超声发生器5072PR-73PR-77PR-(EN)中文说明书

- 格式:docx

- 大小:173.92 KB

- 文档页数:11

六通道超声波发生器使用说明书深圳己道科技有限公司目录1概述 (3)2功能部件 (3)2.1前面板 (3)2.2后面板 (4)3接口、功能及技术指标 (4)3.1环境接口 (4)3.2电气接口 (4)3.3结构尺寸 (6)4功能及技术指标 (6)4.1主要功能 (6)4.2技术指标 (6)5基本操作 (7)5.1显示 (7)5.2操作 (9)5.3开机、关机 (11)5.4外部急停使能 (11)5.5总启动、停止 (12)6使用规范 (12)7异常情况处理 (12)8技术支持 (12)1概述六通道超声波发生器(以下简称发生器)可同时输出6通道同频、不同相的超声波信号,具备自动扫频和频率追踪功能,在不同负载状态下6个换能器同时有效谐振,并且1组3个换能器之间相位可调。

发生器可以独立使用,通过面板元件来设置各项功能和参数。

本文介绍了发生器的功能部件,描述了发生器的使用方法。

2功能部件2.1前面板a.液晶显示器,数字化显示所有状态及参数;b.选择按钮,选中需要设置的参数;c.手轮,配合选择按钮设置参数;d.启动/停止按钮,启动或关闭超声信号输出;e.急停使能开关,使能或禁能外部急停信号;f.RS-485通信插座,连接上位机通信线;g.外控IO插座,连接防爆柜IO插头,内含振子类型选择和急停信号。

2.2后面板a.电源开关,接通或关断发生器总电源;b.电源插座,连接电源线;c.散热风扇1、2,排风口,冷却发生器内部元件;d.超声信号插座,输出A、B、C、D、E、F共六个通道的超声信号;e.超声信号接线柱,也是超声信号输出端,内部与超声信号插座并联,便于连接示波器或U型接线端子,红色接线柱为正极,黑色为负极。

3接口、功能及技术指标3.1环境接口a.供电电源:AC220V,50Hz,3000VA;b.环境温度:0℃-45℃;c.环境湿度:1%-95%,无凝露。

3.2电气接口a.电源插座采用带保险管座的三线品字插座,配2.5方的三芯电源线。

Using anatomical intelligence to assess LV functionPhilips EPIQ ultrasound systemEPIQ is the most intelligent Philips premium ultrasound ever, offering a complete setof easy-to-use quantitative tools to turn reproducible data into information to help guidetreatment. Leading-edge Anatomical Intelligence Ultrasound (AIUS) is the heart of EPIQand is designed to elevate the ultrasound system from a passive to an actively adaptivedevice. Speckle strain echocardiography is a novel technique designed to allow cliniciansto quickly and easily assess myocardial deformation (strain) in day-to-day practice,going beyond ejection fraction in the assessment of left ventricular (LV) function.The ZeroClick technology of the Automated Cardiac Motion Quantification A.I.(aCMQ A.I.)tool drives automation to provide reproducible 2D Global Longitudinal Strain (GLS)speckle measurements.ChallengeIn today’s cardiology practice, assessment of LV function is no longer limited to evaluation of ejection fraction. Speckle strain echocardiography is a novel technique for use in imaging myocardial deformation (strain). Strain imaging has proven to provide important incremental information in various clinical settings. Areas that hold great promise include the detectionof subclinical heart disease (when other systolic functional parameters are normal), the evaluationof myocardial ischemia and viability, and serial assessment of different cardiomyopathies.For cardiologists to incorporate strain results into their clinical decision-making, it is vital that they can have confidence that various echocardiographic systems generate the same values for a given patient. They also want to be sure that results are not operator-dependent, but rather reproducible by different operators and at different times. In addition, for strain analysis to be practical, it cannot be too time-consuming. Currently, the most important practical limitations of routine clinical incorporation of strain imaging include its impact on workflow efficiency, observer variability, and inter-vendor inconsistency, driven by the fact that different manufacturers may use different tracking algorithms.Analysis and case studies provided by Professor Alex Lee, Division of Cardiology and Professor Cheuk-Man YU, Institute of Vascular Medicine,The Chinese University of Hong KongaCMQ A.I. automatically generates GLS measurements from these 2D images obtained from apical 4-, 3-, and 2-chamber views of a normal heart, with no manual marking of anatomic landmarks required to initiate analysis.SolutionAs with many other technologies, automation is the key to achieving workflow efficiency and measurement reproducibility of strain echocardiography in a busy clinical practice. Conventional ways to initiate GLS measurement require manual tracing of the endocardial border or at least manual location of anatomic landmarks such as the mitral annulus and LV apex. This inevitably slows workflow and introduces human error and observer variability, hence limiting practical use of strain imaging. With the aCMQ A.I. tool of Philips EPIQ, GLS can be obtained with ZeroClick technology within a few seconds after acquisition of 2D images from the three routine apical views (4-chamber, 2-chamber, and long-axis).ImpactEnhancement of workflow efficiency, improvement in reproducibility, and resolution of inter-vendor algorithm discrepancy as a result of full automation are expected to help promote widespread adoption of this novel technique in daily practice.Data comparisonWe studied the inter-vendor agreement of GLSmeasurement in 35 patients. Patients had transthoracic echocardiography performed on EPIQ and on anultrasound system of a different vendor within the same day, and the images were analyzed for GLS using aCMQ A.I.and the strain analysis software of the other vendor. We observed excellent inter-vendor agreement(bias = -0.47%, 95% limits of agreement = -4.06% to 3.12%, coefficient of variation = 2.5%; r = 0.92, P<0.0001).aCMQ A.I.AverageD i f f e r e n c eV e n d o r 2-30 -25 -20 -15 -10 -5105-5-10-30 -25 -20 -15 -10 -5 0CorrelationBland-Altman plot:Inter-vendor agreement for GLS measurement2A 59-year-old male was admitted to the coronary care unit for acute chest pain occurring over the preceding 14 hours. ECG showed ST segment elevation over the inferior leads. Echocardiography showed severe hypokinesia over the inferior and inferoseptal segments from basal to mid levels, without obvious regional wall motion abnormality in the rest of the LV segments. Strain analysis with aCMQ A.I. showed not only markedly reduced longitudinal strains in the inferior, inferoseptal, and inferolateral segments, but also mildly impaired longitudinal strains in the anterior, anteroseptal, and anterolateral segments and the apical cap. Coronary angiogram revealed sequential severely stenotic culprit obstructions (70-90%) in the dominant right coronary artery (RCA) and multiple significant stenoses (50-70%) in the proximal and distal left anterior descending artery (LAD), with a non-dominant normal circumflex. This case illustrates how strain echocardiography can help identify infarction (indicated by positive strain, i.e., paradoxical systolic lengthening, in the basal inferior segment), peri-infarct schema in the RCA territory, and remote ischemia in the LAD territory. Percutaneous coronary intervention (PCI) was performed to the RCA and staged PCI was performed to the LAD.Case study one Inferior myocardialinfarctionCase study one illustrates how strain echocardiography can help identify infarction (coded blue), peri-infarct schema in the RCA territory, and remote ischemia in the LAD territory (salmon pink).3A 60-year-old female with history of well-controlled hypertension presented with recurrent episodes of syncope. Holter study revealed episodes ofnon-sustained ventricular tachycardia. ECG showed low QRS voltage and poor R wave progression in the precordial leads. Echocardiography showed concentric increase in LV wall thickness, ejection fraction = 47%, dilated left atrium, restrictive filling of mitral inflow, and thickened mitral and aortic valves. Bone marrow biopsy showed plasma cell dysplasia and rectal biopsy Case study twoAmyloidosisrevealed amyloid infiltration with positive Congo red stain, confirming the diagnosis of AL amyloidosis. Echocardiographic strain analysis showed markedlyreduced GLS (-6%) despite only mildly impaired ejection fraction. This case illustrates that GLS is more sensitive than ejection fraction to reveal LV systolic dysfunction and a relative “apical sparing” pattern of GLS is an easily recognizable, accurate, and reproducible method of differentiating cardiac amyloidosis from other causes of LV hypertrophy.ConclusionsStrain imaging holds great promise in providing incremental information on cardiac function in many clinical settings. With the advent of AIUS through a computerized automation technique to enhance efficiency and reproducibility, as well as validation of inter-manufacturer agreement in strain measurement algorithms, it is foreseeable that strain echocardiography can become a standard echocardiographic technique to evaluate cardiac function in today’s cardiology practices.Case study two shows GLS to be more sensitive than ejection fraction in revealing LV systolic dysfunction and that the relative “apical sparing” pattern of GLS is easily recognizable.Philips Healthcare is part of Royal Philips /healthcare **********************Printed in The Netherlands 4522 991 02471 * APR 2014© 2014 Koninklijke Philips N.V .All rights are reserved.Philips Healthcare reserves the right to make changes in specifications and/or to discontinue any product at any time without notice or obligation and will not be liable for any consequences resulting from the use of this publication.Please visit /epiq。

