罗克韦尔自动化控制系统介绍

- 格式:ppt

- 大小:29.44 MB

- 文档页数:62

罗克韦尔plc教程罗克韦尔PLC(Programmable Logic Controller)是一种智能化控制设备,用于自动化控制系统中的物理过程。

它主要用于工业领域,可以对各种机器和设备进行编程控制,以实现自动化生产和过程控制。

本文将为您介绍罗克韦尔PLC的基本原理、编程语言和应用领域。

罗克韦尔PLC的基本原理是通过运算逻辑控制器(CPU)、输入/输出模块(I/O)和编程软件来实现自动化系统的控制。

PLC的CPU是核心部件,负责接收和处理输入信号,根据预设的程序逻辑进行运算和判断,然后输出控制信号。

输入模块负责接收各种传感器信号,例如温度、压力和流量等,而输出模块则负责控制执行器或执行装置,例如电机、阀门和传动装置等。

罗克韦尔PLC使用一种叫做Ladder Diagram(梯形图)的编程语言。

梯形图是模拟继电器控制电路的图形化表示方法,它使用电路图中的接点、线圈和控制器等元素,通过逻辑运算和顺序控制来实现自动化控制。

在梯形图中,输入接点表示输入信号,输出线圈表示输出信号,而控制器则表示逻辑运算和条件判断。

罗克韦尔PLC的编程软件通常是基于图形界面的,用户可以通过拖拽和连接元件来编写和调试程序。

编程软件提供了丰富的函数和指令集,例如逻辑运算、数学运算、定时器和计数器等,使得编写程序更加方便和灵活。

此外,编程软件还提供了在线监视和调试的功能,可以实时查看和修改程序的运行状态。

罗克韦尔PLC广泛应用于各个领域的自动化控制系统中。

在工业生产中,PLC可以用于控制生产线的自动化操作,例如输送线、装配机器和包装机等。

在电力系统中,PLC可以用于控制发电机和变电站设备,实现电力系统的安全运行。

在交通系统中,PLC可以用于控制信号灯、闸门和电梯等,提高交通流量和安全性。

尽管罗克韦尔PLC具有很多优点,例如可靠性高、适应性强和易于编程,但也存在一些挑战和限制。

首先,PLC的成本较高,不适合小规模和低成本的控制系统。

Controllogix介绍自从罗克韦尔自动化1987年进入中国以来,其产品在制造加工业得到了广泛的应用。

罗克韦尔公司在自控领域拥有许多著名的品牌,AB(AllenBradley)是其品牌之一,包括五十万种以上的产品,并提供工业控制和系统解决方案。

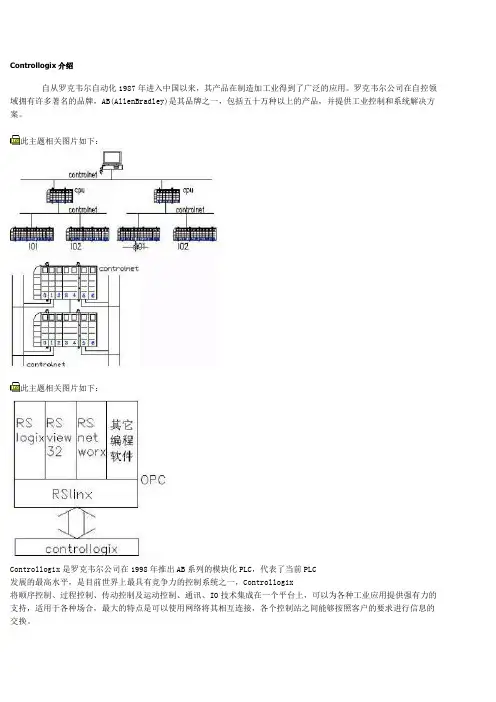

此主题相关图片如下:此主题相关图片如下:Controllogix是罗克韦尔公司在1998年推出AB系列的模块化PLC,代表了当前PLC发展的最高水平,是目前世界上最具有竞争力的控制系统之一,Controllogix将顺序控制、过程控制、传动控制及运动控制、通讯、IO技术集成在一个平台上,可以为各种工业应用提供强有力的支持,适用于各种场合,最大的特点是可以使用网络将其相互连接,各个控制站之间能够按照客户的要求进行信息的交换。

Controllogix采用框架式结构,所有得模块都插在框架的背板上,背板支持模块的热插拔。

下图(见附件一)展示了典型的网络架构:从图中可以看出,Controllogix的网络能力可以使控制器的IO端子不必放在本地,而是可以放在工艺现场,cpu框架可以通过总线(controlnet)来完成信息的传递,有点像传统的dcs结构,这种方式大大的拓展了Controllogix的应用范围。

