Motor Vehicles, Model Year 1995

- 格式:pdf

- 大小:545.98 KB

- 文档页数:5

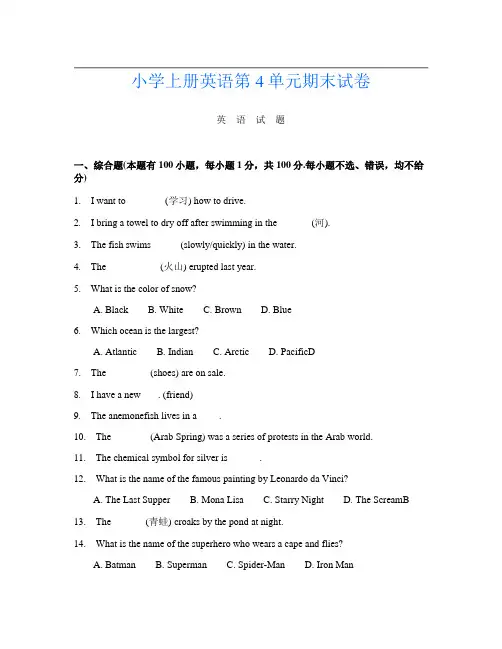

小学上册英语第4单元期末试卷英语试题一、综合题(本题有100小题,每小题1分,共100分.每小题不选、错误,均不给分)1.I want to _______ (学习) how to drive.2.I bring a towel to dry off after swimming in the ______ (河).3.The fish swims _____ (slowly/quickly) in the water.4.The __________ (火山) erupted last year.5.What is the color of snow?A. BlackB. WhiteC. BrownD. Blue6.Which ocean is the largest?A. AtlanticB. IndianC. ArcticD. PacificD7.The ________ (shoes) are on sale.8.I have a new ___. (friend)9.The anemonefish lives in a ____.10.The _______ (Arab Spring) was a series of protests in the Arab world.11.The chemical symbol for silver is ______.12.What is the name of the famous painting by Leonardo da Vinci?A. The Last SupperB. Mona LisaC. Starry NightD. The ScreamB13.The ______ (青蛙) croaks by the pond at night.14.What is the name of the superhero who wears a cape and flies?A. BatmanB. SupermanC. Spider-ManD. Iron Man15. A __________ is a natural phenomenon that can impact ecosystems.16.Which fruit is red and often used in pies?A. BananaB. CherryC. OrangeD. GrapesB17.Sand, silt, and clay are examples of different types of ______.18.My ________ (玩具名称) is a great partner in games.19.My favorite color is ___ (red).20. A ________ (植物遗传多样性) is crucial for resilience.21.I like to watch _______ (电影) with my family.22.I like to listen to ______ (音乐) while studying. It helps me focus better and feel ______ (放松).23. D.BerlinHow many legs does a spider have?A. SixB. EightC. Ten24.The __________ were ancient monuments built by the Mayans. (金字塔)25.The _______ of an object can be determined by its interaction with other objects.26.Many plants change color in ______ (秋天).27.My favorite fruit is a ______ (草莓). It is sweet and juicy.28.What is the primary color of a cherry?A. YellowB. GreenC. RedD. BlueC Red29.What animal is famous for its black and white stripes?A. LionB. ZebraC. PandaD. SkunkB30.What do you call the place where animals are kept for public display?A. ZooB. FarmC. ParkD. Sanctuary31.Which of these is a type of fish?A. SalmonB. ChickenC. PorkD. BeefA32.I watched a _______ (小鹦鹉) mimic sounds.33.The __________ (工业革命) changed the way people worked and lived in the 18th century.34.What do you call an animal that hunts for food?A. PredatorB. PreyC. ScavengerD. HerbivoreA Predator35.What is the name of the famous palace located in France?A. Buckingham PalaceB. Kensington PalaceC. Palace of VersaillesD. Neuschwanstein Castle36.What color is the sky on a clear day?A. GreenB. BlueC. RedD. YellowB37.During winter, we have snowball fights and make ________ (雪人). It’s a fun________ (活动).38.The pH scale ranges from to ______.39.The best time to see stars is when it's ______.40.The garden has many _______ that bloom in spring.41.How many teeth does a typical adult human have?A. 28B. 30C. 32D. 34C42.The _____ (公鸡) crows at dawn to wake everyone up. 公鸡在黎明时鸣叫,叫醒每个人。

