制样条件对抗冲共聚PP悬臂梁冲击强度测试结果的影响

- 格式:pdf

- 大小:164.93 KB

- 文档页数:3

制样温度对聚丙烯产品力学性能的影响聚丙烯是一种常见的塑料材料,广泛应用于各个领域,包括包装、家具、汽车零部件等。

制样温度是指在制备聚丙烯产品过程中,熔融聚丙烯塑料的温度。

制样温度对聚丙烯产品的力学性能有着重要的影响。

下面将从强度、韧性和冷却速率几个方面来介绍制样温度对聚丙烯产品力学性能的影响。

首先是强度方面。

聚丙烯材料的强度主要包括拉伸强度、弯曲强度和冲击强度。

制样温度的变化对聚丙烯产品的强度有着直接影响。

一般来说,较高的制样温度可以提高聚丙烯产品的拉伸强度和弯曲强度。

这是因为较高的温度会使聚丙烯分子链更加流动,增强了分子链之间的相互作用,提高了产品的结晶度和分子间结合力。

较高的制样温度还可以降低聚丙烯产品的内部应力,减少产品的缺陷,进而提高产品的冲击强度。

其次是韧性方面。

制样温度还对聚丙烯产品的韧性有着重要的影响。

韧性是指材料在受力过程中发生塑性变形的能力。

一般来说,较高的制样温度可以提高聚丙烯产品的韧性。

这是因为较高的温度可以增加聚丙烯分子链的流动性,使其在拉伸或弯曲过程中更容易发生塑性变形,增加了产品的韧性。

制样温度与冷却速率之间也存在一定的关系。

冷却速率是指产品从高温状态到室温时的冷却速度。

制样温度较高时,产品冷却速率较慢,这会使聚丙烯分子链在冷却过程中有足够的时间重新排列和结晶,从而增强了产品的结晶度和结晶度分布;制样温度较低时,产品冷却速率较快,聚丙烯分子链没有足够的时间重新排列和结晶,导致产品的结晶度较低。

较高的结晶度通常与较高的强度和韧性相关。

过高的制样温度也可能导致产品的结晶度过高,从而降低产品的韧性。

制样温度对聚丙烯产品的力学性能有着显著的影响。

在实际应用中,制样温度的选择应根据产品所需力学性能的要求进行合理调整。

如何提高抗冲共聚聚丙烯2500H的低温抗冲击性能李淑娟;常素萍【摘要】介绍了聚丙烯抗冲共聚物2500 H的生产工艺和产品的结构性能,针对低温冲击强度对聚丙烯抗冲共聚物的重要性做了阐述。

从工艺控制的角度出发,结合抗冲聚丙烯2500H,着重从生产过程中的催化剂及原料的精制情况、产品熔融指数( MFR)、乙烯用量、异丙醇用量几个方面进行了认真的分析,得出了提高产品低温冲击强度的有效途径。

%The production processes and the structure and properties of polypropylene impact copolymer 2500 H was introduced, and the importance of the low-temperature impact strength of impact copolymer polypropylene was elaborated. From the perspective of process control, combining copolymer polypropylene 2500H and focusing on the process of the production, several aspects of catalysts and refining of raw materials, the melt flow rate ( MFR) , the amount of ethylene and isopropanol were analyzed carefully, and effective way to improve the low-temperature impact strength of the product was obtained.【期刊名称】《广州化工》【年(卷),期】2014(000)023【总页数】3页(P187-188,193)【关键词】抗冲共聚聚丙烯;乙丙橡胶;冲击强度;异丙醇【作者】李淑娟;常素萍【作者单位】神华宁夏煤业集团煤炭化学工业分公司烯烃公司,宁夏银川750411;神华宁夏煤业集团煤炭化学工业分公司质检中心,宁夏银川 750411【正文语种】中文【中图分类】TQ316.37抗冲共聚聚丙烯是一种比较理想的聚丙烯(PP)产品,具有良好的抗冲击性能,同时不乏强度高,刚性大,耐热性能好及低温韧性等优点,主要用于汽车、消费性产品、器具和包装,以及办公家具、医用产品及药品包装市场[1-3],发展潜力较大。

制样温度对聚丙烯产品力学性能的影响作者:胡文婷来源:《中国化工贸易·下旬刊》2019年第05期摘要:在实际的工作过程中,我们可以得知在很多种情况下制作聚丙烯产品时可能会出现不合格、不达标的状况。