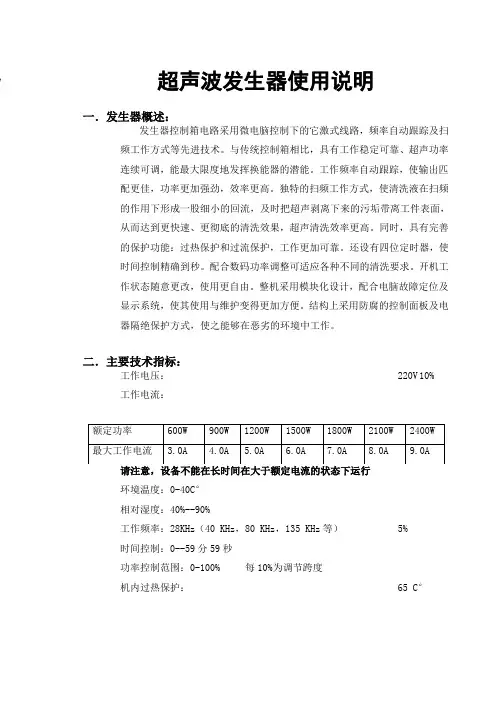

超声波发生器使用说明一.发生器概述:发生器控制箱电路采用微电脑控制下的它激式线路,频率自动跟踪及扫频工作方式等先进技术。

与传统控制箱相比,具有工作稳定可靠、超声功率连续可调,能最大限度地发挥换能器的潜能。

工作频率自动跟踪,使输出匹配更佳,功率更加强劲,效率更高。

独特的扫频工作方式,使清洗液在扫频的作用下形成一股细小的回流,及时把超声剥离下来的污垢带离工件表面,从而达到更快速、更彻底的清洗效果,超声清洗效率更高。

同时,具有完善的保护功能:过热保护和过流保护,工作更加可靠。

还设有四位定时器,使时间控制精确到秒。

配合数码功率调整可适应各种不同的清洗要求。

开机工作状态随意更改,使用更自由。

整机采用模块化设计,配合电脑故障定位及显示系统,使其使用与维护变得更加方便。

结构上采用防腐的控制面板及电器隔绝保护方式,使之能够在恶劣的环境中工作。

二.主要技术指标:工作电压:220V 10%工作电流:环境温度:0-40C°相对湿度:40%--90%工作频率:28KHz(40 KHz,80 KHz,135 KHz等)5%时间控制:0--59分59秒功率控制范围:0-100% 每10%为调节跨度机内过热保护:65 C°三.面板功能说明:分体式机型面板四.使用说明:(以分体式机型为例,整体式机型功能相同)面板功能介绍:LCD 显示屏幕:用于显示定时,功率大小,频率,电流等正常工作状态 ON/OFF 键:用于控制发生器的工作或暂停; SET 键:设定键,用于选择所要调整的功能; +键:在设置参数时增加数值; –键:在设置参数时减少数值6.详细参数:采用他激式电路,先进的单片机控制,高亮度液晶(LCD )屏幕显示,结构小巧,外形美观大方定性高,通用性好,能量转换效率高。

菜单式操作,调整、使用方便简单可显示:功率、清洗时间、频率、电流。

数字式功率调节:10%~100%自由调节 频率自动跟踪、扫频设置定时加 频率加 电源开关增加功率减少功率 功能显示定时减频率减启动/停数字调频功能清洗定时功能低电流报警功能过电流保护功能自动开关机功能频率范围宽:20KHZ~40KHZ通用功率范围宽:600~1500W通用外形尺寸:(LXWXH)380X300X150mm若选用高频(60KHZ以上频率)或大功率请致电本公司操作说明将机器安放在通风干燥处,接好电源和输出接头,打开电源,显示工作状态;1.功率设定:按一下“SET”键,屏幕显示“POWER SET(功率设定)”按“+、-”键调整功率大小;设定完成后约5秒自动返回工作模式;Power SetP=100%2.定时模式:按两下“SET”键,屏幕显示“TIMER SET(定时设定)”,此时按“+、-”键调整到所需时间,设定好后约5秒自动记忆。

多频超声波发生器HM-1000操作说明书(版本)一、性能简介1、国际领先的IGBT驱动模式,保证功率的均衡及稳定。

2、具有软性启动功能,可防止主机瞬间启动电流过大。

3、具有外部驱动(Remote Control)功能,方便远程操控。

4、具扫频功能(约±1KHz)。

5、三种频率自动或手动变频交换输出(爆洗功能),清洗效果更佳。

6、通过频率的数字生成和调节,在10%到100%的范围内可调的输出功率始终可用,恒定的输出功率和间隔功能有效确保清洗物精确的超声波辐射。

7、LED功率和状态指示灯以及显示详细数字的LCD数码屏,确保操作方便安全。

8、发生器系列配有不同的防护功能,例如智能冷却系统以及短路,空转和过载保护功能,以确保最高的工作安全性。

9、绝佳散热设计,可适应于长时间清洗运行。

10、防腐蚀机箱设计,运行不受使用环境的制约。

二、主要技术参数工作电压:AC220V 50/60Hz ±10%工作电流:请注意,设备不能在长时间在大于额定电流的状态下运行。

工作电流工作环境:0-40℃相对湿度:40%-90%工作频率:40/80/120KHz ±10%时间控制:0--59分59秒功率控制范围:占空比调节1-99%外型尺寸:H X W X L=138X308X428二、面板功能说明电源开关:电源开关为整机的总电源开关,往上拨为开,往下拨为关。

