Hydroxylation of phenol with hydrogen peroxide catalyzed by Fe- and AIFe-Bentonite

- 格式:pdf

- 大小:279.76 KB

- 文档页数:5

间苯二酚生产工艺流程英文回答:The production process of catechol, also known as pyrocatechol or 1,2-dihydroxybenzene, involves several steps. Catechol is an important compound used in the manufacturing of dyes, pharmaceuticals, and antioxidants.The first step in the production process is the hydroxylation of phenol. Phenol is reacted with hydrogen peroxide in the presence of a catalyst, typically a transition metal complex such as vanadium or manganese. This reaction converts phenol into catechol.After the hydroxylation step, the catechol is purified through a series of separation and purification processes. This may include distillation, crystallization, and filtration. The goal is to remove impurities and obtain a high-purity catechol product.Once the catechol is purified, it can be further processed into various derivatives or used directly in applications. For example, catechol can be converted into resorcinol through a diazotization reaction. Resorcinol is used in the production of rubber, adhesives, and flame retardants.Another example of catechol derivative is pyrogallol, which is produced by the oxidation of catechol. Pyrogallol has applications in photography, hair dyes, and as a reducing agent in chemical reactions.Overall, the production process of catechol involves hydroxylation of phenol followed by purification and potential conversion into derivatives. The specific details and conditions of the process may vary depending on the desired purity and applications of the final product.中文回答:间苯二酚的生产工艺流程包括几个步骤。