我们从实验中查找出聚丙烯产品的力学性能不达标的问题的原因所在,但查找原因的过程中出现了发现了一些规律性问题:模具的温度变化会使得力学性能发生变化,而模具温度变化又可以由机械本身的温度变化或者模具温控箱失控等原因产生,并且我们发现力学性能的变化与模具的温度变化呈现出一定的规律性。

关键词:注塑温度;模具温度;结晶度;拉伸屈服强度;悬臂梁冲击强度;挠曲模具1 影响实验结果的因素我们都知道,影响塑料实验结果的因素有很多,在大范围上可以分为两个方面,分别是内在原因和外在原因。

内在原因包括塑料本身的分子量,大小以及分布结构和内部缺陷等,外在原因包括工作人员操作、机械本身、测试过程、放置过程等。

注塑制品的质量。

包括内部质量和外部质量。

一般来说,内部质量一般指性质的好坏水平,外部质量指的也是眼可以看到的,形态等。

内部质量指的是和聚合物有关的结晶、变形、内应力分布等,这些聚合物大都可以直接影响其结构形态,还与一些力学相关的性质有关,比如:拉伸、弯曲、冲击等。

因此,产品的内部质量至关重要,可以直接影响产品的使用性能和使用寿命,想要提高产品的使用性能和使用范围,就需要改变传统的技术,将一些新材料和新技术应用到其中,在加工过程中需要注意一个问题是研究高分子的结构形态,这个可以直接影响产品的整个质量和整体要求。

2 实验部分2.1 实验仪器整个实验过程需要的工具包括单螺杆式注塑机;万能试验机;悬臂梁冲击试验机;切口机;恒温恒湿箱;电子数显千分尺,除这些还有一些小的比较基础的零件。

这些机器都有特定的型号和出厂公司,工作人员在实验时要按照具体的规定购买。

2.2 样品在实验中需要对拉伸的强度进行测量,所以需要一个拉伸屈服强度测试样条,该样条的聚丙烯颗粒样品是按照MA17225的制作方法制作而成,在制作时一定要严格把握好样品的尺寸,否则尺寸出现的一些微小误差很可能会直接影响实验结果,导致最终实验结果出现误差,该样条的长宽高分别为216、12.7、3.2,其中宽度的误差可以上下挑动0.5,需要注意的是这些数据的单位都是毫米。

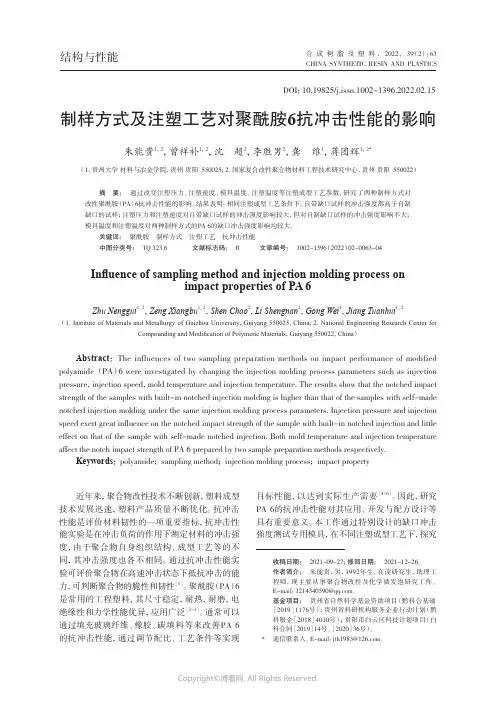

结构与性能CHINA SYNTHETIC RESIN AND PLASTICS合 成 树 脂 及 塑 料 , 2022, 39(2): 63DOI:10.19825/j.issn.1002-1396.2022.02.15近年来,聚合物改性技术不断创新,塑料成型技术发展迅速,塑料产品质量不断优化。

