALEURS DU FACTEUR µ EN FONCTION DE a/bD E µD E µ1,00 1,05 1,10 1,15 1,20 1,25 1,30 1,35 1,40 1,45 1,50 1,60 1,70 1,75 1,80 1,90 2,002,2492,3592,4642,5632,6582,7482,8332,9142,9903,0633,1323,2603,3753,4283,4793,5733,6592,252,502,753,003,504,004,505,006,007,008,009,0010,0020,0050,00100,003,8423,9904,1114,2134,3734,4934,5864,6624,7734,8534,9134,9604,9975,1655,2265,300PSA PEUGEOT - CITROËN&$287&+28&6 5,*,',7( %$66( 7(03(5$785(' 11/11+,6725,48( (7 '2&80(17 &,7(6+,6725,48(9.1.1.CREATION•OR: 01/11/1983 - CREATION DE LA NORME.9.1.2.OBJET DE LA MODIFICATION•A: 01/07/1990 - REFONTE COMPLETE DE LA NORME.•B: 15/10/1997 - REPRISE SOUS IDEM.'2&80(176 &,7(69.2.1.DOCUMENTS PSA9.2.1.1.NormesD471053, D471098.9.2.1.2.Autres9.2.2.DOCUMENTS EXTERIEURSASTMD1053(01/1985)(48,9$/(17 $REN1528&21)250( $0276 &/()6OR:01/11/1983 B:15/10/1997Usage Public。