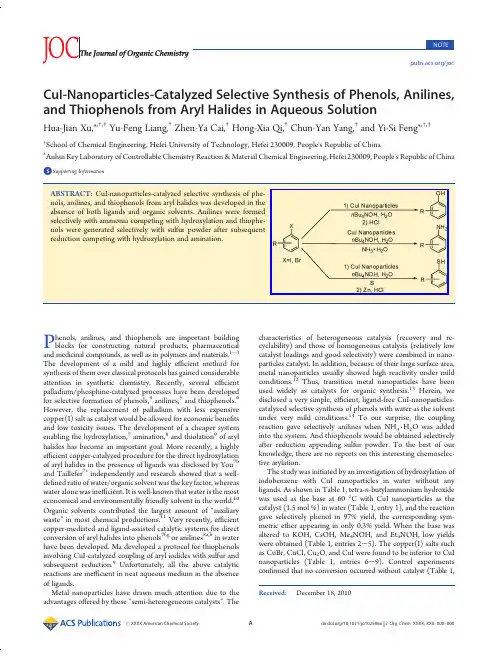

NOTE/joc CuI-Nanoparticles-Catalyzed Selective Synthesis of Phenols,Anilines, and Thiophenols from Aryl Halides in Aqueous SolutionHua-Jian Xu,*,†,‡Yu-Feng Liang,†Zhen-Ya Cai,†Hong-Xia Qi,†Chun-Yan Yang,†and Yi-Si Feng*,†,‡†School of Chemical Engineering,Hefei University of Technology,Hefei230009,People's Republic of China‡Anhui Key Laboratory of Controllable Chemistry Reaction&Material Chemical Engineering,Hefei230009,People's Republic of China b Supporting InformationP henols,anilines,and thiophenols are important building blocks for constructing natural products,pharmaceutical and medicinal compounds,as well as in polymers and materials.1-3 The development of a mild and highly efficient method for synthesis of them over classical protocols has gained considerable attention in synthetic chemistry.Recently,several efficient palladium/phosphine-catalyzed processes have been developed for selective formation of phenols,4anilines,5and thiophenols.6 However,the replacement of palladium with less expensive copper(I)salt as catalyst would be allowed for economic benefits and low toxicity issues.The development of a cheaper system enabling the hydroxylation,7amination,8and thiolation9of aryl halides has become an important goal.More recently,a highly efficient copper-catalyzed procedure for the direct hydroxylation of aryl halides in the presence of ligands was disclosed by You7b and Taillefer7c independently and research showed that a well-defined ratio of water/organic solvent was the key factor,whereas water alone was inefficient.It is well-known that water is the most economical and environmentally friendly solvent in the world.10 Organic solvents contributed the largest amount of“auxiliary waste”in most chemical productions.11Very recently,efficient copper-mediated and ligand-assisted catalytic systems for direct conversion of aryl halides into phenols7f,g or anilines8a,b in water have been developed.Ma developed a protocol for thiophenols involving CuI-catalyzed coupling of aryl iodides with sulfur and subsequent reduction.9Unfortunately,all the above catalytic reactions are inefficient in neat aqueous medium in the absence of ligands.Metal nanoparticles have drawn much attention due to the advantages offered by these“semi-heterogeneous catalysts”.The characteristics of heterogeneous catalysis(recovery and re-cyclability)and those of homogeneous catalysis(relatively low catalyst loadings and good selectivity)were combined in nano-particles catalyst.In addition,because of their large surface area, metal nanoparticles usually showed high reactivity under mild conditions.12Thus,transition metal nanoparticles have been used widely as catalysts for organic synthesis.13Herein,we disclosed a very simple,efficient,ligand-free CuI-nanoparticles-catalyzed selective synthesis of phenols with water as the solvent under very mild conditions.14To our surprise,the coupling reaction gave selectively anilines when NH33H2O was added into the system.And thiophenols would be obtained selectively after reduction appending sulfur powder.To the best of our knowledge,there are no reports on this interesting chemoselec-tive arylation.The study was initiated by an investigation of hydroxylation of iodobenzene with CuI nanoparticles in water without any ligands.As shown in Table1,tetra-n-butylammonium hydroxide was used as the base at60°C with CuI nanoparticles as the catalyst(1.5mol%)in water(Table1,entry1),and the reaction gave selectively phenol in97%yield,the corresponding sym-metric ether appearing in only0.3%yield.When the base was altered to KOH,CsOH,Me4NOH,and Et4NOH,low yields were obtained(Table1,entries2-5).The copper(I)salts such as CuBr,CuCl,Cu2O,and CuI were found to be inferior to CuI nanoparticles(Table1,entries6-9).Control experiments confirmed that no conversion occurred without catalyst(Table1,Received:December18,2010entry 10).Low yields were obtained when the reaction time,temperature,or amount of CuI nanoparticles were reduced (Table 1,entries 11-14).The optimal conditions of 1.5mol %of CuI nanoparticles,3.0equiv of n Bu 4NOH in water at 60°C were used for further investigations.With this e fficient system in hand we next extended the scope of the substrate to various aryl iodide derivatives (Table 2).We found that the reaction was applicable to a broad range of derivatives and was not a ffected strongly by electron-donating or electron-withdrawing groups.But,the reactions seemed to be sensitive to the steric hindrance on the substrate.For example,1-chloro-2-iodobenzene was hydroxylated under optimized con-ditions,only 47%isolated yield was obtained.Fortunately,the reaction was accelerated signi ficantly at elevated temperature and longer reaction time.Almost quantitative conversions were obtained from 4-iodobenzoic acid and 2-iodobenzoic acid to the corresponding products.Although aryl bromides are less reactive than aryl iodides,the greater interest for industrial applications fixed our attention.In spite of the slightly higher temperature that was needed,a series of phenols were generated from activated aryl bromides (Table 3).We only obtained a few phenols whose yields are very close to the catalyst loading (Table 1,entries 16-20)with bromobenzene as substrate.The yield decreased with reactiontemperature elevating,probably because n Bu 4NOH decom-posed at higher temperature (Table 1,entry 19).However,we were able to obtain phenol in good yield (78%)when the amount of catalyst was increased to 110mol %(Table 1,entry 20).This method was extended successfully to aryl bromides with elec-tron-donating substituents such as p -or o -methyl and p -,or o -methoxy.1-and 2-bromonaphthalenes were also converted selec-tively into the corresponding naphthols under these conditions.Inspired by metal-catalyzed chemoselective N -or O -arylations,15we wondered whether N -arylation would take place when aqueous NH 3solution was added into the system with existing N,O nucleophilic competition.To our delight,the N -arylation readily occurred even at room temperature,and the product of O -arylation was detected in small quantity (<3%).Next,the scope of aryl iodides was investigated for the N -arylation reaction with aqueous ammonia at room temperature inTable 1.Optimization of Hydroxylation of Aryl Halides Catalyzed by CuI Nanoparticles in Water aentry X [Cu](mol %)base T /°C yield/%b 1I CuI(np(1.5))n Bu 4NOH 60972I CuI(np(1.5))KOH 60573I CuI(np(1.5))CsOH 60634I CuI(np(1.5))Me 4NOH 60795I CuI(np(1.5))Et 4NOH 60876I CuBr(10)n Bu 4NOH 60197I CuCl(10)n Bu 4NOH 60168I Cu 2O(10)n Bu 4NOH 60159I CuI(10)n Bu 4NOH 603310I n Bu 4NOH 60trace 11I CuI(np(1.5))n Bu 4NOH 508012I CuI(np(1.0))n Bu 4NOH 607113I CuI(np(1.0))n Bu 4NOH 808314c I CuI(np(1.5))n Bu 4NOH 607515d Br CuI(np(10))n Bu 4NOH 60trace 16d Br CuI(np(10))n Bu 4NOH 801117d Br CuI(np(50))n Bu 4NOH 804218d ,e Br CuI(np(50))n Bu 4NOH 804519d Br CuI(np(50))n Bu 4NOH 902720dBr CuI(np(110))n Bu 4NOH 807821d ,eClCuI(np(110))n Bu 4NOH8012aReaction conditions:halogenated benzene (1.0mmol),base (3.0equiv),H 2O (2.0mL)under N 2for 24h.b Determined by GC.cReaction time is 15h.d Reaction time is 48h.e With 5.0equiv of n Bu 4NOH.np =nanoparticles.Table 2.Hydroxylation ofAryl Iodides Catalyzed by CuINanoparticles in Water aaCuI nanoparticles (1.5mol %),Ar -I (1.0mmol),40%n Bu 4NOH aq (2.0mL/3.0equiv)at 60°C under N 2for 24h;isolated yield.b At 80°C for 36h.Table 3.Hydroxylation of Aryl Bromides Catalyzed by CuI Nanoparticles in Water aaCuI nanoparticles (1.5mol %),Ar -Br (1.0mmol),40%n Bu 4NOH aq (2.0mL/3.0equiv)at 80°C under N 2for 48h;isolated yield.b With 110mol %of CuI nanoparticles,n Bu 4NOH 40%aq (3.3mL/5.0equiv).water (Table 4).In general,all the aryl iodides gave the correspond-ing anilines with good to excellent yields.Ortho substituents had no obvious e ffect on yields of products to some extent,and a variety of functional groups could be tolerated in the reaction.Although little p -nitroaniline was detected when p -nitrobro-mobenzene was reacted with aqueous ammonia at room tem-perature,73%yield was obtained when the reaction was carried out at 80°C for 48h.Futhermore,p -nitroaniline was obtained with 87%yield when 3.0mol %of CuI nanoparticles and 10.0equiv of NH 3were applied.As shown in Table 5,all the examined aryl and heteroaryl bromides coupled with aqueous ammonia to a fford the corresponding anilines with good to excellent yields.On the other hand,aryl bromides bearing electron-donating substituents were less e ffective.In addition,the reactivity of aryl chlorides decreased dramatically in the present system.16We were pleased to observe that the coupling reaction produces selectively thiophenols after subsequent reduction when sulfur powder was added instead of aqueous ammonia (Table 6).17Aryl thiols were obtained with both inactivated and activated aryl iodide derivatives.No matter if the aryl iodides were electron-rich,electron-poor,or sterically hindered,all of them a fforded good to excellent yields.Moreover,aryl thiols of high yield were obtained with aryl bromides bearing electron-withdrawing groups.Low conversions occurred for inactivated aryl bromides.Since chemoselective N -arylation and S -arylation were accom-plished as opposed to O -arylation,a competitive experiment was performed to check out which arylation reaction would occur when the three substrates existed at the same time (Scheme 1).Under the standard conditions (see SI),iodobenzene was reacted in the presence of both NH 33H 2O and S,thiophenolTable 4.CuI-Nanoparticles-Catalyzed Amination of ArylIodides withNH 33H 2O at Room Temperature in Water aaCuI nanoparticles (1.5mol %),Ar -I (1.0mmol),40%n Bu 4NOH aq (1.3mL/2.0equiv),commercial 28%aqueous NH 3(5.0equiv)at room temperature (25°C)under N 2for 24h;isolated yield.b Reaction time is 48h.c At 45°C.d 4,40-Diiodobiphenyl as substrate,commercial 28%aqueous NH 3(10.0equiv).Table 5.CuI-Nanoparticles-Catalyzed Amination of Aryl Bromides aaCuI nanoparticles (3.0mol %),Ar -Br (1.0mmol),40%n Bu 4NOH aq (1.3mL/2.0equiv),commercial 28%aqueous NH 3(10.0equiv)at 80°C under N 2for 48h;isolated yield.Table 6.CuI-Nanoparticles-Catalyzed Synthesis of Thiophenols from Aryl Halides in Water aaCuI nanoparticles (1.5mol %),Ar -X (1.0mmol),40%n Bu 4NOH aq (1.3mL/2.0equiv),sulfur power (3.0equiv)at 40°C under N 2for 24h;isolated yield.b At room temperature (25°C).c With 3.0mol %CuI nanoparticles at 80°C for 48h.Scheme 1.Experiment of Intermolecular CompetitionScheme 2.One-Pot Synthesis of 4-Aminophenol from 1-Bromo-4-iodobenzenewas formed selectively after reductive step,proving the order ofS >N >O.Aminophenols constitute a common structural motif in var-ious potentially useful therapeutic agents and drug candidates.18The similarity in conditions between N -arylation and O -arylation suggested that the present protocol could be used as a tandem reaction,and this was indeed the case (Scheme 2).The synthesis of 4-aminophenol was achieved by hydroxylation of the C -I bond of 1-bromo-4-iodobenzene,followed by amination of the C -Br bond on increasing the temperature and reaction time.It was a heterogeneous process and the catalyst was recyclable with slight loss of activity (Table 7).19After completion of amination of iodobenzene,the catalyst was recovered from the reaction mixture by centrifugation and reused for the fresh reaction and only a slight decrease in catalytic activity was observed.In addition,in the TEM analysis of CuI nanoparticles,interestingly,the shape and size of the nanoparticles remainedunchanged before and after the reaction (Figure 1a -c).Likewise,the powder X-ray di ffraction analysis exhibited identical peaks for both the fresh and recovered CuI nanoparticles (Figure 1d,e).In conclusion,we have demonstrated that selective O -arylation,20N -arylation,and S -arylation could be achieved in water without assisted ligand at relatively mild conditions (no higher than 80°C).4a A variety of aryl iodides and bromides could be coupled with available n Bu 4NOH,NH 33H 2O,and S in this simple and e fficient protocol to give the corresponding products in high yields.The competition experiment showed that S had the best reactivity.Furthermore,the catalyst could be reused for three cycles with slight loss of its activity.’EXPERIMENTAL SECTIONGeneral Procedure for Hydroxylation of Aryl Iodides.An oven-dried Schlenk tube equipped with a magnetic stirring bar was charged with CuI nanoparticles (1.5mol %,2.9mg),the aryl iodides if a solid (1mmol).The tube was evacuated and backfilled with nitrogen.Under a counter flow of nitrogen,aryl iodides if a liquid (1mmol,1equiv)and degassed 40%tetra-n -butylammonium hydroxides water solution (2.0mL)were added.The tube was sealed and the mixture was allowed to stir at 60°C for 24h.The reaction mixture was then allowed to cool to ambient temperature,then 10mL of ethyl acetate and 1mL of HCl (37%)were added.For the general workup and detailed experi-ments,please see the Supporting Information.’ASSOCIATED CONTENTbSupporting Information.Preparation of the catalyst,general synthetic procedures,and characterization of products.This material is available free of charge via the Internet at .’AUTHOR INFORMATIONCorresponding Author*E-mail:hjxu@ and ysfeng@.’ACKNOWLEDGMENTWe gratefully acknowledge financial support from the Na-tional Natural Science Foundation of China (Nos.20802015,21072040,21071040).We thank Yong-Qiang Zhao in this research group for reproducing some results in Tables 2-6.’REFERENCES(1)For phenols:(a)Tyman,J.H.P.Synthetic and Natural Phenols ;Elsevier:New York,1996.(b)Rappoport,Z.The Chemistry of Phenols ;Wiley-VCH:Weinheim,Germany,2003.(2)For anilines:(a)Weissermel,K.;Arpe,H.J.Industry Organic Chemistry ;Wiley-VCH:Weinheim,Germany,1997;(b)Lawrence,S.A.Amines:Synthesis Properties and Application ;Cambridge University Press:Cambridge,UK,2004.(3)For thiophenols:(a)Thuillier,A.;Metzner,P.Sulfur Reagents in Organic Synthesis ;Academic Press:New York,1994.(b)Anastas,P.;Warner,J.C.Green Chemistry:Theory and Practice ;Oxford University Press:Oxford,UK,1998.(4)(a)Willis,M.C.Angew.Chem.,Int.Ed.2007,46,3402.(b)Anderson,K.W.;Ikawa,T.;Tundel,R.E.;Buchwald,S.L.J.Am.Chem.Soc.2006,128,10694.(c)Sergeev,A.G.;Schulz,T.;Torborg,C.;Spannenberg,A.;Neumann,H.;Beller,M.Angew.Chem.,Int.Ed.2009,48,7595.(d)Schulz,T.;Torborg,C.;Sch €a ffner,B.;Huang,J.;Zapf,A.;Kadyrov,R.;B €o rner,A.;Beller,M.Angew.Chem.,Int.Ed.2009,48,918.Figure 1.(a)TEM image of fresh CuI nanoparticles;(b)TEM image of CuI nanoparticles after the third catalytic cycle;(c)TEM image of fresh CuI nanoparticles at 50nm;(d)XRD pattern of fresh CuI nanoparticles;(e)XRD pattern of CuI nanoparticles after the third catalytic cycle.Table 7.Recyclability of CuI Nanoparticlesrun catalyst recovery (%)product yield (%)c1a 95952b 89873b8280aCuI nanoparticles (1.5mol %),iodobenzene (1.0mmol),40%n Bu 4NOH aq (1.3mL/2.0equiv),commercial 28%aqueous NH 3(5.0equiv)at 25°C under N 2for 24h.b The recovered catalyst was used under identical reaction conditions to thoseforthe first run.cDetermined by GC.(e)Gallon,B.J.;Kojima,R.W.;Kaner,R.B.;Diaconescu,P.L.Angew. Chem.,Int.Ed.2007,46,7251.(f)Chen,G.S.;Chan,A.S.C.;Kwong, F.Y.Tetrahedron Lett.2007,48,473.(g)Dumrath,A.;Wu,X.F.; Neumann,H.;Spannenberg,A.;Jackstell,R.;Beller,M.Angew.Chem., Int.Ed.2010,49,8988.(5)(a)Shen,Q.;Hartwig,J.F.J.Am.Chem.Soc.2006,128,10028.(b)Surry,D.S.;Buchwald,S.L.J.Am.Chem.Soc.2007,129,10354.(c) Schulz,T.;Torborg,C.;Enthaler,S.;Sch€affner,B.;Dumrath,A.; Spannenberg,A.;Neumann,H.;B€o rner,A.;Beller,M.Chem.—Eur.J. 2009,15,4528.(d)Vo,G.D.;Hartwig,J.F.J.Am.Chem.Soc.2009, 131,11049.(e)Lundgren,R.J.;Peters,B.D.;Alsabeh,P.G.;Stradiotto, M.Angew.Chem.,Int.Ed.2010,49,4071.(f)Lee,D.Y.;Hartwig,J.F. Org.Lett.2005,6,1169.(6)Yi,J.;Fu,Y.;Xiao,B.;Cui,W.C.;Guo,Q.X.Tetrahedron Lett. 2011,52,205.(7)(a)Kormos, C.M.;Leadbeater,N. E.Tetrahedron2006, 62,4728.(b)Zhao,D.B.;Wu,N.J.;Zhang,S.;Xi,P.H.;Su,X.Y.; Lan,J.B.;You,J.S.Angew.Chem.,Int.Ed.2009,48,8729.(c)Tlili,A.; Xia,N.;Monnier,F.;Taillefer,M.Angew.Chem.,Int.Ed.2009,48,8725.(d)Ren,Y.L.;Cheng,L.;Tian,X.Z.;Zhao,S.;Wang,J.J.;Hou,C.D. Tetrahedron Lett.2010,51,43.(e)Maurer,S.;Liu,W.;Zhang,X.;Jiang, Y.;Ma,D.Synlett2010,976.(f)Yang,D.;Fu,H.Chem.—Eur.J.2010, 16,2366.(g)Jing,L.;Wei,J.;Zhou,L.;Huang,Z.;Li,Z.;Zhou,X.Chem. Commun.2010,4767.(8)(a)Wu,Z.;Jiang,Z.;Wu,D.;Xiang,H.;Zhou,. Chem.2010,1854.(b)Meng,F.;Zhu,X.;Li,Y.;Xie,J.;Wang,B.;Yao,J.; Wan,.Chem.2010,6149.(c)Xu,H.;Wolf,C.Chem. Commun.2009,3035.(d)Jiang,L.;Lu,X.;Zhang,H.;Jiang,Y.;Ma,D. .Chem.2009,74,4542.(e)Wang,D.;Cai,Q.;Ding,K.Adv.Synth. Catal.2009,351,1722.(f)Guo,Z.;Guo,J.;Song,Y.;Wang,L.;Zou,G. anomet.Chem.2009,23,150.(g)Xia,N.;Taillefer,M.Angew. Chem.,Int.Ed.2009,48,337.(h)Kim,J.;Chang,mun. 2008,3052.(i)Elmkaddem,M.K.;Fischmeister,C.;Thomas,C.M.; Renaud,mun.2010,925.(j)Ntaganda,R.;Dhudshia,B.; Macdonald,C.L.B.;Thadani,mun.2008,6200.(k) Anderson,C.A.;Taylor,P.G.;Zeller,M.A.;Zimmerman,. Chem.2010,75,4848.(l)Wu,X.F.;Darcel,.Chem. 2009,4753.(m)Gao,X.;Fu,H.;Qiao,R.;Jiang,Y.;Zhao,. Chem.2008,73,6864.(n)Tao,C.Z.;Li,J.;Fu,Y.;Liu,L.;Guo,Q.X. Tetrahedron Lett.2008,49,70.(o)Markiewicz,J.T.;Wiest,O.;Helquist, .Chem.2010,75,4887.(p)Yang,C.T.;Fu,Y.;Huang,Y.B.;Yi, J.;Guo,Q.X.;Liu,L.Angew.Chem.,Int.Ed.2009,48,7398.(q)Tao, C.Z.;Liu,W.W.;Lv,A.F.;Sun,M.M.;Tian,Y.;Wang,Q.;Zhao,J. Synlett2010,1355.(9)Jiang,Y.;Qin,Y.;Xie,S.;Zhang,X.;Dong,J.;Ma,.Lett. 2009,11,5250.(10)(a)Grieco,anic Synthesis in Water;Blackie A&P: London,UK,1998.(b)Li,C.J.Chem.Rev.2005,105,3095.(c)Blackmond, D.G.;Armstrong,A.;Coomber,V.;Wells,A.Angew.Chem.,Int.Ed.2007, 46,3798.(d)Minakata,S.;Komatsu,M.Chem.Rev.2009,109,711.(11)(a)Sheldon,R.A.Green Chem.2005,7,267.(b)Li,C.J.;Trost,B.M.Proc.Natl.Acad.Sci.U.S.A.2008,105,13197.(12)Astruc,D.;Lu,F.;Aranzaes,J.R.Angew.Chem.,Int.Ed.2005, 44,7852.(13)(a)Thathagar,M.B.;Beckers,J.;Rothenberg,G.J.Am.Chem. Soc.2002,124,11858.(b)Thathagar,M.B.;Beckers,J.;Rothenberg,G. Green Chem.2004,6,215.(c)Rout,L.;Sen,T.K.;Punniyamurthy,T. Angew.Chem.,Int.Ed.2007,46,5583.(d)Rout,L.;Jammi,S.; Punniyamurthy,.Lett.2007,9,3397.(e)Jammi,S.;Sakthivel, S.;Rout,L.;Mukherjee,T.;Mondal,S.;Mitra,R.;Saha,P.; Punniyamurthy,.Chem.2009,74,1971.(f)Sreedhar,B.; Arundhathi,R.;Reddy,P.L.;Kantam,.Chem.2009,74,7951.(14)The preparation method of CuI nanoparticles was inspired by the work of Qian’s group on preparation of CuI nanorods:Li,X.L.; Zhu,X.Y.;Duan,T.L.;Qian,Y.T.Solid State Commun.2006,138, 526.(15)For selected examples of chemoselective N-or O-arylation reactions:(a)Shafir,A.;Lichtor,P.A.;Buchwald,S.L.J.Am.Chem.Soc.2007,129,3490.(b)Job,G.E.;Buchwald,.Lett.2002,4,3703.(c)Maiti,D.;Buchwald,S.L.J.Am.Chem.Soc.2009,131,17423.(16)For example,the reaction of p-nitrochlorobenzene with aque-ous NH3solution afforded17%conversion and11%yield under the present system for72h.No further attempts to optimize this reaction have been made.For detailed explanation of the reactivity of aryl chlorides,see:Mukhopadhyay,S.;Rothenberg,G.;Sasson,Y.Adv. Synth.Catal.2001,343,274.(17)The reaction proceeded smoothly at40°C to give aryl disulfides exclusively,which underwent reductive cleavage when treated with zinc dust and diluted hydrochloric acid to yield the thiophenols.(18)(a)Zavitz,K.Patent PCT Int.Appl.WO2004091522,2004.(b)Matsuki,Y.;Dan,J.;Fukuhara,K.;Ito,T.;Nambara,T.Chem.Pharm. Bull.1988,36,1431.(19)Leaching study proved that it is intrinsically heterogeneous,see the Supporting Information.For leaching studies of metal nanoparticles,see: (a)Gaikwad,A.V.;Holuigue,A.;Thathagar,M.B.;ten Elshof,J.E.; Rothenberg,G.Chem.—Eur.J.2007,13,6908.(b)Pach o n,L.D.;Rothenberg,anomet.Chem.2008,22,288.(20)Tentative proposals on the mechanism of hydroxylation about ion exchange werefigured out,please see Scheme S1-S3in the Supporting Information.。