抗冲击性能是评价材料韧性的一项重要指标,抗冲击性能实验是在冲击负荷的作用下测定材料的冲击强度,由于聚合物自身组织结构、成型工艺等的不同,其冲击强度也各不相同。

通过抗冲击性能实验可评价聚合物在高速冲击状态下抵抗冲击的能力,可判断聚合物的脆性和韧性[1]。

聚酰胺(PA)6是常用的工程塑料,其尺寸稳定,耐热,耐磨,电绝缘性和力学性能优异,应用广泛[2-3]。

通常可以通过填充玻璃纤维、橡胶、碳填料等来改善PA 6的抗冲击性能,通过调节配比、工艺条件等实现目标性能,以达到实际生产需要[4-6]。

因此,研究PA 6的抗冲击性能对其应用、开发与配方设计等具有重要意义。

本工作通过特别设计的缺口冲击强度测试专用模具,在不同注塑成型工艺下,探究制样方式及注塑工艺对聚酰胺6抗冲击性能的影响朱能贵1,2,曾祥补1,2,沈 超2,李胜男2,龚 维1,蒋团辉1,2*(1. 贵州大学 材料与冶金学院,贵州 贵阳 550025;2. 国家复合改性聚合物材料工程技术研究中心,贵州 贵阳 550022)摘要:通过改变注塑压力、注塑速度、模具温度、注塑温度等注塑成型工艺参数,研究了两种制样方式对改性聚酰胺(PA)6抗冲击性能的影响。

结果表明:相同注塑成型工艺条件下,自带缺口试样的冲击强度都高于自制缺口的试样;注塑压力和注塑速度对自带缺口试样的冲击强度影响较大,但对自制缺口试样的冲击强度影响不大;模具温度和注塑温度对两种制样方式的PA 6的缺口冲击强度影响均较大。

关键词:聚酰胺 制样方式 注塑工艺 抗冲击性能 中图分类号:TQ 323.6 文献标志码:B 文章编号:1002-1396(2022)02-0063-04Influence of sampling method and injection molding process onimpact properties of PA 6Zhu Nenggui1,2,Zeng Xiangbu1,2,Shen Chao2,Li Shengnan2,Gong Wei1,Jiang Tuanhui1,2(1. Institute of Materials and Metallurgy of Guizhou University,Guiyang 550025,China;2. National Engineering Research Center for Compounding and Modification of Polymeric Materials,Guiyang 550022,China)Abstract:The influences of two sampling preparation methods on impact performance of modified polyamide (PA)6 were investigated by changing the injection molding process parameters such as injection pressure,injection speed,mold temperature and injection temperature. The results show that the notched impact strength of the samples with built-in notched injection molding is higher than that of the samples with self-made notched injection molding under the same injection molding process parameters. Injection pressure and injection speed exert great influence on the notched impact strength of the sample with built-in notched injection and little effect on that of the sample with self-made notched injection. Both mold temperature and injection temperature affect the notch impact strength of PA 6 prepared by two sample preparation methods respectively.Keywords:polyamide; sampling method; injection molding process; impact property收稿日期:2021-09-27;修回日期:2021-12-26。

气相配料比对抗冲聚丙烯结构及性能的影响

吴建;朱树平

【期刊名称】《石化技术与应用》

【年(卷),期】2014(032)004

【摘要】采用红外光谱、凝胶渗透色谱、差示扫描量热等方法研究了气相反应器中气相配料比对抗冲聚丙烯(PP)树脂结构及性能的影响.结果表明,当

n(C2H4)/n(C2H4+ CaH6)由0.390降低至0.375时,抗冲PP的弯曲模量可由835.7 MPa提高至859.4 MPa;当n(H2)/n(C2H4)由0.030提高到0.035时,抗冲PP中橡胶相的重均相对分子质量可由32.2×104降至29.2×104,抗冲PP的23℃悬臂梁缺口冲击强度可由47.8 kJ/m2提高至48.5 kJ/m2.

【总页数】3页(P315-317)