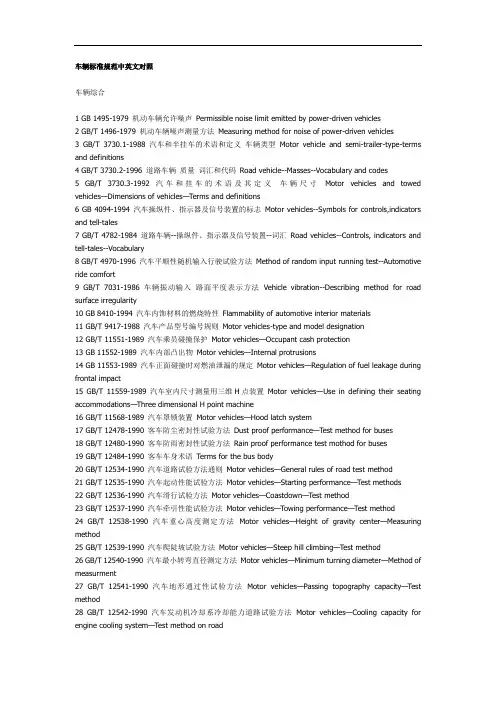

车辆标准规范中英文对照车辆综合1 GB 1495-1979 机动车辆允许噪声Permissible noise limit emitted by power-driven vehicles2 GB/T 1496-1979 机动车辆噪声测量方法Measuring method for noise of power-driven vehicles3 GB/T 3730.1-1988 汽车和半挂车的术语和定义车辆类型Motor vehicle and semi-trailer-type-terms and definitions4 GB/T 3730.2-1996 道路车辆质量词汇和代码Road vehicle--Masses--Vocabulary and codes5 GB/T 3730.3-1992 汽车和挂车的术语及其定义车辆尺寸Motor vehicles and towed vehicles—Dimensions of vehicles—Terms and definitions6 GB 4094-1994 汽车操纵件、指示器及信号装置的标志Motor vehicles--Symbols for controls,indicators and tell-tales7 GB/T 4782-1984 道路车辆--操纵件、指示器及信号装置--词汇Road vehicles--Controls, indicators and tell-tales--Vocabulary8 GB/T 4970-1996 汽车平顺性随机输入行驶试验方法Method of random input running test--Automotive ride comfort9 GB/T 7031-1986 车辆振动输入路面平度表示方法Vehicle vibration--Describing method for road surface irregularity10 GB 8410-1994 汽车内饰材料的燃烧特性Flammability of automotive interior materials11 GB/T 9417-1988 汽车产品型号编号规则Motor vehicles-type and model designation12 GB/T 11551-1989 汽车乘员碰撞保护Motor vehicles—Occupant cash protection13 GB 11552-1989 汽车内部凸出物Motor vehicles—Internal protrusions14 GB 11553-1989 汽车正面碰撞时对燃油泄漏的规定Motor vehicles—Regulation of fuel leakage during frontal impact15 GB/T 11559-1989 汽车室内尺寸测量用三维H点装置Motor vehicles—Use in defining their seating accommodations—Three dimensional H point machine16 GB/T 11568-1989 汽车罩锁装置Motor vehicles—Hood latch system17 GB/T 12478-1990 客车防尘密封性试验方法Dust proof performance—Test method for buses18 GB/T 12480-1990 客车防雨密封性试验方法Rain proof performance test mothod for buses19 GB/T 12484-1990 客车车身术语Terms for the bus body20 GB/T 12534-1990 汽车道路试验方法通则Motor vehicles—General rules of road test method21 GB/T 12535-1990 汽车起动性能试验方法Motor vehicles—Starting performance—Test methods22 GB/T 12536-1990 汽车滑行试验方法Motor vehicles—Coastdown—Test method23 GB/T 12537-1990 汽车牵引性能试验方法Motor vehicles—Towing performance—Test method24 GB/T 12538-1990 汽车重心高度测定方法Motor vehicles—Height of gravity center—Measuring method25 GB/T 12539-1990 汽车爬陡坡试验方法Motor vehicles—Steep hill climbing—Test method26 GB/T 12540-1990 汽车最小转弯直径测定方法Motor vehicles—Minimum turning diameter—Method of measurment27 GB/T 12541-1990 汽车地形通过性试验方法Motor vehicles—Passing topography capacity—Test method28 GB/T 12542-1990 汽车发动机冷却系冷却能力道路试验方法Motor vehicles—Cooling capacity for engine cooling system—Test method on road29 GB/T 12543-1990 汽车加速性能试验方法Motor vehicles—Acceleration performance—Test method30 GB/T 12544-1990 汽车最高车速试验方法Motor vehicles—Maximum speed—Test method31 GB/T 12545-1990 汽车燃料消耗量试验方法Motor vehicles—Fuel consumption test method32 GB/T 12546-1990 汽车隔热通风试验方法Motor vehicles—Ventilation and heat insulation—Test method33 GB/T 12547-1990 汽车最低稳定车速试验方法Motor vehicles—Minimum stable speed—Test method34 GB/T 12549-1990 汽车操纵稳定性术语及其定义Automotive controllability and stability—Terms and definitions35 GB/T 12674-1990 汽车质量(重量)参数测定方法Motor vehicles—Weight parameter—Measuring method36 GB/T 12677-1990 汽车技术状况行驶检查方法Motor vehicles—Technical condition—Inspection method37 GB/T 12678-1990 汽车可靠性行驶试验方法Reliability running test method for automobiles38 GB/T 12679-1990 汽车耐久性行驶试验方法Motor vehicles—Durability running—Test method39 GB/T 13860-1992 地面车辆机械振动测量数据的表述方法Mechanical vibrations--Land vehicles-Method for reporting measured data40 GB/T 14168-1993 汽车制动液类别图形标志Motor vehicles--Graphical symbols to designate brake fluid types41 GB/T 14172-1993 汽车静侧翻稳定性台架试验方法Static roll stability test method for motor vehicles42 GB/T 15089-1994 机动车辆分类Motor vehicles--Classification43 GB 15740-1995 汽车防盗装置性能要求Motor vehicle--Protective devices against unauthorized use--Performance requirments44 GB/T 16735-1997 道路车辆车辆识别代号(VIN)位置与固定Road vehicles--Vehicle identification number(VIN)--Location and attachment45 GB/T 16736-1997 道路车辆车辆识别代号(VIN)内容与构成Road vehicles--Vehicle identification number(VIN)--Content and structure46 GB/T 16737-1997 道路车辆世界制造厂识别代号(WMI)Road vehicles--World manufacturer identifier(WMI)code47 GB/T 16738-1997 道路车辆世界零件制造厂识别代号(WPMI) Road vehicler--World parts manufacturer identifier(WPMI)code48 GB 7258-1997 机动车运行安全技术条件Safety specifications for motor vehicles operating on roads49 GB 13094-1997 客车结构安全要求The safety requirements for bus construction50 GB/T 16888-1997 客车安全顶窗The escape hatch of bus汽车发动机1 GB/T 5923-1986 汽车柴油机燃油滤清器的试验方法Test methods of fuel filters for automotive compression ignition engines2 GB/T 5924-1986 汽车柴油机燃油滤清器的试验值及分级Test values and classification of fuel filters for automotive compression ignition engines3 GB/T 12781-1991 汽车供油系气阻试验方法Motor vehicles—Vapor lock for fuel system—Test method4 GB/T 12782-1991 汽车采暖性能试验方法Motor vehicle—Heating performance—Test method5 GB/T 14169-1993 汽车空气滤清器接头A型和B型Air filter connections for motor vehicles--Types A and B6 GB/T 14170-1993 载货汽车空气滤清器滤芯尺寸规范Air filter elements for trucks--Dimensions7 GB/T 8409-1999 汽车发动机旋装式机油滤清器连接尺寸Road vehicles--Intermal combustion engines--Spin-on filters for lubrication oil--Dimension8 GB/T 17653-1999 汽车柴油机旋装式燃油滤清器安装和连接尺寸Road vehicles--Spin-on fuel filters for combustion-ignition engines--Mounting and dimensions9 GB/T 17692-1999 汽车用发动机净功率测试方法Measurement methods of net power for automotive engines汽车底盘与车身1 GB 1589-1989 汽车外廓尺寸限界Outside dimension limits of motor vehicles2 GB/T 2933-1995 充气轮胎用车轮和轮辋的术语、规格代号和标志Wheels/rims for pneumatic tyres--Nomenclature,designation and marking3 GB/T 3487-1996 汽车轮辋规格系列Rim contours for motor vehicles4 GB/T 4095-1995 载货汽车辐板式车轮在轮毂上的安装尺寸Disc wheels for trucks--Dimensional characteristics of attachment on hub5 GB/T 4784-1984 使用非石油基制动液的汽车液压制动软管总成Brake hose assemblies for hydraulic braking systems of motor vehicles used with a non-petroleum base hydrau-lic fluids6 GB/T 5334-1995 轿车钢制车轮性能要求和试验方法Performance requirements and test methods of passenger car steel wheels7 GB/T 5335-1985 汽车制动装置液压试验的连接器Automobile hydraulic pressure test connection for braking equipment8 GB/T 5345-1985 制动液容器的标记Labelling of containers for brake fluid9 GB/T 5620.1-1985 汽车和挂车制动名词术语及其定义制动系种类、组成、力学及现象The terms and definitions of braking of automotive vehicles and their trailers--Types,constituent elements,braking mechanics and phenomenon of braking system10 GB/T 5620.2-1985 汽车和挂车制动名词术语及其定义零部件The terms and definitions of braking of automotive vehicles and their trailers--The parts and components of braking equipment11 GB/T 5909-1995 载货汽车车轮性能要求和试验方法Performance requirements and test methods of truck wheels12 GB/T 5911-1986 转向盘尺寸Steering wheel--Dimensions13 GB/T 5921-1986 汽车和挂车气压制动系部件上接口的识别标记Motor vehicles and towed vehicles--Air braking systems--Identification of connections on units14 GB/T 5922-1986 汽车和挂车气压制动装置压力测试连接器Motor vehicles and towed vehicles--Pressure test connection for compressed-air pneumatic braking equipment15 GB/T 6792-1996 客车车身骨架应力、形变测量方法Measure method of stress and deformation for bus budy skeleton16 GB 7062-1986 汽车气制动软管总成Automotive air brake hose assemblies17 GB 7063-1994 汽车护轮板The wheel guards of motor vehicles18 GB/T 7680-1987 液力变矩器性能试验方法Hydrodynamic torque converter--Method of performance tests19 GB/T 10484-1989 汽车真空制动软管总成Vacuum brake hose assemblies for motor vehicle20 GB/T 11549-1989 汽车安全带总成性能要求和试验方法Motor vehicles—Safety belt assemblies—Performance requirements and test methods21 GB 11550-1995 汽车座椅头枕性能要求和试验方法Motor vehicles--Seats head vestraints--Performance requirements and test methods22 GB 11555-1994 汽车风窗玻璃除雾系统的性能要求及试验方法Motor vehicles--Windshield demisters--Performance requirements and test methods23 GB 11556-1994 汽车风窗玻璃除霜系统的性能要求及试验方法Motor vehicles--Windshield defrosters--Performance requirements and test methods24 GB/T 11558-1989 汽车安全带用卷收器性能要求和试验方法Motor vehicles—Retractors for safety belt—Performance requirements and test methods25 GB 11561-1989 汽车加速器控制系统的技术要求Motor vehicles—Accelerator control systems—Technical requirements26 GB 11562-1994 汽车驾驶员前方视野要求及测量方法Motor vehicles--Forward visibility for drivers--Requirements and measurement methods27 GB/T 11563-1995 汽车H点确定程序Motor vehicles--Procedure for H-point determination28 GB 11565-1989 轿车风窗玻璃刮水器刮刷面积Passenger cars—Windshield wipers—Wiped areas29 GB 11566-1995 轿车外部凸出物Passenger car--External protrusions30 GB 11567-1994 汽车和挂车侧面及后下部防护装置要求Motor vehicles and trailers--Lateral and underrun protections--Requirements31 GB/T 11611-1989 汽车液压制动系金属管、内外螺纹管接头和软管端部接头Motor vehicles—Hydraulic braking systems—Pipes tapped holes, male fittings and hose end fittings32 GB/T 12482-1990 客车侧窗平面玻璃规格系列Side window flat glasses systematization for buses33 GB/T 12483-1990 客车风窗、后窗玻璃规格系列Buses windscreen and rear window glass—Systematization34 GB/T 12673-1990 汽车主要尺寸测量方法Molor vehicles—Basic dimensions—Measuring method35 GB/T 12780-1991 货车、客车制动器台架试验方法Trucks and buses—Brake—Bench test methods36 GB/T 13051-1991 汽车机械式变速器动力输出孔连接尺寸Motor vehicles—Connections for PTO37 GB/T 13053-1991 客车驾驶区尺寸Bus driver compartment dimensions38 GB/T 13054-1991 客车驾驶区尺寸术语Bus driver compartment dimensions terms39 GB/T 13055-1991 客车乘客区尺寸Bus passenger compartment dimensions40 GB/T 13056-1991 客车乘客区尺寸术语Bus passenger compartment dimension terms41 GB/T 13057-1991 客车驾驶员座椅尺寸规格Bus driver seat—Dimensions42 GB/T 13058-1991 客车驾驶员座椅技术条件Bus drivers seat—Technical specification43 GB/T 13059-1991 客车乘客座椅尺寸规格Bus passenger seat—Dimensions44 GB/T 13060-1991 客车乘客座椅技术条件Bus passenger seat—Technical specifications45 GB/T 13061-1991 汽车悬架用空气弹簧橡胶气囊Air spring for automotive suspension—Rubber bellows46 GB 13594-1992 汽车防抱制动系统性能要求和试验方法Vehicles anti-lock braking systems performence requiremants and test procedures47 GB/T 13604-1992 汽车转向球接头尺寸Motor vehicles—Steering ball joints—Dimensions48 GB 14166-1993 汽车安全带性能要求和试验方法Motor vehicles--Safety belt assemblies--Performance requirements and test methods49 GB 14167-1993 汽车安全带安装固定点Motor vehicles--Safety belt anchorages50 GB/T 14171-1993 汽车气制动系管路螺纹孔和管接头外螺纹Motor vehicles--Pneumatic braking systems--Tapped holes and male fittings51 GB 15083-1994 汽车座椅系统强度要求及试验方法Motor vehicles--Seat systems--Strengthrequirements and test methods52 GB 15084-1994 汽车后视镜的性能和安装要求Motor vehicles--Rear view mirrors--Requirements of performance and installation53 GB 15085-1994 汽车风窗玻璃刮水器、洗涤器的性能要求及试验方法Motor vehicles--Windshield wipers and washer systems--Performance requirements and test methods54 GB 15086-1994 汽车门锁及门铰链的性能要求和试验方法Motor vehicles--Door locks and door hinges--Performance requirements and test methods55 GB/T 15087-1994 汽车牵引车与全挂车机械连接装置强度试验Motor vehicles--Drawbar couplings and eyes for hinged drawbars--Strength test56 GB/T 15088-1994 汽车半挂车牵引座牵引销强度试验Motor vehicles--Fifth wheel coupling pins--Strength test57 GB/T 15704-1995 轿车车轮冲击试验方法Passenger cars--Wheels--Impact test procedure58 GB/T 15705-1995 载货汽车驾驶员操作位置尺寸Trucks--Operating position demensions of driver59 GB 15741-1995 汽车和挂车号牌板(架)及其位置The license plates (crackets) and its position on motor vehicles and trailer60 GB 15743-1995 轿车侧门强度Passenger car--Strength of side doors61 GB 16897-1997 制动软管Brake hose62 GB/T 17346-1998 轿车脚踏板的侧向间距Passenger cars--Lateral spacing of foot controls63 GB 11557-1998 防止汽车转向机构对驾驶员伤害的规定The stipulation protecting drivers from being injured by motor vehicle steering mechanism64 GB/T 17351-1998 汽车车轮双轮中心距Dual spaeing of vechicle wheels65 GB 17354-1998 汽车前、后端保护装置Front and rear protective devices for passenger cars66 GB/T 17578-1998 客车上部结构强度的规定Provisions of strength for the Superstructure of bus67 GB 12676-1999 汽车制动系统结构、性能和试验方法Road vehicles-Braking systems-Structure performance and test methods68 GB 17675-1999 汽车转向系基本要求Steering system of motor vehicles-Basic requirements69 GB/T 17676-1999 天然气汽车和液化石油气汽车标志Natural gas vehicle and liquefied petroleum gas vehicle Identification marks车辆通用零部件1 GB/T 1359-1978 汽车与挂车气制动接头型式与尺寸Pneumatic brakes for motor vehicls and their trailers-couplings--Types and dimensions2 GB/T 7726.1-1998 铰接式客车机械连接装置术语Mechanical connections of articulated bus Glossary3 GB/T 7726.2-1998 铰接式客车机械连接装置技术要求Mechanical connections of articulated bus Technical requirements4 GB/T 7726.3-1998 铰接式客车机械连接装置球头销Mechanical connections of articulated bus Ball pin5 GB/T 7726.4-1998 铰接式客车机械连接装置球形衬套Mechanical connections of articulated bus Ball socket6 GB/T 7726.5-1998 铰接式客车机械连接装置伸缩篷Mechanical connections of articulated bus Telescopic tarpaulin车用电子、电气设备与仪表1 GB 4599-1994 汽车前照灯配光性能Photometric characteristics of headlamps for motor vehicles2 GB/T 4659-1984 汽车前照灯类型、主要尺寸和连接尺寸Type,main size and mounted dimension of headlamps for motor vehicle3 GB 4660-1994 汽车前雾灯配光性能Photometric characteristics of front fog lamps for motor vehicles4 GB/T 5053.1-1985 汽车与挂车之间24N 型电连接器Electrical connections between motor vehicles and towed vehicles--Type 24N5 GB/T 5053.2-1985 汽车与挂车之间12N 型电连接器Electrical connections between motor vehicles and towed vehicles--Type 12N6 GB/T 5053.3-1985 汽车与挂车之间电连接器的试验方法与要求Test methods and requirements of electrical connections between motor vehicles and towed vehicles7 GB/T 5054-1985 汽车与挂车的七芯电缆线Seven-core connecting cable of motor vehicles and towed vehicles8 GB/T 5337-1985 汽车电器、灯具和仪表名词术语Nomenclature and terminology for automotive electrical equipment, lighting and instrumentation9 GB 5920-1994 汽车前和后位(侧)灯、示廓灯和制动灯配光性能Photometric characteristics of front and rear position (side)lamps, end-outline marker lamps and stop lamps for motor vehicles and their trailers 10 GB/T 6784-1986 M10×1平座火花塞及其气缸盖安装孔Spark plug M10×1 with flat seating and cylinder head housing11 GB/T 6785-1986 M12×1.25 平座火花塞及其气缸盖安装孔Spark plug M12×1.25 with flat seating and cylinder head housing12 GB/T 6786-1986 M14×1.25 平座火花塞及其气缸盖安装孔Spark plug M14×1.25 with flat seating and cylinder head housing13 GB/T 6787-1986 M14×1.25 矮型平座火花塞及其气缸盖安装孔Compact spark plug M14×1.25 with flat seating and cylinder head housing14 GB/T 6788-1986 M14×1.25 矮型锥座火花塞及其气缸盖安装孔Compact spark plug M14×1.25 with conical seating and