羟基自由基氧化能力双氧水英文回答:Hydroxyl free radical is a highly reactive and unstable molecule that contains a hydroxyl group (OH). It is formed in the body as a byproduct of various metabolic processes and can also be generated in the environment through the action of ultraviolet radiation on water vapor. The hydroxyl free radical is known for its strong oxidizing ability, which means it can readily react with and damage other molecules in the body, such as DNA, proteins, and lipids.The oxidation ability of the hydroxyl free radical is due to its unpaired electron, which makes it highlyreactive and capable of initiating chain reactions of oxidation. This can lead to cellular damage and contribute to the development of various diseases, including cancer, cardiovascular diseases, and neurodegenerative disorders.One common example of the damaging effects of the hydroxyl free radical is its reaction with double bonds in unsaturated fatty acids, leading to the formation of lipid peroxides. These peroxides can further react with other molecules, leading to a cascade of oxidative damage in the body.Hydrogen peroxide, on the other hand, is a well-known oxidizing agent that can also generate hydroxyl free radicals through a process known as the Fenton reaction. This reaction involves the interaction of hydrogen peroxide with transition metal ions, such as iron or copper, to produce hydroxyl free radicals. This further underscores the oxidative potential of hydrogen peroxide and itsability to induce cellular damage.Overall, the hydroxyl free radical and its associated oxidative ability play a significant role in various physiological and pathological processes in the body. Understanding the mechanisms of hydroxyl free radical generation and its effects on cellular components iscrucial for developing strategies to mitigate oxidativedamage and its associated health implications.中文回答:羟基自由基是一种高度活泼和不稳定的分子,含有一个羟基(OH)。