频率切换:频率切换多档开关为控制超声波工作频率的开关,AT为自动频率切换(40/80/120KHz),MT为手动频率切换分为三种工作频率段F1-40KHz、F2-80KHz、F3-120KHz。

功率调节:功率调节电位器为控制超声波输出功率大小的电位器,顺时针调节为从小到大,逆时针调节为从大到小,可调整超声功率范围为10—100%。

功率调节指示:功率调节指示分为10个LED指示档位,根据功率调节电位器调整功率的大小亮LED,当全部都灭时,超声波输出功率为0;当全部都亮时,超声波输出功率为100%。

型号5072PR,5073PR,5077PR超声波发生器/接收器用户手册根据欧洲废电子电气指令2002/96 / EC设备,此符号表示产品不得作为未分类处理市政废物,但应单独收取。

请参考您当地的奥林巴斯NDT您所在国家/地区的退货和/或收款系统的经销商。

所有©2008 Olympus NDT。

所有。

本手册的任何部分不得以任何形式或方式复制或传播,电子或机械,包括复印,录音或任何信息存储和检索系统,未经奥林巴斯NDT书面许可,除非允许依法。

有关信息,请联系:infoOlympusNDT.。

Panametrics,Panametrics-NDT和Panametrics-NDT标志是Panametrics的商标公司本文档中提及的其他产品名称可能是其各自的商标公司,仅供鉴定。

印在美利坚合众国。

保修5072PR,5073PR和5077PR超声波脉冲发生器接收机已经设计和制造为优质产品。

收到证件后,仔细检查资料运输期间可能发生的外部或部损坏。

通知承运人由于承运人通常承担损害赔偿责任,因此立即交付任何损失装船。

保存包装材料,运单和其他运输单据建立损害索赔。

通知运营商后,请联系奥林巴斯NDTTM,以便我们可以协助损坏索赔,并在必要时提供更换设备。

奥林巴斯NDT保证5072PR,5073PR和5077PR超声波脉冲发生器接收器在材料和工艺上没有缺陷,为期一年(十二个月)从装运之日起。

本保修仅适用于已使用的设备方式如本说明书所述,并没有遭受过度滥用,尝试未经授权的修复或修改。

在本保修期,奥林巴斯无损检测责任仅限于修理或更换一个有缺陷的单位。

奥林巴斯NDT 不保证5072PR,5073PR和5077PR超声波脉冲发生器接收器适合使用或适用任何特定的应用或目的。

奥林巴斯NDT不对后果或不承担任何责任偶然的损害,包括财产损失和/或人身伤害。

除了我们标准一年保修,奥林巴斯NDT还提供可选的两年保修(略)。

目录保修................................................. .................................................. . (iii)目录 ............................................... .. (v)一般说明.............................................. .. (1)1.1特别声明和印刷公约............................................ (2)1.2如果您有文档评论............................................ . (3)史............................................... .................................................. (3)1.4技术帮助............................................... .................................................. (4)1.5产品使用............................................... .................................................. (4)开箱检查............................................. .. (5)仪器控制和I / O连接器......................................... ...........3.1前面板3.1.1电源开关............................................. .................................................. .. (9)3.1.2脉冲重复频率控制(PRF)....................................... .. (9)3.1.3脉冲电压(5077PR)......................................... ............................................103.1.4传感器频率选择控制(5077PR)....................................... (11)3.1.5能量(5072PR,5073PR)......................................... (11)3.1.6阻尼(5072PR,5073PR)......................................... (12)3.1.7增益/衰减(dB)......................................... .................................................143.1.8低通滤波器............................................ .................................................. . (14)3.1.9高通滤波器............................................ .................................................. (14)3.1.10模式切换............................................. .................................................. (15)3.1.11 T / R连接器........................................... .................................................. (15)器............................................. .................................................. .. (15)3.2后面板............................................... .................................................. .....................153.2.1 RFOUT ............................................. .................................................. .................163.2.2 EXT TRIGIN ............................................ .................................................. (16)3.2.3 + SYNCOUT ............................................ .................................................. . (17)4.规格............................................... . (19)5.操作............................................... .................................................. (23)5.1示波器要求............................................... . (23)5.2初始设置............................................. .................................................. .....................235.3通过传输............................................. .................................................. .....295.4调谐峰波幅方波脉冲(仅限5077PR) (34)5.5传感器的电压和功率限制......................................... (34)6.故障排除与维护............................................. . (37)6.1基本故障排除............................................... .................................................. (37)6.2克服电噪声干扰............................................. . (37)6.3申请协助............................................... .................................................. ...38文件评论................................................ .. (39)1.一般说明型号5072PR,5073PR和5077PR手动控制超声波脉冲发生器 - 接收器为常规和高频应用提供构建模块。

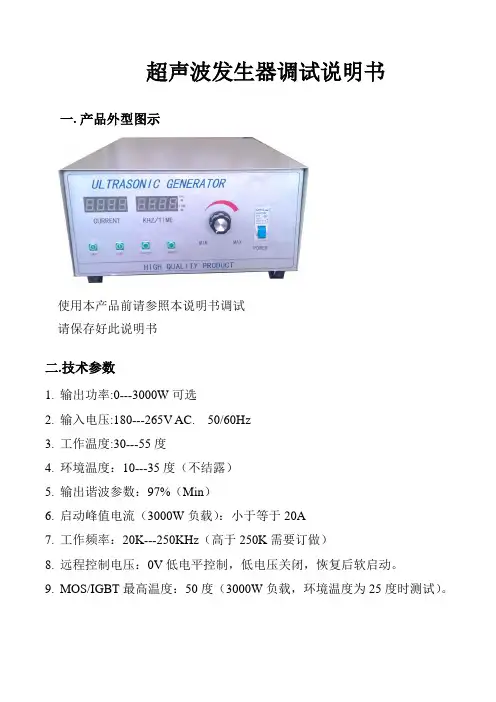

超声波发生器调试说明书一.产品外型图示使用本产品前请参照本说明书调试请保存好此说明书二.技术参数1.输出功率:0---3000W可选2.输入电压:180---265V AC. 50/60Hz3.工作温度:30---55度4.环境温度:10---35度(不结露)5.输出谐波参数:97%(Min)6.启动峰值电流(3000W负载):小于等于20A7.工作频率:20K---250KHz(高于250K需要订做)8.远程控制电压:0V低电平控制,低电压关闭,恢复后软启动。

