BOSENSE气动离合器和制动器样本

- 格式:pdf

- 大小:1.82 MB

- 文档页数:28

气动离合器标准气动离合器是一种利用气体动力来实现离合功能的一种设备。

它由主离合器和辅助离合器组成,广泛应用于工程机械、汽车、船舶等领域。

为了确保气动离合器的安全性和可靠性,在使用过程中需要遵守一系列相关的标准,并遵循相关的技术要求。

1. 国家标准GB/T 12847:气动离合器该标准规定了气动离合器的术语和定义、尺寸和连接尺寸、性能要求、试验方法、检验规则和标志、使用说明书等内容,涵盖了气动离合器的各个方面。

2. 行业标准JB/T 9196:冶金设备用气动离合器技术条件该标准针对冶金设备使用的气动离合器,对其技术要求进行了详细规定,包括离合器的型号和规格、传动扭矩、尺寸和连接尺寸、工作压力和温度范围、试验方法等。

3. 企业标准某某公司Q/QMXX:气动离合器技术标准各个气动离合器生产企业会根据自己的研发和生产经验,制定企业标准,包括产品的质量要求、技术参数、生产工艺和检验方法等内容。

企业标准通常在国家和行业标准的基础上进行补充和细化。

4. 设计规范ASME PTC19.1-2005:离合器和制动器性能检定规范该设计规范主要针对机械设备上的离合器和制动器,提供了离合器和制动器性能的检定方法,包括功率损失的测量、动态响应性能的测量等内容,对于气动离合器的设计和优化提供了参考依据。

5. 安全规范ISO 4414:气动动力系统的一般规则和安全要求该国际标准规定了气动动力系统的一般要求和安全要求,包括系统的设计和安装、操作和维护、标志和警告等内容。

在使用气动离合器时,需要遵循ISO 4414的要求,确保系统的安全性。

总之,气动离合器的标准包括国家标准、行业标准、企业标准、设计规范和安全规范,这些标准覆盖了气动离合器的设计、制造、安装、检验和使用等方面。

遵守这些标准,可以确保气动离合器的质量和性能,提高工作的安全可靠性。

定义科技名词定义中文名称:空压离合器英文名称:air actuated clutch定义1:主、从动部分在同轴线上传递动力或运动时,具有接合或分离功能的装置。

应用学科:机械工程(一级学科);机械零件(二级学科);离合器(三级学科)定义2:在主传动装置中,使主、从动轴结合或脱离的传动组件。

应用学科:水产学(一级学科);渔业船舶及渔业机械(二级学科)气动离合器相关介绍工作原理通过按压一个旋转的东西让另一个本来停止的东西旋转起来的物体。

如:汽车的场合,起动时要先靠离合器的传导来使引擎旋转起来。

气动离合器:气动离合器顾名思义是靠空压来连接,靠复归弹簧来放开。

气动离合器在各种业界被以各种方法使用着,和其他的离合器相比有很多的利点,即使是相同机能也持有很优越的性能。

与磁粉离合器的比较气动式产品和电磁式产品的性能优势比较1.气动产品工作中的反应速度快出30%2.气动传输的动转矩大出40%3.摩擦板的使用寿命长出6倍4.气动产品仅消耗电磁产品60%的能量5.散热能力高出30%常用型号和功能介绍空压离合制动器与一般的电磁式相比,不会发生因放热效果过高而减弱转矩及产生电气火花。

能确保大工作量的完成。

并且,转矩控制的范围广,最适合于张力控制器。

由空压压力作动使得起动柔和,停止动作平稳,热能回收简单。

通过控制器的操作,调整,平稳进行连接,充分发挥制动性能。

由于构造简单,实现长期使用化,容易维修。

CSMP<微型〉把CSCP(标准型)小型化,省资源,省空间微型产品。

●微型空压离合器把标准型空压离合器(CSCP)所有特长吸取进来,再进一步轻量化,小型化。

是所有机械小型化设计之必需制品。

CSCP<标准型〉适合过酷使用的耐久性和不产生电气火花的信赖设计。

●标准型空压离合器是空压离合器的代表。

由空气压在广范围内调整转矩。

散热效果好,摩擦板厚,适用于高频度,高负荷,连续滑动等过酷的使用条件。

调整空气压使起动柔和。

也可以作为扭力限制器来使用CDP<双面型〉安装简单的双面型。

气动离合器配件名称大全

以下是一些气动离合器配件的常见名称:

1. 气动离合器活塞

2. 气动离合器壳体

3. 气动离合器压盘

4. 气动离合器摩擦片

5. 气动离合器压盘螺钉

6. 气动离合器弹簧

7. 气动离合器离合轴

8. 气动离合器离合器盖

9. 气动离合器双盘离合器片

10. 气动离合器压盖螺钉

11. 气动离合器调整螺纹

12. 气动离合器内齿

13. 气动离合器传感器

14. 气动离合器密封圈

15. 气动离合器气缸体

16. 气动离合器控制阀

17. 气动离合器释放轴

18. 气动离合器弹簧压板

19. 气动离合器减震垫

这只是一部分配件名称的列表,实际上还有更多的配件名称,根据具体的离合器型号和制造商可能会有所不同。

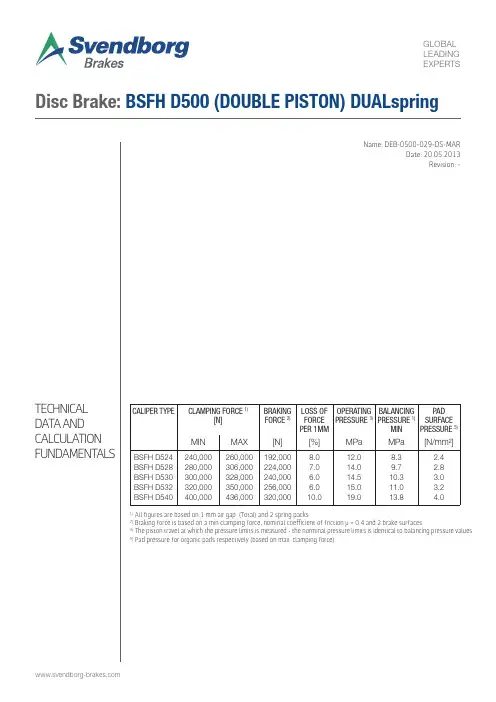

TECHNICAL DA T A AND CALCULA TION FUNDAMENT ALSName: DEB-0500-029-DS-MARDate: 20.05.2013Revision: -Disc Brake: BSFH D500 (DOUBLE PISTON) DUALspring1) All figures are based on 1 mm air gap (Total) and 2 spring packs2) Braking force is based on a min clamping force, nominal coefficient of friction μ = 0.4 and 2 brake surfaces.3)The piston travel at which the pressure limits is measured - the norminal pressure limits is identical to balancing pressure values 5)Pad pressure for organic pads respectively (based on max. clamping force)CALIPER TYPECLAMPING FORCE 1)[N]BRAKING FORCE 2)LOSS OF FORCE PER 1MM OPERATING PRESSURE 3)BALANCING PRESSURE 1)MIN PADSURFACE PRESSURE 5)MINMAX[N][%]MPaMPa[N/mm²]BSFH D524BSFH D528BSFH D530BSFH D532 BSFH D540240,000280,000300,000320,000 400,000260,000306,000328,000350,000 436,000192,000224,000240,000256,000 320,0008.07.06.06.0 10.012.014.014.515.0 19.08.39.710.311.0 13.82.42.83.03.24.0SpecificationThe braking torque M B is calculated from following formula where:a is the number of brakes acting on the discF B is the braking force according to table above [N] or calculated from formula D O is the brake disc outer diameter [m]The actual braking torque may vary depending on adjustment of brake and friction coefficient.M B = a · F B ·[Nm](D 0 - 0,2)2DUALSPRING Weight of caliper without bracket: Approx. 780 kg Overall dimensions without base plate: 698 x 530 x 533 (+C) mm Pad width: 200 mm Pad area: (organic) 110,000 mm 2 (*) Max. wear of pad: (organic) 10 mm (*)Nominal coefficient of friction: μ = 0.4 Total piston area - each caliper half: 2 x 145 cm 2 = 290 cm 2 Total piston area - each caliper: 4 x 145 cm 2 = 580 cm 2 Volume for each caliper at 1 mm stroke: 60 cm 3 Volume for each caliper at 3 mm stroke: 180 cm 3 Actuating time (guide value for calculation): 0.4sec Pressure connection/P-port: G3/8, ISO 288Air breathing connection/A-port: G3/8, ISO 288 Drain connection/L-port: G1/4, ISO 288 Recommended pipe size: 16/12 mm Operating temperature range - general from -20°C to +70°C(For temperatures outside this range contact Svendborg Brakes)(C = Brake disc thickness)(*) On each brake pad.BRAKING TORQUECALCULATION FUNDAMENTALSF B = F C · 2 · µDisc Brake: BSFH D500 (DOUBLE PISTON) DUALspring。