cylinder head housing15 GB/T 6789-1986 M14×1.25 锥座火花塞及其气缸盖安装孔Spark plug M14×1.25 with conical seating and cylinder head housing16 GB/T 6790-1986 M18×1.5 平座火花塞及其气缸盖安装孔Spark plug M18×1.5 with flat seating and cylinder head housing17 GB/T 6791-1986 M18×1.5 锥座火花塞及其气缸盖安装孔Spark plug M18×1.5 with conical seating and cylinder head housing18 GB/T 7360-1987 汽车与挂车照明和信号装置的工作电压及其测量Working voltages and their measurement for lights and lighting signal devices fitted to motor vehicles and towed vehicles19 GB/T 7825-1987 火花塞Spark plugs20 GB/T 10485-1989 汽车和挂车外部照明和信号装置基本环境试验Basic environmental testing of lighting and light signalling devices for motor vehicles and their trailers21 GB/T 12548-1990 汽车速度表、里程表检验校正方法Motor vehicles—Speedometer and odometer—Calibration method22 GB 15082-1994 汽车用车速表Motor vehicles--Speed meters23 GB 15235-1994 汽车倒车灯配光性能Photometric characteristics of reversing lamps for motor vehicles and their trailers24 GB 15742-1995 汽车电喇叭的性能要求及试验方法Automotive--Electric horn--Performance requirements and test methods25 GB/T 17348-1998 道路车辆会车光束倾斜角随载荷变化的测量Motor vehicle--Measurement of variations in dipped beam headlamp angle as a function of load26 GB/T 17349.1-1998 道路车辆汽车诊断系统词汇Road vehicles--Diagnostic systems for motor vehicles--Vocabulary27 GB/T 17349.2-1998 道路车辆汽车诊断系统图形符号Rord vehicle Diagnostic systym Graphical symbols28 GB 17509-1998 汽车和挂车转向信号灯配光性能Photometric characteristics of direction indicators for motor vehicles and their trailers29 GB 17510-1998 摩托车光信号装置配光性能Photometric characteristics of light-signalling devices for motorcycles30 GB 4785-1998 汽车及挂车外部照明和信号装置的安装规定Prescription for installation of the external lighting and light signalliug devices for motor vehicles and their trailers31 GB 11554-1998 汽车及挂车后雾灯配光性能Photometric characteristics of rear fog lamp for motor vehicles and their tralers32 GB 11564-1998 机动车回复反射器Retro refletor for motor vehicles33 GB 5948-1998 摩托车白炽丝光源前照灯配光性能Photometric characteristics of motocycle headlamps epuipped with filament light sources汽车1 GB/T 918.1-1989 道路车辆分类与代码机动车Classification and code for road vehicles—Motor vehicle2 GB/T 918.2-1989 道路车辆分类与代码非机动车Classification and code for road vehicles—Non-motor vehicle3 GB/T 1332-1991 载货汽车定型试验规程Trucks—Engineering approval evaluation program4 GB/T 1333-1977 汽车产品质量定期检查试验规程Test code for regular quality inspection of automobile products5 GB/T 4780-1984 载货汽车车身名词、术语Glossary of truck body6 GB/T 4971-1985 汽车平顺性名词术语和定义Terms and definitions--Automotive ride comfort7 GB/T 5902-1986 汽车平顺性脉冲输入行驶试验方法Method of pulse input running test--Automobile ridecomfort8 GB/T 6104-1985 机动工业车辆名词术语Powered industrial trucks--Terminology9 GB/T 6323.1-1994 汽车操纵稳定性试验方法蛇行试验Controllability and stability test procedure for automobiles--Pylon course slalom test10 GB/T 6323.2-1994 汽车操纵稳定性试验方法转向瞬态响应试验(转向盘转角阶跃输入) Eontrollability and stability test procedure for automobiles--Steering transient response test(Steering wheel angle step input)11 GB/T 6323.3-1994 汽车操纵稳定性试验方法转向瞬态响应试验(转向盘转角脉冲输入) Contorllability and stability test procedure for automobiles--Steering transient response test(Steering wheel angle pulse input)12 GB/T 6323.4-1994 汽车操纵稳定性试验方法转向回正性能试验Controllability and stability test procedure for automobiles--Returnability test13 GB/T 6323.5-1994 汽车操纵稳定性试验方法转向轻便性试验Controllability and stability test procedure for automobiles--Steering efforts test procedure14 GB/T 6323.6-1994 汽车操纵稳定性试验方法稳态回转试验Controllability and stability test procedurefor automobiles--Steady static circular test procedure15 GB/T 7361-1987 半挂牵引车的制动及电路连接位置Brake and electrical connection locations of semi-trailer towing vehicle16 GB/T 7362-1987 全挂牵引车和货车的制动及电路连接位置Brake and electrical connection locations of truck andtrailer-towing vehicle17 GB/T 11380-1989 客车车身涂层技术条件Technical requirement for bus body coating18 GB/T 11381-1989 客车顶部静载试验方法Method of static load test for bus top19 GB/T 11382-1989 客车前保险杠效能试验方法正面固定式障壁碰撞试验Effect test procedure of front bumper for bus--Head-on collision with fixed wall20 GB/T 11709-1989 客车产品质量定期检查试验规程The regulated inspecting test procedure for bus21 GB/T 12427-1990 客车产品系列型谱Series and spectrum of buses22 GB/T 12428-1990 客车装载质量计算方法Laden mass calculation of buses23 GB/T 12429-1990 客车车身二氧化碳气体保护焊焊接质量要求及检验方法The quality requirement and test method for the carbon-dioxide arc welding of coach-body24 GB/T 12430-1990 客车乘客扶手杆的固定件基本型式与规格尺寸Basic type and size of fixings for passenger hand-rails in buses25 GB/T 12431-1990 客车乘客扶手杆断面Sections of passengers hand-rails in buses26 GB/T 12432-1990 客车乘客门门泵技术条件Specification for passenger door cylinder of buses27 GB/T 12433-1990 客车乘客门门泵试验方法Testing method for passenger door cylinder of buses28 GB/T 12675-1990 微型货车出厂检验方法Test methods of inspection after production for mini-truck29 GB/T 13043-1991 客车定型试验规程Buses—Engineering approval evaluation program30 GB/T 13044-1991 轻型客车定型试验规程Light buses—Engineering approval evaluation program31 GB/T 13046-1991 轻型客车产品质量定期检查试验规程Testing regulations for light bus and light van periodical inspection32 GB/T 16887-1997 卧铺客车技术条件Specification for sleeper bus33 GB/T 5910-1998 轿车质量分布Passenger car Mass distribution34 GB/T 17347-1998 商用道路车辆尺寸代码Commercial road vehicles Dimensional codes专用汽车1 GB/T 9465.1-1988 高空作业车分类Aerial platform--Classification2 GB/T 9465.2-1988 高空作业车技术条件Aerial platform--Specification3 GB/T 9465.3-1988 高空作业车试验方法Test methods for aerial platform4 GB/T 12503-1995 电视机通用技术条件Generic specification for TV vans5 GB/T 17350-1998 专用汽车和专用半挂车术语和代号Terms and marks in special automobiles and semi-trailers拖拉机1 GB/T 1592-1986 农业拖拉机动力输出轴Power take-off for agricultural tractors2 GB/T 1593.1-1996 农业轮式拖拉机后置式三点悬挂装置第1部分: 1、2、3和4类Agricultural wheeled tractors--Rear-mounted three-point linkage--Part 1: Categories 1,2,3 and 43 GB/T 1593.2-1987 农用轮式拖拉机三点悬挂装置第二部分: 1N类Agricultural wheeled tractors--Three-point linkage--Part 2: CategorY 1 N4 GB/T 1593.3-1987 农业轮式拖拉机三点悬挂装置第三部分: 0 类Agricultural wheeled tractors--Three-point linkage--Part 3: Categories 05 GB 1593.4-1987 农用轮式拖拉机三点悬挂装置第四部分:0类Agricultural wheeled tractors--Three-point linkage--Part 4: Category 06 GB/T 2777-1992 农业拖拉机动力输出轴安全防护罩型式尺寸和强度要求Power take-off safety shield for agricultural tractors--Types, dimensions and strength specifications7 GB/T 2778-1992 农业拖拉机动力输出皮带轮圆周速度和宽度Power take-off pulley for agricultural tractors--Peripheral speed and width8 GB/T 2779-1992 拖拉机拖挂装置型式尺寸和安装要求Tractor's connective equipment for trailers--Types, dimensions and mounting requirements9 GB/T 2780-1992 农业拖拉机牵引装置型式尺寸和安装要求Darwbars for agricultural tractors--Types dimensions and mounting requirements10 GB/T 3373-1982 拖拉机和农业、林业机械用轮辋Rims for tractors,agricultural and forestry machines11 GB/T 3871.1-1993 农业轮式和履带拖拉机试验方法第1 部分通用要求Test methods for agricultural wheeled and tracklaying tractors--Part 1: General requirements12 GB/T 3871.2-1993 农业轮式和履带拖拉机试验方法第2 部分整机参数测定Test methods for agricultural wheeled and tracklaying tractors--Part 2: Measurements of tractor parameters13 GB/T 3871.3-1993 农业轮式和履带拖拉机试验方法第3 部分动力输出轴功率试验Test methods for agricultural wheeled and tracklaying tractors--Part 3: PTO power tests14 GB/T 3871.4-1993 农业轮式和履带拖拉机试验方法第4 部分液压提升能力和输出功率试验Test methods for agricultural wheeled and tracklaying tractors--Part 4: Hydraulic lifting capacity and power tests15 GB/T 3871.5-1993 农业轮式和履带拖拉机试验方法第5 部分转向和离合器操纵试验Test methods for agricultural wheeled and tracklaying tractors--Part 5: Turning and clutch operating tests16 GB/T 3871.6-1993 农业轮式和履带拖拉机试验方法第6 部分制动试验Test methods for agricultural wheeled and tracklaying tractors--Part 6: Braking tests17 GB/T 3871.7-1993 农业轮式和履带拖拉机试验方法第7 部分视野测定Test methods for agricultural wheeled and tracklaying tractors--Part 7: Measurements of operator's field vision18 GB/T 3871.8-1993 农业轮式和履带拖拉机试验方法第8 部分噪声测量Test methods for agricultural wheeled and tracklaying tractors--Part 8: Measurements of noise19 GB/T 3871.9-1993 农业轮式和履带拖拉机试验方法第9 部分牵引功率试验Test methods for agricultural wheeled and tracklaying tractors--Part 9: Drawbar power tests20 GB/T 3871.10-1993 农业轮式和履带拖拉机试验方法第10部分低温起动试验Test methods for agricultural wheeled and tracklaying tractors--Part 10: Low temperature starting tests21 GB/T 3871.11-1993 农业轮式和履带拖拉机试验方法第11部分高温适应性试验Test methods for agricultural wheeled and tracklaying tractors--Part 11: Suitability tests for hot atmosphere22 GB/T 3871.12-1993 农业轮式和履带拖拉机试验方法第12部分使用试验Test methods for agricultural wheeled and tracklaying tractors--Part 12: Working tests23 GB/T 4329-1984 农业拖拉机三点悬挂装置锁销尺寸Three-point-linkage for agricultural tractors--Dimensions of linch pins24 GB/T 6229-1995 手扶拖拉机试验方法Methods of test for walking tractor25 GB/T 6236-1986 农业拖拉机驾驶座标志点Agricultural tractors--Operator's seat index point26 GB/T 6238-1986 农业拖拉机驾驶室的门道、紧急出口与驾驶员的工作位置尺寸Agricultural tractors--Access, exit and the operator's workplace--Dimensions27 GB 6376-1995 拖拉机噪声限值Noise limitation for tractors28 GB/T 6960.1-1995 拖拉机术语整机Tractor terminology--Complete tractor29 GB/T 6960.2-1995 拖拉机术语传动系Tractor terminology--Transmission system30 GB/T 6960.3-1995 拖拉机术语制动系Tractor terminology--Braking system31 GB/T 6960.4-1995 拖拉机术语行走系Tractor terminology--Running gears and undercarriages32 GB/T 6960.5-1995 拖拉机术语转向系Tractor terminology--Steering system33 GB/T 6960.6-1995 拖拉机术语液压悬挂系及牵引、拖挂装置Tractor terminology--Hydraulic hitch system and drawbar, hook34 GB/T 6960.7-1995 拖拉机术语驾驶室、驾驶座和覆盖件Tractor terminology--Cab, seat and sheet metal35 GB/T 6960.8-1986 拖拉机名词术语第八部分履带行走系统Tractor terminology--Part 8: Endless track installation for track laying tractor36 GB/T 6961-1986 拖拉机动力输出轴和牵引装置的使用要求Operating requirements for tractor power take-off and drawbars37 GB/T 6972-1986 农业轮式拖拉机驾驶座振动的测量Agricultural wheeled tractors--Operator's seat--Measurement of trahsmitted vibration38 GB/T 7120-1986 农用轮式拖拉机三点悬挂农具快速挂接器3N类Three-Point hitch implement quick-attaching coupler of agricultural wheeled tractors--Category 3N39 GB 7121-1986 农林轮式拖拉机防护装置强度试验方法和验收条件Agricultural and forestry wheeled tractors--Protective structures--Test method in the strength and acceptance conditions40 GB/T 7927-1987 手扶拖拉机振动测量方法Method of measurement for walking tractor vibration41 GB/T 8421-1987 农业轮式拖拉机驾驶座传递振动的评价指标Agricultural wheeled tractors--Operator seat--Evaluation criteria of transmitted vibration42 GB/T 10176-1988 手扶拖拉机牵引装置和动力输出皮带轮Walking tractors--Drawbar and pulley of power take off43 GB/T 10910-1989 农业轮式拖拉机驾驶员全身振动的测量Agricultural wheeled tractors—Measurement of whole-body vibration of the operator44 GB/T 10911-1989 农业轮式拖拉机和后悬挂农具的匹配Matching of agricultural wheeled tractors and rear mounted implements45 GB/T 10916-1989 农业轮式拖拉机前悬挂装置第一部分: 1、2类Agricultural wheeled tractors—Front-mounted linkage —Part 1: Category 1, 246 GB/T 10917-1989 农用轮式拖拉机前置动力输出轴Front-mounted power take-off for agricultural wheeled tractors47 GB/T 13875-1992 手扶拖拉机通用技术条件The general specification for walking tractors48 GB/T 13876-1992 农业轮式拖拉机驾驶员全身振动的评价指标Agricultural wheeled tractors--Evaluation criteria of whole body vibration of the operator49 GB/T 13877-1992 农业拖拉机和自走式机具密封驾驶室加压系统试验方法Agricultural tractors and self-propelled machines--Test method for enclosure pressurization systems50 GB/T 13878-1992 农业拖拉机和自走式机具封闭驾驶室采暖和通风系统性能试验方法Agricultural tractors and self-propelled machines--Performance of heating and ventilation systems in closed cabs--Method of test51 GB/T 14226-1993 草坪和园艺拖拉机三点悬挂装置Lawn and garden tractors--Three-point hitch52 GB/T 14785-1993 拖拉机和农林机械车轮侧向负载疲劳试验方法Wheels side load fatigue test methods for tractors, agricultural and forestry machines53 GB/T 14786-1993 拖拉机和农林机械车轮扭转疲劳试验方法Wheels torsion fatigue test methods for tractors, agricultural and forestry machines54 GB 15369-1994 农林拖拉机和机械安全技术要求第三部分: 拖拉机Tractors and machinery for agriculture and forestry--Technical means for ensuring safety--Part 3: Tractors55 GB/T 15370-1994 农业轮式和履带拖拉机通用技术条件General Specifications for agricultural wheeled and tracking tractors56 GB/T 15832-1995 林业轮式和履带拖拉机通用技术条件General specifications for forestry wheeled and tracklaying tractors57 GB/T 15833-1995 林业轮式和履带拖拉机试验方法Test methods for forestry wheeled and tracklaying tractors58 GB/T 6235-1997 农业拖拉机驾驶座及主要操纵装置位置尺寸Agricultural tractors--Operator's seating accommodation--Dimensions59 GB/T 16877-1997 拖拉机禁用与报废Prohibition and scrapping for tractors60 GB/T 17122-1997 草坪和园艺乘座式拖拉机动力输出套管Lawn and garden ride-on (riding) tractors--Power take-off61 GB/T 17123-1997 草坪和园艺乘座式拖拉机单点套管式悬挂装置Lawn and garden ride-on (riding) tractors--One-point tubular sleeve hitch62 GB/T 17124-1997 草坪和园艺乘座式拖拉机牵引杆Lawn and garden ride-on (riding) tractors--Drawbar63 GB/T 6232-1998 农林拖拉机和机械车轮在轮毂上安装尺寸Tractors and machinery for agriculture and forestry-Wheel-to-hub fixing dimensions挂车1 GB/T 4330-1984 农业挂车Agricultural trailer2 GB/T 4331-1984 农用挂车试验方法Test methods for agricultural trailers3 GB/T 4606-1984 道路车辆半挂车鞍座50号牵引销主要尺寸和安装、互换性尺寸Road vehicles--50 semi-trailer fifth wheel coupling pin--Basic and mounting/interchangeability dimensions4 GB/T 4607-1984 道路车辆半挂车鞍座90号牵引销主要尺寸和安装、互换性尺寸Road vehicles--90 semi-trailer fifth wheel coupling pin--Basic and mounting/interchangeability dimensions5 GB/T 4781-1984 牵引车与全挂车的机械连接装置互换性Mechanical connection between towing vehicle and full trailers for interchangeability6 GB/T 6420-1986 货运挂车系列型谱Freight trailer series pedigree7 GB/T 13872-1992 货运挂车定型试验规程Trailer--Rules for the identification test8 GB/T 13873-1992 货运挂车试验方法Trailer--Test procedure9 GB/T 13874-1992 货运挂车质量定期检查试验规程Trailer--Rules for the periodic quality inspection test10 GB/T 13880-1992 半挂牵引车牵引座的安装Road vehicles--Semi trailer fifth wheel mounting11 GB/T 13881-1992 牵引车与挂车之间气制动管连接器Pneumatic braking connections between motor vehicles and towed vehicles12 GB/T 13202-1997 摩托车轮辋系列Series of motorcycle rims13 GB/T 17275-1998 货运全挂车通用技术条件Technical requirements for freight full trailers摩托车。