【作者】吴建;朱树平

【作者单位】中国石油兰州化工研究中心,甘肃兰州730060;中国石油兰州石化公司乙烯厂,甘肃兰州730060

【正文语种】中文

【中图分类】TQ325.1+4

【相关文献】

1.新型聚丙烯纤维对抗裂砂浆性能的影响 [J], 潘永洪;伍贤翠;孔海香

2.成核剂对抗冲共聚聚丙烯性能的影响 [J], 姜慧婧;王居兰;田广华

3.β-成核剂对抗冲共聚聚丙烯及其复合材料结晶性能的影响 [J], 李丽;彭蓉;杨世元

4.过氧化物对抗冲共聚聚丙烯结构与性能影响的研究 [J], 陈坤;王俊琪;杨世元;谢昕;巩红光

5.浅议配料比对木纤维/聚丙烯复合材料性能的影响 [J], 彭亮

因版权原因,仅展示原文概要,查看原文内容请购买。

悬臂梁冲击试验悬臂梁冲击试验是对材料的脆性(或韧性)进行测量的另一种试验方法,对使用简支梁冲击试验中冲不断的材料,使用悬臂梁冲击试验就显得特别重要。

1.定义无缺口试样悬臂梁冲击强度:无缺口试样在悬臂梁冲击破坏过程中所吸收的能量与试样原始横截面积之比,用KJ/m2表示;缺口试样悬臂梁冲击强度:指缺口悬臂梁试验在冲击破坏过程中所吸收的能量与试样缺口处原始横截面积之比,用KJ /m2表示;反置缺口式样悬臂梁冲击强度:指反置缺口试样在冲击破坏过程中所吸收的能量与试样缺口处原始横截面积之比,试验时摆锤的冲击方向为缺口的背面,用KJ/m2表示;平行冲击:对层压增强材料在悬臂梁冲击试验中摆锤的冲击方向平行于板材的层压面;完全破坏:指试样断裂成两段或多段;铰链破坏:指断裂的试样由没有刚性的很薄表皮连在一起的一种完全破坏;部分破坏:指除铰链破坏以外的不完全破坏;不破坏:指试样未破坏,只是产生弯曲变形并有应力发白现象产生;2.方法原理由已知能量的摆锤一次冲击垂直固定成悬臂梁的试样,测量试样破坏时所吸收的能量。

摆锤的冲击线与试样的夹具和试样的缺口的中心线相隔一定距离。

3.方法要点1)试验机必须有一套可替换的摆锤,以保证吸收的能量在摆锤容量范围内;若有几个摆锤都能满足要求,应选用能量最大者;不同摆锤所测结果不能相互比较;2)试样可用模具直接经压塑或注塑;也可从压塑或注塑的板材上经机械加工制成。

试样的缺口可在铣床、刨床或专用缺口加工机上加工。

3)对于各向异性材料应分别按平行和垂直板材的某一特征方向分别切取试样。

对于各向异性的材料,通常是冲击平行于板面的试样侧面。

4)试验时首先抬起并锁住摆锤,把试样放在虎钳中并按图1-1的要求夹住试样。

测定缺口试样时,缺口应在摆锤冲击刃的一侧面;然后释放摆锤;记录试样吸收的冲击能并对摩擦损失进行修正。

被测试样可能出现前述4种破坏类型种的某一种或一种以上,此时应把其中属于完全破坏和铰链破坏的测定值用以计算其算术平均值;在出现部分破坏时,如果要求报告此种部分破坏的测定值,应用字母P 表示;对完全不破坏的试样不报告其数值,并用NB 表示。

塑料悬臂梁冲击强度检测能力验证姜侃;陈海玲;张吉雷;郑会保【摘要】为了研制塑料悬臂梁冲击性能能力验证试样,评价实验室塑料悬臂梁冲击性能检测能力,依据GB/T 1843-2008,ISO 180:2000和CNAS(中国合格评定国家认可委员会)所制定的程序文件实施能力验证计划,采用S S≤0.3σ 准则对试样进行均匀性检验,采用t检验法对试样进行稳定性检验,使用Z比分数法判定实验室的检测结果.结果表明:能力验证试样的均匀性和稳定性均符合要求;对32家实验室的悬臂梁冲击性能能力验证结果的统计显示,结果满意的为29家,结果有问题或不满意的为3家.%To develop proficiency testing samples for determination of Izod impact strength of plastics,and to evaluate the testing ability of laboratories for determination of Izod impact strength ofplastics,according to the procedures prescribed in GB/T 1843 -2008,ISO 180:2000 and CNAS (China National Accreditation Service for Conformity Assessment),the uniformity tests for samples were carried out on the basis of the guideline of SS ≤0.3σ,and the stability tests for samples were carried out on the basis of the t -test method.The testing results of laboratories were evaluated by the Z -score method.The results show that:the uniformity and stability of proficiency testing samples were in conformity with the requirements;the statistical analysis on proficiency testing of Izod impact strength of 32 laboratories showed that there were 29 laboratories whose results were satisfied and 3 laboratories whose results were suspected or unsatisfied.【期刊名称】《理化检验-化学分册》【年(卷),期】2017(053)011【总页数】4页(P791-794)【关键词】塑料;悬臂梁冲击强度;能力验证;均匀性;稳定性【作者】姜侃;陈海玲;张吉雷;郑会保【作者单位】中国兵器工业集团第五三研究所,济南 250031;中国兵器工业集团第五三研究所,济南 250031;中国兵器工业集团第五三研究所,济南 250031;中国兵器工业集团第五三研究所,济南 250031【正文语种】中文【中图分类】TQ320.77;TB99悬臂梁冲击强度是实验室条件下研究规定类型试样在规定条件下的抗冲击行为,并以此评价和衡量聚烯烃、聚酯等塑料材料抗冲击性能的重要参数[1]。