不同酸浓度MCM-41分子筛的合成与表征摘要:用C16TMABr表面活性剂作为模板,采用TEOS硅源水解法合成MCM-41介孔分子筛。

分别对在碱性环境、以及高、中、低、三种不同酸浓度的条件下合成的MCM-41分子筛使用TG/DTA、红外光谱、低温N2吸附等测试手段对其进行表征。

结果表明:四种条件下均能合成MCM-41 分子筛,机离子浓度、反应温度和煅烧等对MCM-41分子筛的介孔孔径有重要影响,而pH 值则影响MCM-41的热稳定性。

关键字: MCM-41;分子筛;合成;低温N2吸附;红外光谱无机多孔材料因具有较大的比表面积和吸附容量,而被广泛应用与催化和吸附载体中。

按孔径大小来分,多孔材料可分为微孔、介孔和大孔材料。

近年来出现了一类新型的有序介孔氧化硅材料M41S。

其显著的特点是具有规则排列、大小均匀的纳米孔道结构及高的比表面积和大的吸附容量,在催化、吸附与分离、纳米材料组装及生物化学等众多领域有广泛的应用前景。

而在新型的介孔氧化硅中,MCM-41分子筛是最具代表性的一种。

MCM-41 是具有六方规则排列的一维孔道结构,孔径大小均匀,在一定范围内可连续调节,具有高的热稳定性。

它是利用分子自组织的方法得到的介孔固体物质【1-6】,其有序排列的较大孔径(1.5—10nm),将沸石分子筛的规则孔径以微孔范围拓展到介孔领域。

这对于在沸石分子筛难以完成的大分子催化、吸附与分离等过程,无疑展示了广阔的前景,在小尺寸效应、表面效应及量子效应等方面也提供了物质基础。

本文通过以十六烷基三甲基溴化氨(C16TMABr)为表面活性剂,在三种不同酸浓度下合成MCM-41分子筛,并研究了对MCM-41分子筛结构性能的影响。

一、试验方法1、MCM-41 分子筛的合成酸性合成:将HCl加入持续搅拌的C16TMBr的水溶液中,搅拌15min,然后将TEOS逐滴滴入不断搅拌的混合溶液中。

滴定完成后再继续搅拌2h,置于装有聚四氟乙烯内衬的反应釜中110℃水热处理48h。

摘要2,5-二甲基苯酚是非常重要的有机合成中间体。

用于合成吉非罗齐(Gemfibrozil) 、树脂、染料、医药、香料、消毒剂等。

传统的合成方法使用大量酸碱,对设备腐蚀严重,对环境污染大。

本课题研究在合适的催化剂催化下,以H2O2为氧化剂,使对二甲苯直接羟基化生成2,5-二甲基苯酚。

课题进行了如下研究:1、研究了铜酞菁作为催化剂的较佳条件。

较佳条件为:1.2g铜酞菁,6mL 对二甲苯和15mL H2O2水溶液加入到40mL乙腈中,反应温度65℃,反应时间2h,对二甲苯转化率为57.39%,2,5-二甲基苯酚选择性和收率分别为44.20%和25.37%。

反应操作简单,铜酞菁为工业有机颜料,价格便宜,而且便于与体系分离,可以重复利用。

该反应遵从自由基反应机理。

2、研究了钛硅分子筛TS-1作为催化剂时的较佳条件。

较佳条件为5.0g TS-1,10mL对二甲苯和4mL H2O2溶液加入到40 mL乙腈中,反应温度75℃,反应时间6h,对二甲苯转化率为61.68%,收率为43.66%,选择性为70.78%。

添加冰醋酸0.5mL对反应有利,2,5-二甲基苯酚的收率提高至47.15%。

反应操作简单,TS-1为非均相催化剂,便于与体系分离,可以重复利用。

该反应遵从亲电反应机理。

3、研究了TS-1的改性方法,以提高催化活性:(1)硫酸改性后,使得催化活性增强,转化率达到73.61%,收率为57.34%,选择性高达77.89%。

而磷酸和醋酸改性都会使得催化活性下降。

酸改性后TS-1的形貌特征并没有明显变化,但会改变骨架钛的含量和Ti-OH含量。

(2)氨水和四丙基氢氧化铵(TPAOH)改性会使分子筛孔道被刻蚀,介孔增多,接触面积增大,提高催化活性,氨水改性后的催化结果最好,转化率76.99%,收率57.07%,选择性74.13%。