在上图的基础上可以方便的构建成AB典型三层结构的网络,这种网络可以把所有的系统设备有机地结合为一个整体,成为当前的ERP系统中的一个组成部分。

鉴于工业现场的高可靠性要求,Controllogix可以提供完善的控制器冗余功能,采用热备的方式构建控制器,两个框架采用完全相同的配置,之间使用同步电缆连接,不仅控制器可以采用热备,通讯网络也可以采用相似的方式进行热备,如下图(见附件二):除以上的部分可以热备外,控制器的电源也可以进行热备,这样大大提高了控制器的运行的可靠性。

在组建通讯网络时,Ethernet/ip、controlnet是比较常用的通讯协议,除此之外,Controllogix还支持devicenet、DH+、RS232、DH485等。

罗克韦尔自动化能源管理系统概述协助用户优化其电力及动力的运用,这就是我们的使命!罗克韦尔自动化在推进用户优化其制造才干、提高消费效率,以及增强牢靠性方面,处于全球抢先位置。

我们提供超值的信息和自动化处置方案,用于监视、剖析和控制动力的运用,从而降低能耗本钱。

这一优化方案的重要组成局部就在于从车间级到整个企业,了解和管理动力的供应与消耗。

罗克韦尔自动化为您提供动力计量、电能控制、供暖、通风、空调、制冷以及车间辅佐设备的自动化控制处置方案。

复杂地说,您可以从罗克韦尔自动化获取一切动力系统需求的处置方案,包括我们丰厚阅历和出色的功用。

处置方案* 动力计量* 电能及控制* 供暖、通风、空调及制冷* 工厂效能明天,制造业的竞争越来越剧烈,如何及时地在预算内完成消费目的,同时又能将运作本钱降到最低,曾经成为具有应战性的义务。

为了完成这一目的,与您的协作同伴并肩作战是至关重要的,它必需具有跨行业的运用项目设计以及系统实施阅历―能提供您所需的处置方案、资源和技术,从而为您在业内的竞争赢得时间。

片面的产品、丰厚的知识和工程阅历十分重要,同时还需可以高效地任务,有凝聚力的组织架构,以及弱小的咨询才干。

当您与罗克韦尔自动化电力和动力管理处置方案树立业务同伴关系后,您可以取得专家团队的支持,他们结合了400余名工程师的阅历,精心为您提供全方位的处置方案。

全方位处置方案注重效果的工程归根结底,用户自动化项目的成功与否,取决于技术实力和系统集成商团队的管理技巧。

经过与罗克韦尔自动化协作,您可以取得项目管理和系统集成的专业阅历,这样有助于您取得商业成功。

罗克韦尔自动化团队包括项目主管、运用工程师以及系统和硬件设计师。

简言之,您将为您的项目和系统取得一致的专家级建议。

为您的系统指定一名阅历丰厚的项目主管,由他担任一切罗克韦尔自动化的任务,并授权其停止实施。

因此,项目主管是独一正式的联络人。

同时,他还担任协调项目团队的一切活动,包括管理推销授权、控制柜装配和质量控制,从而保证您的项目可以准时完工。

课程安排第 1 天• 定义运动控制• 识别运动控制系统部件及功能 • 应用基本运动控制概念 • 识别数字伺服运动控制器的部件 •识别伺服驱动器的功能第 2 天• 识别交流和直流伺服电机的功能 • 识别反馈元件的功能 • 识别软件伺服环的功能 • 应用运动配置文件• 应用电子齿轮和凸轮运动曲线 •运动控制基础知识:集成练习课程编号:CCN130课程目的完成本课程后,您应该能够说明对所有罗克韦尔自动化运动控制系统通用的基本运动控制概念。