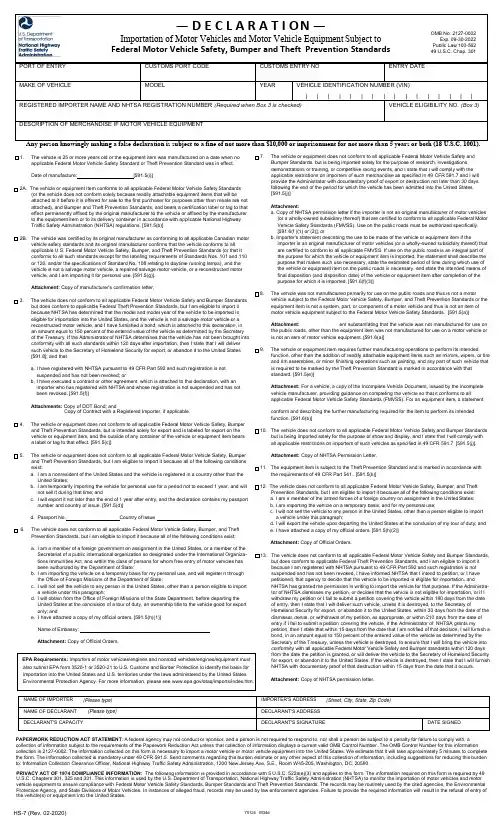

HS-7 (Rev. 02-2020)75124 –M34d— D E C L A R A T I O N —Importation of Motor Vehicles and Motor Vehicle Equipment Subject to Federal Motor Vehicle Safety, Bumper and Theft Prevention StandardsPORT OF ENTRY CUSTOMS PORT CODE CUSTOMS ENTRY NO ENTRY DATEMAKE OF VEHICLEMODELYEARVEHICLE IDENTIFICATION NUMBER (VIN) ||||||||||||||||REGISTERED IMPORTER NAME AND NHTSA REGISTRATION NUMBER (Required when Box 3 is checked) VEHICLE ELIGIBILITY NO. (Box 3)DESCRIPTION OF MERCHANDISE IF MOTOR VEHICLE EQUIPMENTAny person knowingly making a false declaration is subject to a fine of not more than $10,000 or imprisonment for not more than 5 years or both (18 U.S.C. 1001).1. The vehicle is 25 or more years old or the equipment item was manufactured on a date when noapplicable Federal Motor Vehicle Safety Standard or Theft Prevention Standard was in effect.Date of manufacture:[591.5(i)]2A. The vehicle or equipment item conforms to all applicable Federal Motor Vehicle Safety Standards(or the vehicle does not conform solely because readily attachable equipment items that will beattached to it before it is offered for sale to the first purchaser for purposes other than resale are not attached), and Bumper and Theft Prevention Standards, and bears a certification label or tag to that effect permanently affixed by the original manufacturer to the vehicle or affixed by the manufacturer to the equipment item or to its delivery container in accordance with applicable National Highway Traffic Safety Administration (NHTSA) regulations. [591.5(b)]2B. The vehicle was certified by its original manufacturer as conforming to all applicable Canadian motorvehicle safety standards and its original manufacturer confirms that the vehicle conforms to all applicable U.S. Federal Motor Vehicle Safety, Bumper, and Theft Prevention Standards (or that it conforms to all such standards except for the labeling requirements of Standards Nos. 101 and 110 or 120, and/or the specifications of Standard No. 108 relating to daytime running lamps), and the vehicle is not a salvage motor vehicle, a repaired salvage motor vehicle, or a reconstructed motor vehicle, and I am importing it for personal use. [591.5(g)].Attachment: Copy of manufacturer's confirmation l etter.3.The vehicle does not conform to all applicable Federal Motor Vehicle Safety and Bumper Standards but does conform to applicable Federal Theft Prevention Standards, but I am eligible to import it because NHTSA has determined that the model and model year of the vehicle to be imported is eligible for importation into the United States, and the vehicle is not a salvage motor vehicle or a reconstructed motor vehicle, and I have furnished a bond, which is attached to this declaration, in an amount equal to 150 percent of the entered value of the vehicle as determined by the Secretary of the Treasury. If the Administrator of NHTSA determines that the vehicle has not been brought intoconformity with all such standards within 120 days after importation, then I state that I will deliversuch vehicle to the Secretary of Homeland Security for export, or abandon it to the United States [591.8]; and thata. I have registered with NHTSA pursuant to 49 CFR Part 592 and such registration is not suspended and has not been revoked; orb. I have executed a contract or other agreement, which is attached to this declaration, with an importer who has registered with NHTSA and whose registration is not suspended and has not been revoked. [591.5(f)]Attachments: Copy of DOT Bond; andCopy of Contract with a Registered Importer, if applicable.4.The vehicle or equipment does not conform to all applicable Federal Motor Vehicle Safety, Bumper and Theft Prevention Standards, but is intended solely for export and is labeled for export on the vehicle or equipment item, and the outside of any container of the vehicle or equipment item bears a label or tag to that effect. [591.5(c)]5.The vehicle or equipment does not conform to all applicable Federal Motor Vehicle Safety, Bumper and Theft Prevention Standards, but I am eligible to import it because all of the following conditions exist:a. I am a nonresident of the United States and the vehicle is registered in a country other than the United States;b. I am temporarily importing the vehicle for personal use for a period not to exceed 1 year, and will not sell it during that time; andc. I will export it not later than the end of 1 year after entry, and the declaration contains my passport number and country of issue. [591.5(d)]d. Passport No.Country of Issue6.The vehicle does not conform to all applicable Federal Motor Vehicle Safety, Bumper, and Theft Prevention Standards, but I am eligible to import it because all of the following conditions exist:a. I am a member of a foreign government on assignment in the United States, or a member of the Secretariat of a public international organization so designated under the International Organiza- tions Immunities Act, and within the class of persons for whom free entry of motor vehicles has been authorized by the Department of State;b. I am importing the vehicle on a temporary basis for my personal use, and will register it through the Office of Foreign Missions of the Department of State;c. I will not sell the vehicle to any person in the United States, other than a person eligible to import a vehicle under this paragraph;d. I will obtain from the Office of Foreign Missions of the State Department, before departing the United States at the conclusion of a tour of duty, an ownership title to the vehicle good for export only; ande. I have attached a copy of my official orders. [591.5(h)(1)]Name of Embassy:Attachment: Copy of Official Orders.7.The vehicle or equipment does not conform to all applicable Federal Motor Vehicle Safety and Bumper Standards, but is being imported solely for the purpose of research, investigations, demonstrations or training, or competitive racing events, and I state that I will comply with the applicable restrictions on importers of such merchandise as specified in 49 CFR 591.7 and I will provide the Administrator with documentary proof of export or destruction not later than 30 days following the end of the period for which the vehicle has been admitted into the United States. [591.5(j)]Attachment:a. Copy of NHTSA permission letter if the importer is not an original manufacturer of motor vehicles (or a wholly-owned subsidiary thereof) that are certified to conform to all applicable Federal Motor Vehicle Safety Standards (FMVSS). Use on the public roads must be authorized specifically. [591.6(f )(1) or (2)]; orb. Importer's statement describing the use to be made of the vehicle or equipment item if theimporter is an original manufacturer of motor vehicles (or a wholly-owned subsidiary thereof) that are certified to conform to all applicable FMVSS. If use on the public roads is an integral part of the purpose for which the vehicle or equipment item is imported, the statement shall describe the purpose that makes such use necessary, state the estimated period of time during which use of the vehicle or equipment item on the public roads is necessary, and state the intended means of final disposition (and disposition date) of the vehicle or equipment item after completion of the purpose for which it is imported. [591.6(f)(3)]8.The vehicle was not manufactured primarily for use on the public roads and thus is not a motorvehicle subject to the Federal Motor Vehicle Safety, Bumper, and Theft Prevention Standards or the equipment item is not a system, part, or component of a motor vehicle and thus is not an item of motor vehicle equipment subject to the Federal Motor Vehicle Safety Standards. [591.5(a)] Attachment: Importer’s statem ent substantiating that the vehicle was not manufactured for use on the public roads, other than the equipment item was not manufactured for use on a motor vehicle or is not an item of motor vehicle equipment. [591.6(a)] 9.The vehicle or equipment item requires further manufacturing operations to perform its intendedfunction, other than the addition of readily attachable equipment items such as mirrors, wipers, or tire and rim assemblies, or minor finishing operations such as painting, and any part of such vehicle that is required to be marked by the Theft Prevention Standard is marked in accordance with that standard. [591.5(e)]Attachment: For a vehicle, a copy of the Incomplete Vehicle Document, issued by the incomplete vehicle manufacturer, providing guidance on completing the vehicle so that it conforms to allapplicable Federal Motor Vehicle Safety Standards (FMVSS). For an equipment item, a statement issued by the item’s manufacturer identifying the applicable FMVSS to which the item does not conform and describing the further manufacturing required for the item to perform its intended function. [591.6(b)]10. The vehicle does not conform to all applicable Federal Motor Vehicle Safety and Bumper Standardsbut is being imported solely for the purpose of show and display, and I state that I will comply with all applicable restrictions on importers of such vehicles as specified in 49 CFR 591.7. [591.5(j)].Attachment: Copy of NHTSA Permission Letter.11. The equipment item is subject to the Theft Prevention Standard and is marked in accordance withthe requirements of 49 CFR Part 541. [591.5(k)] 12. The vehicle does not conform to all applicable Federal Motor Vehicle Safety, Bumper, and TheftPrevention Standards, but I am eligible to import it because all of the following conditions exist: a. I am a member of the armed forces of a foreign country on assignment in the United S tates; b. I am importing the vehicle on a temporary basis, and for my personal use;c. I will not sell the vehicle to any person in the United States, other than a person eligible to import a vehicle under this paragraph;d. I will export the vehicle upon departing the United States at the conclusion of my tour of duty; ande. I have attached a copy of my official orders. [591.5(h)(2)]Attachment: Copy of Official Orders.13. The vehicle does not conform to all applicable Federal Motor Vehicle Safety and Bumper Standards,but does conform to applicable Federal Theft Prevention Standards, and I am eligible to import it because I am registered with NHTSA pursuant to 49 CFR Part 592 and such registration is not suspended and has not been revoked, I have informed NHTSA that I intend to petition, or I have petitioned, that agency to decide that the vehicle to be imported is eligible for importation, andNHTSA has granted me permission in writing to import the vehicle for that purpose. If the Administra-tor of NHTSA dismisses my petition, or decides that the vehicle is not eligible for importation, or if I withdraw my petition or I fail to submit a petition covering the vehicle within 180 days from the date of entry, then I state that I will deliver such vehicle, unless it is destroyed, to the Secretary ofHomeland Security for export, or abandon it to the United States, within 30 days from the date of the dismissal, denial, or withdrawal of my petition, as appropriate, or within 210 days from the date of entry if I fail to submit a petition covering the vehicle. If the Administrator of NHTSA grants mypetition, then I state that within 15 days from the date that I am notified of that decision, I will furnish a bond, in an amount equal to 150 percent of the entered value of the vehicle as determined by the Secretary of the Treasury, unless the vehicle is destroyed, to ensure that I will bring the vehicle into conformity with all applicable Federal Motor Vehicle Safety and Bumper standards within 120 days from the date the petition is granted, or will deliver the vehicle to the Secretary of Homeland Security for export, or abandon it to the United States. If the vehicle is destroyed, then I state that I will furnish NHTSA with documentary proof of that destruction within 15 days from the date that it occurs.Attachment: Copy of NHTSA permission letter.NAME OF IMPORTER (Please type) IMPORTER'S ADDRESS (Street, City, State, Zip Code)NAME OF DECLARANT (Please type)DECLARANT'S ADDRESSDECLARANT'S CAPACITYDECLARANT'S SIGNATURE DATE SIGNEDEPA Requirements: Importers of motor vehicles/engines and nonroad vehicles/engines/equipment must also submit EPA form 3520-1 or 3520-21 to U.S. Customs and Border Protection to identify the basis for importation into the United States and U.S. territories under the laws administered by the United States Environmental Protection Agency. For more information, please see /otaq/imports/index.htm.PAPERWORK REDUCTION ACT STATEMENT : A federal agency may not conduct or sponsor, and a person is not required to respond to, nor shall a person be subject to a penalty for failure to comply with, a collection of information subject to the requirements of the Paperwork Reduction Act unless that collection of information displays a current valid OMB Control Number. The OMB Control Number for this information collection is 2127-0002. The information collected on this form is necessary to import a motor vehicle or motor vehicle equipment into the United States. We estimate that it will take approximately 5 minutes to complete the form. The information collected is mandatory under 49 CFR 591.5. Send comments regarding this burden estimate or any other aspect of this collection of information, including suggestions for reducing this burden to: Information Collection Clearance Officer, National Highway Traffic Safety Administration, 1200 New Jersey Ave, S.E., Room W45-205, Washington, DC, 20590.PRIVACY ACT OF 1974 COMPLIANCE INFORMATION: The following information is provided in accordance with 5 U.S.C. 522a(e)(3) and applies to this form. The information required on this form is required by 49 U.S.C. Chapters 301, 325 and 331. This information is used by the U.S. Department of Transportation, National Highway Traffic Safety Administration (NHTSA) to monitor the importation of motor vehicles and motor vehicle equipment to ensure compliance with Federal Motor Vehicle Safety Standards, Bumper Standards and Theft Prevention Standards. The records may be routinely used by the cited agencies, the Environmental Protection Agency, and State Divisions of Motor Vehicles. In instances of alleged fraud, records may be used by law enforcement agencies. Failure to provide the required information will result in the refusal of entry of the vehicle(s) or equipment into the United States.OMB No. 2127-0002Exp. 09-30-2022 Public Law 100-562 49 U.S.C. Chap. 301。

机动车道英语English: A motor vehicle lane, also known as a 'carriageway' or'driving lane,' is a designated area on a road that is intended for the use of motor vehicles only. These lanes are typically marked with lines or signs to indicate that they are separate from pedestrian walkways or bike lanes. Motor vehicle lanes are designed to safely accommodate cars, trucks, motorcycles, and other motorized vehicles, allowing for efficient traffic flow and minimizing the risk of accidents. They are an essential component of road infrastructure in urban, suburban, and rural areas, serving as the primary means of transportation for many individuals and businesses.中文翻译: 机动车道,也称为“行车道”或“驾驶车道”,是道路上指定供机动车辆使用的区域。

这些车道通常用线条或标志标明,以示与行人路或自行车道分开。

机动车道旨在安全地容纳汽车、卡车、摩托车和其他机动车辆,从而实现交通流畅,并最大程度地减少事故风险。

它们是城市、郊区和农村地区道路基础设施的重要组成部分,为许多个人和企业提供主要的交通方式。

必修4Unit 3 A taste of English humour能力演练一、语法填空An old man who lived in a small street in the city of Mumbai had to put up 1 the nuisance(烦心事)of having boys play cricket outside his house at night.One evening when the boys were 2 (particular)noisy,he went out to talk to them.He explained that he was happiest 3 he could see or hear boys playing his favourite game,cricket.He said he would give them 25 rupees(卢比)each week to play in the street at night.The boys were thrilled.They were being paid to do something they enjoyed! At the end of the first week they 4 (knock)at the old man s door and asked him to pay them,and so he did.The second week when they asked for 5 (pay)he said he had run out of money and sent them away with only 15 rupees.The third week the man said he had not 6 received his pension and gave them only 10 rupees.The boys were very 7 (disappoint)but there was not much they could do about 8 .The fourth week the man said he could not afford to pay them 25 rupees 9 he had promised,but would give them 5 rupees each week without fail.This was too much for the boys.“You expect us to play seven days 10 week for a merely 5 rupees!”they yelled.“Go to blazes.”They stormed away and never played on the street again.二、完形填空阅读下面短文,掌握其大意,然后从1~15各题所给的四个选项(A、B、C和D)中,选出最佳选项。