P-1723-18-SV 5/16Printed in USASvendborg Brakes' comprehensive product range makes us your answer to one-stop brake shopping and supply. Our complete braking solutions include extensive design services, market-leading products, a quality-focused supply chain and unmatched after salesservices.Hydraulic Brakes - FailsafeSpring applied/hydraulic released failsafe disc brakes commonly used for parking or emergency stopping in case of power failure. Brake model and spring pack selection sized to suit specific application and customerrequirements. Brakes are available in either Dualspring or Monospring design and in standard finish or a corrosion resistant finish.Hydraulic Brakes - ActiveActive brakes are hydraulic applied/spring released discbrakes typically used for stopping, tensioning or holding purpose. The hydraulic pressure ensures a constant braking torque throughout the life of the pads. Brakes are available in either Dualspring or Monospring design and in standard finish or a corrosion resistant finish.Hydraulic Brakes - CustomApplication specific brakes such as Mill Brakes, Drawworks Brakes and Elevator Brakes are available to meet different customer and application requirements.Depending on the application, these brakes are offered with steel yokes and different types of certifications including DNV , ABS and API. Brakes are available in a standard finish or a corrosion resistant finish.Hydraulic Power Units -On/Off / 2 Stage Braking / SOBO ® iQOptional controlled braking sequence for use with Svendborg calipers.Controlled braking is used to prevent a hard/abrupt braking sequence. HPU is available with cabinet / enclosure and various options and accessories.Hydraulic Power Units - Application SpecificSpecific application HPU's forConveyors, Mills, Drawworks, Hoists, Cranes, Elevators etc. Each design is engineered and tested in cooperation with our customers, so we make sure all requirements are met.SOBO ® iQ ControllerSOBO ® iQ is a revolutionary soft braking technology for a variety of applications including Conveyors, Cranes, Hoists, Water Gates,Bridges, Barge Unloaders etc. If youneed safe and consistent stopping times independent of load or if you require to stop within a certain distance SOBO ® iQ is the answer.Brake DiscsSvendborg Brakes can supply brake discs according toapplication requirements. Standard sizes as well as custom sizes and special designs such as split discs are available.R&D & Test Center Extensive testing in our full scale test center is second to none and your guarantee for top quality. We have a strong tradition for R&D investments and an invaluable accumulated know-how. Our focus on innovation and testing is core to our company.Service OrganizationSvendborg Brakes field service technicians ensure correct adjustment of brakes, hydraulics and SOBO ®. A preventative maintenance visit minimizes downtime. A detailed service report including recommendations is always provided.Global FootprintOur global organization is always close to our customers. This means we can quickly be on site even in the most remote locations, which minimizes the downtime for our customers.OEM Spares & AccessoriesOEM spare parts are worth far more than compromising on price, quality and safety. We guarantee that all our products meet orexceed local regulations and safety standards.Engineering Support Our engineering team ensures your braking system is sized right for your project. We include our hydraulic, mechanical and electrical engineering team on each project. Trust is what we deliver to our customers. If anyone can do it,we can.Customer Service & Application SupportNorth America: +1 303 285 1271***********************South America: +56 23 203 9150***********************INDUSTRIALGet ConnectedThe Altra Newsroom makes it quick and easy for you to get the news you need when you need it. From new literature releases to trade show schedules, the news is at your fingertips 24 hours a day./newsroomEverything AltraFrom the Altra homepage you can connect to all of our brands, and visit our market portals to find solutions for yourspecific needs.Literature PortalConveniently download and request Altra's latest catalogs, brochures, service manuals and more on the Literature Portal. Find thelatest product information to meet your power transmission requirements by going to any Altra brand website and clicking onthe Literature tab.Like us on Facebook and follow us on Twitter for up to the minute news you can use. Link with us on LinkedIn, follow us on Google+, and find us on YouTube to watch training videos and application movies.Altra Industrial Motion The Power Of ExperienceAmeridrives Couplings Ameridrives Power Transmission Bauer Gear Motor Bibby Turboflex Boston GearDelroyd Worm Gear Formsprag Clutch Guardian Couplings Huco Dynatork Industrial Clutch Inertia DynamicsKilian Manufacturing Lamiflex Couplings Marland Clutch Matrix International Nuttall Gear Stieber ClutchSvendborg Brakes TB Wood’s Twiflex Limited Warner Electric Warner Linear Wichita ClutchOnline Resources。