本课程旨在让您了解运动控制的概念、术语、功能及应用。

此外,您还将使用每节课讨论的概念和原理来了解运动控制应用项目如何工作。

本课程将帮助您建立牢固的必要基础,以便今后学习运动控制系统的维护和编程所需的技能。

本课程不针对运动控制系统设计或特定运动控制软件编程。

如果您要寻求这些方面的培训,应参加相关的罗克韦尔自动化培训课程,参加之前请确保您已符合这些课程的课前要求。

运动控制运动控制基础知识课程描述动力、控制与信息解决方案GMST10-PP247B-ZH-E版权所有 ©2010 罗克韦尔自动化有限公司。

保留所有权利。

美国印刷。

适合参加者为了工作而需要了解基本运动控制概念的人员,或者为了参加其他运动控制课程而需要学习这些概念以满足课前条件的人员应参加本课程。

课前要求参加本课程不需要满足任何特定课前要求。

但是, 以下几点将很有帮助:• 基本电学、电子学和计算机概念方面的背景 •控制器操作的基本知识技术要求罗克韦尔自动化将提供学员在课堂内使用的所有 技术。

学员在参加本课程时不必具备任何技术。

动手练习在整个课程期间,您将有机会通过各种涉及罗克韦尔自动化运动控制硬件的动手练习来实践所学的技能。

您还将有机会通过完成集成练习来组合和实践多项 关键技能。

学员资料为增强和促进您的学习体验,课程包中提供了以 下资料:•学员手册,其中包含主题列表和练习。

您将使用此手册来跟随讲课内容、记笔记和完成练习。

Lllll 附件一:罗克韦尔自动化智能MCC介绍目录第一部分罗克韦尔智能MCC优势第二部分罗克韦尔智能MCC技术特点1、内置DeviceNet通讯电缆2、木线支撑3、完全抽屉式和省力的抽出、插入操作机构4、抽屉式回路种类齐全5、智能电机保护和控制元件6、可提供专业的测试工具和软件7、可提供专业的操作软件8、ArcShield防弧结构第三部分罗克韦尔智能MCC与常规MCC的制造成本对比第四部分首钢迁钢罗克韦尔智能MCC使用报告第五部分罗克韦尔智能M C C与其它公司产品比较第六部分罗克韦尔智能M C C国内部分业绩第一部分罗克韦尔智能M C C优势1.设计方便简单,大量减少设计院设计时间及工作量1)基本不用考虑太多二次回路设计和外部控制电缆设计;2)专业设计软件设计配合设计,不需考虑具体器件型号规格及其一次回路元器件之间的配合;2.安装调试简单省时,可靠性高1)MCC基本没有控制电缆,因此可以减少施工量和80%控制电缆和电缆桥架数量。

2)不需要对系统进行打点,可以大大减少调试时间。

3)不需要PLC I/O端子柜及中间继电器柜,可以大大减少故障点。

4)防护等级高与普通低压柜及普通MCC柜,能过适应恶劣环境。

3.运行1)智能器件的超强保护及预报警功能,确保系统运行正常;2)不需要PLC I/O端子及中间继电器及大量硬接线,大大减少故障隐患,保证安全运行。

4.维修1)智能器件的应用使系统维护变被动维护或定期检修为主动维护和预防性维护;2)所有元器件正面安装,便于维护;3)智能器件的更换不需要重新设置(只有DeviceNet有该功能)。

5.管理及控制一体化,实现整体信息化1)设备网(DEVICE NET, IEC及国家标准)为实时网络,可以实时上传数据。

2)远程实时监控MCC运行。

通过三网集成,无缝连接(Net Links)技术将设备层信息集成至车间,工厂直至企业层。

3)为生产执行系统(MES),电脑化维修管理系统(CMMS),企业资产管理(EAM)及企业资源管理(ERP) 系统提供极其便利的管理,监控一体化信息平台。

罗克韦尔自动化PLC及运用研究罗克韦尔自动化软硬件在现阶段的发展中得到了广泛的应用,在各个行业均有涉猎,在实践中应用罗克韦尔自动化PLC可以提升其系统的稳定性、其相关操作也具有一定的便捷性,在实践中得到了技术人员的普遍认可,对此本文主要对罗克韦尔自动化PLC及运用进行了简单的探究。

标签:罗克韦尔自动化;PLC;运用罗克韦尔自动化的ControlLogix 控制系统,主要就是基于PLC 以及DCS 融合的模式构建形成的一种集成控制模式,在实践中有效的转变了传统模式的PLC弊端,可以通过实时控制、数据采集以及系统组态目标开发等相关内容在实践中对于过程进行系统的控制、顺序控制以及传动系统的控制,可以讲将通讯网进行系统的集成,将其构建在一个相对较为统一的平台模式之上,通过系统的实际开发与应用,有效的降低其实际的维护成本,可以提升对于整个过程的控制能力。

对此本文主要基于某水泥项目中罗克韦尔自动化PLC的运用为例,探究了罗克韦尔自动化PLC在实践中的作用。

一、罗克韦尔自动化PLC 控制系统在实践中的具体应用罗克韦尔的软件在应用过程中,主要可以划分为上位软件、下位软件以及接口驱动软件等相关内容,其中其上位人机界面软件普遍应用的就是RSView SE 套装软件,在一线中应用的为 4.0 版本,在二线中应用为 5.0 版本;其下位组态编程软件主要应用的就是RSLogix 5000 16 版本软件;接口驱动软件应用为为RSLinx;其网络配置软件主要应用RSNetworx for ContolNet。