车管所办理退车流程英文回答:Vehicle Deregistration Process at the DMV.The process of deregistering a vehicle at the Department of Motor Vehicles (DMV) varies depending on the state. However, there are some general steps that apply to most states.1. Gather the necessary documents: You will need to bring the following documents to the DMV:Vehicle title.Vehicle registration.Proof of insurance.Driver's license.2. Complete the necessary paperwork: The DMV will provide you with a form to complete. This form will ask for information about the vehicle, including the make, model, year, VIN, and license plate number.3. Pay the fees: You will need to pay a fee to deregister the vehicle. The fee varies depending on the state.4. Surrender the license plates: You will need to surrender the license plates to the DMV.5. Receive a receipt: The DMV will give you a receipt for the transaction. This receipt is proof that the vehicle has been deregistered.中文回答:车管所办理退车流程。

汽车世界第一辆汽车(1886年 Benz Patent Motorwagen)瑞典Koenigsegg CCX超跑 2008版汽车,即本身具有动力得以驱动,不须依轨道或电力架设,得以机动行驶之车辆。

广义来说,具有四轮行驶的车辆,普遍多称为汽车。

虽然,长久以来学术各界对「谁是第一位汽车发明者」皆有不同的看法及论述,未有完全一致性的看法,但是,绝大部份学者皆将德国工程师卡尔·奔驰视为第一位发明者[1]。

汽车历史蒸汽车∙1888年,法国自行车商人埃米尔·罗杰斯(Emile Roger)获得朋驰的许可,开始生产商用汽车。

安全性环境保护主条目:环境保护2008每千人拥有汽车比率 601+ 501-600 301-500 151-300 101-150 61-100 41-60 21-40 11-20 0-10定义与分类各国法律依汽车的使用方式、大小、功能,所付予的定义与分类:日本定义∙使用内燃机行使的车辆,超过三轮以上,或二轮但是排气量大于125mL分类∙乘用车:以搭载人员为主的车o普通自动车:总重5吨以下,载重3吨以下,载人10人以下o普通机车:排气量125mL以上400mL以下两轮车o小型机车:排气量400mL以上两轮车∙载运车:载货空间大于载人空间的车或载运10人以上的车o中型自动车:总重5吨以上11吨以下,载重3吨以上6吨以下,载人10人以上29人以下o大型自动车:总重11吨以,载重6.5吨以上,载人30人以上∙特殊作业车:不属于以上两者,且有运输之外的主要用途o小型特殊自动车:有运输外用途最高速15km以下全长4.7m以下、全幅1.7m以下、全高2.8m以下o大型特殊自动车:有运输外用途不符上述小型标准者中华人民共和国分类∙小型、微型非营运载客汽车∙摩托车∙拖拉机∙其他机动车基本构造说明:词汇内容选用多数汽车公司所拥有的科技词汇为对象,不计少数汽车公司的科技词汇。

词汇名称与中译名称皆以台湾汽车工业或学术机构常用的美式英语名称为对象,不使用日式英语词汇。

1.Kraftwagen, Automobil, Kurzwort Auto, mehrspuriges Kraftfahrzeug werden zum Transport von Personen und/oder Gutern, zum Ziehen von Fahrzeug oder zur Arbeitstung; angetrieben gewohnlich durch Verbrennungmotor oder eine Kombination von beiden (Hybridantrieb). Man unterscheidet Personenkraftwagen und Nutzkraftwagen. Personenkraftwagen(Pkw) wurden fruher meist nach der GroBe des Hubraums unterteilt in Kleinwagen (bis 1,0 Liter), Mittelklassewagen(von 1,1 bis 2,0 L) und Oberklassewagen (uber 2,0 L). Die Ubergange zwischen den einzelnen Kategorien sind heute jedoch flieBend. Ein anderes Unterscheidungsmerkmal ist die Ausfuhrung der Karosserie: Der geschlossene Wagen wird als 4-6 Sizter mit 2-4 Turen gebaut (Limousine) ,mit erweitertem Innenraum (Kombiwagen) oder zweiturig , meist zweisitzig , sportlich geformat (Coupe) ; Heckraumklappen sind bei allen Ausfuhrungen moglich...此段英文翻译:1.motor vehicles, automotive, short car mehrspuriges vehicle for transport of persons and / or goods, for drawing of vehicle or arbeitstung; driven usually by verbrennungmotor, or a combination of both (hybrid). there are passenger cars and commercial vehicles. passenger vehicles (cars) were used usually after the gross of cylinder capacity, divided into small cars (up to 1.0 liters), read (from 1.1 to2.0 l) and oberklassewagen (about 2.0 l). the ubergange between categories are today fluently. another distinguishing feature is the execution of the body: the closed car is 4 - 6 sizter with 2 - 4 doors built (sedan), with an expanded interior (station wagon) or zweiturig, usually zweisitzig, athletic geformat (coupe); heckraumklappen for all background possible.此段中文翻译:1.一个汽车,汽车,汽车,汽车mehrspuriges运送人员和/或材料,或用于牵引车辆驱动arbeitstung;通常通过verbrennungmotor或这两者的组合(混合)。