碱改性后TS-1的形貌特征也没有明显变化,但碱改性会瓦解掉部分骨架结构,并且产生锐钛矿TiO2晶相。

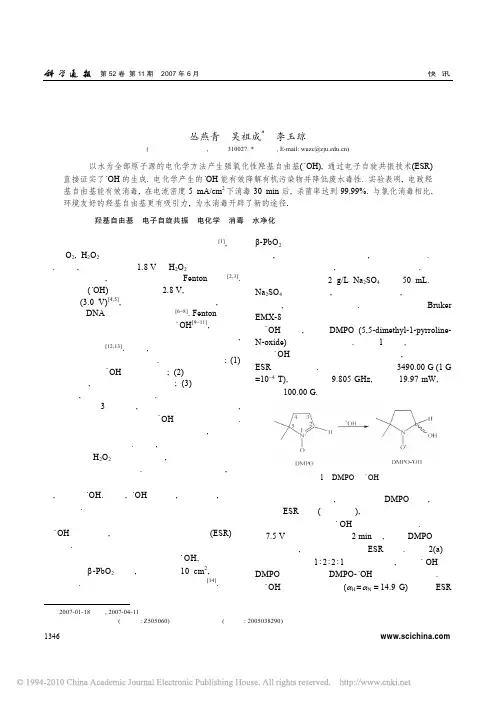

第52卷 第11期 2007年6月快 讯1346 水为全原子源的电致羟基自由基及其应用丛燕青 吴祖成* 李玉琼(浙江大学环境工程系, 杭州 310027. * 联系人, E-mail: wuzc@)摘要 以水为全部原子源的电化学方法产生强氧化性羟基自由基(·OH), 通过电子自旋共振技术(ESR)直接证实了·OH 的生成. 电化学产生的·OH 能有效降解有机污染物并降低废水毒性. 实验表明, 电致羟基自由基能有效消毒, 在电流密度5 mA/cm 2下消毒30 min 后, 杀菌率达到99.99%. 与氯化消毒相比, 环境友好的羟基自由基更有吸引力, 为水消毒开辟了新的途径.关键词 羟基自由基 电子自旋共振 电化学 消毒 水净化2007-01-18收稿, 2007-04-11接受浙江省自然科学基金(批准号: Z505060)和中国博士后基金(批准号: 2005038290)资助项目环境友好的水处理技术是当前的研究热点[1], 尤其是O 2, H 2O 2等无二次污染的氧化剂引起了广泛关注. 但是, 氧化势能只有1.8 V 的H 2O 2不足以降解持久性有机污染物, 需与亚铁离子形成Fenton 试剂[2,3]. 羟基自由基(·OH)的氧化势能为2.8 V, 仅次于氧化性最强的氟(3.0 V)[4,5], 可引起各种氧化性破坏, 如污染物降解、DNA 损伤、细胞失活等[6~8]. Fenton 反应、离子辐射和光催化过程已证实存在·OH [9~11], 这些方法通常需外加过渡金属复合物或乙腈等有毒溶剂, 易造成二次污染[12,13]. 因此, 研究更加清洁安全的强氧化性自由基技术是有必要的. 本研究构想如下: (1)产生强氧化性的·OH 用于水处理; (2) 使用清洁的反应剂和溶剂, 水则是最理想的物质; (3) 尽量不添加辅助试剂, 避免引入有毒物质.基于上述3点考虑, 我们以水作为全部原子源, 利用电化学方法产生高活性的·OH 来治理环境污染. 电化学技术是非常有前景的绿色处理技术, 其主要的反应剂是清洁的电子. 通常, 电化学过程主要产生氧气、臭氧、H 2O 2等分子氧化剂, 但它们对持久性有机污染物的降解效率不高. 除这些分子氧化剂外, 在一定条件下电化学过程也可以产生强氧化性的自由基, 尤其是·OH. 然而, ·OH 寿命短, 检测困难, 研究还不完善. 本文考察了通过电化学手段以价廉的水作为全部原子源而不仅仅是简单的原子供体产生·OH 的可能性, 并运用电子自旋共振技术(ESR)获取证据.实验采用无隔膜电化学池生成·OH, 阳极为经 过氟改性的β-PbO 2电极, 有效面积10 cm 2, 阴极为 不锈钢网. 阳极制备在前期工作中已有介绍[14]. 采用β-PbO 2电极主要是因为其较高的过氧电位和强催化活性, 且化学性能稳定、价廉, 适于工业应用. 实验中采用直流稳压电源, 利用循环泵强化传质. 反应液 为去离子水配制的2 g/L Na 2SO 4溶液50 mL. 此处 Na 2SO 4仅为电解质, 以提高导电能力, 并不参与电极反应, 实验在常温下进行. 采用德国生产的Bruker EMX-8顺磁电子自旋共振仪捕捉电化学过程产生的·OH 信号, 选择DMPO (5,5-dimethyl-1-pyrroline- N-oxide) 作为自旋捕集剂. 如图1所示,该化合物可以和·OH 反应生成稳定的自旋加合物,从而易于被ESR 波谱仪捕捉. 仪器设置为中心场 3490.00 G (1 G =10−4 T), 微波频率 9.805 GHz, 功率 19.97 mW, 扫描宽度100.00 G.图1 DMPO 与·OH 反应在未通电情况下, 将水溶液与DMPO 混合, 没有检测到ESR 信号(图未给出), 这与水在没有发生物理或化学变化时不存在·OH 的事实是一致的. 当溶液在7.5 V 电压下电解反应 2 min 后, 加入DMPO 并迅速关闭电源, 立即检测溶液的ESR 波谱. 从图2(a)可以看到明显的1:2:2:1四重峰谱线, 这是·OH 与DMPO 加合形成的DMPO-·OH 的典型特征波谱. 根据·OH 超精细耦合常数(αH =αN = 14.9 G)模拟的ESR快 讯第52卷 第11期 2007年6月1347波谱如图2(b)所示, 可见实验结果与模拟波谱吻合. 当溶液中加入·OH 清除剂异丙醇后重复上述过程, 获得的ESR 信号强度大幅下降. 上述结果表明, 电化学过程确实产生了·OH.图2 电化学过程产生·OH 的ESR 波谱(a) 实验; (b) 模拟证实·OH 的产生对电化学行为的研究有极大的促进作用. 在前期工作中, 我们发现氯酚废水在电化学作用下快速降解[15,16], 其降解中间产物主要有苯醌、对苯二酚、反丁烯二酸、草酸等. 苯醌是毒性最大的中间产物, 氯酚废水的毒性主要取决于氯酚和苯醌的浓度. 图3为电化学反应中4-氯酚的典型降解曲线, 从中可以看到, 4-氯酚的浓度随处理时间迅速下降, 苯醌在反应40 min 后达到最大浓度, 随后其浓图3 电化学降解4-氯酚操作条件: 初始氯酚浓度 100 mg/L, pH 6, Na 2SO 4 5 g/L,电流密度3.5 mA/cm 2度缓慢降低, 而且苯醌的最大浓度比氯酚的初始浓度低十分之一以上. 有机酸毒性较低, 可用生物方法降解处理. 这样, 电化学处理100 min 后, 氯酚废水的毒性已大大降低, 其中电化学产生的・OH 起了关键作用.电化学产生·OH 的证实, 也为电化学消毒开辟了新的途径. 环境中存在大量有害微生物, 对人类的健康造成很大威胁. 相对于传统的氯化消毒而言, 电化学消毒是非常有吸引力的. 但常规的电化学消毒主要通过电催化产生活性氯来达到杀菌目的. 尽管这在水处理界已被广泛接受, 但是, 由于电解生成过量的活性氯, 它是否也有产生潜在致癌性副产物的风险一直是人们争议的话题. 到目前为止, 被确定的消毒副产物已有700多种, 三卤甲烷是其中最常见的一类[17]. 美国国家环保局对于消毒剂和消毒副产物执行总三卤甲烷最大浓度0.08 mg/L 标准[18]. 发展更加安全和有效的消毒技术已日渐重要.考虑到电化学产生的·OH 比活性氯氧化性更强且环境友好, 我们考察了仅依靠·OH 来进行电化学消毒的可能性. 实验所用的污染水由无菌去离子水、 Na 2SO 4电解质和埃希氏菌液人工配制. 图4(a)显示了在5 mA/cm 2的电流密度下, 电化学消毒30 min 后, 杀菌率达到99.99%. 由于溶液中没有氯离子存在, 不可能有活性氯生成, 电化学产生的·OH 起了主要的消毒作用. 作为对比, 在上述合成废水中加入400 mg/L NaCl,在相同条件下进行实验, 结果如图4(b)所示. 比较图4(a)和(b), 添加NaCl 后杀菌率略有提高, 但二者杀菌效果非常接近. 可见, 仅依靠·OH 来图4 不同物质的电化学消毒效率操作条件: 电流密度 5 mA/cm 2, 埃希氏菌密度4.9×105 cfu/mL第52卷 第11期 2007年6月快 讯1348 进行电化学消毒是可行的, 且能避免有毒副产物的产生. 此外, 由于具有超强的氧化能力, ·OH 还可使一些活性氯难以杀死的细菌失活.本研究通过电化学手段以水作为全部原子源产生的·OH 应用于环境保护领域具有显著优势, 可有效降解持久性有毒污染物, 亦可用于水消毒, 并排除了氯化消毒产生致癌副产物的困扰. 鉴于·OH 的广泛应用, 我们的研究也为发展基于·OH 的氧化处理技术和合成技术提供了新的思路.参 考 文 献1 Meunier B. Chemistry: Catalytic degradation of chlorinated phe-nols. Science, 2002, 296(5566): 270—2712 Vione D, Maurino V, Minero C, et al. New processes in the envi-ronmental chemistry of nitrite. 2. The role of hydrogen peroxide. Environ Sci Technol, 2003, 37(20): 4635—46413 Theruvathu J A, Aravindakumar C T, Flyunt, R, et al. Fentonchemistry of 1,3-dimethyluracil. J Am Chem Soc, 2001, 123(37): 9007—90144 Buxton G V, Greenstock C L, Helman W P, et al. Critical reviewof rate constants for reactions of hydrated electrons, hydrogen at-oms and hydroxyl radicals in aqueous solution. J Phys Chem Ref Data, 1988, 17(2): 513—8865 Bach R D, Dmitrenko O. The “somersault” mechanism for theP-450 hydroxylation of hydrocarbons. The intervention of transient inverted metastable hydroperoxides. J Am Chem Soc, 2006, 128(5): 1474—14886 Perez-Estrada L A, Malato S, Gernjak W, et al. Photo-fenton deg-radation of diclofenac: Identification of main intermediates and degradation pathway. Environ Sci Technol, 2005, 39(21): 8300—83067 Bohne C, Faulhaber K, Giese B, et al. Studies on the mechanism ofthe photo-induced DNA damage in the presence of acridizinium salts-involvement of singlet oxygen and an unusual source for hy-droxyl radicals. J Am Chem Soc, 2005, 127(1): 76—85 8 Sallustio B C, DeGraaf Y C, Weekley J S, et al. Bioactivation ofcarboxylic acid compounds by UDP-glucuronosyltransferases to DNA-damaging intermediates: Role of glycoxidation and oxidative stress in genotoxicity. Chem Res Toxicol, 2006, 19(5): 683—691 9 Southworth B A, Voelker B M. Hydroxyl radical production viathe photo-fenton reaction in the presence of fulvic acid. Environ Sci Technol, 2003, 37(6): 1130—113610 房豪杰, 欧阳彬, 秦艳, 等. 水相CS 2与·OH 反应的研究. 科学通报, 2005, 50(20): 2195—219811 Foley S, Rotureau P, Pin S, et al. Radiolysis of confined water:Production and reactivity of hydroxyl radicals. Angew Chem Int Ed, 2005, 44(1): 110—11212 Poole J S, Shi X, Hadad C M, et al. Reaction of hydroxyl radicalwith aromatic hydrocarbons in nonaqueous solutions: A laser flash photolysis study in acetonitrile. J Phys Chem A, 2005, 109(11): 2547—255113 Sorokin A, SJris J L, Meunier B. Efficient oxidative dechlorinationand aromatic ring cleavage of chlorinated phenols catalyzed by iron sulfophthalocyanine. Science, 1995, 268(5214): 1163—1166 14 Wu Z C, Zhou M H. Partial degradation of phenol by advancedelectrochemical oxidation process. Environ Sci Technol, 2001, 35(13): 2698—270315 Wu Z C, Cong Y Q, Zhou M H, et al. p-Nitrophenol abatement bythe combination of electro-catalysis and activated carbon. Chem Eng J, 2005, 106(1): 83—9016 Wu Z C, Cong Y Q, Zhou M H, et al. Removal of phenolic com-pounds by electro-assisted advanced process for wastewater puri-fication. Korean J Chem Eng, 2002, 19(5): 866—87017 Blatchley Ⅲ E R, Margetas D, Duggirala R. Copper catalysis inchloroform formation during water chlorination. Water Res, 2003, 37(18): 4385—439418 Environmental Protection Agency. Disinfectants, disinfection by-products, final rule —National Primary Drinking Water Regula-tions. Federal Register, 1998, 63(241): 69390—69476。