主要应用的硬件为罗克韦尔的ControlLogix 平台的CPU 以及IO 模块。

二、网络介绍及应用1.控制以及信息网络在实践中基于水泥项目的相关工艺流程,其一线项目主要可以一线项目与二线项目两种模式,在实践中可以通过以下方式对于项目生产进行网描述:(1)EtherNet/IP.此种网络在实践中主要就是通过与计算机的人机界面软件RSView SE开展以太网通讯方式进行各种数据的交换,进而实现对实际现场设备的有效的人机监控与管理。

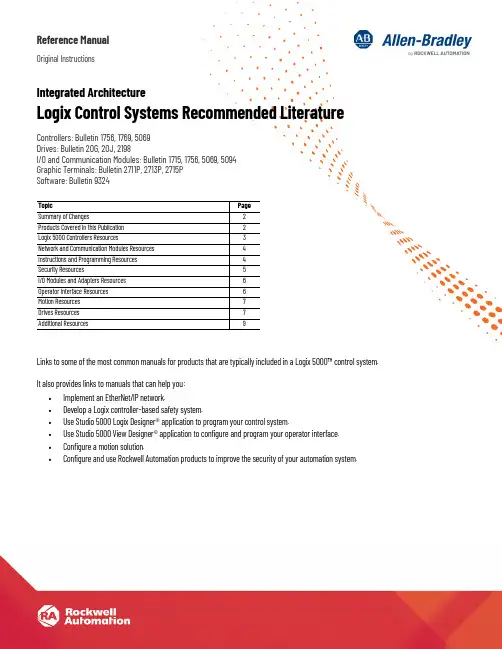

Reference ManualOriginal InstructionsIntegrated ArchitectureLogix Control Systems Recommended Literature Controllers: Bulletin 1756, 1769, 5069Drives: Bulletin 20G, 20J, 2198I/O and Communication Modules: Bulletin 1715, 1756, 5069, 5094Graphic Terminals: Bulletin 2711P, 2713P, 2715PSoftware: Bulletin 9324Links to some of the most common manuals for products that are typically included in a Logix 5000™ control system. It also provides links to manuals that can help you:•Implement an EtherNet/IP network.•Develop a Logix controller-based safety system.•Use Studio 5000 Logix Designer® application to program your control system.•Use Studio 5000 View Designer® application to configure and program your operator interface.•Configure a motion solution.•Configure and use Rockwell Automation products to improve the security of your automation system. Topic PageSummary of Changes2Products Covered in this Publication2Logix 5000 Controllers Resources3Network and Communication Modules Resources4Instructions and Programming Resources4Security Resources5I/O Modules and Adapters Resources6Operator Interface Resources6Motion Resources7Drives Resources7Additional Resources92Rockwell Automation Publication IASIMP-RM001J-EN-P - September 2021Logix Control Systems Recommended Literature Reference ManualSummary of ChangesThis publication contains the following new or updated information. This list includes substantive updates only and is not intended to reflect all changes.Products Covered in this PublicationYou can find common manuals for these products in this publication.Controllers•1756 Series ControlLogix® Controllers, GuardLogix® Controllers, ControlLogix Redundancy Modules •5069 Series CompactLogix™ Controllers, Compact GuardLogix Controllers •1769 Series CompactLogix Controllers, Compact GuardLogix ControllersDrives•Kinetix® 5100, 5300, 5500, and 5700 Servo Drives •PowerFlex® 755T Drives with TotalFORCE® technologyStudio 5000 Design Environment•Studio 5000 Logix Designer® application •Studio 5000 View Designer® application •Studio 5000® Application Code ManagerI/O and Communication Modules•1756 ControlLogix I/O Modules and EtherNet/IP Communication Modules •Compact 5000™ I/O Modules and EtherNet/IP Communication Modules •FLEX 5000™ I/O Modules and EtherNet/IP Communication Modules •1715 Redundant I/O Modules •EtherNet/IP AdaptersOperator Interface•PanelView™ 5510 and PanelView 5310 Terminals•PanelView™ Plus 7 Standard and Performance TerminalsTopicPage Added ControlLogix 5580 Redundant Controllers User Manual to Logix 5000 Controllers resources 3Added Logix Designer Compare Tool User Manual to Programming resources 5Added CIP Security Proxy User Manual to Security resources5Added Studio 5000 View Designer software manuals to Operator Interface resources 6Added Kinetix 5300 Single-axis EtherNet/IP Servo Drives manuals to Drives resources7Added PowerFlex Drives with TotalFORCE Control Programming Manual - Firmware Revision 10 or later to Drives resources 7Added replacement guides to Drives resources7Logix Control Systems Recommended Literature Reference ManualOther Integrated Architecture System ProductsFor products not covered in this manual, go to the Technical Documentation Center at rok.auto/techdocs to browse documentation collections organized by product family. Or go to Literature Library at rok.auto/literature to search for documentation by catalog number, product name, or publication number.Logix 5000 Controllers ResourcesReference and task-based information to help you install, configure, and operate Logix controllers.Selection and Specifications•1756-SG001, ControlLogix System Selection Guide•1756-TD001, ControlLogix and GuardLogix Controllers Technical Data