ORIGINAL :UNITED NATIONS of July 20, 1995E/ECE/324 )Rev.1/Add.94/Amend.4/Corr.1E/ECE/TRANS/505 )February 21, 2005STATUS OF UNITED NATIONS REGULATIONECE 95UNIFORM PROVISIONS CONCERNING THE APPROVAL OF:VEHICLES WITH REGARD TO THE PROTECTION OF THEOCCUPANTS IN THE EVENT OF A LATERAL COLLISIONIncorporating:00 series of amendments Date of Entry into Force: 06.07.95 Corr. 2 to 00 series of amendments Date of Entry into Force: 10.03.95 01 series of amendments Date of Entry into Force: 12.08.98 Supplement 1 to the 01 series of amendments Date of Entry into Force: 14.11.99 Corr. 1 to the 01 series of amendments Date of Entry into Force: 08.11.00 Corr. 3 to the 00 series of amendments Date of Entry into Force: 26.06.02 02 series of amendments Date of Entry into Force: 16.07.03 Supplement 1 to the 02 series of amendments Date of Entry into Force: 12.08.04ORIGINAL :UNITED NATIONS of July 20, 1995 E/ECE/324)E/ECE/TRANS/505 )Rev.1/Add.94/Amend.4/Corr.1February 21, 2005TITLE:Lateral Collision ProtectionISSUE:3 Regulation No. 95Mar/2005PAGE: IUNITED NATIONS AGREEMENTCONCERNING THE ADOPTION OF UNIFORM TECHNICAL PRESCRIPTIONS FOR WHEELED VEHICLES, EQUIPMENT AND PARTS WHICH CAN BE FITTED AND/OR BE USED ON WHEELED VEHICLES AND THE CONDITIONS FOR RECIPROCAL RECOGNITION OFAPPROVALS GRANTED ON THE BASIS OF THESE PRESCRIPTIONS(*)(Revision 2, including the amendments which entered into force on October 16, 1995)Addendum 94: Regulation No. 95Amendment 4 ErratumUNIFORM PROVISIONS CONCERNING THE APPROVAL OF VEHICLES WITH REGARD TO THEPROTECTION OF THE OCCUPANTS IN THE EVENT OF A LATERAL COLLISION(*)Former title of the Agreement:Agreement Concerning the Adoption of Uniform Conditions of Approval and Reciprocal Recognition of Approval for Motor Vehicle Equipment and Parts, done at Geneva on March 20, 1958.ORIGINAL :UNITED NATIONS of July 20, 1995REGULATION NO. 95UNIFORM PROVISIONS CONCERNING THE APPROVAL OF VEHICLES WITH REGARD TO THE PROTECTION OF THE OCCUPANTS IN THE EVENT OF A LATERAL COLLISIONCONTENTSREGULATION1. Scope2. Definitions3. Application for approval4. Approval5. Specifications and tests6. Modification of the vehicle type7. Conformity of production8. Penalties for non-conformity of production9. Production definitely discontinued10. Transitional provisions11. Names and addresses of technical services responsible for conducting approval tests, and ofadministrative departmentsANNEXESAnnex 1 - Communication concerning the approval or extension or refusal or withdrawal of approval or production definitely discontinued of a vehicle type with regard to protection of occupants inthe event of a lateral collision, pursuant to Regulation No. 95Annex 2 - Arrangements of the approval markAnnex 3 -Procedure for determining the "H" Point and the actual torso angle for seating positions in motor vehiclesAppendix 1 -Description of the three dimensional "H" Point machine (3-D H machine)Appendix 2 -Three dimensional reference systemAppendix 3 -Reference data concerning seating positionsAnnex 4 -Collision test procedureAppendix 1 -Determination of performance dataAppendix 2 -The procedure for calculating the viscous criterion for EUROSID 1 TITLE:Lateral Collision Protection ISSUE:1 Regulation No. 95Oct/2003PAGE: IIORIGINAL :UNITED NATIONS of July 20, 1995REGULATION NO. 95Annex 5 -Mobile deformable barrier characteristicsAppendix 1 - Force-deflection curves for static testsAppendix 2 - Force-deflection curves for dynamic testsAnnex 6 -Technical description of the side impact dummyAnnex 7 -Installation of the side impact dummyAnnex 8 -Partial testTITLE:Lateral Collision Protection ISSUE:1 Regulation No. 95Oct/2003PAGE: IIIORIGINAL :UNITED NATIONS of July 20, 1995REGULATION NO. 951.SCOPEThis Regulation applies to the lateral collision behaviour of the structure of the passengercompartment of M1 and N1 categories of vehicles where the R Point of the lowest seat is notmore than 700 mm from ground level when the vehicle is in the condition corresponding to thereference mass defined in Paragraph 2.10. of this Regulation.2.DEFINITIONSFor the purposes of this Regulation:2.1."Approval of a vehicle" means the approval of a vehicle type with regard to the behaviour ofthe structure of the passenger compartment in a lateral collision;2.2."Vehicle type"means a category of power-driven vehicles which do not differ in suchessential respects as:2.2.1.the length, width and ground clearance of the vehicle, in so far as they have a negative effecton the performance prescribed in this Regulation;2.2.2.the structure, dimensions, lines and materials of the side walls of the passenger compartmentin so far as they have a negative effect on the performance prescribed in this Regulation;2.2.3.the lines and inside dimensions of the passenger compartment and the type of protectivesystems, in so far as they have a negative effect-on the performance prescribed in thisRegulation;2.2.4.the siting of the engine (front, rear or centre);2.2.5.the unladen mass, in so far as there is a negative effect on the performance prescribed in thisRegulation;2.2.6.the optional arrangements or interior fittings in so far as they have a negative effect on theperformance prescribed in this Regulation;2.2.7.the type of front seat(s) and position of the "R" Point in so far as they have a negative effecton the performance prescribed in this Regulation;2.3."Passenger compartment" means the space for occupant accommodation, bounded by theroof, floor, side walls, doors, outside glazing and front bulkhead and the plane of the rearcompartment bulkhead or the plane of the rear-seat back support;2.4."R Point" or "seating reference point" means the reference point specified by the vehiclemanufacturer which:2.4.1.has co-ordinates determined in relation to the vehicle structure;2.4.2.corresponds to the theoretical position of the point of torso/thighs rotation (H Point) for thelowest and most rearward normal driving position or position of use given by the vehiclemanufacturer for each seating position specified by him;TITLE:Lateral Collision Protection ISSUE:1 Regulation No. 95Oct/2003PAGE: 1ORIGINAL :UNITED NATIONS of July 20, 19952.5."H Point" is as established by Annex 3 to this Regulation;2.6."Capacity of the fuel tanks" means the fuel-tank capacity as specified by the manufacturerof the vehicle;2.7."Transverse plane" means a vertical plane perpendicular to the median longitudinal verticalplane of the vehicle;2.8."Protective system" means devices intended to restrain and/or protect the occupants;2.9."Type of protective system" means a category of protective devices which do not differ insuch essential respects as their:technologygeometryconstituent materials;2.10."Reference mass" means the unladen mass of the vehicle increased by a mass of 100 kg(that is the mass of the side impact dummy and its instrumentation);2.11."Unladen mass" means the mass of the vehicle in running order without driver, passengersor load, but with the fuel tank filled to 90% of its capacity and the usual set of tools and sparewheel on board, where applicable;2.12."Mobile deformable barrier" means the apparatus with which the test vehicle is impacted. Itconsists of a trolley and an impactor;2.13."Impactor" means a crushable section mounted on the front of mobile deformable barrier;2.14."Trolley"means a wheeled frame free to travel along its longitudinal axis at the point ofimpact. Its front supports the impactor.3.APPLICATION FOR APPROVAL3.1.The application for approval of a vehicle type with regard to the protection of the occupants inthe event of a lateral collision shall be submitted by the vehicle manufacturer or by his dulyaccredited representative.3.2.It shall be accompanied by the undermentioned documents in triplicate and the followingparticulars:3.2.1. a detailed description of the vehicle type with respect to its structure, dimensions, lines andconstituent materials;3.2.2.photographs and/or diagrams and drawings of the vehicle showing the vehicle type in front,side and rear elevation and design details of the lateral part of the structure;3.2.3.particulars of the vehicle's mass as defined by Paragraph 2.11. of this Regulation;3.2.4.the lines and inside dimensions of the passenger compartment;3.2.5. a description of the relevant side interior fittings and protective systems installed in thevehicle.TITLE:Lateral Collision Protection ISSUE:1 Regulation No. 95Oct/2003PAGE: 2ORIGINAL :UNITED NATIONS of July 20, 1995 TITLE:Lateral Collision ProtectionISSUE:1 Regulation No. 95Oct/2003PAGE: 33.3.The applicant for approval shall be entitled to present any data and results of tests carried out which make it possible to establish that compliance with the requirements can be achieved on prototype vehicles with a sufficient degree of accuracy.3.4. A vehicle which is representative of the type to be approved shall be submitted to the technical service responsible for conducting the approval tests.3.4.1.A vehicle not comprising all the components proper to the type may be accepted for tests provided that it can be shown that the absence of the components omitted has no detrimental effect on the performance prescribed in the requirements of this Regulation.3.4.2. It shall be the responsibility of the applicant for approval to show that the application of Paragraph 3.4.1 is in compliance with the requirements of this Regulation. 4.APPROVAL4.1. If the vehicle type submitted for approval pursuant to this Regulation meets the requirements of Paragraph 5 below, approval of that vehicle type shall be granted.4.2.In case of doubt, account shall be taken, when verifying the conformity of the vehicle to the requirements of this Regulation, of any data or test results provided by the manufacturer which can be taken into consideration in validating the approval test carried out by the technical service.4.3.An approval number shall be assigned to each type approved. Its first two digits (at present 01 corresponding to the 01 series of amendments) shall indicate the series of amendments incorporating the most recent major technical amendments made to the Regulation at the time of issue of the approval. The same Contracting Party may not assign the same approval number to another vehicle type.4.4.Notice of approval or of extension or of refusal of approval of a vehicle type pursuant to this Regulation shall be communicated by the Parties to the Agreement applying this Regulation by means of a form conforming to the model in Annex l to this Regulation and photographs and/or diagrams and drawings supplied by the applicant for approval, in a format not exceeding A4 (210 x 297) mm or folded to that format and on an appropriate scale.4.5.There shall be affixed to every vehicle conforming to a vehicle type approved under this Regulation, conspicuously and in a readily accessible place specified on the approval form, an international approval mark consisting of:4.5.1.a circle surrounding the Letter "E" followed by the distinguishing number of the country whichhas granted approval;(1)(1)1 for Germany,2 for France,3 for Italy,4 for the Netherlands,5 for Sweden,6 for Belgium,7 for Hungary,8 for the Czech Republic,9 for Spain, 10 for Yugoslavia, 11 for the United Kingdom, 12 for Austria, 13 for Luxembourg, 14 for Switzerland, 15 (vacant), 16 for Norway, 17 for Finland, 18 for Denmark, 19 for Romania, 20 for Poland, 21 for Portugal, 22 for the Russian Federation, 23 for Greece, 24 for Ireland, 25 for Croatia, 26 for Slovenia, 27 for Slovakia, 28 for Belarus, 29 for Estonia, 30 (vacant), 31 for Bosnia and Herzegovina, 32 for Latvia, 33 (vacant), 34 for Bulgaria, 35-36 (vacant), 37 for Turkey, 38-39 (vacant), 40 for The former Yugoslav Republic of Macedonia, 41 (vacant), 42 for the European Community (Approvals are granted by its Member States using their respective ECE symbol), 43 for Japan, 44 (vacant), 45 fort Australia and 46 for Ukraine. Subsequent numbers shall be assigned to other countries in the chronological order in which they ratify the Agreement Concerning the Adoption of Uniform Technical Prescriptions for Wheeled Vehicles, Equipment and Parts which can be Fitted and/or be Used on Wheeled Vehicles and the Conditions of for Reciprocal Recognition of Approvals Granted on the Basis of these Prescriptions for Motor Vehicle Equipment and Parts, or in which they accede to that Agreement, and the numbers thus assigned shall be communicated by the Secretary-General of the United Nations to the Contracting Parties to the Agreement.ORIGINAL :UNITED NATIONS of July 20, 1995 TITLE:Lateral Collision ProtectionISSUE:1 Regulation No. 95Oct/2003PAGE: 44.5.2. the number of this Regulation, followed by the Letter "R", a dash and the approval number, to the right of the circle prescribed in Paragraph 4.5.1.4.6.If the vehicle conforms to a vehicle type approved, under one or more other Regulations Annexed to the Agreement, in the country which has granted approval under this Regulation, the symbol prescribed in Paragraph 4.5.1. need not be repeated; in this case the Regulation and approval numbers and the additional symbols of all the Regulations under which approval has been granted in the country which has granted approval under this Regulation shall be placed in vertical columns to the right of the symbol prescribed in Paragraph 4.5.1. 