Quantitation of hydroxyl radical during Fenton oxidationfollowing a single addition of iron and peroxideMichele E.Lindsey,Matthew A.Tarr*Department of Chemistry,University of New Orleans,New Orleans,LA 70148,USAReceived 2October 1998;accepted 15July 1999AbstractChemical probes were used to study the formation of hydroxyl radical in aqueous iron±hydrogen peroxide reaction.Hydroxyl radical formation rate and time dependent concentration were determined in pure water,in aqueous fulvic acid (FA)and humic acid (HA)solutions,and in natural surface waters.Indirect determinations of hydroxyl radical were made by quantitating hydroxyl radical reactions with probe compounds under controlled conditions.High probe concentrations were used to determine radical formation rates and low probe concentrations were used to determine time dependent radical concentration.Two independent probes were used for intercomparison:benzoic acid and 1-propanol.Good agreement between the two probes was observed.Natural water matrices resulted in lower radical formation rates and lower hydroxyl radical concentrations,with observed formation rate and yield in natural waters up to four times lower than in pure water.HA and FA also reduced hydroxyl radical formation under most conditions,although increased radical formation was observed with FA at certain pH values.Hydroxyl radical formation increased linearly with hydrogen peroxide concentration.Ó2000Elsevier Science Ltd.All rights reserved.Keywords:Fenton oxidation;Hydroxyl radical;Degradation;Iron;Hydrogen peroxide;Natural water1.IntroductionNumerous studies have investigated the use of Fen-ton chemistry for pollutant degradation or remediation (Graf et al.,1984;Puppo,1992;Yoshimura et al.,1992;Zepp et al.,1992).In these applications,hydrogen per-oxide is converted to hydroxyl radical in a catalytic cycle with cationic iron acting as catalyst.The high reactivity of hydroxyl radical is advantageous since it readily de-grades a wide array of pollutants (reaction with alkanes,k 107±109M À1s À1;reaction with alkenes and aro-matics,k 109±1010M À1s À1).Unfortunately this ad-vantage is also an important drawback since the hydroxyl radical often reacts with non-pollutant species present at higher concentration.Furthermore,the cata-lytic cycle is in¯uenced by pH,iron complexation,iron solubility,and iron redox cycling between the +2and +3states.In order to better understand the use of Fenton chemistry for pollutant degradation in waste streams or contaminated sites,a better understanding of matrix e ects is needed.This report focuses on the e ects of natural water matrices on hydroxyl radical formation and scavenging.Iron/peroxide systems have been used to degrade a number of contaminants,mostly in the aqueous phase.Degradation of the herbicides 2,4-D,2,4,5-T,and atr-azine in aqueous solution by Fe (II)/H 2O 2or Fe (III)/H 2O 2has been reported (Pignatello,1992).Reactions were pH sensitive,and acidic conditions were necessary for iron solubility.Vella and Munder (1993)used Fe (II)/H 2O 2for the degradation of phenolic compounds in water.Again,acidic conditions (pH 4)were used.Although complete elimination of the parent compound could be achieved for chlorinated and otherphenols,Chemosphere 41(2000)409±417*Corresponding author.Fax:+1-504-280-6860.E-mail address:mtarr@ (M.A.Tarr).0045-6535/00/$-see front matter Ó2000Elsevier Science Ltd.All rights reserved.PII:S 0045-6535(99)00296-9the presence of phosphate signi®cantly hindered degradation.To allow reaction at near neutral pH,researchers have utilized iron chelating agents(Sun and Pignatello, 1992,1993).Several iron chelates were found to be ac-tive in Fenton oxidation although the chelator was also degraded at a slower rate(Sun and Pignatello,1992). Naturally occurring compounds can act as metal che-lators.For example,inorganic salts,humic acids(HAs), fulvic acids(FAs),and organic colloids have been shown to exhibit signi®cant metal complexation(Pettersson et al.,1997;Ganguly et al.,1998;Klein and Niessner, 1998;Rose et al.,1998;Roux et al.,1998).Commercial applications of Fenton chemistry to remediation of contaminated soil are currently in use. These methods add both iron and peroxide to the sat-urated zone,and utilize iron chelators and peroxide stabilizers(Watts and Dilly,1996;Greenburg et al., 1997).Such applications have been successful in reme-diating the saturated zone after petroleum leakage from an underground storage tank.However,conditions for such remediation have typically been developed from empirical observations of degradation e ciency rather than from a fundamental understanding of the HOádynamics.Furthermore,a large excess of peroxide is often used.Fenton reagents have also been used for degradation of bio-recalcitrant perchloroethylene(PCE)and poly-chlorinated biphenyls(PCBs)adsorbed on sand(Sato et al.,1993).Treatment required adjustment of the pH to3with degradation severely limited at pH7.Even at optimum pH,PCB treatment still yielded chlorinated degradation products,indicating incomplete degrada-tion.Further studies on degradation of PCBs indicated that dissolved PCBs are much more readily degraded by hydroxyl radical than are PCBs sorbed to sand(Sedlak and Andren,1994).Some studies involving soil/water systems have re-lied on naturally occurring iron in soils to react with added H2O2(Croft et al.,1992;Watts et al.,1993). However,water insoluble pollutants adsorb to the surface of soil particles thus impeding degradation.Due to the di culty of oxidation across the liquid±solid boundary,high stoichiometric amounts of H2O2were required to achieve complete degradation of the pol-lutants in these environments(Watts et al.,1993). Again,a lack of understanding of the HOáand pollu-tant degradation dynamics was overcome in these sys-tems simply by using an excess of peroxide,rather than adjusting other parameters to optimize the degradation e ciency.The e ciency of hydroxyl radical production from peroxide is a ected by a number of factors,including pH,iron oxidation state,and iron chelation.Phosphate has been reported to inhibit hydroxyl radical production (Vella and Munder,1993),and additional reports indi-cate either inhibition(Croft et al.,1992)or acceleration (Puppo,1992)of HOáproduction in the presence of various ligands.Once formed,hydroxyl radicals may be lost through reaction with matrix mon matrices include FA and HA in natural freshwaters,as well as inorganic species in brackish waters.Due to the relatively high concentration of matrix species,generally only a small fraction of the radicals formed can react with the pol-lutant.This process is a major limitation of Fenton chemistry for degradation of pollutants in the presence of matrix constituents,and results in increased peroxide demand and higher costs.Although signi®cant research has focused on Fenton systems and quantitation of hydroxyl radical concen-tration,several important issues have not yet been ad-dressed.Some researches(Ravikumar and Gurol,1994; Lin and Gurol,1998)have measured loss of hydrogen peroxide as an indicator for hydroxyl radical formation. This approach is not entirely su cient because not all peroxide degraded is converted to hydroxyl radical,and hence measurement of peroxide loss does not allow di-rect determination of[HOá].Other researchers have measured hydroxyl radical concentration under steady state[HOá]conditions,primarily in photochemical sys-tems(Haag and Hoign e,1985;Zhou and Mopper, 1990).While this approach is applicable to photo-chemical systems,it is not representative of common Fenton systems in which peroxide is added in a single dose,resulting in non-steady state[HOá].Additional studies have attempted to quantitate hydroxyl radical under non-steady state conditions(Tomita et al.,1994; Mizuta et al.,1997);however,due to a number of fac-tors,these reports did not provide conclusive hydroxyl radical information.In this study,chemical probes were used to measure both hydroxyl radical formation rate and time depen-dent hydroxyl radical concentration under non-steady state conditions.Methods were developed that allow these determinations in pure water and natural waters, allowing assessment of the role of natural matrices on Fenton oxidations.2.ExperimentalMaterials.Puri®ed water was obtained by further puri®cation of distilled water with a NanopureUV (Barnstead)water treatment system.Natural water samples were collected from sites in Southeast Louisiana at Crawford Landing(CL)on the West Pearl River and from a small water body connecting Lake Pontchartrain and Lake Maurepas(LM).The LM water contained a higher concentration of dissolved organic carbon and inorganic species than the CL water.All natural water samples were®ltered using pre-combusted0.5l m glass410M.E.Lindsey,M.A.Tarr/Chemosphere41(2000)409±417®ber®lters(Machery±Nagel,Rund®lter MN,Alberta, Canada)and were stored in the dark at4°C.Natural water samples were used directly or were diluted with pure water.Suwannee River FA and HA standard ma-terials were purchased from the International Humic Substances Society.FA and HA concentrations are reported as mg FA lÀ1and mg HA lÀ1.The carbon content of these materials are52.44%and52.55%by weight,respectively.Hydrogen peroxide(EM science,$30%)was stan-dardized using iodometric titration(Christian,1994). Iron(II)perchlorate(99+%)was purchased from Alfa. Benzoic acid(BA)(99.5+%),p-hydroxybenzoic acid (99+%),and2,4-dinitrophenylhydrazine(DNPH)(70%) were purchased from Aldrich.Propionaldehyde(98%) was purchased from Fluka,and1-propanol(PrOH) (99+%)was purchased from Mallinkrodt.Dimethyl sulfoxide(certi®ed ACS)and acetonitrile(HPLC grade) were obtained from Fisher.All reagents were used as received.Hydroxyl radical trapping.Both benzoic acid and n-propanol were used as probes for hydroxyl radical. Benzoic acid has a known reaction rate constant of 4.2´109MÀ1sÀ1with hydroxyl radical in aqueous media(Buxton et al.,1988).This reaction produces p-hydroxybenzoic acid(p-HBA)as well as o-HBA, m-HBA,and other products.The fraction of p-HBA produced per reaction was taken from(Zhou and Mopper,1990),who reported5X87Æ0X18moles HOáreacted per mole p-HBA produced.1-Propanol reacts with hydroxyl radical in aqueous media at a rate of 2.8´109MÀ1sÀ1to form propionaldehyde in46%yield (Buxton et al.,1988).BA or PrOH solutions of various concentrations were prepared in pure and natural water.At time zero, a single dose of hydrogen peroxide and a single dose of Fe(II)were added with vigorous mixing.These additions resulted in time zero concentrations of 0.2±1.0mM H2O2and0.2±0.53mM Fe(II).Reactions were stirred,kept in the dark,and maintained at20°C. After a given time interval,reactions were quenched by addition of a su cient amount of a quencher that e ectively outcompeted the probe molecule for reaction with hydroxyl radical.For benzoic acid probe studies, 0.5ml of PrOH was added per10ml of reaction solution.For PrOH probe studies,4ml of dimethyl sulfoxide(DMSO)containing5mM DNPH were added per10ml of reaction solution.These amounts of added quencher had rates of reaction with hydroxyl radical of 50±5600times greater than the probe;therefore,it was assumed that upon addition of quencher,no signi®cant reaction of probe with hydroxyl radical occurred.The resulting products of probe-hydroxyl radical reaction were then analyzed as described below.Each of these experiments produced a single time point.Repetition of the experiment for di erent times then enabled recon-struction of time dependent data from the individual experiments.Quantitation of products.Reaction products were quantitated by high performance liquid chromatography using a Hewlett-Packard1090liquid chromatograph.A Spherisorb ODS-2column(5l m particle size,25cm length´4.6mm id)was used for all separations.Benzoic acid and hydroxybenzoic acids were sepa-rated using the following procedure(Zhou and Mopper, 1990).Samples were brought to pH2±3using HCl then loaded onto a1.5ml loop.After injection,the analytes were pre-concentrated on-column during the initial 3min,then were eluted by increasing the solvent strength.The elution gradient was:water at pH$2.5(A) and acetonitrile(B);0±3min15%B,3±13min linear to 75%B,13±15min linear to100%B.The¯ow rate was 1.0ml minÀ1.Analytes were detected by absorbance at 254nm.For natural water samples it was necessary to ®lter the samples before injection to remove particulates. This was accomplished by raising the pH to P8using NaOH then passing the sample through a0.2l m nylon ®lter(Cole Parmer).The pH adjustment eliminated loss of benzoic acid and hydroxybenzoic acids on the®lters by forming the more soluble ionized species.After®l-tration,the pH was re-adjusted to2±3using HCl and the sample was analyzed as above.Both benzoic acid and p-hydroxybenzoic acid were stable under these condi-tions over the time required for analysis.Propionaldehyde,the product of1-propanol reac-tion with hydroxyl radical,was quantitated following derivitization with DNPH(Coutrim et al.,1993).The derivitization was carried out by adding5mM DNPH in DMSO and allowing12h for the derivitization to occur.Extended time periods(up to48h)did not a ect the concentration of propionaldehyde detected. The derivitized product was injected using a50l l loop.The elution gradient was:water(A)and aceto-nitrile(B);0±2min50%B,2±16min linear to100% B.The analytes were detected by absorbance at 254nm.Hydrogen peroxide determination.Hydrogen peroxide was determined by titration(Christian,1994).In this method,excess IÀplus a catalyst was added to the hy-drogen peroxide solution to form IÀ3.The IÀ3was then titrated with thiosulfate.Hydrogen peroxide was quantitated at di erent times after addition of Fe2 ,and it was assumed that any further Fenton reaction was quenched upon the addition of excess IÀ.3.Results and DiscussionHydroxyl radical quantitation.In a system with both sources and sinks for hydroxyl radical,the change in [HOá]with respect to time is described by Zhou and Mopper(1990):M.E.Lindsey,M.A.Tarr/Chemosphere41(2000)409±417411d HO áa d t F Àk p HO áP Àk S i HO á S iÀk HO HO á 21where F is the formation rate of hydroxyl radical,and the remaining negative terms are loss due to reaction with probe (P),with scavengers (S),and self reaction,respectively.This