Specifications•1769-SG001, CompactLogix System Selection Guide•5069-TD002, CompactLogix and Compact GuardLogix Technical Data SpecificationsDesign Considerations•1756-RM094, Logix 5000™ Controllers Design Considerations Reference Manual•LOGIX-RM002, Estimated Logix 5000 Controller Instruction Execution Times Reference ManualManuals•ControlLogix and GuardLogix controllers user manuals-1756-UM543, ControlLogix® 5580 and GuardLogix 5580 Controllers User Manual-1756-UM015, ControlLogix 5580 Redundant Controllers User Manual-1756-UM022, GuardLogix 5570 Controllers User Manual-1756-UM001, ControlLogix System User Manual (for ControlLogix® 5570 and ControlLogix® 5560 controllers)-1756-UM535, ControlLogix 5570/5560 Redundancy User Manual•CompactLogix and Compact GuardLogix controllers user manuals-5069-UM002, CompactLogix 5480 User Manual-5069-UM001, CompactLogix 5380 and Compact GuardLogix 5380 Controllers User Manual-1769-UM021, CompactLogix 5370 Controllers User Manual-1769-UM022, Compact GuardLogix 5370 Controllers User Manual•Safety system reference manuals for GuardLogix and Compact GuardLogix controllers-1756-RM012, GuardLogix 5580 and Compact GuardLogix 5380 Controller Systems Safety Reference Manual-1756-RM099, GuardLogix 5570 and Compact GuardLogix 5370 Controller Systems Safety Reference Manual-1756-RM093, GuardLogix Controller Systems Safety Reference Manual (for GuardLogix 5570, GuardLogix 5560, and 1768 CompactGuardLogix Safety controllers using RSLogix 5000® version 20 and earlier)Rockwell Automation Publication IASIMP-RM001J-EN-P - September 20213Logix Control Systems Recommended Literature Reference ManualReplacement Guidelines•1756-RM100, Replacement Guidelines: Logix 5000 Controllers Reference ManualGuidelines for replacing the following:-ControlLogix 5560 or ControlLogix 5570 controller with a ControlLogix 5580 controller-GuardLogix 5560 or GuardLogix 5570 controller with a GuardLogix 5580 controller-CompactLogix5370L3controller to CompactLogix 5380 controllerNetwork and Communication Modules ResourcesReference and task-based information to help you design and implement an Ethernet network, and use EtherNet/IP communication modules in a Logix 5000 control system.Selection and Specifications•1756-TD003, 1756 ControlLogix Communication Modules SpecificationsDesign and Application Considerations•ENET-RM002, Ethernet Design Considerations Reference Manual•ENET-AT001, EtherNet/IP QuickConnect Application Technique•ENET-AT002, EtherNet/IP Socket Interface Application Technique•ENET-AT006, EtherNet/IP Parallel Redundancy Protocol Application Technique•ENET-AT007, EtherNet/IP Device Level Ring Application TechniqueManuals•ENET-UM006, EtherNet/IP Network Configuration User Manual-Overview of EtherNet/IP communication modules in Logix 5000 control systems; describes features and tasks that are common toEtherNet/IP network devices•ENET-UM004, ControlLogix EtherNet/IP Network Devices User Manual-Describes features and tasks that are specific to 1756 ControlLogix EtherNet/IP communication modules in Logix 5000 control systems •CNET-RM001, ControlNet to EtherNet/IP Migration Reference Manual-Provides information to migrate from an existing ControlNet® network to an EtherNet/IP™ networkInstructions and Programming ResourcesInformation to help you use Studio 5000 Logix Designer application to program your control system.Logix 5000 Controllers Instructions•1756-RM003, General Instructions Reference Manual•MOTION-RM002, Motion Instructions Reference Manual•1756-RM006, Advanced Process Control and Drives Instructions Reference Manual•1756-RM095, GuardLogix Safety Application Instruction Set Reference Manual•1756-RM087, Execution Time and Memory Use Reference Manual4Rockwell Automation Publication IASIMP-RM001J-EN-P - September 2021Logix Control Systems Recommended Literature Reference Manual Logix 5000 Controllers Common ProceduresThese manuals describe common procedures for programming and operating Logix 5000 controllers: 1756 ControlLogix, 1756 