9.MOS/IGBT最高温度:50度(3000W负载,环境温度为25度时测试)。

三.功能说明:1.功率调节:调节功率电位器,功率可以从零到额定功率可调。

2.电源开关:1为开启,O为关断。

3.显示窗:显示发生器工作时的电流。

4.电源线:连接机器与市电的连接器件。

注意接地要良好。

5.输出接线口:超声清洗机与发生器的连接处。

注意正负极性不可接反。

6.远程控制:为发生器的软启动接口,不断电源来控制超声波的启停。

使用时只需把插头内的短接线拆除外接一个开关或继电器就行。

给它一个开关信号。

7.散热风扇:为主功率器件散热。

四.机器显示及接口图标1.面板图电流显示频率/时间显示时间增加时间减少功能键开关键功率调节电源开关按键说明:电流显示:显示当前工作的电流。

频率/时间、显示:显示当前工作的频率或时间,当KHZ指示灯亮时显示的是频率,当TIME指示灯亮时显示的是时间。

时间为倒计时。

功率调节:工作的时候用来调输出功率的大小。

电源开关:是发生器的总电源开关,向上为开向下为关。

增加键:用来调节设定时间增加的。

减少键:用来调节设定时间减少的。

功能键:切换频率和时间显示的。

如果当前显示的是时间,按一下功能键就显示频率,反之按一下就显示时间。

在切换频率和时间显示的时候超声波会停止工作,所以超声波工作的时候不要操作此按键。

开关键:用来开启或关闭超声波的。

按一下开启,再按一下关闭。

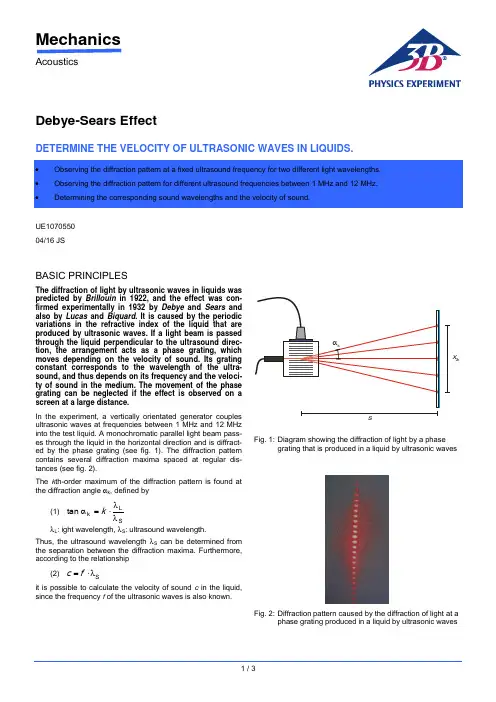

MechanicsAcousticsDebye-Sears EffectDETERMINE THE VELOCITY OF ULTRASONIC WAVES IN LIQUIDS.UE1070550 04/16 JSBASIC PRINCIPLESThe diffraction of light by ultrasonic waves in liquids was predicted by Brillouin in 1922, and the effect was con-firmed experimentally in 1932 by Debye and Sears and also by Lucas and Biquard . It is caused by the periodic variations in the refractive index of the liquid that are produced by ultrasonic waves. If a light beam is passed through the liquid perpendicular to the ultrasound direc-tion, the arrangement acts as a phase grating, which moves depending on the velocity of sound. Its grating constant corresponds to the wavelength of the ultra-sound, and thus depends on its frequency and the veloci-ty of sound in the medium. The movement of the phase grating can be neglected if the effect is observed on a screen at a large distance.In the experiment, a vertically orientated generator couples ultrasonic waves at frequencies between 1 MHz and 12 MHz into the test liquid. A monochromatic parallel light beam pass-es through the liquid in the horizontal direction and is diffract-ed by the phase grating (see fig. 1). The diffraction pattern contains several diffraction maxima spaced at regular dis-tances (see fig. 2).The k th-order maximum of the diffraction pattern is found at the diffraction angle αk , defined by(1) SLk tan λλ⋅=αk λL : ight wavelength, λS : ultrasound wavelength.Thus, the ultrasound wavelength λS can be determined from the separation between the diffraction maxima. Furthermore, according to the relationship(2) S λ⋅=f cit is possible to calculate the velocity of sound c in the liquid, since the frequency f of the ultrasonic waves is also known.Fig. 1: D iagram showing the diffraction of light by a phasegrating that is produced in a liquid by ultrasonic wavesFig. 2: D iffraction pattern caused by the diffraction of light at aphase grating produced in a liquid by ultrasonic wavesLIST OF APPARATUS1 Ultrasonic cw Generator with Probe 1002576 (U100061) 1 Test Vessel, Complete 1002578 (U10008)1 Laser Diode for D-S Effect, Red 1002577 (U10007)1 Laser Diode for D-S Effect, Green 1002579 (U10009)1 Pocket Measuring Tape,2 m 1002603 (U10073)1 Ultrasonic Coupling Gel 1008575 (XP999)SET-UP∙Fill the test vessel with distilled water and place it about3 m from the projection screen.∙Mount the multi-frequency probe vertically in the holder of the test vessel and connect it to the PROBE output of the ultrasonic generator (see Fig. 3).∙Mount the red laser diode in the laser holder of the test vessel and connect it to the LASER output of the ultra-sonic generator.Fig. 3: Experiment set-up for the diffraction of light at a phase grating produced in a liquid by ultrasonic waves EXPERIMENT PROCEDURE∙Measure the distance s between the multi-frequency probe and the screen.∙Switch on the ultrasonic cw generator.∙Switch on the laser and the multi-frequency probe.∙Set the frequency to 1 MHz.∙Adjust the amplitude of the transducer signal, and by means of the three adjusting screws of the transducer holder adjust the orientation of the multi-frequency probe so that standing waves are generated.∙On the screen measure the distance x2k between the –k th order and the +k th order diffraction maxima.∙Increase the frequency in steps of 1 MHz up to 12 MHz, and for each frequency measure the distance x2k and de-termine the diffraction order k.∙Replace the red laser diode with a green one and make a similar set of measurements. SAMPLE MEASUREMENTS AND EVALUA-TIONs =325 cmTable 1: Experiment data with light of wavelength λL = 652 nm (red laser)Table 2: Experiment data with light of wavelength λL = 532 nm (green laser)It is necessary to measure the distance s between the ultra-sound generator and the screen used to observe the diffrac-tion pattern, and the distance x2k between the -k th and the +k th diffraction maxima. From these two distances, it is possi-ble to calculate the diffraction angle αk for the k th-order maxi-mum, given by:sx⋅=α2tan2kk.This leads to the following equation for determining the ultra-sound wavelength λS:L2kS2λ⋅⋅⋅=λxsk.This is the equation by which the sound wavelengths in the right-hand column of both tables were calculated.3B Scientific GmbH, Rudorffweg 8, 21031 Hamburg, Germany, Figure 4 shows the calculated sound wavelength as a function of the frequency of the ultrasonic waves. The hyperbola curve was calculated according to Equation (2) as:fc =λS with s m 1482=cThe velocity of sound c determined by this curve-fitting proce-dure is in excellent agreement with the literature value.510f / M H zλ μ/ mFig. 4: S ound wavelength λS in water as a function of the fre-quency f。

医疗超声仪使用方法说明书一、产品概述医疗超声仪(以下简称“仪器”)是一种用于医学影像采集和分析的专业设备。

本使用说明书将详细介绍仪器的使用方法和注意事项,以帮助用户正确、安全地操作仪器。

二、仪器结构和功能1. 仪器结构仪器由以下部分组成:- 主机:包含仪器的核心控制和处理模块;- 显示屏:用于显示采集的超声影像和相关数据;- 手持探头:用于接触患者的皮肤,采集超声信号;- 操作面板:用于用户选择操作模式、调节参数等。