4.7. The approval mark shall be clearly legible and shall be indelible.4.8. The approval mark shall be placed close to or on the vehicle data plate affixed by the manufacturer.4.9. Annex 2 to this Regulation gives examples of approval marks.5.SPECIFICATIONS AND TESTS5.1. The vehicle shall undergo a test in accordance with Annex 4 to this Regulation.5.1.1.The test will be carried out on the driver's side unless asymmetric side structures, if any, are so different as to affect the performance in a side impact. In that case either of the alternatives in Paragraph 5.1.1.1. or 5.1.1.2. may be used by agreement between the manufacturer and test authority.5.1.1.1.The manufacturer will provide the authority responsible for approval with information regarding the compatibility of performances in comparison with the driver's side when the test is being carried out on that side.5.1.1.2. The approval authority, if concerned as to the construction of the vehicle, will decide to have the test performed on the side opposite the driver, this being considered the least favourable. 5.1.2.The Technical Service, after consultation with the manufacturer, may require the test to be carried out with the seat in a position other than the one indicated in Paragraph 5.5.1. ofAnnex 4. This position shall be indicated in the test report.(1)5.1.3.The result of this test shall be considered satisfactory if the conditions set out in Paragraphs 5.2. and 5.3. below are satisfied.(1)Until September 30, 2000, for the purposes of the test requirements, the range of normal longitudinal adjustments shall be limited such that the H-point lies within the length of the door aperture.ORIGINAL :UNITED NATIONS of July 20, 19955.2.Performance criteria5.2.1.The performance criteria, as determined for the collision test in accordance with the Appendixto Annex 4 to this Regulation shall meet the following conditions:5.2.1.1. the head performance criterion (HPC) shall be less than or equal to 1,000; when there is nohead contact, then the HPC shall not be measured or calculated but recorded as "No HeadContact."5.2.1.2. the thorax performance criteria shall be:(a) Rib Deflection Criterion (RDC) less than or equal to 42 mm;(b) Soft Tissue Criterion (VC) less or equal to 1.0 m/sec.For a transitional period of two years after the date specified in Paragraph 10.2. of thisRegulation the V * C value is not a pass/fail criterion for the approval testing, but this valuehas to be recorded in the test report and to be collected by the approval authorities. After thistransitional period, the VC value of 1.0 m/sec shall apply as a pass/fail criterion unless theContracting Parties applying this Regulation decide otherwise.5.2.1.3. the pelvis performance criterion shall be:Pubic Symphysis Peak Force (PSPF) less than or equal to 6 kN.5.2.1.4. the abdomen performance criterion shall be:Abdominal Peak Force (APF) less than or equal to 2.5 kN internal force (equivalent to externalforce of 4.5 kN).5.3.Particular Requirements5.3.1.No door shall open during the test.5.3.2.After the impact, it shall be possible without the use of tools to:5.3.2.1 open a sufficient number of doors provided for normal entry and exit of passengers, and ifnecessary tilt the seat-backs or seats to allow evacuation of all occupants;5 3.2.2. release the dummy from the protective system;5.3.2.3. remove the dummy from the vehicle;5.3.3.no interior device or component shall become detached in such a way as noticeably toincrease the risk of injury from sharp projections or jagged edges;5.3.4.ruptures, resulting from permanent deformation are acceptable, provided these do notincrease the risk of injury;5.3.5.if there is continuous leakage of liquid from the fuel-feed installation after the collision, the rateof leakage shall not exceed 30 g/min; if the liquid from the fuel-feed system mixes with liquidsfrom the other systems and the various liquids cannot easily be separated and identified, allthe liquids collected shall be taken into account in evaluating the continuous leakage. TITLE:Lateral Collision Protection ISSUE:1 Regulation No. 95Oct/2003PAGE: 5ORIGINAL :UNITED NATIONS of July 20, 19956.MODIFICATION OF THE VEHICLE TYPE6.1.Any modification affecting the structure, the number and type of seats, the interior trim orfittings, or the position of the vehicle controls or of mechanical parts which might affect theenergy-absorption capacity of the side of the vehicle, shall be brought to the notice of theadministrative department granting approval. The department may then either:6.1.1.consider that the modifications made are unlikely to have an appreciable adverse effect andthat in any case the vehicle still complies with the requirements, or6.1.2.require a further test report from the technical service responsible for conducting the tests;6.1.2.1. Any modification of the vehicle affecting the general form of the structure of the vehicle or anyvariation in the reference mass greater than 8% which in the judgement of the authority wouldhave a marked influence on the results of the test shall require a repetition of the test asdescribed in Annex 4.6.1.2.2. If the technical service, after consultation with the vehicle manufacturer, considers thatmodifications to a vehicle type are insufficient to warrant a complete retest then a partial testmay be used. This would be the case if the reference mass is not more than 8% differentfrom the original vehicle or the number of front seats is unchanged. Variations of seat type orinterior fittings need not automatically entail a full retest. An example of the approach to thisproblem is given in Annex 8.6.2.Confirmation or refusal of approval, specifying the alteration, shall be communicated by theprocedure specified in Paragraph 4.4. above to the Parties to the Agreement which apply thisRegulation.6.3.The competent authority issuing an extension of approval shall assign a series number toeach communication form drawn up for such an extension.7.CONFORMITY OF PRODUCTIONThe conformity of production procedures shall comply with those set out in the Agreement,Appendix 2 (E/ECE/324-E/ECE/TRANS/505/Rev.2), with the following requirements:7.1.Every vehicle approved under this Regulation shall be so manufactured as to conform to thetype approved by meeting the requirements set out in Paragraph 5 above.7.2.The holder of the approval shall ensure that for each type of vehicle at least the testsconcerning the taking of measurements are carried out.7.3.The authority which has granted type approval may at any time verify the conformity controlmethods applied in each production facility. The normal frequency of these verifications shallbe once every two years.TITLE:Lateral Collision Protection ISSUE:1 Regulation No. 95Oct/2003PAGE: 6ORIGINAL :UNITED NATIONS of July 20, 19958.PENALTIES FOR NON-CONFORMITY OF PRODUCTION8.1.The approval granted in respect of a vehicle type, pursuant to this Regulation, may bewithdrawn if the requirement laid down in Paragraph 7.1. above is not complied with, or if thevehicle or vehicles selected have failed to pass the checks prescribed in Paragraph 7.2.above.8.2.If a Contracting Party to the Agreement applying this Regulation withdraws an approval it haspreviously granted, it shall forthwith so notify the other Contracting Parties applying thisRegulation by means of a communication form conforming to the model in Annex 1 to thisRegulation.9.PRODUCTION DEFINITELY DISCONTINUEDIf the holder of the approval completely ceases to manufacturer a type of vehicle approved inaccordance with this Regulation, he shall so inform the authority which granted theapproval. Upon receiving the relevant communication that authority shall inform thereof theother Parties to the 1958 Agreement applying this Regulation by means of a communicationform conforming to the model in Annex 1 to this Regulation.10. TRANSITIONAL PROVISIONS10.1.As from the official date of entry into force of Supplement 1 to the 02 series of amendments,no Contracting Party applying this Regulation shall refuse to grant ECE approval under thisRegulation as amended by Supplement 1 to the 02 series of amendments.10.2.As from 12 months after the entry into force of the 02 series of amendments ContractingParties applying this Regulation shall grant ECE approvals only to those types of vehicleswhich comply with the requirements of this Regulation as amended by the 02 series ofamendments.10.3.As from 60 months after the entry into service of the 02 series of amendments ContractingParties applying this Regulation may refuse first national registration (first entry into service) ofvehicles which do not meet the requirements of this Regulation as amended by the 02 seriesof amendments.10.4.As from 36 months after the entry into force of Supplement 1 to the 02 series of amendmentsContracting Parties applying this Regulation shall grant ECE approvals only to those types ofvehicles which comply with the requirements of this Regulation, as amended by Supplement 1to the 02 series of amendments.10.5.As from 84 months after the entry into force of Supplement 1 to the 02 series of amendmentsContracting Parties applying this Regulation may refuse first national registration (first entryinto service) of vehicles which do not meet the requirements of this Regulation as amendedby Supplement 1 to the 02 series of amendments.S AND ADDRESSES OF TECHNICAL SERVICES RESPONSIBLE FORCONDUCTING APPROVAL TESTS, AND OF ADMINISTRATIVE DEPARTMENTSThe Contracting Parties to the Agreement applying this Regulation shall communicate to theUnited Nations secretariat the names and addresses of the technical services responsible forconducting approval tests, and of the administrative departments which grant approval and towhich forms certifying approval or extension, or refusal or withdrawal of approval, issued inother countries, are to be sent.TITLE:Lateral Collision Protection ISSUE:2 Regulation No. 95Oct/2004PAGE: 7ORIGINAL :UNITED NATIONS of July 20, 1995TITLE:Lateral Collision Protection ISSUE:2Regulation No. 95 Oct/2004PAGE: 8ANNEX 1(maximum format: A4 (210 x 297 mm))COMMUNICATIONissued by: Name of administration: (1) ............................................................................................................................................................concerning: (2) APPROVAL GRANTEDAPPROVAL EXTENDEDAPPROVAL REFUSEDAPPROVAL WITHDRAWNPRODUCTION DEFINITELY DISCONTINUEDof a vehicle type with regard to protection of occupants in the event of a lateral collision pursuant to Regulation No. 95Approval No. .....Extension No............. l.Trade name or mark of the power-driven vehicle ................................................................................ 2.Vehicle type ......................................................................................................................................... 3.Manufacturer's name and address ...................................................................................................... 4.If applicable name and address of manufacturer's representative ..................................................... 5.Vehicle submitted for approval on ....................................................................................................... 6.Side impact dummy utilized ES-1/ES-2. (2)7.Technical service responsible for conducting approval tests .............................................................. 8.Date of test report ................................................................................................................................ 9.Number of test report .......................................................................................................................... 10. Approval granted/refused/extended/withdrawn. (2) (1)Distinguishing number of the country which has granted/extended/refused/withdrawn approval (see approval provisions in the Regulation).(2)Strike out what does not apply.ORIGINAL :UNITED NATIONS of July 20, 199511. Position of approval mark on the vehicle.............................................................................................12. Place.....................................................................................................................................................13. Date......................................................................................................................................................14. Signature..............................................................................................................................................15. The list of documents deposited with the Administrative Service which has granted approval isAnnexed to this communication and may be obtained on request.TITLE:Lateral Collision Protection ISSUE:2 Regulation No. 95Oct/2004PAGE: 9ÝÑËÒÌÎÇ :E.C.E.© InterRegs Ltd 2004ÑÎ×Ù×ÒßÔ :UNITED NATIONS of July 20, 1995Ì×ÌÔÛæLateral Collision Protection ×ÍÍËÛæ1Regulation No. 95 Oct/2003ÐßÙÛæ 10ANNEX 2ARRANGEMENTS OF THE APPROVAL MARKMODEL AøÍ»» п®¿¹®¿°¸ ìòëò ±º ¬¸·-λ¹«´¿¬·±²÷ ̸» ¿¾±ª» ¿°°®±ª¿´ ³¿®µ ¿ºº·¨»¼ ¬± ¿ ª»¸·½´» -¸±©- ¬¸¿¬ ¬¸» ª»¸·½´» ¬§°» ½±²½»®²»¼ ¸¿-ô ©·¬¸ ®»¹¿®¼ ¬± ¬¸» °®±¬»½¬·±² ±º ¬¸» ±½½«°¿²¬- ·² ¬¸» »ª»²¬ ±º ¿ ´¿¬»®¿´ ½±´´·-·±²ô ¾»»² ¿°°®±ª»¼ ·² ¬¸» Ò»¬¸»®´¿²¼- øÛì÷ °«®-«¿²¬ ¬± λ¹«´¿¬·±² Ò±ò çëò ̸» ¿°°®±ª¿´ ²«³¾»® ·²¼·½¿¬»- ¬¸¿¬ ¬¸» ¿°°®±ª¿´ ©¿- ¹®¿²¬»¼ ·² ¿½½±®¼¿²½» ©·¬¸ ¬¸» ®»¯«·®»³»²¬- ±º λ¹«´¿¬·±² Ò±ò çë ¿- ¿³»²¼»¼ ¾§ ¬¸» ðï -»®·»- ±º ¿³»²¼³»²¬-òMODEL BøÍ»» п®¿¹®¿°¸ ìòêò ±º ¬¸·-λ¹«´¿¬·±²÷̸» ¿¾±ª» ¿°°®±ª¿´ ³¿®µ ¿ºº·¨»¼ ¬± ¿ ª»¸·½´» -¸±©- ¬¸¿¬ ¬¸» ª»¸·½´» ¬§°» ½±²½»®²»¼ ¸¿- ¾»»² ¿°°®±ª»¼ ·² ¬¸» Ò»¬¸»®´¿²¼- øÛì÷ °«®-«¿²¬ ¬± λ¹«´¿¬·±²- Ò±-ò çë ¿²¼ îì (1)øײ ¬¸» ½¿-» ±º ¬¸» ´¿¬¬»® λ¹«´¿¬·±²ô ¬¸» ¿¼¼·¬·±²¿´ -§³¾±´ ©¸·½¸ º±´´±©- ¬¸» λ¹«´¿¬·±² ²«³¾»® ·²¼·½¿¬»- ¬¸¿¬ ¬¸» ½±®®»½¬»¼ ¿¾-±®°¬·±² ½±ó»ºº·½·»²¬ ·- ïòíð ³óï÷ò ̸» º·®-¬ ¬©± ¿°°®±ª¿´ ²«³¾»®- ·²¼·½¿¬» ¬¸¿¬ ¿¬ ¬¸» ¼¿¬» ©¸»² ¬¸» ®»-°»½¬·ª» ¿°°®±ª¿´- ©»®» ¹®¿²¬»¼ô λ¹«´¿¬·±² çë ·²½±®°±®¿¬»¼ ¬¸» ðï -»®·»- ±º ¿³»²¼³»²¬- ¿²¼ λ¹«´¿¬·±² Ò±ò îì ·²½±®°±®¿¬»¼ ¬¸» ðí -»®·»- ±º ¿³»²¼³»²¬-ò øï÷̸» ´¿¬¬»® ²«³¾»® ·- ¹·ª»² ±²´§ ¿- ¿² »¨¿³°´»ò。