GuardLogix, 1769 CompactLogix, 1769 Compact GuardLogix, 5069 CompactLogix, and Studio 5000 Logix Emulate™.1756-PM001, Logix 5000 Controllers Common Procedures Programming Manual (provides links to the manuals in the following list)•1756-PM010, Add-On Instructions Programming Manual•1756-PM013, ASCII Strings Programming Manual•1756-PM020, Data Access Programming Manual•1756-PM002, EDS AOP Guidelines for Studio 5000 Logix Designer Programming Manual•1756-PM009, Function Block Diagram Programming Manual•1756-PM018, IEC 61131-3 Compliance Programming Manual•1756-PM019, Import/Export Project Components Programming Manual•1756-PM015, Information and Status Programming Manual•1756-PM004, I/O and Tag Data Programming Manual•1756-PM008, Ladder Diagram Programming Manual•1756-PM014, Major, Minor, and I/O Faults Programming Manual•1756-PM012, Messages Programming Manual•1756-PM017, Nonvolatile Memory Card Programming Manual•1756-PM011, Produced and Consumed Tags Programming Manual•1756-PM021, Program Parameters Programming Manual•1756-PM016, Security Programming Manual•1756-PM006, Sequential Function Charts Programming Manual•1756-PM007, Structured Text Programming Manual•1756-PM005, Tasks, Programs, and Routines Programming ManualProgramming Manuals•LOGIX-UM003, Studio 5000 Application Code Manager User Manual•LOGIX-UM006, Logix Designer and Library Object Manager User Manual•LDCT-UM001, Logix Designer Compare Tool User Manual•LOGIX-UM001, PhaseManager™ Software User Manual•1756-RM084, Import/Export Reference Manual•1756-RM085, Converting PLC-5® or SLC™ 500 Logic to Logix5550® Logic Reference ManualSecurity ResourcesResources to help you configure and use Rockwell Automation products to improve the security of your automation system.•SECURE-UM001, Security Configuration User Manual•SECURE-RM001, System Security Design Guidelines•SECURE-AT001, CIP Security™ with Rockwell Automation Products Application Technique•1783-UM013, CIP Security Proxy User ManualRockwell Automation Publication IASIMP-RM001J-EN-P - September 20215Logix Control Systems Recommended Literature Reference ManualI/O Modules and Adapters ResourcesReference and task-based information to help you install, configure, and operate I/O modules in a Logix 5000 control system. The products in this section are compatible with our newest controller platforms. To find manuals for other distributed I/O families, visit our Technical Documentation Center at rok.auto/techdocs.Selection and Specifications•1756-TD002, ControlLogix I/O Modules Technical Data Specifications•1715-TD001, 1715 Redundant I/O System Technical Data Specifications•5069-TD001, Compact 5000 I/O Modules and EtherNet/IP Adapters Technical Data Specifications•5094-TD001, FLEX 5000 I/O Modules Technical Data SpecificationsManuals•1756 ControlLogix I/O Modules-1756-UM058, ControlLogix Digital I/O Modules User Manual-1756-UM009, ControlLogix Analog I/O Modules User Manual•1715 Redundant I/O System-1715-UM001, 1715 Redundant I/O System User Manual•Compact5000I/O Modules-5069-UM007, Compact 5000 EtherNet/IP Adapters User Manual-5069-UM004, Compact 5000 Digital I/O Modules User Manual (includes standard and safety I/O)-5069-UM005, Compact 5000 Analog I/O Modules User Manual-5069-UM006, Compact 5000 Series High-speed Counter Modules User Manual-5069-UM003, Compact 5000 I/O Serial Module User Manual•FLEX 5000 I/O Modules-5094-UM005, FLEX 5000 EtherNet/IP Adapters User Manual-5094-UM001, FLEX 5000 Standard and Safety Digital I/O Modules User Manual-5094-UM002, FLEX 5000 Analog I/O Modules User Manual-5094-UM003, FLEX 5000 High-speed Counter Module User Manual-5094-UM007, FLEX 5000 Analog Isolated Current/Voltage/HART Input and Output ModulesOperator Interface ResourcesReference and task-based information to help you install, configure, and operate graphic terminals in a Logix 5000 control system. To find manuals for other PanelView products, visit our Technical Documentation Center at rok.auto/techdocs.Selection and