2. 仪器功能仪器具备以下功能:- 采集超声影像:通过手持探头接触患者体表,采集超声信号并生成图像;- 影像调节:用户可以调节影像的亮度、对比度等参数,优化显示效果;- 数据分析:仪器可对采集的数据进行实时分析和计算,提供相关测量结果;- 存储和传输:仪器支持影像和数据的存储,并可通过接口进行传输和共享。

三、使用准备1. 环境要求在使用仪器之前,请确保以下环境满足要求:- 温度:仪器应在15-30摄氏度的环境中使用;- 湿度:相对湿度应在30%-75%范围内;- 电源:仅使用额定电压和频率的电源供电,确保电源稳定。

2. 前期准备在使用仪器之前,请完成以下准备工作:- 检查仪器外观,确保无异常;- 打开仪器电源,并等待系统启动完成;- 连接手持探头,并确认连接稳固。

四、操作流程1. 操作界面仪器启动后,将显示操作界面。

界面包括图像显示区、参数调节区等。

用户可根据需要,调整操作界面和显示设置。

2. 采集超声影像(1)选择采集模式:根据具体需要,选择超声模式、扫描模式等;(2)定位手持探头:将手持探头移到待检部位,并确保与皮肤充分接触;(3)开始采集:点击相应按钮或触摸屏幕,开始采集超声信号;(4)影像调节:根据需要,调节图像亮度、对比度等参数;(5)保存影像:若满意采集结果,可选择保存影像。

3. 数据分析和测量仪器可对采集的数据进行进一步分析和测量,包括但不限于测量距离、测量角度等操作。

1.0目的:正确操作设备,确保设备正常运行,保证正常生产和产品质量.

2.0适用范围:本公司所有超声波点焊机操作人员及机修人员.

3.0工作原理及结构:

3.1超声波点焊机是一种固相焊接机,焊件之间的连接是

通过声学系统的高频弹性振动以及在工件之间静压力

的夹持作用下实现的.

3.2PC系列超声波点焊机主要由机架、换能系统、机头、

超声波发生器、程序控制器等主要部件,组成;

4.0操作规程:

4.1本机应放置在环境温度0℃-40℃室内空气干燥、无腐

蚀气体、振动小的地方;

4.2接通电源,单相220V;并接好地线;

4.3接通气源;

4.4打开发生器电源,电源指示灯亮;

4.5设定功率、预压、焊接、保压时间;

4.6根据焊接牢固度修正参数;

5.0功率调整:开机后,将应焊工件的试样搁在上下焊头间,

对功率进行缓慢调整,即拨动(功率设定)拨码开关,顺序渐进(每次可调整数为10),如10、20、30、40……直至被焊工件达到焊接牢固的要求。

即为功

率之最佳设定;

6.0停机:停止工作时,将电源开关关闭;

7.0日常维护及注意事项:

7.1保持点焊机及其工作台清洁卫生;

7.2保持点焊头干净清洁,作业时网纹中不可夹杂其它硬

物,尤其铁钉类,以免损伤机器或影响焊接效果;

7.3长期焊接铝材会带来上下焊头的吸附,清定期视焊面

情况用铜丝刷按焊头面网纹方向轻轻刷抹,以清洁网

纹内的吸附物,防止焊面与工件在焊接时的粘接;

7.4本机焊头网纹面使用寿命(在保持不退火状态下)一

般为10万次,当达到使用寿命或网纹磨损时,可由机

修进行修复后再使用;

8.0相关文件:《超声波点焊机使用说明书》。

N&DN系列(LCD)超声波细胞粉碎机使用说明书宁波新芝生物科技股份有限公司地址:宁波市国家高新技术园区木槿路65号 315013电话:传真:网址:一. 概述随着生物产业的发展,应用超声波细胞粉碎机所做的实验要求也随之提高,如对样品温度的测定、控制,低温冷却样品及整机的智能化程度的提高等等,都提出了新的要求,为进一步完善此类仪器的各项性能,我公司在现有各种型号的超声波细胞粉碎机的基础上,吸收国外最新技术,结合微电脑控制、选频、测温、保护等软硬件技术而研制的超声波细胞粉碎机,它具有技术先进、性能可靠、操作简便、外型美观、显示清晰明亮、测温控温精确等优点。

超声波细胞粉碎机是一种利用强超声在液体中产生空化效应,对物质进行超声处理的多功能、多用途的仪器,能用于动植物组织、细胞、细菌、芽胞菌种的破碎,同时可用来乳化、分离、分散、匀化、提取、脱气、清洗及加速化学反应等等。

该机广泛应用于生物化学、微生物学、药物化学、表面化学、物理学、动物学、农学、医学、制药等领域教学、科研、生产。

Ф18 3/4”20-25KHz 200-950W 200 - 500mlФ20 3/4” -1000mlФ25 1” -1200ml本机由超声波发生器和超声波换能器组件两大部分组成。

超声波发生器(电源)是将220VAC、50Hz的单相电通过变频器件变为20-25kHz、约600V的交变电能、并以适当的阻抗与功率匹配来推动换能器,作纵向机械振动,振动波通过浸入在样品溶液中的钛合金变幅杆对被破碎的各类细胞产生空化效应,从而达到破碎细胞之目的。

其电原理由整流电源,开关电源、变频系统、功率放大器、锁相频率自动跟踪器、功率调节器、功率检测器、功率保护器及微电脑控制等组成。

换能器组件是由压电振子、变幅放大器所组成的产生机械能的聚能变幅装置。

仪器功能键说明(见附图):变幅杆选择开关航空插(超声)保险丝-8A保险丝-5A电源插座五. 参数设置:图2.面板和按键1.按安装图说明安装好本仪器,用专用的电源线连接发生器背面的电源插座,把换能器组件的信号输入接头与信号输出接口连接好。

HKD-1027超声波性能简介:本电源是采用全数字设计的多功能、高性能、高可靠性的超声波专用功率源。

(一)采用微电脑控制和数字频率合成技术,频率自动跟踪。

(二)数字式超声功率连续可调,使用更灵活,功率更强,工作更稳定。

(二)具有完善的保护功能:过热保护、过流保护和过压保护。

(四)四位数码管显示频率、电流、工作状态和定时直观清晰。

(五)提供远程外控接口,方便与其它控制设备的连接。

(六)扫频速度和扫频宽度数字化调整,可变水花、声音,调试方便直观。

主要技术指标:工作电压:220V 10%工作电流:请注意,设备不能长时间在大于额定电流的状态下运行环境温度:0-45 相对湿度:40%-90%工作频率:80KHz以下功率控制范围:0-100% 8 级数控调节(功率条指示)机内过热保护:65 C三、面板功能说明:1.显示窗:显示工作频率,电流大小,功率等级,工作状态及故障情况。