equation does not represent steady state conditions,but rather the rate of change in hy-droxyl radical concentration with respect to time.Therefore,this equation is applicable under non-steady state conditions.As [P]increases,the term Àk p HO á P will dominate the loss terms.Under these conditions,the total moles of P reacted will be stoichiometrically related to the total moles of HO áformed (Blough,1988),provided that the reaction product does not react signi®cantly with hy-droxyl radical.Since in this study product concentration was always considerably lower than the probe concen-tration,we assumed no signi®cant loss of product due to hydroxyl radical reaction.In the case of low probe concentrations,if [P]is small enough so that k p HO á P ( S i HO áS i k HO HO á 2,then d HO á a d t will be relatively una ected by the probe.In such cases,the concentration of hydroxyl radical in the absence of the probe can be calculated from the second order rate law R p k p HO á P 2 HO á R p a f k p P g 3 HO á avg R p a f k p P avg g4where R p is the rate of probe reaction,k p is the second order rate constant,and avg indicates time averaged values.Over short time intervals,the value for R p was calculated from the linear change in the concentration of the product resulting from probe-HO áreaction.This approach is valid when [HO á]and [P]do not change signi®cantly in the time interval.Validation of experimental approach .In order to con®rm that the approach used here is valid,several experiments were undertaken.The ®rst set of experi-ments involved measurement of product yield as a function of probe concentration.These experiments al-lowed de®nition of high probe concentrations (useful for determination of total HO áformation)and low probe concentration (useful for determination of HO ácon-centration with minimal perturbation by the probe).Product formation was quantitated as a function of re-action time for several probe concentrations.Data for benzoic acid experiments in several matrices are pre-sented in Fig.1.In all matrices,as the benzoic acid concentration increased,the amount of product in-creased,indicating that higher concentrations of benzoic acid were better able to outcomplete the naturalscavengers for reaction with HO á.At su ciently high benzoic acid concentrations,further increases in con-centration resulted in little increase in product yield,as seen by a plateau in the curves in Fig.1at higher [BA].Such behavior has been observed previously (Tomita et al.,1994).These data indicate that no additional trapping of HO ácould be achieved by increasing [BA],and therefore at these concentrations the benzoic acid must be trapping essentially all of the HO á.Under these conditions,the total moles of product obtained is directly proportional to the total moles HO áproduced (for benzoic acid,the proportionality factor is 5.9(Zhou and Mopper,1990)).Increased content of LM water resulted in a lower total amount of HO átrapped in the plateau region (above 5mM BA).This result is most likely due to a decrease in the e ciency of radical production in the presence of the natural water matrix.This result was also evident in time dependent measurements of total HO áproduced,as will be discussed below.As the benzoic acid concentration was lowered,the yield of product decreased.In order to determine hy-droxyl radical concentration in the absence of the added probe,it was necessary that the probe had a negligible e ect on hydroxyl radical concentration.We used the ratio of product yield at low [BA]to product yield at the high [BA]plateau to determine the extent of perturba-tion caused by the addition of benzoic acid.For exam-ple,in a 50/50mixture of pure water with LM water,0.5mM BA has a product yield of only 4%of the yield for P 5mM BA.In contrast,the product yield for 0.5mM BA in pure water was 40%of the yield at 5mM BA.Based on these results,we selected benzoic acid concentrations for use in further experiments to deter-mine HO áproduction and HO áconcentration.For HO áproduction,we used benzoic acid concentrations intheFig.1.Moles of hydroxyl radical trapped as a function of probe concentration (benzoic acid)in pure water and several dilutions of LM water.All data were acquired 10min after the addition of iron (II)perchlorate and H 2O 2at time zero concentrations of 0.2and 0.5mM,respectively.412M.E.Lindsey,M.A.Tarr /Chemosphere 41(2000)409±417plateau region(typically9mM),and for[HOá]mea-surements we used benzoic acid concentrations that had product yields of less than10%of the maximum yield on the plateau(typically0.2mM).Also illustrated in Fig.1is the e ect of increased matrix components on HOáscavenging.As the per-centage of natural water increased,higher concentra-tions of benzoic acid were required to reach the plateau region.These results indicate the higher level of scav-engers in the natural water,therefore requiring a higher benzoic acid concentration to trap all of the hydroxyl radical formed.The presence of these scavengers also minimized the perturbation at low benzoic acid concentrations.Similar studies using propanol as probe were also conducted,and the results are presented in Fig.2.For pure water,complete trapping could be achieved above 100mM PrOH.In contrast to the benzoic acid probe, propanol did not signi®cantly perturb the[HOá]with propanol concentrations below$2mM.For LM water, the PrOH product yield did not plateau as was observed for benzoic acid.Even with propanol concentrations as high as1M,the product yield did not plateau.Therefore PrOH was not used to determine formation rate of HOáin natural waters.However,measurement of[HOá]in natural water was deemed feasible at propanol concen-trations below$10mM.The use of higher concentra-tions of PrOH as compared to benzoic acid is likely a result of the lower rate constant for propanol reaction with hydroxyl radical.Propanol and benzoic acid are distinct probes with di erent mechanisms of reaction with hydroxyl radical. We used such distinct probes to eliminate any possible bias of a single parison of the BA and PrOH results under the same conditions showed good agree-ment.These results can be seen in Fig.3,and are dis-cussed further below.The strong agreement between data from these distinct probes indicate that the probes introduced little or no bias into these measurements.For example,complexation of iron by benzoic acid was de-termined to be insigni®cant,as any such interaction would have resulted in divergent results for the two probes.Measurement of HOáProduction.Hydroxyl radical production was measured in pure water,CL water,LM water,and aqueous solutions of Suwannee River HA and FA.For these experiments,benzoic acid was used as probe at a concentration of9mM(pH$3).The total moles of HOáproduced was measured as a function of time after a single addition of Fe(II)and H2O2.A comparison of moles HOáproduced as a function of time for pure water and the two natural waters is pre-sented in Fig.4.The CL water matrix showed slightly lower HOáproduction than pure water,and the LM water matrix showed dramatically lower production than pure water.After20min,the reaction in pure water had produced$3X5Â10À6mol of HOá,while in CL water only$3Â10À6mol HOáwere produced,and in LM water only$0X8Â10À6moles HOáwere produced. These data indicate that the natural water matrices used here resulted in a lower e ciency of hydroxyl radical formation compared to pure water.Observed rates of formation of hydroxyl radical were also lower in the natural waters than in pure water.We measured the initial rates of hydroxyl radical formation from the ini-tial slopes of the curves in Fig.4,and the resulting values are presented in Table1.Suwannee River HA and FA also showed decreased hydroxyl radical formation.Fig.5illustrates the for-mation of HOávs time for various concentrations of HA and FA.HA caused a more dramatic decrease inradicalFig.2.Moles of hydroxyl radical trapped as a function ofprobe concentration(PrOH)in pure water and dilutions of LMwater.All data were acquired10min after the addition of iron(II)perchlorate and H2O2at time zero concentrations of0.2and0.5mM,respectively.The x-axis is presented with a loga-rithmic scale due to the large range of propanol concentrationsused.Fig.3.Measured time dependent hydroxyl radical concentra-tion(symbols)based on reaction with benzoic acid(0.2mM,pH 4.3)or PrOH(1mM,pH 6).Curves are polynomial®tsto the data points.Matrix is CL water.M.E.Lindsey,M.A.Tarr/Chemosphere41(2000)409±417413production than FA.The initial rate of hydroxyl radical production was decreased by 11%in the presence of 30mg l À1FA and by 27%in the presence of 30mg l À1HA.For HA,the initial hydroxyl radical production rate showed a linear decrease over the range of HA concentrations studied,as illustrated in Fig.6.Since the FA and HA solutions (with 9mM BA)were very close in pH to pure water (with 9mM BA),and since no additional inorganic species were present,these data indicate that dissolved natural organic matter can have a dramatic e ect on hydroxyl radical formation as well as scavenging.Hydroxyl radical formation was assessed as a func-tion of pH with and without added FA.The total moles of HO áformed was measured at 20and 300s after mixing Fe 2 and peroxide.Fig.7represents total moles of HO áformed in a 300s time interval as a function of pH and FA content.The highest yield of hydroxyl radical was observed at pH 3.1,which is in good agreement with previous studies (Pignatello,1992).At this pH,addition of FA resulted in a slight decrease in radical production.However,as the pH was increased,the FA had the opposite e ect,with increased radical production at increased [FA].Furthermore,the e ect of pH was minimized at the highest FA concentration.The data for a 20s time interval showed similar results.The distribution of Fe 2 and Fe 3 is sensitive to pH,with the Fe 2 state becoming less stable with increasing pH,and the formation of oxides and hydroxides also increases with increasing pH.It is therefore reasonable to expect,as has been previously observed (Pignatello,1992),that Fenton production of hydroxylradicalFig.6.Initial rate of hydroxyl radical formation as a function of HA concentration.Benzoic acid used as probe at 9mM,(pH $3).Fig.5.Total moles of HO áformed as a function of time for aqueous FA (a)and HA (b)solutions.Benzoic acid used as probe at 9mM (pH $3).Fig.4.Total moles of HO áformed as a function of time for pure water (pH 3.1),CL water (pH 3.3),and LM water (pH 3.6).Benzoic acid used as probe at 9mM.Table 1Observed initial rate for hydroxyl radical formation in pure water and natural waters Water Initial rate (M s À1)DOC a (mg C l À1)Puri®ed 1.2´10À6<0.003CL 1.0´10À629.9LM0.3´10À6123aDissolved organic carbon.414M.E.Lindsey,M.A.Tarr /Chemosphere 41(2000)409±417becomes less e cient at higher pH.Also previously observed is that iron chelation minimizes these pH ef-fects by stabilizing the chelated Fe 2 ion (Sun and Pig-natello,1993).Our results provide evidence that iron chelation by FA results in stabilization of Fe 2 with respect to pH.At low pH,Fe 2 stability is high,and any chelation of iron by FA has only a small e ect on HO áformation.At higher pH,chelation by FA likely results in increased Fe 2 stability,resulting in a marked increase in Fenton reaction yield upon addition of FA.Previous reports have indicated pseudo ®rst order loss of H 2O 2in the presence of Fe (II)(Walling,1975),Fe (III)+light (Pignatello,1992),and iron oxides (Lin and Gurol,1998).Our peroxide data also indicate ®rst order behavior,although the kinetic behavior did not stabilize until 30±60s after the addition of peroxide.An illustration of this behavior is given in Fig.8.Previous studies did not monitor kinetics at such short times.Our observations were consistent over a wide range of per-oxide concentrations (5±100mM).A possible explana-tion is that initially all of the iron is present as Fe 2 ,which can react with H 2O 2to form HO á.As this reaction proceeds,the concentration of Fe 2 declines,and con-sequently the rate of H 2O 2consumption and HO áfor-mation decline.The loss of Fe 2 is eventually balanced by formation of Fe 2 through reduction of Fe 3 by re-action with peroxide or hydroperoxyl radical,and a steady state Fe 2 concentration is reached.At this point (>60s),pseudo ®rst order loss of H 2O 2is observed.This explanation is also supported by evidence that the HO áformation rate is signi®cantly higher in the ®rst 60s.The in¯uence of hydrogen peroxide concentration on hydroxyl radical production was also assessed.The moles of HO áformed increased linearly with increasing [H 2O 2].The hydroxyl radical formation was measured at20s and 300s intervals after mixing Fe 2 and H 2O 2.The data are presented in Fig.9.The slope of the line was greater at 300s than at 20s,indicating that increasing H 2O 2concentration will result in more signi®cant in-creases in hydroxyl radical over longer time periods.The above observations could be used in evaluating the e ciency of Fenton oxidation in a given matrix.Three possible explanations exist for the observed dif-ferences in the natural water matrices:(1)the rate of peroxide reaction with iron may be altered by iron complexation (Croft et al.,1992;Puppo,1992)with matrix components,(2)Fe (II)/Fe (III)redox cycling may be altered by complexation (Croft et al.,1992)or by the presence of oxidants /reductants in the matrix,or (3)peroxide may be consumed by reaction with matrix components.This method provides a basic understand-ing of the time dependent radical formation rate and allows direct assessment of matrix e ects onradicalFig.8.Plot of ln[H 2O 2]vs time after addition of peroxide to solution of 0.5mM Fe 2 (aq).Line is linear regression to the data points for t P 60s.Fig.9.Total moles of HO áformed as a function of hydrogen peroxide concentration.Benzoic acid used as probe at 9mM (pH 3.1).Measurements made 20and 300s after mixing Fe 2 and H 2O 2in purewater.Fig.7.Total moles of HO áformed as a function of pH for pure water and aqueous FA.Benzoic acid used as probe at 9mM.Lower pH was achieved by addition of perchloric acid,and higher pH was achieved by addition of NaOH.Measurements made 300s after mixing Fe 2 and H 2O 2.M.E.Lindsey,M.A.Tarr /Chemosphere 41(2000)409±417415。