关于抗冲击聚苯乙烯(PS-1)悬冲强度测试结果再现性的探讨蔡莲婷;周玉新;何永钊【摘要】抗冲击聚苯乙烯(PS-1)悬臂梁缺口冲击强度测试是与制样、环境状态调节、铣缺口、测试环节等多个要素相关的条件实验,这些实验条件直接影响了冲击强度的再现性.由于仪器等条件限制,月前国内各生产厂家执行的制样及检测标准不完全一致,导致分析结果可比性差.本文注重讨论如何提高PS-1悬臂梁冲击强度测试结果的再现性问题,使不同生产企业的抗冲击聚苯乙烯(PS-1)的悬臂梁冲击强度结果有较好的可比性.%The test of Izod notched impact strength of PS-1 relates to sample preparation, environmental state regulation, milling notch, test course and so on. These test conditions influence the reproducibility of impact strength test results. Because of the restriction of instruments, sampling and test standard adopted by national laboratories is inconsistent, which results in poor comparability of analysis results. In this paper, how to improve the reproducibiltty of Izod impact strength test results of PS-1 was discussed, which can result in preferable comparability of analysis results of Izod impact strength of PS-1 in different production enterprises.【期刊名称】《当代化工》【年(卷),期】2012(041)006【总页数】4页(P555-557,561)【关键词】制样条件;铣缺口;测试条件;相对偏差;正交实验设计;数理统计;再现性【作者】蔡莲婷;周玉新;何永钊【作者单位】中国石化广州分公司,广东广州510700;中国石油抚顺石化公司乙烯化工厂,辽宁抚顺113004;中国石油抚顺石化公司乙烯化工厂,辽宁抚顺113004【正文语种】中文【中图分类】TQ325.2抗冲击聚苯乙烯(全文简写为PS-1)是一种重要的热塑性塑料,国内生产能力约为50万t,分布在全国近10个省份。