Specifications•VIEW-SG001, Visualization Solutions Selection Guide•2715P-TD001, PanelView 5510 Terminals Technical Data Specifications•2713P-TD001, PanelView 5310 Terminals Technical Data Specifications•2711P-TD008, Bulletin 2711P PanelView Plus 7 Standard Terminals Technical Data Specifications•2711P-TD009, Bulletin 2711P PanelView Plus 7 Performance Terminals Technical Data Specifications6Rockwell Automation Publication IASIMP-RM001J-EN-P - September 2021Logix Control Systems Recommended Literature Reference ManualManuals•9343-GR001, Studio 5000 View Designer Getting Results Guide•9324-UM001, Studio 5000 View Designer User Manual•2715P-UM001, PanelView 5510 Terminals User Manual•2713P-UM001, PanelView 5310 Terminals User Manual•2711P-UM007, Bulletin 2711P PanelView Plus 7 Standard Terminals User Manual•2711P-UM008, Bulletin 2711P PanelView Plus 7 Performance Terminals User ManualMotion ResourcesReference and task-based information to help you configure and startup a motion solution.•MOTION-UM003, Integrated Motion on the EtherNet/IP Network Configuration and Startup User Manual•MOTION-RM003, Integrated Motion on the EtherNet/IP Network Reference Manual (AXIS_CIP_DRIVE attributes and integrated motion on the EtherNet/IP network control modes and methods)•MOTION-UM002, Motion Coordinate System User Manual•MOTION-AT005, Motion System Tuning Application Technique (tuning a Kinetix drive system)•IA-AT003, Integrated Architecture and CIP Sync™ Configuration Application Technique•MOTION-UM001, SERCOS and Analog Motion Configuration and Startup User ManualDrives ResourcesReference and task-based information to help you install, configure, and operate Allen-Bradley® Drives in a Logix 5000 control system. To find manuals for other Kinetix Servo Drive or PowerFlex Drive products, visit our Technical Documentation Center at rok.auto/techdocs.Selection and Specification•Kinetix EtherNet/IP Servo Drives-KNX-SG001, Kinetix Motion Control Selection Guide-KNX-TD003, Kinetix Servo Drives Specifications Technical Data-KNX-TD004, Kinetix Motion Accessories Specifications Technical Data•PowerFlex 755T AC Drives-PFLEX-SGOO2, PowerFlex Low Voltage Drive Selection Guide-750-TD100, PowerFlex 750-series Products with TotalFORCE Control Technical DataRockwell Automation Publication IASIMP-RM001J-EN-P - September 20217Logix Control Systems Recommended Literature Reference ManualManuals•Kinetix 5100 Single-axis EtherNet/IP Servo Drives-KNX-RM011, Kinetix 5100 Drive Systems Design Guide-2198-UM004, Kinetix 5100 Single-axis EtherNet/IP Servo Drives User Manual•Kinetix 5300 Single-axis EtherNet/IP Servo Drives-KNX-RM012, Kinetix 5300 Drive Systems Design Guide-2198-UM005, Kinetix 5300 Single-axis EtherNet/IP Servo Drives User Manual•Kinetix 5500 EtherNet/IP Servo Drives-KNX-RM009, Kinetix 5500 Drive System Design Guide-2198-UM001, Kinetix 5500 Servo Drives User Manual•Kinetix 5700 EtherNet/IP Servo Drives-KNX-RM010, Kinetix 5700 Drive Systems Design Guide-2198-UM002, Kinetix 5700 Servo Drives User Manual-2198-RM001, Kinetix 5700 Safe Monitor Functions Safety Reference Manual•PowerFlex 755T AC Drives-750-UM004, PowerFlex 755/755T Integrated Safety - Safe Torque Off Option Module User Manual-750-UM005, PowerFlex 755/755T Integrated Safety Functions Option Module User Manual-750-PM101, PowerFlex Drives with TotalFORCE Control Programming Manual - Firmware Revision 10 or later-750-PM100, PowerFlex Drives with TotalFORCE Control Programming Manual - Firmware Revision 6 or earlier-750-RM100, PowerFlex 750-Series Products with TotalFORCE Control Reference ManualReplacement Guidelines•Kinetix 5100 EtherNet/IP Servo Drives-2198-RM004, Kinetix 300 to Kinetix 5100 Servo Drives-2198-RM003, Ultra3000 to Kinetix 5100 Servo Drives•Kinetix 5300 EtherNet/IP Servo Drives-2198-RM005, Kinetix 350 to Kinetix 5300 Servo Drives-2198-RM006, Ultra3000 Digital Servo Drives to Kinetix 5300 Servo Drives•Kinetix 5500 EtherNet/IP Servo Drives-2093-AP001, Kinetix 2000 Multi-axis Servo Drives