四川大学博士学位论文苯在催化剂作用下直接氨基化/羟基化研究姓名:***申请学位级别:博士专业:物理化学指导教师:***20030401四川大学博士学位论文苯在催化剂作用下直接氨基化/羟基化研究物理化学专业博士研究生:陈彤指导教师:田安民教授摘要通过活化芳环的C.H键,将所需官能团直接引入芳环,实现芳烃的直接功能化,是目前极具挑战性的课题之一,也是当今合成化学的研究热点。

苯胺和苯酚都是重要的有机化工原料,本论文设计了一组镍基催化剂,用之于直接将氨基/羟基引入苯环合成苯胺/苯酚的反应,将传统的多步骤合成反应变为一步反应,成功实现了苯胺I苯酚的绿色合成。

应用热分析方法和等离子体原子发射光谱分析,对设计的Ni基催化剂的制备过程、制备规律进行了研究,发现样品中载体与负载组分及负载组分间,在热分解前就存在相互作用,这种相互作用对其热分解过程有很大的影响。

负载一种组分时,载体与负载组分的作用削弱了硝酸盐与结晶水的作用,增强了硝酸根与金属离子的结合,使负载金属盐失去结晶水的温度降低,而最终分解温度升高;负载多种组分时,负载组分与载体之间以及负载组分之间的相互作用,削弱了金属与硝酸根的结合力,使负载的各金属盐的最终分解温度降低。

样品上的负载组分、浸渍顺序、热分解过程等制备方法,对样品中载体与负载组分及负载组分之间的相互作用均有很大的影响,使得样品的热分解机理的不同,造成其热分解动力学模型的差异;锆物种与载体的相互作用强于铈物种,锆、铈合浸过程中,锆与载体优先发生作用。

相同控制含量条件下,制备方法对催化剂样品中实际负载组分的含量有很大影响。

用X.射线衍射、X.射线光电子能谱、程序升温还原、氢吸附和氧吸附测试等对催化剂进行了表征。

由于催化剂组成不同、制备方法不同,载体与负载组分及负载组分间产生的相互作用就不同,因而负载的金属组分的分散状态和分散程度也就不同。

本文所研究的催化剂体系中,锆物种的分散效果最好。

这些分散状态和分散程度的差异,使得催化剂上镍氧化物品相生成情况、铈锆固溶体生成情况、催化剂的还原情况(尤其是低温还原情况)、催化剂对氢和氧的吸附能力有很大差异。

TS-1/H2O2绿色催化体系研究现状魏珍妮,黄鑫,张丽桦,南洋,刘肖飞(中国石油石油化工研究院兰州化工研究中心,甘肃兰州730060)摘要:钛硅分子筛是1种绿色友好的新型催化剂,广泛用于多种催化体系。

其中钛硅分子筛(TS-1)与过氧化氢(H2O2)组成的绿色催化氧化体系受到了较多科研工作者的关注,不仅仅是因为该体系具有反应条件温和、工艺流程短、产物选择性高等优势,该体系还能应用于烷烃氧化、烯烃氧化、酚羟基化、醇氧化及酮肟化等多个领域,且跟据现已完成的丙烯环氧化及环己酮氨肟化的工业化应用表明,该技术成本较低,很容易实现装置扩能、改造的需求。

由此看来,TS-1/H2O2催化体系符合当今化工行业的绿色友好的发展趋势。

关键词:钛硅分子筛;过氧化氢;绿色催化体系中图分类号:TQ426.94文献标识码:B文章编号:1671-4962(2022)01-0001-03Research status of TS-1/H2O2green catalytic systemWei Zhenni,Huang Xin,Zhang Lihua,Nan Yang,Liu Xiaofei(Lanzhou Petrochemical Research Center,PetroChina Petrochemical Research Institute,Lanzhou730060,China)Abstract:Titanium silicon molecular sieve is a new kind of green friendly catalyst,widely used in a variety of catalytic systems. Titanium silicon molecular sieve(TS-1)and hydrogen peroxide(H2O2)green catalytic oxidation system draw the attention of manyresearchers,not only because the system had advantages of mild reaction conditions,short technological process,high selectivity, but also because it can be applied for alkane oxidation,olefin oxidation,phenol hydroxylation,alcohol and ketone oxime oxide,and other fields.According to the industrial application of propylene epoxidation and cyclohexanone oxime,the cost of this technology was low,and it was easy to meet the needs of plant expansion and transformation.Therefore,TS-1/H2O2catalytic system was in line with the green and friendly development trend of the current chemical industry.Keywords:titanium silicon molecular sieve;hydrogen peroxide;green catalytic systemTS-1型钛硅分子筛是1种具有MFI拓扑结构的沸石类分子筛,其基本结构单元由硅氧4面体和钛氧4面体相互连接而形成的8个5元环构成。