2.启动/停止:控制超声启动和停止[恢复出厂数据]。

3.扫频开关:选择正常工作状态或扫频工作状态[确认此项进入下一项]。

4.时间加:设置定时工作值(设置显示“ ON/OFF )[频率加]。

5.时间减:设置定时工作值(设置显示时间“”)[频率减]。

6.功率加:增大输出功率(设置显示电流“”)。

7.功率减:减小输出功率(设置显示频率“”)。

8.电源开关:控制220V电压。

注:本说明中显示内容中的“ X”为数字,其它为字母。

以下同。

小括号()中的功能需要与电源开关配合实现功能。

中括号[]中的功能需要和控制板上的工厂短路接口配合实现功能。

四、使用说明:1.“电源开关”:将机器安放在通风干燥处,接好电源和输出接头。

当打开电源时显示窗口将显示产品出产序列号。

然后显示“----”表示扫描显示状态控制按键。

2.“启动/停止”键功能:打开电源后如果上次关电源时是开启超声状态,那么这次开电源就会自动开启超声。

如果上次关电源时是待机状态,那么这次开电源也会是待机状态,这时显示窗口显示“-OFF”然后再按“启动/停止”,电源就会启动,并显示“”“”“-ON-”。

Instruction sheet3B SCIENTIFIC ® PHYSICS®Ultrasound generator with accessories for the Debye-Sears experiment and for demonstrating standing ul-trasonic waves.Safety instructionsBefore switching on the ultrasound generator and ac-cessories, carefully read the following instructions for the sake of your safety and for the safety of the equip-ment.•The slits in the device are for ventilation and must be kept clear to avoid overheating the equipment.It is recommended that the device be placed on its own stand (also included).•Before switching on the device make sure that it is adjusted to the mains voltage you intend to use.Make sure that you keep within the operating speci-fications.•Never try to push objects through the slits in the device since this could cause short circuits or elec-tric shocks.•Only use 3B’s own ultrasound transducer with the “PROBE” connection. Be careful, voltages may be as high as 70 V.•Do not use the ultrasound transducer for a lengthy period without contact to fluids. Otherwise the transducer may overheat and be destroyed.•Do not turn on the U10007 laser diode if there arepeople standing in the beam. This is a class II laser with power < 1 mW. Do not look into the beam or aim it at other people or animals.•Beware: high-powered ultrasound! Do not use the probe on people or animals.Contents1.Introduction ............................................7ponents ............................................72.1Ultrasound generator - operating elements 72.2Set-up for test container 82.3Lens on glass slide 82.4Laser diode (U10008)83.Experiment procedure ..............................83.1General instructions for experiments 83.2Debye-Sears effect93.3Projection of standing ultrasonic waves94.Technical details .....................................101.1.Ultrasound generator 104.2.Ultrasonic transducer 104.3.Test vessel 10Ultrasonic CW generator U10006Laser diode for Debye-Sears effect U10007Test vessel U100088/03 ALF1Laser diode 2Test vessel3Ultrasonic transducer2311. IntroductionIn 1932 Debye and Sears demonstrated for the first time how light is refracted when passing through a fluid ex-cited to high-frequency oscillation. The maxima and minima in density act here like the grid elements of an optical diffraction grating. The grating constant corresponds to the ultrasonic wavelength and is thus dependent on the frequency of the ultrasound and the speed of sound in the medium through which the sound is travelling.The CW (continuous wave) generator with its accompa-nying broad-band ultrasound transducer, along with an adjustable test vesseland its integrated laser holder, mean that it is possible for the first time to demon-strate this phenomenon to schoolchildren and college students alike using simple and compact equipment. The equipment can demonstrate both frequency de-pendence (with four different frequencies) and the ul-trasonic wavelength in various fluids, allowing the speed of sound in the medium to be calculated.It is also possible to project standing ultrasonic waves by inserting an optical lens between the laser source and the ultrasonic waves. The waves are then projected by the diverging laser beam.2. Components2.1Ultrasound generator - operating elements1Mains switch2On/off switch for laser3Connector socket for laser4Control light for laser5Connector socket for ultrasonic transducer6Control light for ultrasonic transducer7Monitor output8On/off switch for ultrasound9Frequency selection switchbl Voltage displaybm Voltage setting The ultrasound generator generates continuous high-power ultrasonic waves (CW = continuous wave). The voltage bm can be adjusted between 5 and 65 V. There is an LCD display for the voltage output bl. The trans-mitted voltage can be switched off separately 8. The frequency can be set to one of four frequencies (1, 2, 4 or 8 MHz) 9. An additional monitor output 7 allows the output frequency to be determined precisely with the aid of an oscilloscope or a frequency counter. A suitable output 3is provided to supply power to a laser diode. This can also be switched off separately 2.Adjustment of mains voltageThe ultrasound generator can operate with 230 V or 115 V mains voltage. A voltage selector switch is situ-ated on the rear of the casing and is hidden beneath the covering to the right of the rear panel. A screw-driver is used to alter the switch setting (see illustra-tion). If the mains voltage is altered, the fuse needs to be changed to suit the mains voltage. A T630 mA fuse should be used with 115 V mains voltage and a T315 mA fuse for 230 V mains.Warning:Unplug from the mains before altering the mains set-ting.No voltage may be applied to the device while making the adjustment,1 2 3 4567bmbl981Remove the two screws from the rear panelling and take off the panel. The voltage selector switch is revealed.2Fuse115 V630 mA230 V315 mA3An arrow indicates the voltage that is currently set. Adjust usinga screwdriver inserted into the slit.2.2Set-up for U10008 test container1Adjustment screw for changing the angle of the transducer2Lid3Transducer holder4Ultrasonic transducer (supplied with U10006)5Securing screw for laser diode6Slot for lens holder7Laser holder8Securing screw for ultrasonic transducer9Glass vesselStanding ultrasonic waves are generated in a special container. It allows the angle of incidence of the waves to be set precisely to the perpendicular by means of a special holder for the ultrasound transducer.The test vessel consists of a glass vessel with a lid and a holder for the transducer, three adjustment screws to set the alignment for the standing wave and a laser holder perpendicular to the axis of the waves which also has a holder for a lens so that the ultrasonic waves and the Debye-Sears effect can be projected.2.3Lens on a glass slideA plane-convex lens is attached to a rectangular slide. This is inserted into the slot in the laser holder of the test container for experiments involving projection.1Plano-convex lens (f=100 cm)2Glass slide3Grip The following illustration shows how the lens shouldbe properly placed in the test container.2.4 Laser diode (U10007)1Laser beam window2Laser module jacket3Plug for connecting to ultrasound generator4Connecting leadClass II laser diode for demonstrating the Debye-Sears effect and projecting ultrasonic waves for use with the ultrasound generator and test container.3. Experiment procedure3.1General instructions for experimentsPay attention to the following instructions if the ex-periment is to work:•Use water that contains as little air as possible since air bubbles disturb both the ultrasound field and the refraction of the laser beam.•Any air bubbles around the probe should be re-moved.•Allow for the maximum distance between the test container and the projection screen.•When no measurements are being made, the ul-trasound should be switched off so that the test fluid does not heat up.1234567891231 2 3 4•For precise measurements, also measure the tem-perature and include this in the comparison.•When using high voltage at any frequency and when the transducer is properly aligned, at least 3 orders of diffraction should be visible.•The projection experiment is much more sensitive to the angle of the transducer than the refraction experiment. Thus for this experiment the conditions for generating standing waves need to be adhered to more precisely.3.2Debye-Sears effectThe wavelength of the ultra-sonic waves in the Debye-Searsexperiment (photo left, 4 MHzin water) can be determinedfor various different test fluids(water, glycerine, cooking oil).This means measuring the dis-tance s between the ultra-sound transducer and the re-fracted image. Then the num-ber of orders of refraction Nand distance between the -nthand +nth bands x can be de-termined. Since the wavelength of the laser light λL is known then:(1)λλsL =2N sxgives the ultrasonic wavelength λs. The individual vari-ables can be calculated as in the following diagram. The ultrasonic frequency n is measured at the monitorsocket. Then the speed of sound c in the fluid is givenby:(2)c = λsνExample results:1. Waterv = 4 MHz, s = 2.90 m, N = 4, x = 4.1 cm, λL = 650 nm therefore: λs = 367.8 µm, c = 1471 m/s(Table: 1480 m/s at 20°C)2. Glycerinev = 4 MHz, s = 2.90 m, N = 2, x = 1.6 cm, λL = 650 nm therefore: λ = 471.2 µm, c = 1885 m/s(Table: 1900 m/s at 25°C)3.3Projection of standing ultrasonic waves Direct projection of ultrasonic waves can be an inter-esting extension tothe experiment. Thesound wave is pro-jected by inserting aconvex lens into thelaser beam so thatthe beam is di-verged. The densityvariations in thestanding wave thenappear as light anddark regions on theprojection screen(see photographright). To determinethe wavelength fromthe diffraction im-age and the geometry involved, as well as the focal length f of the lens in air (100 mm in this case), corrections due to the glass walls of the vessel and the test fluid also need to be considered.The light refraction method as described in 3.2 is thus better suited for calculating the wavelength precisely. The precise equation for λs in the projection experi-ment is:(3)λsxNfgnans fg gna an==−−−−+−+21g1FL12g12FLThe distance a1 between the glass wall towards the lens and the distance a2 can be approximated as half the internal width of 9.6 cm. The thickness of the glass g1 and g2is about 4 or 5 mm. The refractive indices n FL for the test fluid and n g for the glass may be measured or taken from tables.xN = 5N = 3N = 4N = 2N = 1N = 0N = 6sg1g2a1a2λLλssx N = 3N = 2N = 0N = 1N = -1N = -2 N = -3N is the number of bright maxima and x the separa-tion between them.The speed of sound in the medium can now be calcu-lated once again from the measured frequency n us-ing equation (2).Note:With the U10008 test vessel it is only possible to set up a good projection of the standing ultrasonic wave at a frequency of 4 MHz. At 2 MHz and especially at 1 MHz ultrasonic waves reflected from the bottom of the con-tainer are superimposed destructively on the imping-ing ultrasonic beam. Only for 4 MHz waves is the dif-ference in the path length of the order of several wave-lengths. At 8 MHz the amplitude of the emitted wave is too small and also the absorption is much greater (the absorption coefficient is proportional to the square of the frequency). This means that no clear standing waves are produced.Example results:Water:a 1 = a 2 = 4.8 cm, f = 10 cm, n FL = 1.33, n g = 1.45,s =3.03 m, n = 4 MHz, x = 8.9 cm, g 1 = 5 mm, g 2 = 4 mm therefore: λ = 397 µm, c = 1590 m/s (Table: 1480 m/s at 20°C)4. Technical details4.1Ultrasound generator (U10006)Frequency:1, 2, 4, 8 MHz adjustable Output signal:Sine wave, continuously adjustablebetween 5 V pp to approximately 65 V pp . Can be switched off.Red control lightDisplay:3-digit LCD, one decimal place,height of digits 10 mmMonitor signal:TTL, Frequency signalLaser output:3 V DC, max. 300 mW at socket 5.5 mm outer Ø, 2.5 mm inner Ø,Can be switched off.Red control lightDimensions:256 x 86 x 156 mm Mains voltage:115/230 V, 50/60 HzPower consumption:max. 60 VA; 5 VA minimum power(laser and ultrasound switched off)Fuse:T 315 mA (230 V) / T 630 mA (115 V)Ultrasonic transducer Probe diameter:27 mm Active surface area: 2 cm²Cable length: 1 m with BNC socket4.2Test vessel (U10008)Test vessel:100 x 100 x 120 mm Volume:900 ml ser holder:17 mm internal diameter Transducer holder:adjustable, designed for thesupplied transducer Lens on glass slide Lens slide:76 mm x 26 mm Glass slide withroughened gripping surfaceLens:Plano-convex, f = 100 mm(in air), 16 mm Ø4.3Laser diode (U10007)Beam spot:< 6 mm at 3 m Wavelength:650 nm Power:< 1 mW, laser safety class II Supply voltage: 3 V DCCurrent consumption:max. 35 mA Connecting plug: 1 m cable with plug of 5.5 mmouter Ø, 2.5 mm inner ØDimensions:80 mm x 17 mm Ø。