to Kinetix 5500 Servo Drives-2098-AP002, Ultra3000 Digital Servo Drives to Kinetix 5500 Servo Drives•Kinetix 5700 EtherNet/IP Servo Drives-2198-RM002, Kinetix 6000 Servo Drives to Kinetix 5700 Servo Drives•PowerFlex 755T AC Drives-750-RM003, PowerFlex 700AFE to PowerFlex 755TM Regenerative Bus Supply-750-RM004, PowerFlex 700S Phase II Drives to PowerFlex 755TL/TR Drives and PowerFlex 755TM Common Bus Inverters 8Rockwell Automation Publication IASIMP-RM001J-EN-P - September 2021Rockwell Automation Publication IASIMP-RM001J-EN-P - September 20219Logix Control Systems Recommended Literature Reference ManualAdditional ResourcesThese resources also provide helpful information for Logix 5000 control systems.You can view or download publications at rok.auto/literatureResourceDescriptionProduct Selection and Configuration website, rok.auto/systemtoolsProvides tools for product selection, control systems configuration, safety systems configuration, and power and motion systems.Sample Code Library, /global/sample-code/overview.page Share or download logic, HMI, and drives code.Industrial Components Preventive Maintenance, Enclosures, and Contact Ratings Specifications, publication IC-TD002Provides a quick reference tool for Allen-Bradley industrial automation controls and assemblies.Safety Guidelines for the Application, Installation, and Maintenance of Solid-State Control, publication SGI-1.1Designed to harmonize with NEMA Standards Publication No. ICS 1.1-1987 and provides general guidelines for the application, installation, and maintenance of solid-state control in the form of individual devices or packaged assemblies incorporating solid-state components.Industrial Automation Wiring and Grounding Guidelines, publication 1770-4.1Provides general guidelines for installing a Rockwell Automation industrial system.Product Certifications website, rok.auto/certifications .Provides declarations of conformity, certificates, and other certification details.Publication IASIMP-RM001J-EN-P - September 2021Supersedes Publication IASIMP-RM001I-EN-P - May 2020Copyright © 2021 Rockwell Automation, Inc. All rights reserved. Printed in the U.S.A.Rockwell Automation SupportUse these resources to access support information.Documentation FeedbackYour comments help us serve your documentation needs better. If you have any suggestions on how to improve our content, complete the form at rok.auto/docfeedback .Technical Support Center Find help with how-to videos, FAQs, chat, user forums, and product notification updates.rok.auto/support KnowledgebaseAccess Knowledgebase articles.rok.auto/knowledgebase Local Technical Support Phone Numbers Locate the telephone number for your country.rok.auto/phonesupport Technical Documentation Center Access technical documentation organized by product family.rok.auto/techdocs Literature LibrarySearch for installation instructions, manuals, brochures, and technical data publications.rok.auto/literature Product Compatibility and Download Center (PCDC)Get help determining how products interact, check features and capabilities, and find associated firmware.rok.auto/pcdcRockwell Automation maintains current product environmental certification information on its website at rok.auto/pec .Allen-Bradley, Compact 5000, CompactLogix, ControlLogix, expanding human possibility, FactoryTalk, FLEX 5000, GuardLogix, Integrated Architecture, Kinetix, Logix 5000, PanelView, PhaseManager, PLC-5, PowerFlex, Rockwell Automation, Rockwell Software, RSLogix 5000, SequenceManager, SLC, Studio 5000 Logix Designer, Studio 5000 Logix Emulate, Studio 5000 View Designer, and TotalFORCE are trademarks of Rockwell Automation, Inc.CIP Security, CIP Sync, ControlNet, DeviceNet, and EtherNet/IP are trademarks of ODVA, Inc.Trademarks not belonging to Rockwell Automation are property of their respective companies.Rockwell Otomasyon Ticaret A.Ş. Kar Plaza İş Merkezi E Blok Kat:6 34752, İçerenkÖy, İstanbul, Tel: +90 (216) 5698400 EEE YÖnetmeli ğine Uygundur。