中文3100字,2000单词,10500英文字符出处:Sahin S, Yayla P. Effects of processing parameters on the mechanical properties of polypropylene random copolymer[J]. Polymer Testing, 2005, 24(8):1012-1021.本科生毕业设计(论文)外文译文学院专业导师学生学号Effect of testing parameters on the mechanical propertiesofpolypropylene random copolymerSenol Sahin, Pasa Yayla*Mechanical Engineering Department, Engineering Faculty, Kocaeli University, 41040 Kocaeli, Turkey Received 24 January 2005; accepted 2 March 2005 Abstract:The effects of temperature on the impact resistance and hardness of polypropylene random copolymer are studied for a wide range of temperatures. The variations in the mechanical properties with a wide range of strain rates are also evaluated. Finally, the variations in mechanical properties as a function of time after production are studied. Keywords: Polypropylene random copolymer; Mechanical properties; Storage time; Strain rate1. IntroductionThere is a vast literature on processing, morphology, testing and ultraviolet (UV) degradation of polypropylene(PP) [1–3]. However, the literature lacks results on the effects of storage time, outdoor ageing time and the addition of different master batches at different ratios on the mechanical properties. This may be connected to the fact that those investigations are very rigorous and time-consuming. For these reasons, the aim of this paper is to study the influence of testing parameters on the mechanical and thermal properties of injection moulded polypropylene random copolymer(PP-R) samples with different storage times.2. Experiments2.1. MaterialsThe polymer used in this study is a natural colour PP-R, produced by Borealis s. a, trade name RA 130E, and supplied in granular form. The properties of the polymer are given in Table 1.2.2. Specimen preparationA specially designed injection mould was used to produce test samples. The configuration of the moulded test samples is depicted in Fig. 1.All the test samples were injection moulded on a ERATFE 130/95 injection moulding machine. Table 2 shows the specification, set parameters of the machine and the moulding conditions. Unless otherwise mentioned, before testing all the samples were conditioned at room temperature for a period of 30 days.2.3. Tensile testsThe tensile test samples were dumbbell-shaped with dimensions of 156*1014 mm, complying with ISO 527-1 (1993) standard. Tensile tests at various speeds were carried out on the samples. A Z wick Z10, screw-driven universal tensile/compression testing machine equipped with a data acquisition system , was utilised to carry out the tensile tests. Unless otherwise mentioned, a 50 mm/min test speed was used. For strain rate effect investigation, a wide range of speeds from 1 to 1000 mm/min were used. An extensometer was utilised to determine the elastic modules. Tests were carried out at a temperature of 23 8C. From at least threeTable 1Typical properties of polymer used in this studyspecimens for each test series, average values for yield stress(Y), tensile strength(Mpa), elastic modulus(E), strain-to yield(Y), and strain-to-break, 3B, were deduced using the testing program of the controlling computer2.4. Charpy impact testsImpact fracture energy is an important parameter characterizing toughness of materials. Impact values represent the total ability of the material to absorb impact energy, which is composed of two parts: (a) the energy required to break bonds, and (b) the energy consumed in deforming a certain volume of the material. With conventional impact testing equipment (without instrumentation), it is practically impossible to measure separately these two parts. Instrumented impact testing provides valuable information on energies involved in the fracture process, giving individual evaluation of energy for crack initiation and energy required to propagate the crack through the material, which is not possible with the conventional Charpy impact test. In many materials, the formation of the crack at the notch root occurs just prior to or at the peak load. Therefore, it is a reasonable approximation to define the energy up to the peak load as the ‘crack initiation resistance’ [4]. Similarly, post-peak energy is also defined as the ‘crack propagation resistance’ of the material. For many industrial applications, the temperature dependence of impact strength is very interesting and has attracted considerable attention, not only from industry, but also from academic circles [5].The geometry of the Charpy impact test samples was rectangular with dimensions of 80!10!4 mm, conforming to the ISO 179/1eA (2000) standard. A single-edge 458 V-shaped notch (tip radius 0.25 mm, depth 2 mm) was milled in the bars with a fly-cutter using a milling machine.A series of Charpy impact tests were carried out for a wide range of temperatures according to ISO 179/1eU (2000). For setting the test temperature, a mixture of liquid nitrogen and acetone at different ratios was used. The test samples were kept in the cooling medium for at least 30 min before testing.The Charpy impact tests of the notched specimens were conducted at a wide range of temperatures ranging from K 75 to 85 8C, employing a creast Instrumented Charpy Impact Tester (Code 6545/000) at an impact speed of 2.93 m/s. The Charpy impact energy evaluation was based on the linear elastic fracture mechanics (LEFM) analysis to determine impact strength of materials as proposed by Plati and Williams [6]. Charpy impact energy Cv is given bywhere U is the absorbed energy by the sample, B and D are the width and thickness of the samples, respectively, and F is the sample geometry-dependent calibration factor. Bearing in mind the advantages of instrumented Charpy impact tests, both the crack initiation energy, which is consumed up to the maximum force, and the total impact energy, which is the conventional Charpy impact energy, dissipated during whole impact process, were calculated.2.5. Hardness testHardness is defined as the resistance of a material to deformation, particularly permanent deformation,Table 2Specification and set parameters of the injection moulding machine used in this studyindentation or scratching. In general, the most widely used methods to measure hardness are Rockwell and Shore. The Rockwell method is usually used for harder materials , The Shore (or Durometer) method, regulated by ISO 868 (2003), has scales for both softer rubbers and plastics.In this work, Shore D hardness tests were performed at different temperatures using a Z wick 3100 Shore D Durometer hardness tester. All results are the average of three measurements.3. Results and discussion3.1. Tensile testsThe tensile behaviour and ultimate mechanical properties are very importantcharacteristics of semi-crystalline polymers. These macroscopic properties are known to very closely depend on the strain rate, thus an understanding of strain rate dependence of their deformation behaviour is important for encouraging their wide use in engineering and structural applications [7]. Strain rate has a complicated and dramatic effect on materials deformation processes because the energy expended during plastic deformation is largely dissipated as heat. This process was observed to be more prominent at higher loading rates that are associated with adiabatic drawing than during lower loading rates where isothermal drawing occurred [8]. In