超声波发生器使用说明1.准备工作在使用之前,请确保超声波发生器的电源正常,并且已经连接到工作电源。

同时,确保超声波发生器的传感器或探头已经连接到设备,且连接稳固。

2.设置参数-首先,选择所需的工作模式。

超声波发生器通常具有连续波和脉冲波两种模式,连续波适用于一些需要持续输出的应用,而脉冲波适用于需要间歇性输出的应用。

-其次,设置超声波的频率。

频率是指超声波的振动次数,通常以赫兹(Hz)为单位。

根据具体的应用需求,可以选择不同的频率。

常见的频率范围是20kHz到200kHz,具体选择要根据应用来确定。

-最后,根据需要设置超声波的功率。

功率是指超声波发生器输出的能量,通常以瓦特(W)为单位。

根据具体的应用需求,可以选择不同的功率。

较高功率的超声波发生器可以提供更大的声压和更强的穿透能力,但也会消耗更多的电能。

3.开始使用完成参数设置后,可以开始使用超声波发生器了。

-首先,将超声波发生器的电源打开,确保设备处于工作状态。

-然后,根据需要激活超声波的输出。

根据具体设备的操作界面,可以通过按钮或触摸屏等方式来激活超声波发生器的输出。

在连续波模式下,超声波会持续输出;在脉冲波模式下,超声波会按照设定的脉冲频率进行间歇性输出。

-在使用超声波发生器时,需要注意安全。

避免在人员密集的地方使用,以免对人体造成伤害。

同时,注意防护措施,例如佩戴适当的防护眼镜、手套等。

4.维护保养-首先,断开超声波发生器的电源,确保设备处于安全状态。

-然后,使用干净的布或纸巾轻轻擦拭超声波发生器的外表面。

不要使用化学溶剂或水直接清洗设备,以免损坏设备。

-如果发现传感器或探头上有污垢,可以使用特定的清洗剂进行清洗。

请根据具体设备的说明书,按照正确的方法进行清洗。

-在不使用超声波发生器的时候,应将设备存放在干燥的地方,避免潮湿和高温环境。

通过以上的使用说明,您应该可以轻松地使用超声波发生器了。

请记住,在使用过程中要严格按照说明操作,确保设备和人员的安全。

医用超声仪器操作说明书我们为您提供以下的医用超声仪器操作说明书。

操作说明书一、产品概述医用超声仪器是一种常见的医疗设备,用于进行人体内部器官的观察和诊断。

本操作说明书将详细介绍该医用超声仪器的使用方法、操作流程、注意事项等内容。

二、操作流程1. 准备工作在使用医用超声仪器之前,需要确保以下准备工作已经完成:- 检查仪器是否处于正常工作状态,如有故障需及时维修;- 确认使用的超声探头已经连接好,并做好消毒处理;- 打开仪器电源,等待仪器启动并完成自检。