各国轮胎出口相关认证根据伊拉克法令第54号第3章第8条(Law No.54 of 1979 Article 3/Clause 8),伊拉克中央标准质量控制组织(简称COSQC)将于2011年5月1日实施进口前检验、测试及出证方案,旨在限制不符合标准,假冒、伪劣产品进口到伊拉克,及保护其国内消费者、生产商、环境和公共安全免受劣质产品的危害。

伊拉克CoC属于强制认证,由出口商申请,用来给进口商在目的港清关用。

凡是伊拉克管制目录内的所有产品都必须办理,属于一次性的清关文件。

1.伊拉克CoC证书和伊拉克VoC证书是指同一种证书,都是指产品符合性证书,用来给进口商目的港清关。

CoC英文全称:Certificate of ConformityVoC英文全称:Verification of Conformity2.伊拉克COC证书上同时有英语和阿拉伯语双语,该证书用来提供给进口商用于目的港清关。

3.CoC/VoC需要在发货前申请,一旦货物离港是补办不了的,货物到达之后,伊拉克需要在目的港核查。

4.伊拉克在目的港需要重新核查检验,包括以下内容:1)检查CoC证书真伪2)检查到港货物和提交的相关文件是否一致3)检查货物状况4)对被伊拉克海关要求开柜的货物实施包装检查等办理伊拉克CoC需要准备的资料如下:1.装箱单2.形式发票3.产品的测试报告:已经有测试报告的不用重复测试,个别产品需要现场抽样测试的除外4.填好CoC申请表: 空白申请表由办理机构提供5.信用证支付的还需要提供L/C 复印件以上资料审核通过将安排验货,验货通过将签发CoC证书。

注:伊拉克的CoC和叙利亚CoC办理流程一样,不同的是伊拉克需要在目的港核查,而叙利亚需要进口商在进口国申请VOR核价。

叙利亚位于亚洲大陆西部,地中海东岸。

北与土耳其接壤,东同伊拉克交界,南与约旦毗连,西南与黎巴嫩和巴勒斯坦为邻,西与塞浦路斯隔地中海相望。

阿拉伯叙利亚共和国标准计量组织SASMO为保证公民卫生安全和环境卫生,杜绝废物倾销和打击非法或危险货物,根据政府第No. 954/1 和 No. 4113/1 号法案,现已实施产品符合性认证计划CoC 和原产地及价格证明VOR。