general, three stages of plastic deformation were suggested in tensile tests of semicrystalline polymers [9,10]: (1) pre-neck deformation of micro-spherulitic structure that proceeds in the wholesample, (2) large deformation in the neck, which transforms the micro-spherulitic structure to fibrillar structure, and lastly (3) post-neck deformation of the fibrillar structure. In general, in the neck, the polymeric material softens drastically for a very short period, which is associated with a decrease of plastic modulus. However, as the neck develops and exceeds a limiting zone, the morphology changes to that of a fibrillar structure with increase in plastic modulus, termed as strain-hardening.Typical stress–strain curves of the PP-R samples tested at different crosshead speeds are given in Fig. 2. The test samples were not broken at 600% elongation at crosshead speeds up to 25 mm/min, but for the higher test speeds, the samples were ruptured at lower % elongation and had a value of about 38% at crosshead speed of 1000 mm/min. At lower test speeds, the PP-R samples formed a very marked and stable neck with a wide stress-whitening zone; as the test proceeded, the necked zone extended throughout the whole test gauge to the point of rupture at very large deformation values. At this stage, due to strain-hardening there was a gradual increase in the stress as the test proceeded up to rupture. As the test speed increased, the stress-whitening zone narrowed and, at very high crosshead speeds, the remainder of the gauge length was not plastically deformed.The effec ts of cross head speeds on the variations in‘yield stress’, ‘yield strain’ and ‘elastic modulus’ are given in Figs. 3–5, respectively. The behaviour of these properties with log(crosshead speed) was linear and suggested that, like other semi-crystalline polymers, the mechanical properties of PP-R is also very strain rate-sensitive. It has been pointed out that the slope in these figures might vary from one semi-crystalline material to another and could be a good indication to define the strain rate dependency of material [11].3.2. Impact testsThe effect of temperature on the variation of force–time signal obtained from instrumented Charpy impact tests were depicted in Fig. 6, showing remarkable change in nature of the force–time signal as the temperature changes. Fig. 6 shows that up to about 25℃, almost all of the energy isconsumed at crack initiation stage, and the energy consumed during crack propagation stage becomes visible for temperatures above 50℃. At temperatures above 75℃, the specimens were partly fractured, while below this temperature they were completely fractured.The variation of Charpy impact energy with temperature is given in Fig. 7, giving relatively constant impact strength between K75 and 0℃.and then the impact strength rapidly increases with increasing temperature. After 90℃, it becomes impossible to break the sample into two. The phenomenon of characteristic brittle–ductile transition starts after 0℃, indicating the fact that the impact strength deteriorates dramatically as the temperature approaches from higher values to 0℃. These results are practically important from two points of view. First, in practical applications, pipes made from PP-R could be used down to water freezing temperatures, and secondly, transportation and installation of the pipe at lower temperatures are possible. Thus, these two important points require particularattention as the pipes get rather fracture-sensitive at lower temperatures.The Charpy crack initiation and crack propagation fracture resistance evaluation are given in Fig. 8. The figure shows that up to the lower transition temperature of 0℃, about 90% of impact energy is consumed to initiate fracture, but the trend changes as the test temperature increases,implying that crack propagation energy is higher than the crack initiation energies for temperatures above 50℃. For higher temperatures, the crack initiation consumes only about 35% of the total impact energy.4. ConclusionsThis paper outlines experimental results from tensile tests at different crosshead speeds and instrumented Charpy impact tests on notched samples of polypropylene random copolymer over a wide range of temperatures. Special attention was focused on the changes in the tensile properties over a long period of storage after injection. Regarding the effects of on the mechanical properties of polypropylene random copolymer, the following conclusions could be drawn:(1) The tensile properties of the materials are fairly rate sensitive. The properties such as the yield stress, elastic modulus and yield strain of the material increase with strain rate. The variations of these properties with log (crosshead speed) were linear and it is envisaged that the slope in these figures might very from one semi-crystalline material to another and could be a good indicator to define the strain rate dependency of semi-crystalline polymeric materials.(2) The Charpy impact crack initiation and propagation resistances of the material are rather sensitive to the test temperature. For lower temperatures of up to 0℃, relativelybrittle behaviour has been observed. The effect of an increase in temperature becomes visible after 0 and above 85℃the material becomes too ductile to break.(3) The Shore D hardness of the natural PP-R material is diminished with increasing temperature. The decrease in hardness becomes more remarkable after the lower transition temperature of 0℃.5 References[1] E.P. Moore (Ed.), Polypropylene Handbook: Polymerisation, Characterisation, Properties, Applications, Hanser/Gardner, New York, 1996, p. 113.[2] J. Karger-Kocsis (Ed.), Polypropylene—An A–Z Reference, Kluwer, Dordrecht, 1999.[3] J. Karger-Kocsis, Polypropylene: Structure and Morphology, Chapman & Hall, London, 1995.[4] M.P. Manahan Sr., C.A. Cruz Jr., H.E. Yohn, Instrumented impact testing of plastics in limitation of test methods for plastics, in: J.S. Peraro (Ed.), ASTM STP 1390, American Society for Testing and Materials, West Conshohocken, PA, 2000.[5] P.S. Leevers, P. Yayla, M.A. Wheel, Charpy and dynamic fracture testing for rapid crack propagation in polyethylene pipe, Plast. Rubber Compos. Process. Appl. 17 (1992) 247–253.[6] E. Plati, J.G. Williams, Determination of the fracture parameters of polymers in impacts, Polym. Eng. Sci. 15 (1975) 470–477.[7] R. Gensler, C.J.G. Plummer, C. Grein, H.-H. Kausch, Influence of the loading rate on the fracture resistance of isotactic polypropylene and impact modified isotactic polypropylene, Polymer 41 (10) (2000) 3809–3819.[8] A. Dasari, R.D.K. Misra, On the strain rate sensitivity of high density polyethylene and polypropylene, Mater. Sci. Eng. A 358 (2003) 357–371.[9] A.J. Peterlin, Molecular model of drawing polyethylene and polypropylene, J. Mater. Sci. 6 (6) (1971) 490.[10] A. Dasari, S.J. Duncan, R.D.K. Misra, Atomic force microscopy of scratch damage in polypropylene, Mater. Sci. Technol. 18 (10) (2002) 1227–1234.[11] J. Fiebig, M. Gahleitner, C. Paulik, J. Wolfschwenger, Ageing of polypropylene: processes and consequences, Polym. Test. 18 (1999) 257–266.1无规共聚聚丙烯在不同试验参数下对其机械性能的影响Senol Sahin, Pasa Yayla*(科贾埃利大学工学系机械工程系,科贾埃利 41040 土耳其日期2005年1月24日,接受2005年3月2日)摘要:研究一定温度范围内温度对无规共聚聚丙烯(PP-R)的抗冲击性能和硬度的影响;研究了材料的拉伸性能与应变率的关系,在很宽的应变率范围内其多项力学性能受应变率的影响较大;最后研究了PP-R成型后的储存时间与其机械性能的关系。