2. 操作步骤(注意:以下步骤仅供参考,实际操作步骤请参考仪器的使用手册)- 步骤一:根据需要选择合适的探头,并连接到仪器上。

- 步骤二:调整超声图像的亮度、对比度等参数,以获得清晰的图像。

- 步骤三:将超声凝胶涂抹在探头上,以提高超声信号的传输效果。

- 步骤四:将探头放置在需要观察的部位,保持适当的角度和轻微的压力。

- 步骤五:通过仪器操作面板上的控制按钮,调整探头的位置和图像的放大比例等。

- 步骤六:观察超声图像,进行相关的测量和分析。

- 步骤七:完成观察和诊断后,关闭仪器电源,并进行必要的清洁和消毒处理。

三、操作注意事项1. 使用前需仔细阅读仪器的使用手册,并按照规定的操作流程进行操作。

2. 操作人员应该具备相关的医疗背景和专业知识,并经过专业培训。

3. 在操作过程中,需要严格遵守消毒和无菌操作的要求,以避免交叉感染的风险。

4. 仪器的电源和电气部分需要防止水分和其他液体的侵入,以确保设备的安全性能。

5. 注意探头与人体皮肤的接触状态,过度的压力可能会导致不适或损伤。

6. 如有任何异常情况出现或操作不当,应立即停止使用并寻求专业人士的帮助。

四、维护和保养1. 定期检查仪器的各项功能,确保其正常工作。

2. 定期清洁仪器表面和探头,使用符合要求的清洁剂和消毒液进行清洁和消毒。

3. 仪器长时间不使用时,应将其断开电源并妥善保存。

4. 如需维修或更换零部件,应联系指定售后服务商进行操作,不可私自拆卸或修理。

型号5072PR,5073PR,5077PR超声波发生器/接收器用户手册根据欧洲废电子电气指令2002/96 / EC设备,此符号表示产品不得作为未分类处理市政废物,但应单独收取。

请参考您当地的奥林巴斯NDT您所在国家/地区的退货和/或收款系统的经销商。

版权所有©2008 Olympus NDT。

版权所有。

本手册的任何部分不得以任何形式或方式复制或传播,电子或机械,包括复印,录音或任何信息存储和检索系统,未经奥林巴斯NDT书面许可,除非允许依法。

有关信息,请联系:*******************。

Panametrics,Panametrics-NDT和Panametrics-NDT标志是Panametrics的商标公司本文档中提及的其他产品名称可能是其各自的商标公司,仅供鉴定。

印在美利坚合众国。

保修5072PR,5073PR和5077PR超声波脉冲发生器接收机已经设计和制造为优质产品。

收到证件后,仔细检查资料运输期间可能发生的外部或内部损坏。

通知承运人由于承运人通常承担损害赔偿责任,因此立即交付任何损失装船。

保存包装材料,运单和其他运输单据建立损害索赔。

通知运营商后,请联系奥林巴斯NDTTM,以便我们可以协助损坏索赔,并在必要时提供更换设备。

奥林巴斯NDT保证5072PR,5073PR和5077PR超声波脉冲发生器接收器在材料和工艺上没有缺陷,为期一年(十二个月)从装运之日起。

本保修仅适用于已使用的设备方式如本说明书所述,并没有遭受过度滥用,尝试未经授权的修复或修改。

在本保修期内,奥林巴斯无损检测责任仅限于修理或更换一个有缺陷的单位。

奥林巴斯NDT不保证5072PR,5073PR和5077PR超声波脉冲发生器接收器适合使用或适用任何特定的应用或目的。

奥林巴斯NDT不对后果或不承担任何责任偶然的损害,包括财产损失和/或人身伤害。

除了我们标准一年保修,奥林巴斯NDT还提供可选的两年保修(略)。

目录保修................................................. .................................................. . (iii)目录 ............................................... .. (v)一般说明.............................................. .. (1)1.1特别声明和印刷公约............................................ (2)1.2如果您有文档评论............................................ . (3)史............................................... .................................................. (3)1.4技术帮助............................................... .................................................. (4)1.5产品使用............................................... .................................................. (4)开箱检查............................................. .. (5)仪器控制和I / O连接器......................................... ...........3.1前面板3.1.1电源开关............................................. .................................................. .. (9)3.1.2脉冲重复频率控制(PRF)....................................... .. (9)3.1.3脉冲电压(5077PR)......................................... ............................................103.1.4传感器频率选择控制(5077PR)....................................... (11)3.1.5能量(5072PR,5073PR)......................................... (11)3.1.6阻尼(5072PR,5073PR)......................................... (12)3.1.7增益/衰减(dB)......................................... .................................................143.1.8低通滤波器............................................ .................................................. . (14)3.1.9高通滤波器............................................ .................................................. (14)3.1.10模式切换............................................. .................................................. (15)3.1.11 T / R连接器........................................... .................................................. (15)器............................................. .................................................. .. (15)3.2后面板............................................... .................................................. .....................153.2.1 RFOUT ............................................. .................................................. .................163.2.2 EXT TRIGIN ............................................ .................................................. (16)3.2.3 + SYNCOUT ............................................ .................................................. . (17)4.规格............................................... . (19)5.操作............................................... .................................................. (23)5.1示波器要求............................................... . (23)5.2初始设置............................................. .................................................. .....................235.3通过传输............................................. .................................................. .....295.4调谐峰波幅方波脉冲(仅限5077PR) (34)5.5传感器的电压和功率限制......................................... (34)6.故障排除与维护............................................. . (37)6.1基本故障排除............................................... .................................................. (37)6.2克服电噪声干扰............................................. . (37)6.3申请协助............................................... .................................................. ...38文件评论................................................ .. (39)1.一般说明型号5072PR,5073PR和5077PR手动控制超声波脉冲发生器 - 接收器为常规和高频应用提供构建模块。

每仪器设计用于优异的低噪声接收器响应和高性能脉冲发生器控制。

当与适当的传感器和模拟或数字示波器一起使用时,这些脉冲发生器有助于超声波探伤,厚度测量,材料表征,和换能器表征。

应用包括:•缺陷检测•厚度测量•声速测量(用于计算弹性常数)•频谱分析•传感器表征•用于监测材料或工艺的其他测量这些仪器的脉冲发生器部分产生短,大振幅或方波电当应用于超声换能器时,可选择宽度的脉冲被转换成短超声波脉冲。