制样温度对聚丙烯力学性能的影响马兰萍制样温度对聚丙烯力学性能的影响摘要针对聚丙烯产品出现的力学性能达不到优等品技术要求的问题,在查找原因过程中发现:注塑机温度波动、模具温控箱跳闸引起的模具温度变化都会造成产品的力学性能的规律性变化,通过比照试验,发现仪器注塑温度高时测得的试样拉伸屈服强度、悬臂梁冲击强度、挠曲模量均会比实际值低。

而模具温度达不到60℃时制样,测得的试样拉伸屈服强度、挠曲模量均会比实际值低,悬臂梁冲击强度会比实际值高。

关键词注塑温度模具温度结晶度拉伸屈服强度悬臂梁冲击强度挠曲模量1 引言我厂聚丙烯装置生产的产品,近来出现产品力学性能达不到优等品技术要求的现象,针对这一问题我们着重从制备过程查找原因,发现仪器注塑温度有时会超温,模具温控箱有不定时跳闸现象。

影响塑料试验结果的因素很多,有它内在的原因〔如塑料本身的分子量大小、分布结构及取向程度,内部缺陷等〕,也有它外在的原因〔如制备过程、放置过程、测试过程等〕。

注塑制品的质量包括两方面的内容,即内部质量〔性质质量〕和外部质量〔表观质量〕,内部质量是指与聚合物结构形态有关的结晶、取向、变形、翘曲及内应力分布,与力学性质有关的拉伸、弯曲、冲击和变形等,总之,制品的内部质量将直接影响到制品使用性能,影响制品的使用范围和应用领域,欲提高制品使用性能,除在高分子的材料领域里综合一些新材料外,必须在加工过程中注意研究高分子的结构形态并加以解决。

2 实验部分单螺杆式注塑机: METAL FLUID公司MF100型万能试验机: INSTRON公司4465型悬臂梁冲击试验机: CEAST公司RISIL-50型切口机: CEAST公司6828-000型恒温恒湿箱:上海爱斯佩克公司LHU-213型电子数显千分尺:上海量具刃具厂拉伸屈服强度测试样条:聚丙烯颗粒样品按MA17225方法注塑制得。

样条尺寸为:长216mm±;厚悬臂梁冲击强度测试样条:聚丙烯颗粒样品按MA17225方法注塑制得的符合ASTM D 638中Ⅰ型拉伸样条的中间狭长部分截取,用切口机冲缺口。